Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

46 viewsGujarat Technological University

Gujarat Technological University

Uploaded by

D VThis document is an exam for a Metal Forming Analysis course, consisting of 5 questions covering various metal forming topics. Question 1 covers direct vs indirect extrusion processes, forming limit diagrams, and factors affecting drawability. Question 2 defines hot/cold forming and flow stress, explains rolling defects, and covers two-dimensional Mohr's circle and yielding theories. Question 3 discusses clearance in sheet metal operations, springback in bending, and calculating die/punch diameters and force for a blanking operation. Question 4 covers shear on punches and dies, wire drawing processes, and sheet metal press operations. Question 5 defines dry/wet/tube drawing, differences between compound and progressive dies, and analyzing strip rolling using projected arc length equations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Unlocking The Secrets of Gann PDFDocument11 pagesUnlocking The Secrets of Gann PDFfsolomon100% (1)

- Kato30t nk250 PDFDocument4 pagesKato30t nk250 PDFhakimi83100% (1)

- Er Anurag Mishra Heat & Thermodynamics Shri Balaji PublicationsDocument332 pagesEr Anurag Mishra Heat & Thermodynamics Shri Balaji PublicationsJagdeep Kumar75% (4)

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityfeyayel988No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Be Winter 2020Document1 pageBe Winter 2020chandsixNo ratings yet

- Be Winter 2018Document1 pageBe Winter 2018chandsixNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityMaulik PatelNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityfeyayel988No ratings yet

- Elastic Pressure TransducerDocument2 pagesElastic Pressure TransducerNavdeep DobariyaNo ratings yet

- Ask Science ExtremeDocument1 pageAsk Science ExtremeJay JoshiNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityfeyayel990No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityMaulik PatelNo ratings yet

- Be Summer 2023Document2 pagesBe Summer 2023Abc 194748No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityVraj ShahNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityravi upadhyayNo ratings yet

- Be Summer 2014Document1 pageBe Summer 2014chandsixNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityVijayNo ratings yet

- Be Winter 2019Document1 pageBe Winter 2019chandsixNo ratings yet

- MSMDocument2 pagesMSMRam PatelNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityJay PATELNo ratings yet

- Be Winter 2021Document2 pagesBe Winter 2021Omer LalaNo ratings yet

- Be Winter 2015Document1 pageBe Winter 2015chandsixNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityparth patelNo ratings yet

- Be Winter 2018Document2 pagesBe Winter 2018Swastik PanchalNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityfeyayel990No ratings yet

- E D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDocument3 pagesE D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDrRoja A RNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityBhagirath sinh ZalaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universitydevang majithiyaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityKevalNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityTejash SolankiNo ratings yet

- Be Winter 2021Document2 pagesBe Winter 2021Nikesh rampariyaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universitygandhinoman786No ratings yet

- MF7203 Theory of Metal FormingDocument4 pagesMF7203 Theory of Metal FormingKanagarajanNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityRenieNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityTNo ratings yet

- RP 3171926Document2 pagesRP 3171926Kakashi HatakeNo ratings yet

- Winter 18 MMMDocument1 pageWinter 18 MMMRakesh VaghelaNo ratings yet

- Manufacturing Technology Question Papers of JntuaDocument15 pagesManufacturing Technology Question Papers of JntuaHimadhar SaduNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityprince.patelNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityJack SparrowNo ratings yet

- Be Winter 2023Document1 pageBe Winter 2023Abc 194748No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityfeyayel988No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityJay PATELNo ratings yet

- RK University: InstructionsDocument3 pagesRK University: InstructionsShiraj SunasaraNo ratings yet

- r05322003 Metal FormingDocument8 pagesr05322003 Metal FormingSRINIVASA RAO GANTANo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- 115AN01Document2 pages115AN01rammanav3101No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityJaineshNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityfeyayel990No ratings yet

- Be Summer 2019Document1 pageBe Summer 2019rrvvrrvv36No ratings yet

- Mechanical Measurement and MetrologyDocument1 pageMechanical Measurement and MetrologyDhavalMajithiyaNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Be Summer 2018Document2 pagesBe Summer 2018Swastik PanchalNo ratings yet

- Manufacturing: ProcessDocument22 pagesManufacturing: ProcessKKNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universitydevang majithiyaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityDhruvNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- PMMS Schedule 2019-2020 PDFDocument1 pagePMMS Schedule 2019-2020 PDFD VNo ratings yet

- Agravat 8 Sem Project ReportDocument25 pagesAgravat 8 Sem Project ReportD VNo ratings yet

- Manav Garima Yojna 2019-20Document1 pageManav Garima Yojna 2019-20D VNo ratings yet

- CPDP RESUME 043 IcDocument4 pagesCPDP RESUME 043 IcD VNo ratings yet

- Business Model Canvas: Gujarat Technological UniversityDocument6 pagesBusiness Model Canvas: Gujarat Technological UniversityD VNo ratings yet

- (A) (B) (C) (D) (E) : in of The TheDocument11 pages(A) (B) (C) (D) (E) : in of The TheD VNo ratings yet

- Syllabus For Muliple Choice Questions (Admissions Test 2020)Document1 pageSyllabus For Muliple Choice Questions (Admissions Test 2020)D VNo ratings yet

- Name:-LR 6.1 Calendar: Correct Answer: - 2012 Answer DescriptionDocument2 pagesName:-LR 6.1 Calendar: Correct Answer: - 2012 Answer DescriptionD VNo ratings yet

- Name:-LR 2.1 Coding Decoding: Correct Answer: - # Answer DescriptionDocument2 pagesName:-LR 2.1 Coding Decoding: Correct Answer: - # Answer DescriptionD VNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityD VNo ratings yet

- MD GTU Study Material GTU-Paper-Analysis ALL 18092019084700AM PDFDocument20 pagesMD GTU Study Material GTU-Paper-Analysis ALL 18092019084700AM PDFD VNo ratings yet

- If You Have A Garden and A Library, You Have Everything You Need.Document9 pagesIf You Have A Garden and A Library, You Have Everything You Need.D VNo ratings yet

- Solar Water Purifier: Deepak Devasagayam, Mayuresh Kathe, Mayur Patil, Nimish KavishwarDocument5 pagesSolar Water Purifier: Deepak Devasagayam, Mayuresh Kathe, Mayur Patil, Nimish KavishwarD VNo ratings yet

- United States Patent (19) : Int, Cl2. F2SB 27/00, F2SB 15/00, F24J/3/02Document5 pagesUnited States Patent (19) : Int, Cl2. F2SB 27/00, F2SB 15/00, F24J/3/02D VNo ratings yet

- Drinking Such Waters or Using Them in Cooking Leads To Widespread Acute and Chronic Illnesses and Is A Major Cause of Death in Many Countries.Document11 pagesDrinking Such Waters or Using Them in Cooking Leads To Widespread Acute and Chronic Illnesses and Is A Major Cause of Death in Many Countries.D VNo ratings yet

- Final Project Report - Group 7 PDFDocument154 pagesFinal Project Report - Group 7 PDFNhut NguyenNo ratings yet

- United States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997Document8 pagesUnited States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997155No ratings yet

- Sharp Refrigerator sj44lwh1Document28 pagesSharp Refrigerator sj44lwh1Joseph AlbertNo ratings yet

- Name: - AP Physics Worksheet - Mechanical Waves ReviewDocument5 pagesName: - AP Physics Worksheet - Mechanical Waves ReviewMarcial Aguilar BarahonaNo ratings yet

- Generator Characteristics: 1. No-Load Saturation Characteristic (E /I)Document24 pagesGenerator Characteristics: 1. No-Load Saturation Characteristic (E /I)Uma SaluvaNo ratings yet

- Polymer Brushes Via Surface-Initiated Controlled Radical PolymerizationDocument91 pagesPolymer Brushes Via Surface-Initiated Controlled Radical PolymerizationP'Parot Pornlapas100% (1)

- Bearing Defect Diagnosis and Acoustic EmissionDocument40 pagesBearing Defect Diagnosis and Acoustic EmissionHazim HazimNo ratings yet

- ResistorsDocument9 pagesResistorsanon_26317821No ratings yet

- HW 924 6759 Igcsemidtermworksheet2Document51 pagesHW 924 6759 Igcsemidtermworksheet2zaseel86No ratings yet

- Evaluation of Open Pit Mine Slope Stability AnalysisDocument11 pagesEvaluation of Open Pit Mine Slope Stability AnalysisrahultharejaNo ratings yet

- Evaluation of Non-Linear Normal ModesDocument9 pagesEvaluation of Non-Linear Normal ModesEmerson Borges SantanaNo ratings yet

- Om 438906011 W365-3330H N M 2H01 enDocument24 pagesOm 438906011 W365-3330H N M 2H01 enAlejandro LeonNo ratings yet

- Brownian Dynamics Study of Gel-Forming Colloidal Particles: P. H. S. Santos, O. H. Campanella, and M. A. CarignanoDocument7 pagesBrownian Dynamics Study of Gel-Forming Colloidal Particles: P. H. S. Santos, O. H. Campanella, and M. A. CarignanoCarlos GallegosNo ratings yet

- Moeller DF, DVDocument3 pagesMoeller DF, DVPaulo EdilsonNo ratings yet

- OIC-NW Reviewer Blog - Solving Distance by Parallel SailingDocument2 pagesOIC-NW Reviewer Blog - Solving Distance by Parallel SailingJofel Calaycay100% (1)

- Amca 801-01 (R2008) PDFDocument61 pagesAmca 801-01 (R2008) PDFandrés morantes100% (1)

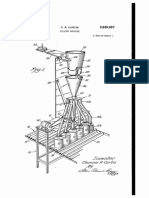

- Powder Filling MachineDocument9 pagesPowder Filling MachineCao Ngoc AnhNo ratings yet

- T-Xy Diagram For PEDDocument109 pagesT-Xy Diagram For PEDTehMarianNo ratings yet

- ADA237190Document66 pagesADA237190sixayo4531No ratings yet

- NIOSH 7400 AsbestosDocument40 pagesNIOSH 7400 AsbestosNicolas ZeballosNo ratings yet

- Math 2 PDFDocument90 pagesMath 2 PDFElrom Jasper Marzo RamosNo ratings yet

- 2014 Guidelines Rockfall RemediationDocument9 pages2014 Guidelines Rockfall RemediationVashdevNo ratings yet

- Graphing Linear EquationDocument6 pagesGraphing Linear EquationVanessa NacarNo ratings yet

- J. Mathematical Model of Once Through MSF: T, Is Obtained From The Relation T (To-Tn) /NDocument11 pagesJ. Mathematical Model of Once Through MSF: T, Is Obtained From The Relation T (To-Tn) /NTino UmbarNo ratings yet

- Fault Slip and Fault NamesDocument4 pagesFault Slip and Fault Namesanima1982No ratings yet

- CIVL5277 Lecture 9 - Design of Bending MembersDocument78 pagesCIVL5277 Lecture 9 - Design of Bending Membersjihe0020No ratings yet

- Chapter 8: Thermal Conductivity and The Mechanism of Heat TransportDocument33 pagesChapter 8: Thermal Conductivity and The Mechanism of Heat TransportConrad MonterolaNo ratings yet

Gujarat Technological University

Gujarat Technological University

Uploaded by

D V0 ratings0% found this document useful (0 votes)

46 views1 pageThis document is an exam for a Metal Forming Analysis course, consisting of 5 questions covering various metal forming topics. Question 1 covers direct vs indirect extrusion processes, forming limit diagrams, and factors affecting drawability. Question 2 defines hot/cold forming and flow stress, explains rolling defects, and covers two-dimensional Mohr's circle and yielding theories. Question 3 discusses clearance in sheet metal operations, springback in bending, and calculating die/punch diameters and force for a blanking operation. Question 4 covers shear on punches and dies, wire drawing processes, and sheet metal press operations. Question 5 defines dry/wet/tube drawing, differences between compound and progressive dies, and analyzing strip rolling using projected arc length equations.

Original Description:

William

Original Title

171905-2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is an exam for a Metal Forming Analysis course, consisting of 5 questions covering various metal forming topics. Question 1 covers direct vs indirect extrusion processes, forming limit diagrams, and factors affecting drawability. Question 2 defines hot/cold forming and flow stress, explains rolling defects, and covers two-dimensional Mohr's circle and yielding theories. Question 3 discusses clearance in sheet metal operations, springback in bending, and calculating die/punch diameters and force for a blanking operation. Question 4 covers shear on punches and dies, wire drawing processes, and sheet metal press operations. Question 5 defines dry/wet/tube drawing, differences between compound and progressive dies, and analyzing strip rolling using projected arc length equations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

46 views1 pageGujarat Technological University

Gujarat Technological University

Uploaded by

D VThis document is an exam for a Metal Forming Analysis course, consisting of 5 questions covering various metal forming topics. Question 1 covers direct vs indirect extrusion processes, forming limit diagrams, and factors affecting drawability. Question 2 defines hot/cold forming and flow stress, explains rolling defects, and covers two-dimensional Mohr's circle and yielding theories. Question 3 discusses clearance in sheet metal operations, springback in bending, and calculating die/punch diameters and force for a blanking operation. Question 4 covers shear on punches and dies, wire drawing processes, and sheet metal press operations. Question 5 defines dry/wet/tube drawing, differences between compound and progressive dies, and analyzing strip rolling using projected arc length equations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

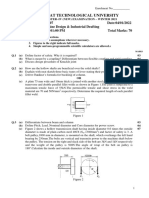

Seat No.: ________ Enrolment No.

___________

GUJARAT TECHNOLOGICAL UNIVERSITY

BE - SEMESTER–VII(NEW) EXAMINATION – SUMMER 2019

Subject Code:2171913 Date:10/05/2019

Subject Name:Metal Forming Analysis

Time:02:30 PM TO 05:00 PM Total Marks: 70

Instructions:

1. Attempt all questions.

2. Make suitable assumptions wherever necessary.

3. Figures to the right indicate full marks.

Q:1 (a) Differentiate direct and indirect extrusion process. 03

(b) Explain a Forming Limit diagram. 04

(c) What is Drawability? List and Discuss factor Affecting to Drawability 07

Q:2 (a) Define the following terms: (i) Hot forming, (ii) Cold Forming, 03

(iii) Flow Stress

(b) Explain various Rolling defects. 04

(c) Give short note on Two-Dimensional Mohr's circle method for stress 07

analysis.

OR

(c) Explain VonMises & Tresca theory of yielding. 07

Q:3 (a) Explain clearance in sheet metal operation. 03

(b) Explain spring back effect in bending process. 04

(c) A cold roll sheet with shear strength of 350MPa & thickness of 3mm is 07

to be Subjected blanking operation. The diameter of blank to be

obtained is 130mm & Clearance 0.075mm.What is the appropriate die &

punch diameter & Punch force for operation?

OR

Q:3 (a) Determine Engineering Strain and True strain. 03

(b) Explain Anistrophy in sheet metal 04

(c) Explain typical arrangement of roll & roll mills with neat sketches. 07

Q:4 (a) What do you understand by shear on punch and die? 03

(b) Explain Wire Drawing processes in brief. 04

(c) Explain various operations performed on sheet metal press machine. 07

OR

Q:4 (a) Define angle of bite and discuss its effect in rolling process. 03

(b) What are the benefits of hydrostatics extrusion process? 04

(c) Explain friction board drop hammer for forging 07

Q:5 (a) Explain Blanking operation with neat sketch. 03

(b) State difference between compound and progressive dies. 04

(c) Discuss analysis of strip rolling derive equation for projected arc length. 07

OR

Q:5 (a) Define (i) dry drawing (ii) wet drawing (iii) tube drawing. 03

(b) How is impression die forging different from closed die forging 04

(c) Explain about importance of Upper bound and Lower bound theorem in 07

metal forming.

********

You might also like

- Unlocking The Secrets of Gann PDFDocument11 pagesUnlocking The Secrets of Gann PDFfsolomon100% (1)

- Kato30t nk250 PDFDocument4 pagesKato30t nk250 PDFhakimi83100% (1)

- Er Anurag Mishra Heat & Thermodynamics Shri Balaji PublicationsDocument332 pagesEr Anurag Mishra Heat & Thermodynamics Shri Balaji PublicationsJagdeep Kumar75% (4)

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityfeyayel988No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Be Winter 2020Document1 pageBe Winter 2020chandsixNo ratings yet

- Be Winter 2018Document1 pageBe Winter 2018chandsixNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityMaulik PatelNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityfeyayel988No ratings yet

- Elastic Pressure TransducerDocument2 pagesElastic Pressure TransducerNavdeep DobariyaNo ratings yet

- Ask Science ExtremeDocument1 pageAsk Science ExtremeJay JoshiNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityfeyayel990No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityMaulik PatelNo ratings yet

- Be Summer 2023Document2 pagesBe Summer 2023Abc 194748No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityVraj ShahNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityravi upadhyayNo ratings yet

- Be Summer 2014Document1 pageBe Summer 2014chandsixNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityVijayNo ratings yet

- Be Winter 2019Document1 pageBe Winter 2019chandsixNo ratings yet

- MSMDocument2 pagesMSMRam PatelNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityJay PATELNo ratings yet

- Be Winter 2021Document2 pagesBe Winter 2021Omer LalaNo ratings yet

- Be Winter 2015Document1 pageBe Winter 2015chandsixNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityparth patelNo ratings yet

- Be Winter 2018Document2 pagesBe Winter 2018Swastik PanchalNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityfeyayel990No ratings yet

- E D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDocument3 pagesE D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDrRoja A RNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityBhagirath sinh ZalaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universitydevang majithiyaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityKevalNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityTejash SolankiNo ratings yet

- Be Winter 2021Document2 pagesBe Winter 2021Nikesh rampariyaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universitygandhinoman786No ratings yet

- MF7203 Theory of Metal FormingDocument4 pagesMF7203 Theory of Metal FormingKanagarajanNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityRenieNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityTNo ratings yet

- RP 3171926Document2 pagesRP 3171926Kakashi HatakeNo ratings yet

- Winter 18 MMMDocument1 pageWinter 18 MMMRakesh VaghelaNo ratings yet

- Manufacturing Technology Question Papers of JntuaDocument15 pagesManufacturing Technology Question Papers of JntuaHimadhar SaduNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityprince.patelNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHet ShahNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityJack SparrowNo ratings yet

- Be Winter 2023Document1 pageBe Winter 2023Abc 194748No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityfeyayel988No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityJay PATELNo ratings yet

- RK University: InstructionsDocument3 pagesRK University: InstructionsShiraj SunasaraNo ratings yet

- r05322003 Metal FormingDocument8 pagesr05322003 Metal FormingSRINIVASA RAO GANTANo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- 115AN01Document2 pages115AN01rammanav3101No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityJaineshNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityfeyayel990No ratings yet

- Be Summer 2019Document1 pageBe Summer 2019rrvvrrvv36No ratings yet

- Mechanical Measurement and MetrologyDocument1 pageMechanical Measurement and MetrologyDhavalMajithiyaNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityyicef37689No ratings yet

- Be Summer 2018Document2 pagesBe Summer 2018Swastik PanchalNo ratings yet

- Manufacturing: ProcessDocument22 pagesManufacturing: ProcessKKNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universitydevang majithiyaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityDhruvNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- PMMS Schedule 2019-2020 PDFDocument1 pagePMMS Schedule 2019-2020 PDFD VNo ratings yet

- Agravat 8 Sem Project ReportDocument25 pagesAgravat 8 Sem Project ReportD VNo ratings yet

- Manav Garima Yojna 2019-20Document1 pageManav Garima Yojna 2019-20D VNo ratings yet

- CPDP RESUME 043 IcDocument4 pagesCPDP RESUME 043 IcD VNo ratings yet

- Business Model Canvas: Gujarat Technological UniversityDocument6 pagesBusiness Model Canvas: Gujarat Technological UniversityD VNo ratings yet

- (A) (B) (C) (D) (E) : in of The TheDocument11 pages(A) (B) (C) (D) (E) : in of The TheD VNo ratings yet

- Syllabus For Muliple Choice Questions (Admissions Test 2020)Document1 pageSyllabus For Muliple Choice Questions (Admissions Test 2020)D VNo ratings yet

- Name:-LR 6.1 Calendar: Correct Answer: - 2012 Answer DescriptionDocument2 pagesName:-LR 6.1 Calendar: Correct Answer: - 2012 Answer DescriptionD VNo ratings yet

- Name:-LR 2.1 Coding Decoding: Correct Answer: - # Answer DescriptionDocument2 pagesName:-LR 2.1 Coding Decoding: Correct Answer: - # Answer DescriptionD VNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityD VNo ratings yet

- MD GTU Study Material GTU-Paper-Analysis ALL 18092019084700AM PDFDocument20 pagesMD GTU Study Material GTU-Paper-Analysis ALL 18092019084700AM PDFD VNo ratings yet

- If You Have A Garden and A Library, You Have Everything You Need.Document9 pagesIf You Have A Garden and A Library, You Have Everything You Need.D VNo ratings yet

- Solar Water Purifier: Deepak Devasagayam, Mayuresh Kathe, Mayur Patil, Nimish KavishwarDocument5 pagesSolar Water Purifier: Deepak Devasagayam, Mayuresh Kathe, Mayur Patil, Nimish KavishwarD VNo ratings yet

- United States Patent (19) : Int, Cl2. F2SB 27/00, F2SB 15/00, F24J/3/02Document5 pagesUnited States Patent (19) : Int, Cl2. F2SB 27/00, F2SB 15/00, F24J/3/02D VNo ratings yet

- Drinking Such Waters or Using Them in Cooking Leads To Widespread Acute and Chronic Illnesses and Is A Major Cause of Death in Many Countries.Document11 pagesDrinking Such Waters or Using Them in Cooking Leads To Widespread Acute and Chronic Illnesses and Is A Major Cause of Death in Many Countries.D VNo ratings yet

- Final Project Report - Group 7 PDFDocument154 pagesFinal Project Report - Group 7 PDFNhut NguyenNo ratings yet

- United States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997Document8 pagesUnited States Patent 19 11 Patent Number: 5,697,468: Russell, Jr. Et Al. (45) Date of Patent: Dec. 16, 1997155No ratings yet

- Sharp Refrigerator sj44lwh1Document28 pagesSharp Refrigerator sj44lwh1Joseph AlbertNo ratings yet

- Name: - AP Physics Worksheet - Mechanical Waves ReviewDocument5 pagesName: - AP Physics Worksheet - Mechanical Waves ReviewMarcial Aguilar BarahonaNo ratings yet

- Generator Characteristics: 1. No-Load Saturation Characteristic (E /I)Document24 pagesGenerator Characteristics: 1. No-Load Saturation Characteristic (E /I)Uma SaluvaNo ratings yet

- Polymer Brushes Via Surface-Initiated Controlled Radical PolymerizationDocument91 pagesPolymer Brushes Via Surface-Initiated Controlled Radical PolymerizationP'Parot Pornlapas100% (1)

- Bearing Defect Diagnosis and Acoustic EmissionDocument40 pagesBearing Defect Diagnosis and Acoustic EmissionHazim HazimNo ratings yet

- ResistorsDocument9 pagesResistorsanon_26317821No ratings yet

- HW 924 6759 Igcsemidtermworksheet2Document51 pagesHW 924 6759 Igcsemidtermworksheet2zaseel86No ratings yet

- Evaluation of Open Pit Mine Slope Stability AnalysisDocument11 pagesEvaluation of Open Pit Mine Slope Stability AnalysisrahultharejaNo ratings yet

- Evaluation of Non-Linear Normal ModesDocument9 pagesEvaluation of Non-Linear Normal ModesEmerson Borges SantanaNo ratings yet

- Om 438906011 W365-3330H N M 2H01 enDocument24 pagesOm 438906011 W365-3330H N M 2H01 enAlejandro LeonNo ratings yet

- Brownian Dynamics Study of Gel-Forming Colloidal Particles: P. H. S. Santos, O. H. Campanella, and M. A. CarignanoDocument7 pagesBrownian Dynamics Study of Gel-Forming Colloidal Particles: P. H. S. Santos, O. H. Campanella, and M. A. CarignanoCarlos GallegosNo ratings yet

- Moeller DF, DVDocument3 pagesMoeller DF, DVPaulo EdilsonNo ratings yet

- OIC-NW Reviewer Blog - Solving Distance by Parallel SailingDocument2 pagesOIC-NW Reviewer Blog - Solving Distance by Parallel SailingJofel Calaycay100% (1)

- Amca 801-01 (R2008) PDFDocument61 pagesAmca 801-01 (R2008) PDFandrés morantes100% (1)

- Powder Filling MachineDocument9 pagesPowder Filling MachineCao Ngoc AnhNo ratings yet

- T-Xy Diagram For PEDDocument109 pagesT-Xy Diagram For PEDTehMarianNo ratings yet

- ADA237190Document66 pagesADA237190sixayo4531No ratings yet

- NIOSH 7400 AsbestosDocument40 pagesNIOSH 7400 AsbestosNicolas ZeballosNo ratings yet

- Math 2 PDFDocument90 pagesMath 2 PDFElrom Jasper Marzo RamosNo ratings yet

- 2014 Guidelines Rockfall RemediationDocument9 pages2014 Guidelines Rockfall RemediationVashdevNo ratings yet

- Graphing Linear EquationDocument6 pagesGraphing Linear EquationVanessa NacarNo ratings yet

- J. Mathematical Model of Once Through MSF: T, Is Obtained From The Relation T (To-Tn) /NDocument11 pagesJ. Mathematical Model of Once Through MSF: T, Is Obtained From The Relation T (To-Tn) /NTino UmbarNo ratings yet

- Fault Slip and Fault NamesDocument4 pagesFault Slip and Fault Namesanima1982No ratings yet

- CIVL5277 Lecture 9 - Design of Bending MembersDocument78 pagesCIVL5277 Lecture 9 - Design of Bending Membersjihe0020No ratings yet

- Chapter 8: Thermal Conductivity and The Mechanism of Heat TransportDocument33 pagesChapter 8: Thermal Conductivity and The Mechanism of Heat TransportConrad MonterolaNo ratings yet