Professional Documents

Culture Documents

Technical Document: Torque Specifications For Proper Spark Plug Installation

Technical Document: Torque Specifications For Proper Spark Plug Installation

Uploaded by

Arnold NuñezCopyright:

Available Formats

You might also like

- How to Build a Global Model Earthship Operation I: Tire WorkFrom EverandHow to Build a Global Model Earthship Operation I: Tire WorkNo ratings yet

- Bujii TorquespecsDocument1 pageBujii TorquespecsFlorin BadeaNo ratings yet

- 2016-09 MSZ Alu Prospekt en PDFDocument12 pages2016-09 MSZ Alu Prospekt en PDFRasid AsepNo ratings yet

- Butterfly ValveDocument43 pagesButterfly ValveAlexjohn2009No ratings yet

- Ukuran Roda Crane LT15TDocument1 pageUkuran Roda Crane LT15TErwin AntoNo ratings yet

- SRSuntour Fork Manual GeneralDocument12 pagesSRSuntour Fork Manual GeneralTomaz BuenoNo ratings yet

- VX3-VX3.5 Frame InstructionsDocument2 pagesVX3-VX3.5 Frame InstructionsIonut MocanuNo ratings yet

- Icfd 20Document4 pagesIcfd 20khanhtranpt0603No ratings yet

- Column 1: Edge Slab DetailDocument1 pageColumn 1: Edge Slab Detaildesigncivil144No ratings yet

- Baldor Generators PGD2 and PGD4 ManualDocument4 pagesBaldor Generators PGD2 and PGD4 ManualsbottomNo ratings yet

- Nipplo Maschio Jic/UNFDocument1 pageNipplo Maschio Jic/UNFPTC learnerNo ratings yet

- HardwareDocument43 pagesHardwareGhribiNo ratings yet

- Generic Mast Mount Installation Instructions - Issue 9Document2 pagesGeneric Mast Mount Installation Instructions - Issue 9ed.survey.ncNo ratings yet

- Unistrut Opm 0295 13 (Page 5c 1)Document1 pageUnistrut Opm 0295 13 (Page 5c 1)jeffuangNo ratings yet

- 30 1235 Honda CRV 02 06 Instal CaridDocument4 pages30 1235 Honda CRV 02 06 Instal CaridenthonytopmakNo ratings yet

- MU' (MK 2) Series Disc Brake CaliperDocument8 pagesMU' (MK 2) Series Disc Brake CaliperghghNo ratings yet

- Tigre 3800 BrosurDocument2 pagesTigre 3800 Brosurmaujard.weinsbergNo ratings yet

- Drawoff SumpDocument1 pageDrawoff SumpmabtesoreroNo ratings yet

- IMM Hypress Hose FittingsDocument80 pagesIMM Hypress Hose FittingsJohn AllenNo ratings yet

- FRFP13 16S SPB314Document39 pagesFRFP13 16S SPB314jyapias_1No ratings yet

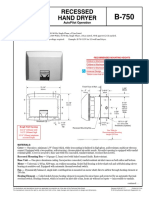

- Recessed Hand Dryer: Technical DataDocument2 pagesRecessed Hand Dryer: Technical Datakalven marquezNo ratings yet

- 65-1501 Victor Equipos OxicombustibleDocument6 pages65-1501 Victor Equipos OxicombustiblecarlosNo ratings yet

- Elkay LZ - SeriesDocument22 pagesElkay LZ - SeriesSteven HerleinNo ratings yet

- AR50 Diaphragm Pump ManualDocument23 pagesAR50 Diaphragm Pump ManualFacundoNo ratings yet

- Trimlineseries™ Recessed Paper Towel Dispenser and Waste ReceptacleDocument1 pageTrimlineseries™ Recessed Paper Towel Dispenser and Waste Receptaclekalven marquezNo ratings yet

- 01c8ac75-a951-4cc6-9205-790ed5720afbDocument1 page01c8ac75-a951-4cc6-9205-790ed5720afbamitNo ratings yet

- Johnson Outboard Prop Nuts WashersDocument3 pagesJohnson Outboard Prop Nuts WashersJSMarine Parts ChinaNo ratings yet

- McAlpine - Plastic Waste Pipe and FittingsDocument8 pagesMcAlpine - Plastic Waste Pipe and FittingsJohn RichardsNo ratings yet

- Process Status: Planning Sheet of Al Mukhtar (1St Order) ORDER#008/10 (M-O81)Document6 pagesProcess Status: Planning Sheet of Al Mukhtar (1St Order) ORDER#008/10 (M-O81)plzmeetmeNo ratings yet

- Catalogo TerminaisDocument12 pagesCatalogo TerminaisPábulo RuannNo ratings yet

- Instalacion de Powerstep Amp ResearchDocument17 pagesInstalacion de Powerstep Amp ResearchAldo PosadaNo ratings yet

- Inventario NeumaticosDocument5 pagesInventario NeumaticosleonardocrespomNo ratings yet

- Parafuso Bits QuadradoDocument1 pageParafuso Bits Quadradojuneenho MattosNo ratings yet

- AADSS1181737Document6 pagesAADSS1181737RennieNo ratings yet

- Article: YB-3541F: Material Color Sat BOM NyataDocument4 pagesArticle: YB-3541F: Material Color Sat BOM NyataKarya Mekar DewatamaliNo ratings yet

- Cherubini Crank-Holder ENDocument2 pagesCherubini Crank-Holder ENAngelo PereiraNo ratings yet

- Instructions-Instrucciones-Consignes: QTY Contents - Contenido - Contenu Tools - Herramienta - Outils ItemDocument4 pagesInstructions-Instrucciones-Consignes: QTY Contents - Contenido - Contenu Tools - Herramienta - Outils ItementhonytopmakNo ratings yet

- Make Tail Wheel Doors From 1/16"x1/8" Balsa Strip StockDocument8 pagesMake Tail Wheel Doors From 1/16"x1/8" Balsa Strip StockJose Antonio Lobo GerardinoNo ratings yet

- Partnumberkey PDFDocument2 pagesPartnumberkey PDFduong nguyenNo ratings yet

- Shimano WH-RS010-R TechDocument1 pageShimano WH-RS010-R Techtareq.sefatNo ratings yet

- Ambitec Price ListDocument40 pagesAmbitec Price ListMohit TyagiNo ratings yet

- Elkay EZ InstallDocument12 pagesElkay EZ InstallSteven HerleinNo ratings yet

- Yamaha Xj-6: Q.TY n.2 Q.TY n.2 Q.TY n.2 Q.TY n.4 Q.TY n.4 Q.TY n.1Document1 pageYamaha Xj-6: Q.TY n.2 Q.TY n.2 Q.TY n.2 Q.TY n.4 Q.TY n.4 Q.TY n.1D17VAZZNo ratings yet

- Butterfly ValvesDocument40 pagesButterfly ValvesThanh ThanhNo ratings yet

- Tank Drawings Example PDFDocument2 pagesTank Drawings Example PDFMiguel OrhlNo ratings yet

- NMO 528940-H: Dual Dimensions in Double Dimensions MMDocument2 pagesNMO 528940-H: Dual Dimensions in Double Dimensions MMDicky SupriadiNo ratings yet

- Footing DetailDocument1 pageFooting DetailAkhila SurendranNo ratings yet

- F-22 Park Jet (Assembly Drawing) PDFDocument1 pageF-22 Park Jet (Assembly Drawing) PDFVikram DamleNo ratings yet

- Portal As #Document1 pagePortal As #Radinal DarmansyahNo ratings yet

- 8FG15 8FD15: MainVehicleSpecificationsDocument3 pages8FG15 8FD15: MainVehicleSpecificationswill wuNo ratings yet

- KITZ Butterfly ValvesDocument40 pagesKITZ Butterfly ValvesOceanexNo ratings yet

- FRMP13-16S-SPB289 - 2Document39 pagesFRMP13-16S-SPB289 - 2jyapias_1No ratings yet

- Ampis-75125 (1) - 230814 - 154450Document13 pagesAmpis-75125 (1) - 230814 - 154450ruslan futkaradzeNo ratings yet

- Pernobolts. Catálogo de Productos Premium 2023Document34 pagesPernobolts. Catálogo de Productos Premium 2023Dimexca CANo ratings yet

- T&S Brass and Bronze Works, Inc.: B-0113-ADF12-BDocument2 pagesT&S Brass and Bronze Works, Inc.: B-0113-ADF12-BSheik Abdul NazeerNo ratings yet

- Recessed Paper Towel Dispenser: Technical DataDocument1 pageRecessed Paper Towel Dispenser: Technical DatakorkieNo ratings yet

- 020-SpecsDocument1 page020-SpecsjoeNo ratings yet

- JSP 2013 Steelman CatalogDocument58 pagesJSP 2013 Steelman CatalogHectorNo ratings yet

- Easy Glider: Build A Comfortable Outdoor Seat in Time For SpringDocument5 pagesEasy Glider: Build A Comfortable Outdoor Seat in Time For SpringDerek Frost100% (1)

- Double Studded AdapterDocument2 pagesDouble Studded AdapterApetrei Dorina100% (1)

Technical Document: Torque Specifications For Proper Spark Plug Installation

Technical Document: Torque Specifications For Proper Spark Plug Installation

Uploaded by

Arnold NuñezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Document: Torque Specifications For Proper Spark Plug Installation

Technical Document: Torque Specifications For Proper Spark Plug Installation

Uploaded by

Arnold NuñezCopyright:

Available Formats

Technical Document

Torque Specifications For Proper Spark Plug Installation

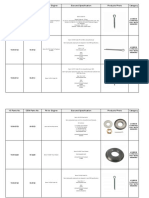

Cast Iron Heads Aluminum Heads

Plug Thread Pound Feet Newton Meters Pound Feet Newton Meters

10mm Gasket Seat 7 - 11 lb. ft. 10 - 15 nm 7 - 11 lb. ft. 10 - 15 nm

12mm Gasket Seat 11 - 19 lb. ft. 15 - 25 nm 11 - 19 lb. ft. 15 - 25 nm

14mm Gasket Seat 26 - 29 lb. ft. 35 - 40 nm 15 - 22 lb. ft. 20 - 30 nm

14mm Tapered Seat 7 - 15 lb. ft. 9 - 20 nm 7 - 15 lb. ft. 9 - 20 nm

18mm Gasket Seat 32 - 38 lb. ft. 43 - 52 nm 28 - 34 lb. ft. 38 - 46 nm

18mm Tapered Seat 15 - 20 lb. ft. 20 - 27 nm 15 - 20 lb. ft. 20 - 27 nm

7/8" - 18 35 - 43 lb. ft. 47 - 58 nm 31 - 39 lb. ft. 42 - 53 nm

Installing Spark Plugs Without A Torque Wrench

14 and 18mm tapered seat plug – tighten 1/16 turn after finger tight; 14 and 18mm gasket seat plug

– tighten 1/2 turn past finger tight; 12mm gasket seat plug – tighten 3/8 turn past finger tight; 10mm

gasket seat plug – tighten 1/4 turn past finger tight.

NOTE: Spark plugs should be installed with clean and dry threads to avoid overtorquing or stretching

the spark plug which can, and often does, result in engine damage.

1/16 Turn 1/4 Turn

Finger Tight Plug

▲ ▲

3/8 Turn 1/2 Turn

X X

▲

X

▲ ▲

October 2006

You might also like

- How to Build a Global Model Earthship Operation I: Tire WorkFrom EverandHow to Build a Global Model Earthship Operation I: Tire WorkNo ratings yet

- Bujii TorquespecsDocument1 pageBujii TorquespecsFlorin BadeaNo ratings yet

- 2016-09 MSZ Alu Prospekt en PDFDocument12 pages2016-09 MSZ Alu Prospekt en PDFRasid AsepNo ratings yet

- Butterfly ValveDocument43 pagesButterfly ValveAlexjohn2009No ratings yet

- Ukuran Roda Crane LT15TDocument1 pageUkuran Roda Crane LT15TErwin AntoNo ratings yet

- SRSuntour Fork Manual GeneralDocument12 pagesSRSuntour Fork Manual GeneralTomaz BuenoNo ratings yet

- VX3-VX3.5 Frame InstructionsDocument2 pagesVX3-VX3.5 Frame InstructionsIonut MocanuNo ratings yet

- Icfd 20Document4 pagesIcfd 20khanhtranpt0603No ratings yet

- Column 1: Edge Slab DetailDocument1 pageColumn 1: Edge Slab Detaildesigncivil144No ratings yet

- Baldor Generators PGD2 and PGD4 ManualDocument4 pagesBaldor Generators PGD2 and PGD4 ManualsbottomNo ratings yet

- Nipplo Maschio Jic/UNFDocument1 pageNipplo Maschio Jic/UNFPTC learnerNo ratings yet

- HardwareDocument43 pagesHardwareGhribiNo ratings yet

- Generic Mast Mount Installation Instructions - Issue 9Document2 pagesGeneric Mast Mount Installation Instructions - Issue 9ed.survey.ncNo ratings yet

- Unistrut Opm 0295 13 (Page 5c 1)Document1 pageUnistrut Opm 0295 13 (Page 5c 1)jeffuangNo ratings yet

- 30 1235 Honda CRV 02 06 Instal CaridDocument4 pages30 1235 Honda CRV 02 06 Instal CaridenthonytopmakNo ratings yet

- MU' (MK 2) Series Disc Brake CaliperDocument8 pagesMU' (MK 2) Series Disc Brake CaliperghghNo ratings yet

- Tigre 3800 BrosurDocument2 pagesTigre 3800 Brosurmaujard.weinsbergNo ratings yet

- Drawoff SumpDocument1 pageDrawoff SumpmabtesoreroNo ratings yet

- IMM Hypress Hose FittingsDocument80 pagesIMM Hypress Hose FittingsJohn AllenNo ratings yet

- FRFP13 16S SPB314Document39 pagesFRFP13 16S SPB314jyapias_1No ratings yet

- Recessed Hand Dryer: Technical DataDocument2 pagesRecessed Hand Dryer: Technical Datakalven marquezNo ratings yet

- 65-1501 Victor Equipos OxicombustibleDocument6 pages65-1501 Victor Equipos OxicombustiblecarlosNo ratings yet

- Elkay LZ - SeriesDocument22 pagesElkay LZ - SeriesSteven HerleinNo ratings yet

- AR50 Diaphragm Pump ManualDocument23 pagesAR50 Diaphragm Pump ManualFacundoNo ratings yet

- Trimlineseries™ Recessed Paper Towel Dispenser and Waste ReceptacleDocument1 pageTrimlineseries™ Recessed Paper Towel Dispenser and Waste Receptaclekalven marquezNo ratings yet

- 01c8ac75-a951-4cc6-9205-790ed5720afbDocument1 page01c8ac75-a951-4cc6-9205-790ed5720afbamitNo ratings yet

- Johnson Outboard Prop Nuts WashersDocument3 pagesJohnson Outboard Prop Nuts WashersJSMarine Parts ChinaNo ratings yet

- McAlpine - Plastic Waste Pipe and FittingsDocument8 pagesMcAlpine - Plastic Waste Pipe and FittingsJohn RichardsNo ratings yet

- Process Status: Planning Sheet of Al Mukhtar (1St Order) ORDER#008/10 (M-O81)Document6 pagesProcess Status: Planning Sheet of Al Mukhtar (1St Order) ORDER#008/10 (M-O81)plzmeetmeNo ratings yet

- Catalogo TerminaisDocument12 pagesCatalogo TerminaisPábulo RuannNo ratings yet

- Instalacion de Powerstep Amp ResearchDocument17 pagesInstalacion de Powerstep Amp ResearchAldo PosadaNo ratings yet

- Inventario NeumaticosDocument5 pagesInventario NeumaticosleonardocrespomNo ratings yet

- Parafuso Bits QuadradoDocument1 pageParafuso Bits Quadradojuneenho MattosNo ratings yet

- AADSS1181737Document6 pagesAADSS1181737RennieNo ratings yet

- Article: YB-3541F: Material Color Sat BOM NyataDocument4 pagesArticle: YB-3541F: Material Color Sat BOM NyataKarya Mekar DewatamaliNo ratings yet

- Cherubini Crank-Holder ENDocument2 pagesCherubini Crank-Holder ENAngelo PereiraNo ratings yet

- Instructions-Instrucciones-Consignes: QTY Contents - Contenido - Contenu Tools - Herramienta - Outils ItemDocument4 pagesInstructions-Instrucciones-Consignes: QTY Contents - Contenido - Contenu Tools - Herramienta - Outils ItementhonytopmakNo ratings yet

- Make Tail Wheel Doors From 1/16"x1/8" Balsa Strip StockDocument8 pagesMake Tail Wheel Doors From 1/16"x1/8" Balsa Strip StockJose Antonio Lobo GerardinoNo ratings yet

- Partnumberkey PDFDocument2 pagesPartnumberkey PDFduong nguyenNo ratings yet

- Shimano WH-RS010-R TechDocument1 pageShimano WH-RS010-R Techtareq.sefatNo ratings yet

- Ambitec Price ListDocument40 pagesAmbitec Price ListMohit TyagiNo ratings yet

- Elkay EZ InstallDocument12 pagesElkay EZ InstallSteven HerleinNo ratings yet

- Yamaha Xj-6: Q.TY n.2 Q.TY n.2 Q.TY n.2 Q.TY n.4 Q.TY n.4 Q.TY n.1Document1 pageYamaha Xj-6: Q.TY n.2 Q.TY n.2 Q.TY n.2 Q.TY n.4 Q.TY n.4 Q.TY n.1D17VAZZNo ratings yet

- Butterfly ValvesDocument40 pagesButterfly ValvesThanh ThanhNo ratings yet

- Tank Drawings Example PDFDocument2 pagesTank Drawings Example PDFMiguel OrhlNo ratings yet

- NMO 528940-H: Dual Dimensions in Double Dimensions MMDocument2 pagesNMO 528940-H: Dual Dimensions in Double Dimensions MMDicky SupriadiNo ratings yet

- Footing DetailDocument1 pageFooting DetailAkhila SurendranNo ratings yet

- F-22 Park Jet (Assembly Drawing) PDFDocument1 pageF-22 Park Jet (Assembly Drawing) PDFVikram DamleNo ratings yet

- Portal As #Document1 pagePortal As #Radinal DarmansyahNo ratings yet

- 8FG15 8FD15: MainVehicleSpecificationsDocument3 pages8FG15 8FD15: MainVehicleSpecificationswill wuNo ratings yet

- KITZ Butterfly ValvesDocument40 pagesKITZ Butterfly ValvesOceanexNo ratings yet

- FRMP13-16S-SPB289 - 2Document39 pagesFRMP13-16S-SPB289 - 2jyapias_1No ratings yet

- Ampis-75125 (1) - 230814 - 154450Document13 pagesAmpis-75125 (1) - 230814 - 154450ruslan futkaradzeNo ratings yet

- Pernobolts. Catálogo de Productos Premium 2023Document34 pagesPernobolts. Catálogo de Productos Premium 2023Dimexca CANo ratings yet

- T&S Brass and Bronze Works, Inc.: B-0113-ADF12-BDocument2 pagesT&S Brass and Bronze Works, Inc.: B-0113-ADF12-BSheik Abdul NazeerNo ratings yet

- Recessed Paper Towel Dispenser: Technical DataDocument1 pageRecessed Paper Towel Dispenser: Technical DatakorkieNo ratings yet

- 020-SpecsDocument1 page020-SpecsjoeNo ratings yet

- JSP 2013 Steelman CatalogDocument58 pagesJSP 2013 Steelman CatalogHectorNo ratings yet

- Easy Glider: Build A Comfortable Outdoor Seat in Time For SpringDocument5 pagesEasy Glider: Build A Comfortable Outdoor Seat in Time For SpringDerek Frost100% (1)

- Double Studded AdapterDocument2 pagesDouble Studded AdapterApetrei Dorina100% (1)