Professional Documents

Culture Documents

Hydrostatic Test Procedure (Rev.1)

Hydrostatic Test Procedure (Rev.1)

Uploaded by

lukmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrostatic Test Procedure (Rev.1)

Hydrostatic Test Procedure (Rev.1)

Uploaded by

lukmanCopyright:

Available Formats

Doc. No.

KHB1277-Q60

Hydrostatic Test Rev. No. 1

Procedure Page 1 of 8

For Approval

Project Title : YY New Field Development

-PHE ONWJ

Customer : PT. Agcia Pertiwi

Item Name : Pipe Bends

1 JAN. 09. 2015 Revised by customer`s comment Y.G.Jin S.H.Shim D.Y.Bae

0 Dec. 29, 2014 First Issued Y.G.Jin J.U.Kim D.Y.Bae

Rev. No. Date Description Prepared Reviewed Approved

KHB Tech Co., Ltd.

Hydrostatic Test Doc. No.

Rev. No.

KHB1277-Q60

1

Procedure Page 2 of 8

Table of Contents

Para. Title Page

1.0 SCOPE 3

2.0 APPLICABLE SPECIFICATION 3

3.0 TEST ITEMS 3

4.0 HYDROSTATIC TEST 4

5.0 TEST PROCEDURE 5

6.0 ACCEPTABLE CRITERIA 7

7.0 DOCUMENT CONTROL 7

KHB Tech Co., Ltd.

Hydrostatic Test Doc. No.

Rev. No.

KHB1277-Q60

1

Procedure Page 3 of 8

1.0 SCOPE

This procedure covers the hydrostatic test of pipe bends.

2.0 APPLICABLE SPECIFICATION

2.1 Code and Standard

□ API-5L Specification for Line Pipes 45th Edition

Factory-Made Wrought Butt-Welding Induction Bends

□ ASME B16.49

for Transportation and Distribution Systems.

□ ASME B31.4 Pipeline Transportation System for Liquid Hydrocarbon

and Other Liquids, 2006

□ ASME B31.8 Gas Transmission and Distribution Piping Systems, 2003

2.2 Purchaser’s Specification

□ Specification for Pipeline Induction Bends (PHEONWJ-W-SPE-0001)

3.0 TEST ITEMS

3.1 Pipe Bends

Size W.T

No. Material Angle Q’ty Remark

(inch) (mm)

Include P.Q

1 API5L-X65 PSL2 12 15.9 90° 9

1 Pcs(Bare)

2 API5L-X65 PSL2 12 15.9 82.8° 1 Bare

2 API5L-X65 PSL2 12 15.9 60° 1 Bare

3 API5L-X65 PSL2 12 15.9 36° 1 Bare

Total 12

Note – W.T : Wall Thickness, MWT. : Minimum Wall Thickness

KHB Tech Co., Ltd.

Hydrostatic Test Doc. No.

Rev. No.

KHB1277-Q60

1

Procedure Page 4 of 8

4.0 HYDROSTATIC TEST

4.1 Hydrostatic testing shall be performed on all items as table 1.

4.2 Test pressure formula is defined as

P = 2St/D

Where P = test pressure (Mpa)

S = 85% of the specified minimum yield strength for X65 (Mpa)

* Minimum yield strength for X65 : 450 Mpa

t = nominal wall thickness of pipe bends (mm)

D = outside diameter of pipe bends (mm)

Table 1. Test Pressure and Holding Time(min.)

Size W.T MWT. Q’ty Test Pressure Holding

No. Material (inch) (mm) (mm) (pcs) Mpa ㎏/㎠ Time(min.)

1 API5L-X65 PSL2 12 15.9 14.3 9 20.51) 209.04 15sec.

2 API5L-X65 PSL2 12 15.9 14.3 1 20.51) 209.04 15sec.

3 API5L-X65 PSL2 12 15.9 14.3 1 20.51) 209.04 15sec.

4 API5L-X65 PSL2 12 15.9 14.3 1 20.51) 209.04 15sec.

Total 12

Note-According to note.b of table.26 , API 5L

4.3 The location of pressure gauge shall be applied as figure 1.

KHB Tech Co., Ltd.

Hydrostatic Test Doc. No.

Rev. No.

KHB1277-Q60

1

Procedure Page 5 of 8

Hydrostatic Test Sketch

Fig.1 Pipe Bends

5.0 TEST PROCEDURE

The hydrostatic test of pipe bends shall be performed on all pipe bends and the

result should be reported on hydrostatic test record.

5.1 Preliminary requirements prior to applying of pressure

1) Checking of the material identification marking

The inspector shall check and verify the identification marking on items.

2) Supports such as scaffold shall be proper type to ensure safe inspection.

In order to be able to inspect all the welded joints, no supports shall be

placed on or over any welded joints of the items.

3) Cleaning of surface and exposure of joints

a. surface to be inspected during the test shall be clean.

No residual paints, liquid enetrant, oil, grease or condensation shall

acceptable.

b. All mechanical or welded joints shall be accessible and exposed for

inspection during the test.

c. The external surface of the items to be tested shall be thoroughly dried

before test.

KHB Tech Co., Ltd.

Hydrostatic Test Doc. No.

Rev. No.

KHB1277-Q60

1

Procedure Page 6 of 8

5.2 Test Gauges

1) The gauges shall be calibrated against a standard deadweight tester or a

calibrated master gauge at least every 12 months if at any time there is

reason to believe that they are in error.

2) Dial indicating pressure gauge used in testing shall be graduated over a

range of about double the intended minimum test pressure, but in no

case shall the range be less than 1-1/2 nor more than 4 times of the test

pressure.

3) Two(2) dial-indicating pressure gauges shall be used in testing items. One

is connected directly to the highest location of the item for correct

indication of the test pressure. The other one is connected where it will be

visible to the operator throughout the duration of the test.

5.3 Fluid Medium and Temperature

1) Clean water will be used as test fluid unless otherwise specified.

2) The metal temperature shall not exceed 120℉(48.9℃) during the close

test, it shall be at least 30℉(-1.1℃) above the minimum design metal

temperature to minimize the risk of brittle fracture during hydrostatic

testing.

5.4 Filling the items with Water

1) Vents shall be provided at all high points of the items in the position in

which it is to be tested to purge possible air pockets while the item is

being filled.

2) The items shall be filled with water.

3) Before applying pressure, the inspector shall check the test equipment to

assure that it is tight and other appurtenances that should not be

subjected to the test pressure have been disconnected or isolated by

valves or other suitable means.

KHB Tech Co., Ltd.

Hydrostatic Test Doc. No.

Rev. No.

KHB1277-Q60

1

Procedure Page 7 of 8

5.5 Application of Pressure

1) For the safety of operator and other personnel, necessary all the means

shall be provided and test area shall be marked.

2) The pressure in the items shall be increased gradually until the required

test pressure has been reached.

3) After the test pressure as required by this procedure have been

maintained for the holding time specified.

5.6 Inspection

1) Inspection for leakage shall be made on the whole body of the items,

especially on weld seams and all areas of high stress concentration.

2) Any leaks or other defects found during the inspection shall be reported

in Nonconformity Report.

5.7 Empting the Items

After successful completion of the hydrostatic test, vents and drains shall be

opened to remove all the water in the items.

6.0 ACCEPTANCE CRITERIA

6.1 The pressure test is satisfactory, if the pressure is borne by the enclosure

without any leakage.

6.2 If any item shows leaks during the hydrostatic test, it shall be rejected.

7.0 DOCUMENT CONTROL

All test results shall be documented on the “Pressure Test Record” exhibit 1 by

inspector.

KHB Tech Co., Ltd.

Hydrostatic Test Doc. No.

Rev. No.

KHB1277-Q60

1

Procedure Page 8 of 8

KHB Tech Co., Ltd.

You might also like

- Cement and Concrete Mineral Admixtures, by Tokyay M., 2016 PDFDocument325 pagesCement and Concrete Mineral Admixtures, by Tokyay M., 2016 PDFAngel Baraoed100% (3)

- DRS - Operation & Control PhilosophyDocument5 pagesDRS - Operation & Control PhilosophyAnand GNo ratings yet

- Organic Chemistry, Second Edition Janice Gorzynski Smith, ch2Document16 pagesOrganic Chemistry, Second Edition Janice Gorzynski Smith, ch2sungyeon heoNo ratings yet

- Bes 800-103Document25 pagesBes 800-103Jose GuerreiroNo ratings yet

- Assignment (Air Pollution)Document7 pagesAssignment (Air Pollution)Durga Prasad Murmu0% (1)

- Valve and Speciality ListDocument4 pagesValve and Speciality Listbandithaguru6338No ratings yet

- 02070-ASC-PRV-DTS-T002 Data Sheet de Tanque de AcidoDocument5 pages02070-ASC-PRV-DTS-T002 Data Sheet de Tanque de Acidohelard68No ratings yet

- MIS-M-DS-04053 50m3 Slop Tank Data Sheet-BDocument2 pagesMIS-M-DS-04053 50m3 Slop Tank Data Sheet-Bhappale2002No ratings yet

- 9 Fiberstrong & Wavistrong Flange Guide Rev2Document46 pages9 Fiberstrong & Wavistrong Flange Guide Rev2George_Wabag_2014No ratings yet

- Mechanical Engineering Training Calendar 2015Document4 pagesMechanical Engineering Training Calendar 2015dharwinNo ratings yet

- Reservior Skid Assl Qap AlfaDocument1 pageReservior Skid Assl Qap AlfaajmainNo ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument39 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesJahidul IslamNo ratings yet

- Datasheet Seaflex 64Document2 pagesDatasheet Seaflex 64rene_angel1No ratings yet

- ATTACHMENT 1-TECHNICAL BID EVALUATION FOR VALVES ATTACHEMENT Camtech Rev 1Document4 pagesATTACHMENT 1-TECHNICAL BID EVALUATION FOR VALVES ATTACHEMENT Camtech Rev 1eko123No ratings yet

- TPP-ABE-PP-1001-0001, Piping Material Take-Off - IDC - 15-Feb-2016Document10 pagesTPP-ABE-PP-1001-0001, Piping Material Take-Off - IDC - 15-Feb-2016OlusayoNo ratings yet

- 2022Document17 pages2022mahdi_g100% (1)

- Binh Nen Khi 3000 Lit-Rk Project-23122015Document1 pageBinh Nen Khi 3000 Lit-Rk Project-23122015Van DiepNo ratings yet

- M14-Oil & Water StrainerDocument31 pagesM14-Oil & Water StrainerAlexNo ratings yet

- Volume3A Mech PDFDocument321 pagesVolume3A Mech PDFSayee Krishnan100% (1)

- S-3000-3160-002 - A - 0010-Construction Procedure For Piping Pressure TestingDocument12 pagesS-3000-3160-002 - A - 0010-Construction Procedure For Piping Pressure TestingMessaoud Goutas100% (1)

- Nawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFDocument29 pagesNawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFAhmed AbidNo ratings yet

- CN Scrubber Dn3500 Rev04Document58 pagesCN Scrubber Dn3500 Rev04becemNo ratings yet

- NT2-L3-M-000!21!00022 MS For Oil Flushing of The Fuel Oil Piping SystemDocument15 pagesNT2-L3-M-000!21!00022 MS For Oil Flushing of The Fuel Oil Piping SystemHuynh Thanh TamNo ratings yet

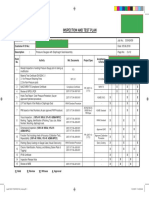

- Inspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Document6 pagesInspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Vidyut UjalaNo ratings yet

- Pipeline Hydrotest PlanDocument73 pagesPipeline Hydrotest PlanfernandoNo ratings yet

- TK02 Rev01Document7 pagesTK02 Rev01mggz_15No ratings yet

- Composite Construction Works For CNG Station at Kovvur, West Godavari District, A.PDocument209 pagesComposite Construction Works For CNG Station at Kovvur, West Godavari District, A.Pvinay1999No ratings yet

- 10 - 254625-300-SP-INT-027 Specifications For Pressure Safety Valve Rev A PDFDocument10 pages10 - 254625-300-SP-INT-027 Specifications For Pressure Safety Valve Rev A PDFkhaireddinNo ratings yet

- Estimate Summary: Change Order Cont. Sales TaxDocument2 pagesEstimate Summary: Change Order Cont. Sales TaxFaizal Sattu100% (1)

- P01-E28-01 Rev 6 Dec 2021 Qualification of FRP Pipe and ComponentsDocument18 pagesP01-E28-01 Rev 6 Dec 2021 Qualification of FRP Pipe and ComponentsMohamed AdelNo ratings yet

- 03-M-U-300819 Installation Instruction For Cold Box of Air Separation PlantDocument40 pages03-M-U-300819 Installation Instruction For Cold Box of Air Separation PlantmahmoudNo ratings yet

- Calculation of Air Content (P/V Plot)Document2 pagesCalculation of Air Content (P/V Plot)Vimin PrakashNo ratings yet

- Vessel Cleaning ProcedureDocument6 pagesVessel Cleaning ProcedureZool HilmiNo ratings yet

- Data Sheet For Barred Tee 010719 PDFDocument1 pageData Sheet For Barred Tee 010719 PDFkandraNo ratings yet

- TP-WMS-05967-DAS-A4-D1-K - Biocide DatasheetDocument9 pagesTP-WMS-05967-DAS-A4-D1-K - Biocide Datasheetbmanojkumar16No ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- Itp Vessel PDFDocument4 pagesItp Vessel PDFBUDAPESNo ratings yet

- Material Requisition For Bolt and Nuts-Rev0Document5 pagesMaterial Requisition For Bolt and Nuts-Rev0altipatlar100% (1)

- QP STD R 009Document104 pagesQP STD R 009p.abdulameen1234No ratings yet

- WPS Asme Ix PDFDocument4 pagesWPS Asme Ix PDFSergiu LungNo ratings yet

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDocument2 pagesMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNo ratings yet

- Mto TankDocument1 pageMto TankHarun Al-RasyidNo ratings yet

- ITPDocument1 pageITPVenkatesh PethurajNo ratings yet

- Stack Fabrication: NIOEC-SP-20-04Document8 pagesStack Fabrication: NIOEC-SP-20-04Ak OraNo ratings yet

- Test Pack Clearance FormatDocument2 pagesTest Pack Clearance FormatKarthikNo ratings yet

- Inspection and Test Plan (ITP)Document7 pagesInspection and Test Plan (ITP)Zulfokar FahdawiNo ratings yet

- XIGA™ Dead-End Ultrafiltration in Water TreatmentDocument32 pagesXIGA™ Dead-End Ultrafiltration in Water TreatmentcysautsNo ratings yet

- Piping Thickness by ScheduleDocument4 pagesPiping Thickness by SchedulekkabbaraNo ratings yet

- Mechanical Datasheet of Black Product (Fuel Oil) Road Tanker Unloading Pump (P-332, P-336)Document4 pagesMechanical Datasheet of Black Product (Fuel Oil) Road Tanker Unloading Pump (P-332, P-336)Gop MangukiyaNo ratings yet

- Tank Fabrication & ErectionDocument72 pagesTank Fabrication & ErectionPramod GrNo ratings yet

- API 650 Tank Nozzle Stand Out - EditableDocument20 pagesAPI 650 Tank Nozzle Stand Out - EditableShaaban NoamanNo ratings yet

- JHF 610-Xgat-Mm (2006 Ac)Document1 pageJHF 610-Xgat-Mm (2006 Ac)Arya Bayu WibisonoNo ratings yet

- Tractebel SpecificationDocument69 pagesTractebel SpecificationShyam MurugesanNo ratings yet

- Pressure - Vacuum Relief Valve - Part 1Document10 pagesPressure - Vacuum Relief Valve - Part 1winarnobNo ratings yet

- Corrosion Rate CalculationDocument2 pagesCorrosion Rate CalculationPawan PatilNo ratings yet

- Rock Shield Material Data SheetDocument1 pageRock Shield Material Data SheetR.S.No ratings yet

- End Plate Thickness CalculationDocument5 pagesEnd Plate Thickness CalculationP s JagatheesanNo ratings yet

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiNo ratings yet

- Pipe Size Calc - Gas - LINDocument1 pagePipe Size Calc - Gas - LINjollyNo ratings yet

- SEWA VI-D SEC - E GRP PipingDocument18 pagesSEWA VI-D SEC - E GRP PipingManu V100% (1)

- Material Test ReportDocument7 pagesMaterial Test Reportjuan carlos suaNo ratings yet

- 104259-MDB-X-0022 RevI1 100209 FINAL PDFDocument178 pages104259-MDB-X-0022 RevI1 100209 FINAL PDFSurya EngineeringNo ratings yet

- FM IS Standard 3600Document14 pagesFM IS Standard 3600SureshNo ratings yet

- A11.18 - Mobilux EP 2Document1 pageA11.18 - Mobilux EP 2Dony LieNo ratings yet

- Blank Sample PQR Form (SAW - Page 1) Procedure Qualification Record (PQR)Document2 pagesBlank Sample PQR Form (SAW - Page 1) Procedure Qualification Record (PQR)GMNo ratings yet

- Initial Assessment of Boiler O&MDocument27 pagesInitial Assessment of Boiler O&MsprotkarNo ratings yet

- Product Catalog PDFDocument979 pagesProduct Catalog PDFa7mos0% (1)

- Me688 UsmDocument39 pagesMe688 UsmKETU PRINCE LEKUNo ratings yet

- Solved ISRO Scientist or Engineer Mechanical 2009 Paper With SolutionsDocument21 pagesSolved ISRO Scientist or Engineer Mechanical 2009 Paper With SolutionsAB RanaNo ratings yet

- Customer Service Email:: Voice Type Multifunctional Gas Detector User's ManualDocument20 pagesCustomer Service Email:: Voice Type Multifunctional Gas Detector User's ManualIGNACIO ANDAURNo ratings yet

- Most and Least Learned Competencies: Republic of The PhilippinesDocument5 pagesMost and Least Learned Competencies: Republic of The PhilippinesLorena De BelenNo ratings yet

- Jurnal Natural: Analysis of Minerals in Cempaka-Madu Gemstone From Aceh Indonesia by Using XRFDocument4 pagesJurnal Natural: Analysis of Minerals in Cempaka-Madu Gemstone From Aceh Indonesia by Using XRFBakryRantoeNo ratings yet

- Sugar Cane LifecycleDocument8 pagesSugar Cane LifecycleCAMILO JOSE DELGADO BOLAÑOSNo ratings yet

- Cyclone SeparateDocument5 pagesCyclone SeparateAMARESH BADIGERNo ratings yet

- Excel BasedDocument24 pagesExcel Basedelha e. maruquinNo ratings yet

- Physicochemical Analysis of Municipal Water in Al Khums LibyaDocument4 pagesPhysicochemical Analysis of Municipal Water in Al Khums LibyaHaider AddewanyNo ratings yet

- Piping, Modules & Skids: PrefabricatedDocument2 pagesPiping, Modules & Skids: PrefabricatedRevankar B R ShetNo ratings yet

- Edxrf VS WDXRF PDFDocument5 pagesEdxrf VS WDXRF PDFkulihat_hijauNo ratings yet

- SSC Junior Engineer Mechanical Recruitment Exam Guide 3rd Edition PDFDocument586 pagesSSC Junior Engineer Mechanical Recruitment Exam Guide 3rd Edition PDFBhavani Gujjari0% (1)

- TENSION MEMBERS Yielding Shear LagDocument28 pagesTENSION MEMBERS Yielding Shear LagEhsan WasimNo ratings yet

- Unit-Iii CapsulesDocument88 pagesUnit-Iii Capsulesteenu josenNo ratings yet

- Identifying Archaeological Metal PDFDocument4 pagesIdentifying Archaeological Metal PDFadonisghlNo ratings yet

- 5282syllabus (NEP2020) CSEDocument109 pages5282syllabus (NEP2020) CSEridhiNo ratings yet

- High Temperature ResinDocument2 pagesHigh Temperature ResinDILIGENT AM11No ratings yet

- Math Past PaperDocument10 pagesMath Past PaperARIHAN SHARMANo ratings yet

- Analy Food Colour Uv-VisDocument13 pagesAnaly Food Colour Uv-VisNoor Zarif100% (1)

- Experimental Study On Flexural Behaviour of Fiber Reinforced Geopolymer Ferrocement Folded PanelDocument8 pagesExperimental Study On Flexural Behaviour of Fiber Reinforced Geopolymer Ferrocement Folded PanelheminNo ratings yet

- Iqwq-Cpp-Grinv-00-0001 - 0Document24 pagesIqwq-Cpp-Grinv-00-0001 - 0வி.சுரேஷ் குமார்100% (1)

- Mud Properties and Measurements Revised 02Document42 pagesMud Properties and Measurements Revised 02Karim Wasi100% (1)