Professional Documents

Culture Documents

MoJet An Improved Jetfan PDF

MoJet An Improved Jetfan PDF

Uploaded by

Sandesh ShenoyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MoJet An Improved Jetfan PDF

MoJet An Improved Jetfan PDF

Uploaded by

Sandesh ShenoyCopyright:

Available Formats

058_062tun0712 Systemair:T&T 25/6/12 11:58 Page 58

TECHNICAL | FAN DEVELOPMENT

An improved

R

jet fan

oad tunnels are often ventilated

by inductive systems with

booster fans, also known as jet

fans, installed near the tunnel

ceiling. A brief summary of physical data is

necessary to better understand the scope

of this paper.

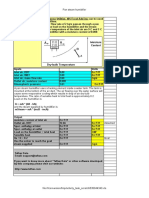

The theoretical impulse force for a jet fan,

thrust, can be calculated as follows:

(1)

This paper presented by Harald Rudelgass and Carlo Barbetta of

In practice a jet fan experiences losses Systemair explores the results of converging nozzles on loss of

and so will not develop the full theoretical

thrust force. impulse, a history of the research and the latest solutionive

The actual thrust can only be found by

measurement. Action and reaction are affecting outlet velocity). The authors warn Manipulating this formula

equal and opposite so the thrust provided the user on calculating the thrust with the

to the air can be evaluated by measuring above formula. It is recommended to (multiplying by )

the reactive force on the fan, as specified in measure the thrust and then calculate the

ISO 13350. The difference between Veff (effective velocity) from the appropriate and solving the equation for

theoretical and real thrust ranges from 0.85 formula [1]. we have:

to 1.05 (values greater than one happen in Since the flow rate in the tunnel will not

some cases where a high hub ratio be zero, formula (1) must be rewritten in the (3)

generates a remarkable annulus velocity, following way :

In order to free as much of the tunnel for

Below: Testing a Mojet fan (2) traffic as possible, booster fans are often

58 Tunnels & Tunnelling International JULY 2012 www.tunnelsandtunnelling.com

058_062tun0712 Systemair:T&T 25/6/12 11:59 Page 59

FAN DEVELOPMENT | TECHNICAL

ahead in the research. The Department of

Notation

Mechanical Engineering of the University of

= force, thrust (N) Padua in Italy and the Centre for Tunnel

Aerodynamics Research at the South Bank

= fluid density (kg/m3)

University in London, UK worked together

= flow rate (m3/s) in a joint research program and improved

= velocity (m/s)

the analysis of k factor.

The major improvements were:

= Kempf factor (-) Creation of a scale model of a real tunnel

= angle between jet stream and longitudinal tunnel axis (°)

cross section (ANAS 505, Italian Road

Authority) at a scale of 1:10.

= distance between fan axis and tunnel roof (m) Creation of a jet fan scale model 1:10

Subscript notation including the typical swirl angles, with

and without silencers.

= effective Both single and pair jet fan scale models

= fan at various distances between the vault

and fan centres. And also analysing

= tunnel effect of distance between jets or pairs.

Benefit analysis of inclining the jet.

installed close to the ceiling. This results in pipe or pipes positioned in the vicinity of a The work done was presented in 1994

the exhaust jet stream not being able to plain plate or plain niche, and not taking [9], 1997 [10] [11], 2000 [12] and today

fully develop. So a portion of jet energy is into account the shape of the tunnel at all. represents the more updated Kempf factor

lost to wall friction. Consequently, formula This research showed the great influence of determination.

(3) has to be rewritten as follows: losses generated through interaction

between jet plumes and fixed surfaces. Technical solution

(4) In 1991 [7] the prolific Rohne presented From formula (4) it is clear that the Kempf

research that in some ways reproduced, factor is an extremely important influence

The effectiveness number k, called the the circular shape of a tunnel: a half on the number of jet fans to be used and

‘Kempf factor’, indicates what portion of cylinder in small scale (maximum radius of consequently installation and running costs.

the impulse force or momentum is actually 400mm and length 2,000mm), with one The data in [9], [10], [11] and [12]

provided by the fan and not lost. pipe positioned in the middle at various confirms that it could vary between 0.65 to

Generally we should assume: distances from vault. 0.78 so any improvement achieved will give

The research carried out to this point had benefits as described above.

= 30m/s two technical limitations:

= 5m/s Pipes do not correctly represent a jet fan Jet fan inclination

And we immediately have a factor of outlet, which has a swirl. Fully reversible booster fans in a

Plain plates or semicircular sections do bidirectional traffic tunnel, or in a

not create boundary surface existing in a unidirectional tunnel that, during

tunnel. maintenance allows two way traffic and

Studies, presented later in this paper, does not allow the adoption of inclination

demonstrate that k can range between 0.65 Also in 1991, N. Costeris [8] resumed the that will only benefit one direction. In some

to 0.78, resulting in a correction factor on Kempf research for a rectangular tunnel cases the inclination is not achievable due

the provided thrust of 0.54 to 0.64. This presenting the dimensionless effectiveness to tunnel clearance demands.

means a loss in thrust of 36 to 46 per cent. of jets. Again the first technical limitation From [10] [11] it was found that from 5°

This is a remarkable amount of energy loss, (above) was an issue. to 10° there is an optimisation of the

and needs an appropriate focus. For the first time graphs showing the k installation efficiency. This method has no

factors were of easy use and directly remarkable application as far as the authors

History applicable to formula four (above, left). are aware.

During the mid 1960s a Swiss engineer, I The author suggested how to improve

Kempf, started to study the influence and the results by using deflectors on air Deflectors

effect of walls on jet streams [2] in a corner outlets, correcting the final thrust by the As far as the authors know Kempf [2]

of rectangular tunnel section model. That cosine of the angle between the jet stream studied the effect of deflection vanes on a

was the first approach trying to determine centreline and the longitudinal tunnel axis. pipe installed in a corner of a rectangular

the effects in an engineered way. Later in Costeris’s comments on use of section in 1965.

1979 E. Rohne [3] resumed the previous deflectors are very clear, that the adoption The research was limited to establishing

work and began an analytical investigation of jet stream deflectors is only considered the effectiveness of an installation that uses

of a simple jet on a plain plate. In 1982 an improvement if the advantages outweigh deflectors. Effectiveness was surely

Rohne [4] also studied the simple jet in a the drawbacks caused by the additional increased due to the directing of the flow

niche. And again in 1985 [5] and 1988 [6] losses through the jet fan, and away from the wall. However from a fan

Rohne studied the effect of two and four consequently the increase of power point of view, the installation of deflectors

simple jets on a plain plate. consumption. on the outlet side or, even worse (in the

All Rohne experiments were purely a During the 1990s there was a big jump case of a fully reversible jet fan), on both

www.tunnelsandtunnelling.com JULY 2012 Tunnels & Tunnelling International 59

058_062tun0712 Systemair:T&T 25/6/12 12:00 Page 60

TECHNICAL | FAN DEVELOPMENT

Impeller Motor Mounting foot Terminal box

Fan casing Tapered duct piece Tapered silencer

Impeller Motor Mounting foot Terminal box

Fan casing Silencer

Above, top: Figure 1, arrangement with

slanted silencer jet fans the conclusion was not a consistent result tunnel clearance. If this is the case, then the

Above, bottom: Figure 2, arrangement due to the large tolerance span. two possible installation arrangements are

with standard jet fan In a second in situ measurement of the feasible (see Figures 1 and 2, above).

Collembey Tunnel in Switzerland, Mart et al These two solutions have the same k

the inlet and outlet, generates a negative [15] improved the measurement technique factor so there is no real need to install the

effect on the fan performances through an reducing the uncertainty down to ± 12 per slanted silencer jetfan type. Silencer

increased drop, and especially on the inlet cent. Here the jet fans were installed in the slanting of 10° or more (normally it is

side, with a non uniform fluidodynamic load corner of a rectangular tunnel section. It between five and 25 per cent) means that

on the axial impeller. was concluded that the thrust of the slatted the plume of the jet fan will be further from

Lotsberg [13] investigated the effect of silencer jet fan was between 11 per cent to the vault of the tunnel, increasing the k

deflectors on large, 1,500mm jet fans in a 21 per cent higher than the one of factor, but at the same time it will hit the

6.6km long tunnel so the loss was limited. conventional straight jet fans. ground of the tunnel, generating a loss.

The test was only done in one direction The above installation was possible since During a fire scenario, if the jet attaches

and they found a high energy loss inside the slanted silencers didn’t interfere with itself to the tunnel floor and moves forward

the fan.

On a fully reversible fan this approach Below: Figure 3, axial fan performance curves

does not give any real benefit. Should the

deflection vanes be attached at some

distance from the fan ends, the pressure

Stall line

drop could be reasonably reduced but only Resistance

a proportion of the spreading plume would line with

Fan nozzle

be captured and turned, so again the characteristic

benefit is reduced.

The use of the deflectors has been

limited and discontinued. No further New operating

Pressure

research has been undertaken. point (with nozzle)

Resistance

line without

Slanted Silencers nozzle

It is clear that the use of silencers has a

beneficial effect on the k factor [9]. A further

improvement is to slant the silencer down

or away from the wall in the case of a niche Constant

power line

positioned jet fan. This technical solution

surely increases the k factor. Original operating

point

In situ measurements on the Balmenrain

and Uznaberg tunnels in Switzerland were

carried out by Pospisil et al [14] but flow

V’1 V2 V1 Volumetric flowrate

measurement error was ± 19 per cent so

60 Tunnels & Tunnelling International JULY 2012 www.tunnelsandtunnelling.com

058_062tun0712 Systemair:T&T 25/6/12 12:00 Page 61

FAN DEVELOPMENT | TECHNICAL

Left, top: Figure 4, tapered silencer jet

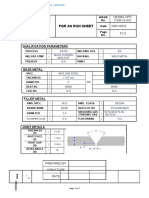

fan arrangment Table 1: Mojet benefits based on 1.5km tunnel

Left, bottom: Figure 5, non-tapered

Standard Jetfan Mojet

silencer jet fan arrangment

Design thrust needed in the 22,803N

as a ‘wall jet’, the air velocity above the jet tunnel including the effect of

may be less than the critical velocity for air velocity inside the tunnel

smoke control, possibly leading to localised as per formula three

smoke back-layering. k factor Kempf 0.73 0.95

This problem has been analysed by

Betta et al [16] and the conclusion was in Static thrust needed from 31,237N 24,003N

terms of energetic operating costs jetfans as per formula four

reduction:

Optimal pitch angle 6° for a free tunnel.

Optimal pitch angle between 2° to 4° for Table 2: Comparison of jet fan performance

a tunnel with a traffic jam (e.g. congested

Standard Jetfan Mojet

traffic or fire scenario).

Jetfan diameter 710mm

This issue may need to be addressed

Jetfan thrust 822N 758N

during the design stage of the project,

possibly resulting in a higher number of jet Resulting Jetfan quantity 38 32

fans in a fire scenario.

Jetfan absorbed power 328kW 28.6kW

Due to the high silencer deflection angle

the thrust developed along the longitudinal Total power 1,246.4kW 915.2kW

tunnel axis has to be corrected by the

Running hours per year 1000h

cosine of the angle.

kWh per year 1,246,400 915,200

The latest technical solution Electricity cost EUR 0.11/kWh

Mojet Total energy cost per year EUR 137,104 EUR 100,672

So far we have seen various technical

efforts in order to maximise the momentum

exchange between booster fans and the Table 3: Financial implications of jet fan choice

fresh air flow induced into the tunnel.

Standard Jetfan Mojet Savings

If we again consider formula one, we can

appreciate that: Formula (4) 31,237N 24,003N -23%

Quantity of jetfans 38 32 -16%

= we have no control since it is a

physical property of the air inside the tunnel Total power 1,246.4kW 915.2kW -27%

Total cost per year EUR 137,104 EUR 100,672 -27%

, = they are linked together in a

directly proportional way. But should qv be

kept constant, and in some ways Vf lower blade pitch angle and higher pressure Blade pitch angle.

increased, the result is an increase in the drops, while still delivering the required Area restriction ratio, of around 1:6.

fan-developed thrust. aerodynamic thrust.

In more technical detail, Tarada [17] [18] The latter seems to cancel all the Playing with all these possibilities we

describes the concept of the ‘Momemtum benefits but, it is not so, since moving have to optimise the combination, including

Jet’ (Mojet) with converging silencers upwards in the fan characteristic curve, the the Kempf factor, to get the maximum

outlets (nozzles) on one or both side of the fan efficiency gets remarkably higher hence performances out of the installed jet fan

fans depending on whether unidirectional there is a benefit. configuration.

or reversible jet fans are needed. So a Another benefit comes from the A work example based on a 1.5km long

significantly greater aerodynamic thrust can inclination of the nozzles, not by as much tunnel can give a clear picture of the final

be obtained, with this converging nozzle as slanted silencers (around 5°) but enough benefits (see Table 1).

arrangement, by accelerating the discharge to notably improve the k installation factor. From the above Table 2 we can now

air into a smaller outlet area. It is important to note that the silencer highlight the advantages.

Naturally there are losses generated by downward inclination can be asymmetric, The above example has been developed

nozzles varying with a square law and keeping the lowest silencer side at the with a number of CFD calculations and it

power demand with a cubic law. same level, thus not increasing the fan has been optimised the many variables.

Axial fans have a steep performance envelope and keeping the same clearance In this particular case, due to a small fan

curve, so the additional pressure drop as a standard jet fan. diameter, the thrust provided by the Mojet

moves up the working point of the fan while We can summarise the variables: is lower than the one provided by a

the volume flow reduction is not so Asymmetric converging silencers. standard jet fan but the k factor and the

remarkable, or it is possible to operate at Inclination (about 5°). absorbed power are better.

www.tunnelsandtunnelling.com JULY 2012 Tunnels & Tunnelling International 61

058_062tun0712 Systemair:T&T 25/6/12 12:01 Page 62

TECHNICAL | FAN DEVELOPMENT

For larger jet fan diameters of 1,000 to

1,250mm, the benefits can be achieved by

increasing the thrust and the restriction area

ratio. So for every fan diameter we should

evaluate all the possible variables to find

the best compromise:

Blade pitch angle and hence volume

flow

Area ratio restriction and hence velocity Jet fan blades

hence thrust

Power

k factor out. Concurrently, various fan engineering giving the possibility to increase the

technical solutions to achieve this have also longitudinal ventilation performances,

Additional benefits been developed. especially on energy consumption. This is a

This technical solution has other correlated The latest, though surely not the final key figure to be considered for present and

positive effects. By reducing the number of one, shows the best technical achievement, future design.

booster fans we can reduce the installation

costs. The cost of original equipment is

Bibliography

also positively affected.

The electrical cable cost represents [1] ISO 13350, Conversion Rules, Appendix C

about 50 to 60 per cent of the total cost in a

[2] “Einfluss der Wandeffekte aut die Treibstrahlwirkung eines Strahlgebläses“ I.Kempf -

longitudinal ventilation system.

Schweizerische Bauzeitung, 1965

Having fewer booster fans and less

power we can save in cable length and [3] “The friction losses on wall caused by jet flows of booster fans“ E. Rohne – BHRA, Sheffield,

diameter. In Italy, the Italian Road Authority U.K., 1979

(ANAS) prescribes that the jet fans and [4] “Jet flow momentum losses of a booster fan when installed in a tunnel niche” E. Rohne – BHRA,

correlated equipments have to withstand New York, U.K., 1982

400°C for two hours, hence the saving in

this part of the installation is remarkable. [5] “The influence of axis distance of two parallel jet flows on the friction losses on walls” E. Rohne –

The last but not the least important point BHRA, Lille, FR, 1985

is that maintenance costs are not normally [6] “The friction losses on walls caused by a row of four parallel jet flows” I,Rohne – BHRA, Durham,

given much thought at the preliminary U.K.,

contract stage of a jet fan order. A reduction

in the number of booster fans means less [7] “Friction losses of a single jet due to its contact with a vaulted ceiling” I.Rohne – BHRA, Brighton,

time inside the tunnel for inspection and U.K., 1991

maintenance purposes. [8] “Impulse fans” N. Costeris – BHRA, Brighton, U.K., 1991

The flexibility of inclined converging

[9] “An experimental study on the longitudinal ventilation system” A.D. Martegani, G. Pavesi, C.

nozzles can be done at any direction. On a

Barbetta – BHRA, Liverpool, U.K., 1994

horizontal plane, on a vertical plane, or a

combination of the two. This feasibility [10] ”The influence of separation,inclination and swirl on single and coupled jet fans installation

allows the use of such technology in round, efficiency” A.D. Martegani, G. Pavesi, C. Barbetta – BHRGroup, Aosta Valley, IT, 1997

rectangular or any shaped tunnel section,

[11] “The effect of jet plume configuration on the installation efficiency of jet fans” R.D. Matthews, M.

even in niches.

Tabarra, B. Kenrick – BHRGroup, Aosta Valley, IT, 1997

Future steps [12] “Experimental investigation of interaction of plain jet fans mounted in series” A.D. Martegani, G.

The Mojet has been demonstrated to have Pavesi, C. Barbetta – BHRGroup, Boston, USA, 2000

a sound physical basis, and the CFD

[13] “Investigation of wall-friction, pressure distribution and the effectiveness of big jet fans with

analysis has supported this. However, true deflection blades in the Fodnes tunnel in Norway” G. Lotsberg – BHRGroup, Aosta Valley, IT, 1997

confirmation can only come with a real

installation, or in a test carried out at a 1:1 [14] “Messungen an der Tunnellufftungsanlage der Tunnels Balmenrain und Uznaberg, Hauptstrasse

scale. It is even better if the test is T8/A8” P. Pospisil, M. Mart, M. Brandt - HBI report 87 – 95 – 10 , CH, 2003

performed by a notified body that has no [15] “Strömungsmessung, Tunnel de Collembey” M. Mart, M. Brandt – HBI report 03 – 100 – 02 ,

interest at all to manipulate the relevant CH, 2004

measurements.

A 1:1 scale test was arranged for 2011 in [16] “Numerical study of the optimization of the pitch angle of an alternative jet fan in a longitudinal

a 600m long tunnel in Spain. This was tunnel ventilation system” V. Betta, F. Cascetta, M. Musto, G. Rotondo – Tunnel and Underground

changed to a test that will be carried out in Technology, pages 164 – 172 , 2009

Italy in 2012. [17] “Impulse ventilation for tunnels – a state of the art review” F. Tarada , R. Brandt – BHRGroup,

New Bruswick, USA , 2009

Conclusions

[18] “Design, testing and application of an energy-efficient longitudinal ventilation system” F. Tarada –

From the mid 1960s until the present day, a

BHRGroup, Dundee, U.K., 2011

lot of dedicated research to establish the k

factor more accurately has been carried

62 Tunnels & Tunnelling International JULY 2012 www.tunnelsandtunnelling.com

You might also like

- Centrifugal Fan Plug Fans enDocument56 pagesCentrifugal Fan Plug Fans enIlya PetrovNo ratings yet

- E Belt PulleyDocument124 pagesE Belt PulleyVina SulistyaNo ratings yet

- Epson 3800 3880 SMDocument306 pagesEpson 3800 3880 SMIon IonutNo ratings yet

- Manual Book Fan Marunda ProjectDocument27 pagesManual Book Fan Marunda Projectlukas rahmaNo ratings yet

- Approved Catalog LEA131.E0 January 2016 PDFDocument88 pagesApproved Catalog LEA131.E0 January 2016 PDFDak SerikNo ratings yet

- Fan Manual - CEDocument30 pagesFan Manual - CEkeyur1109100% (1)

- IGB010.E2-Axial Flow Fan - TDA-TDF-TBE-TDB-TDS - New PDFDocument10 pagesIGB010.E2-Axial Flow Fan - TDA-TDF-TBE-TDB-TDS - New PDFโจ้ สแปร์แร็คNo ratings yet

- Smoke Fans CatalogueDocument54 pagesSmoke Fans CataloguejayanthahhyNo ratings yet

- Systemair AX Installation Manual EngDocument32 pagesSystemair AX Installation Manual EngrkssNo ratings yet

- Fan BlowerDocument16 pagesFan BlowerIjatnaim IsaNo ratings yet

- Centrifugal FanDocument9 pagesCentrifugal FanDTNgoNo ratings yet

- KLS AhuDocument32 pagesKLS AhuKarayev BayramNo ratings yet

- Sf52 Exhaust Fan: Rugged - Low Cost - High CFM - Low MaintenanceDocument15 pagesSf52 Exhaust Fan: Rugged - Low Cost - High CFM - Low MaintenanceFredy SameoneNo ratings yet

- Hovercraft DesainDocument75 pagesHovercraft DesainpaparezaNo ratings yet

- AG 3095 1208AgroLogicClimateControlsEMDocument4 pagesAG 3095 1208AgroLogicClimateControlsEMphamnhonNo ratings yet

- 05 PPT System Effects 06Document60 pages05 PPT System Effects 06Anonymous 6lLH9TMOlNo ratings yet

- O M ManualDocument131 pagesO M Manualagniva dattaNo ratings yet

- Fcu PDFDocument12 pagesFcu PDFonspsnonsNo ratings yet

- Centrifugal Fan BladesDocument1 pageCentrifugal Fan BladesVijay BhanNo ratings yet

- Product Application Guide: Multiple F An Systems - F Ans in Series and ParallelDocument4 pagesProduct Application Guide: Multiple F An Systems - F Ans in Series and ParallelgonvicNo ratings yet

- IGB016.E1-Centrifugal Fan New PDFDocument13 pagesIGB016.E1-Centrifugal Fan New PDFSusan LamNo ratings yet

- Performance Characteristics of Axial FansDocument4 pagesPerformance Characteristics of Axial Fanskutts76No ratings yet

- Mca HVAC SystemDocument12 pagesMca HVAC SystemPrem Chandu BallemNo ratings yet

- York AHU Elect HeaterDocument1 pageYork AHU Elect Heatertan0314No ratings yet

- Tech Sheet - UXN-B1DS2 - Prasana HQDocument1 pageTech Sheet - UXN-B1DS2 - Prasana HQJeghi100% (2)

- Calculating Cooling Load - VRF Wizard Variable 2Document2 pagesCalculating Cooling Load - VRF Wizard Variable 2Baseer AhmadNo ratings yet

- Part 1 - Fundamentals of Airflow, Fans & DuctDocument49 pagesPart 1 - Fundamentals of Airflow, Fans & Ductkhanh.vecNo ratings yet

- EPA2008-Indoor Air Vapor Intrusion Mitigation ApproachesDocument49 pagesEPA2008-Indoor Air Vapor Intrusion Mitigation Approacheskulov1592100% (1)

- Handbook Chapter15 DisplacementVentilationDocument41 pagesHandbook Chapter15 DisplacementVentilationJoao Sousa100% (1)

- HVAC System PDFDocument79 pagesHVAC System PDFBülent KabadayiNo ratings yet

- HVACDocument21 pagesHVACullasNo ratings yet

- How To Select The Right Fan or BlowerDocument6 pagesHow To Select The Right Fan or BlowerASHOKNo ratings yet

- What Is The Basis For Fan SelectionDocument3 pagesWhat Is The Basis For Fan SelectionsmcsamindaNo ratings yet

- Positioning of Air Cooled CondensersDocument9 pagesPositioning of Air Cooled CondensersAlexNo ratings yet

- B1. Fan Laws and Fan Control - RobinsonDocument74 pagesB1. Fan Laws and Fan Control - RobinsonNelly Isabel Narvaez PachecoNo ratings yet

- Training DuctingDocument20 pagesTraining Ductingpanji uteNo ratings yet

- "About Mr. Slim Air Conditioners Training" For Pme Staff 21st September 2015Document165 pages"About Mr. Slim Air Conditioners Training" For Pme Staff 21st September 2015Tun Lin AungNo ratings yet

- Pentaksiran Teori-Assignment DMC 3113Document4 pagesPentaksiran Teori-Assignment DMC 3113sharifahsalmah50No ratings yet

- General Instruction-Centrifugal FanDocument13 pagesGeneral Instruction-Centrifugal FanEd FanunNo ratings yet

- Greenheck-E Axial SBCE - SidewallPropeller - CatalogDocument40 pagesGreenheck-E Axial SBCE - SidewallPropeller - CatalogLuis AlaniaNo ratings yet

- Heat Wheel Technical HandbookDocument29 pagesHeat Wheel Technical Handbooksripriya01No ratings yet

- Coils Selection FormulasDocument3 pagesCoils Selection FormulasalbrgmailNo ratings yet

- 4.6 Fans and BlowersDocument6 pages4.6 Fans and Blowerssrimant1984No ratings yet

- BreatheDocument9 pagesBreatheMohammad Arshad KamarNo ratings yet

- AIF Product Presentation India - July 2000Document52 pagesAIF Product Presentation India - July 2000Kreator Deshmukh100% (1)

- Room PressureDocument6 pagesRoom PressurevysakhNo ratings yet

- On The Theoretical Link Between Design Parameters and Performance in Cross Flow Fans A Numerical and Experimental Study 2005 Computers and FluidsDocument18 pagesOn The Theoretical Link Between Design Parameters and Performance in Cross Flow Fans A Numerical and Experimental Study 2005 Computers and Fluidsankushanks2591No ratings yet

- A Criterion To Define Cross-Flow Fan Design ParametersDocument4 pagesA Criterion To Define Cross-Flow Fan Design ParametersGiuseppe De LuciaNo ratings yet

- BREIDERT DB Series (Soler Palau Co.)Document18 pagesBREIDERT DB Series (Soler Palau Co.)adeel_akhtarNo ratings yet

- Labatory VentilationDocument19 pagesLabatory VentilationLogain SunNo ratings yet

- Fan Calculator (Axial & Centrifugal) - Pressure & Flow - CalQlataDocument9 pagesFan Calculator (Axial & Centrifugal) - Pressure & Flow - CalQlatakaustavNo ratings yet

- Roof Exhaust FanDocument4 pagesRoof Exhaust Fan4uengineerNo ratings yet

- Pan Steam HumidifierDocument1 pagePan Steam HumidifierRahul ChandrawarNo ratings yet

- Stratifistratified Charge EngineDocument14 pagesStratifistratified Charge EngineJay PannaNo ratings yet

- WCFX-V R134a 50-60Hz MS04100D-1016 LoDocument24 pagesWCFX-V R134a 50-60Hz MS04100D-1016 LoaftabNo ratings yet

- Water and Oil Free Screw Compressor Evaluation ReportDocument4 pagesWater and Oil Free Screw Compressor Evaluation ReportdaritiNo ratings yet

- Turbine Choice and Optimization For A Shoreline OWC Wave Energy PlantDocument8 pagesTurbine Choice and Optimization For A Shoreline OWC Wave Energy PlantAhmedNo ratings yet

- M J Clifton-Smith 2007 J. Phys. - Conf. Ser. 75 012017Document10 pagesM J Clifton-Smith 2007 J. Phys. - Conf. Ser. 75 012017Iman SaberiNo ratings yet

- Journal of Wind Engineering and Industrial AerodynamicsDocument17 pagesJournal of Wind Engineering and Industrial Aerodynamicslaney_estelNo ratings yet

- PVJAPRE1976Document1 pagePVJAPRE1976kuttanmolutyNo ratings yet

- Design and CFD Analysis of Convergent and Divergent Nozzle: P.Vinod Kumar, B.Kishore KumarDocument14 pagesDesign and CFD Analysis of Convergent and Divergent Nozzle: P.Vinod Kumar, B.Kishore KumarvamsiNo ratings yet

- Gds Manual Flo2d ProDocument182 pagesGds Manual Flo2d ProbycmNo ratings yet

- Solution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797Document16 pagesSolution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797warepneumomxkhf100% (17)

- SR-36-01-01 HAZOP TOR Rehman Production FacilityDocument30 pagesSR-36-01-01 HAZOP TOR Rehman Production FacilityMuhammad.Saim100% (1)

- Exercise # 1: Statistics and ProbabilityDocument6 pagesExercise # 1: Statistics and ProbabilityAszyla ArzaNo ratings yet

- Base On Solid-Works Design of Compact High EfficieDocument15 pagesBase On Solid-Works Design of Compact High EfficieGorgeNo ratings yet

- Structural and Literary DevicesDocument40 pagesStructural and Literary Devicesapi-237159930No ratings yet

- Amina Ahmed Benchmark Solution Oet Writing Task Practice With CorretionDocument1 pageAmina Ahmed Benchmark Solution Oet Writing Task Practice With CorretionFïzã PäthäñNo ratings yet

- ST200HDocument2 pagesST200HAnjana DissanayakaNo ratings yet

- Nepra ManualDocument60 pagesNepra Manualabdulwasay_bzuNo ratings yet

- KONAN Emmanuel Sales Technical Engineer 16 Juin 23Document1 pageKONAN Emmanuel Sales Technical Engineer 16 Juin 23EMMANUEL KONANNo ratings yet

- Annual Report 2014 PDFDocument153 pagesAnnual Report 2014 PDFகோகுல் இராNo ratings yet

- Uremic EncephalophatyDocument48 pagesUremic EncephalophatySindi LadayaNo ratings yet

- TSB-1139 8SC Wiring DiagramDocument2 pagesTSB-1139 8SC Wiring Diagramxavier marsNo ratings yet

- Module 1 What Is Geography and TourismDocument22 pagesModule 1 What Is Geography and TourismLeanne Abegail EstabilloNo ratings yet

- Background of Philippine Art and Literature in Romantic RealismDocument2 pagesBackground of Philippine Art and Literature in Romantic RealismRaldz CoyocaNo ratings yet

- Bata Shoe Company (Bangladesh) Ltd.Document6 pagesBata Shoe Company (Bangladesh) Ltd.Vurdalack666No ratings yet

- HPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIDocument13 pagesHPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIthe next miamiNo ratings yet

- Allotrope Partners Indonesia Renewable Energy Project AssociateDocument2 pagesAllotrope Partners Indonesia Renewable Energy Project AssociateRizal ZulkarnaenNo ratings yet

- Cne CatalogoDocument4 pagesCne CatalogoPaulo SergioNo ratings yet

- PQR As Run SheetDocument2 pagesPQR As Run SheetAhmed ElsharkawNo ratings yet

- Carbon Capture Corrosion Current Practice 2023Document12 pagesCarbon Capture Corrosion Current Practice 2023Wayne MonneryNo ratings yet

- (A) Design - Introduction To Transformer DesignDocument16 pages(A) Design - Introduction To Transformer DesignZineddine BENOUADAHNo ratings yet

- MGje 6 Fix GX PK Yp RBJ LBRDocument9 pagesMGje 6 Fix GX PK Yp RBJ LBRBANOTH KUMARNo ratings yet

- 9701 s02 ErDocument14 pages9701 s02 ErHubbak KhanNo ratings yet

- TinyMobileRobots TinySurveyor FlyerDocument4 pagesTinyMobileRobots TinySurveyor FlyerfelipeNo ratings yet

- Case Study of WapdaDocument34 pagesCase Study of WapdaImran Chaudhry100% (1)

- Anthropological Thought Session by DR G. VivekanandaDocument277 pagesAnthropological Thought Session by DR G. Vivekanandahamtum7861No ratings yet

- Owner: PT. Baker Hughes User: Cok Gede Reza Description: Modified Safety Pin, Add. Handrail & Add. Anti Slip Step Stair at Pressure Test BayDocument3 pagesOwner: PT. Baker Hughes User: Cok Gede Reza Description: Modified Safety Pin, Add. Handrail & Add. Anti Slip Step Stair at Pressure Test BayMuhammad AlpianNo ratings yet

- Functional Specification For Deck CraneDocument31 pagesFunctional Specification For Deck Craneaiyubi20% (1)