Professional Documents

Culture Documents

Expansion Procedure

Expansion Procedure

Uploaded by

Mani TamilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Expansion Procedure

Expansion Procedure

Uploaded by

Mani TamilCopyright:

Available Formats

EXPANSION PROCEDURE FOR RE-TUBING OF FRESH

COOLING WATER EXCHANGERS TAG NO.

25-E0609A/B/C/D, C3 CONDENSER & 25-E0610, C3 SUB

COOLER

Client Approval :________________________

JOB TITLE : RE-TUBING OF FRSH

COOLING WATER EXCHNAGERS

METHOD STATEMENT

Al-Muftah Contracting Co. WLL

Job No.: J510 APPROVED BY: Doc. Ref.: Oil & Gas Division

Kavindra Jani PO Box 875. Doha-Qatar

AMCOG-DOC-18-02

CHECKED BY:

Contract No.: Rev.:01

SHIJU Pages Tel. No.: Fax No.: Email:

LTC/C/MNT/3164-

A/17 ORIGINATOR 13 Date: 44223333 44223385 mechanical@almuftah.com

RAJASEKAR 11/06/2018

AMCOG-DOC-18-02, Rev.01 Page 1 of 13

TABLE OF CONTENTS

1.0 RECORD OF REVISIONS

2.0 OBJECTIVE

3.0 SCOPE

4.0 REFERENCE

5.0 DEFINITIONS

6.0 RESPOSIBILITIES

7.0 HEALTH, SAFETY & ENVIRONMENT

8.0 EQUIPMENT’s

9.0 DETAILS OF EXCHANGER’S

10.0 METHODOLOGY

11.0 INSPECTION & TESTING

AMCOG-DOC-18-02, Rev.01 Page 2 of 13

1.0 RECORD OF REVISIONS

ISSUED FOR

02 REVIEW & 01 11/06/2018 RAJASEKAR SHIJU K P JANI

COMMENTS

ISSUED FOR

01 REVIEW & 00 17/05/2018 SKD SKD KPJ

COMMENTS

S. CHECKED APPROVED

DESCRIPTIONS REVISION DATE ORIGINATOR

No. BY: BY:

AMCOG-DOC-18-02, Rev.01 Page 3 of 13

2.0 OBJECTIVE:

The objective of this document is to perform the tube to tube sheet expansion for

providing a mechanical strength and sealed joint for the successful re-tubing of Shell

and Tube exchanger’s 25-E0609A/B/C/D & 25-E610. The procedure comply with,

01 safety procedures applicable & precaution/mitigation that need to be taken in

accordance with QG safety rules and regulations.

3.0 SCOPE:

The scope of this procedure is to describe in details of how to make the tube to tube

sheet expansion joint for the Re-Tubing of Condenser 25-E609A/B/CD & 25-E610 as

01 described in the SOW at AMC Workshop or Any AMC recommended designated area

(Sub-Contractor Premises).

4.0 REFERENCE:

QGX-20-00-ME-TS-NA-201_E1 - Shell and Tube Heat Exchanger - Design and

01 Construction

QGX/24/06/ME/DS/NA/209 - Shell and Tube Heat Exchanger Specification Sheet

Equipment Dwg. DK2005-120-01 to 04, Rev.X1 and DK2005-055-01 to 03, Rev.X1

ASME SEC. VIII, Div. 1 - Rules for construction of Pressure Vessel

5.0 DEFINITIONS:

● PROJECT : RE-TUBING OF FRESH COOLING WATER

EXCHANGER’S

● COMPANY : Qatar Gas

● CONTRACTOR : Al-Muftah Contracting Co. WLL

● PROJECT MANAGER : Contractor’s Project Manager

● QA/QC INSPECTOR : Contractor’s QA/QC Inspector

● WORK SITE SUPERVISOR : Contractor’s authorized Work Person

AMCOG-DOC-18-02, Rev.01 Page 4 of 13

6.0 RESPONSIBILITIES:

PROJECT MANAGER

- Shall be responsible for overall work and coordinate with COMPANY & AMC

team and resolve the re-tubing issues while execution.

WORK SUPERVISOR

- Shall be responsible for overall work which allocated to him and he shall report

all job related constraints and update to designated Project Manager and

manage the work progress as per schedule.

QA/QC Inspector

- Shall be responsible to develop and determine all standards to perform

inspection and tests on all procedures and oversee all testing methods and

01 maintain high standards of quality for all process.

- Carryout inspection and checking for all quality related procedures in the site

and ensures activity at the site as per approved method statement and ITP.

- Responsible of all QA/QC documents specific to the job.

7.0 HEALTH,SAFETY & ENVIRONMENT

Daily Tool Box Talk to be performed with all crew at Workshop with heat

mitigation, pinch point issues and scope to be performed each day. Daily

information and communication attached with a signed attendance sheet of all

attending employees there working that day. Listing specific points of interest and

available in several languages.

All jobs above height 1.2mtr must be carried out by using proper scaffolding

platform and proper tagging to be done.

All personnel who works height for the removal of nozzle blind, must wear safety

harness.

All the planned activity and duration must be communicated with all team member

to avoid confusions and loose talk.

If any change in planned activity must have to reported or intimated to COMPANY

person.

Work shop escape routes must be clearly highlighted and properly communicated

to everyone.

HSE-coordinator will monitor site safety requirements & compliance during

execution.

Appropriate PPE’s will be worn by personnel working at site.

Housekeeping will be maintained on regular basis.

AMCOG-DOC-18-02, Rev.01 Page 5 of 13

Adequate rest shelter/tents, first aid box, drinking water, salt tablets will be made

available at site during working hours.

Adequate & appropriate barricades, sign boards & cones will be made available at

work site to control movement of site vehicles and other traffics.

8.0 EQUIPMENT’S

8.1 SPECIAL TOOLS

- Digital Torque Controller Panel (Make - Tritorc/Equivalent, Model- TCW)

- Electric drive for tube expansion (Make - Tritorc/Equivalent, Model- PED2)

- Tube Expander for First Stage Expansion (Make - Tritorc/Equivalent, Model-

T824)

- Spare Mandrel for above Expander(Make - Tritorc/Equivalent, Model- TM8)

- Spare Roll Set for above Expander (Make - Tritorc/Equivalent, Model- TR9A)

01 - Tube Expander for 2nd & 3rd Stage expansion (Make - Tritorc/Equivalent,

Model- T1224)

- Spare Mandrel for above Expander (Make - Tritorc/Equivalent, Model- TM58)

- Tube End facer (Make - Tritorc/Equivalent, Model- TTF750)

- Spare Tool bit for above Facer (Make - Tritorc/Equivalent, Model- TTFB750)

8.2 MEASURING TOOL

- Bore Gauge with Micrometer (or)

- 2 Pin Dial Gauge

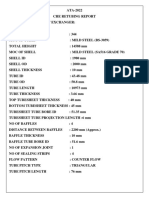

01 9.0 Details of Exchangers for Re-Tubing

Sr. Exchanger Qty. Cate Tube Detail Tube Tube Tube Sheet Tube T-TS Joint

No Details & Tag gory Qty. Material Material Pitch

. No. (Nos) In Total

(Nos)

01 25- 04 O.D 19.05mm 6467 x 4 SA179 SA765-2+N 25.4 Heavy

E0609A/B/C/D A x 2.11 thk. = 25,868 Expanded

-9000L 50mm, Light

Expanded-

47mm

02 25-E0610 01 O.D 19.05mm 5912 x 1 SA179 SA765-2N 23.8 Heavy

A x 2.11 thk. = 5912 Expanded

-12000L 50mm, Light

Expanded-

82mm

AMCOG-DOC-18-02, Rev.01 Page 6 of 13

10.0 WORK METHODOLOGY : To carry out the Tube to Tube Sheet Expansion Work for the

Re-Tubing of Fresh Cooling Water Exchanger’s under Category A

10.1 Tube Pulling/Removal Procedure

01 Inspection of received exchangers for its internal condition.

Record all findings and communicate with COMPANY QA/QC.

Check internal tube cutter, whether it going inside to the old tube or not (due to

internal rib). If it going without any issue, then cut the tube internally from one

side and pull from other side by using pulling power pack. Remove the tube stub by

using stub puller.

If internal tube cutter not going inside smoothly due to tube internal corrosion or

less ID in the fin/internal rib area, then check whether wall thickness reduction by

using reaming tool is applicable. But due to extensive of corrosion on the tube

internal area, wall thickness reduction may not be feasible. So that, finally go for

drawing the whole tube from one side by suing the following steps.

Thread mandrel into the old tube with impact wrench. (No damage will cause due

to impact wrench.)

Mount pulling gun onto mandrel.

Switch to forward cycle till expansion joint breaks once joint breaks switch to auto

cycle by pressing ‘AUTO’ button till tube is completely removed from tube sheet

area.

When tube is free, a tool can be inserted into jaws to enable the tube to be pulled

by hand.

Unscrew the mandrel from pulled tube and proceed to next tube.

The tube removal will be step by step by pulling 25% (approx. 1600) of alternate

tubes from each row.

Clean the tube sheet hole and after satisfactory inspection by COMPANY QC,

proceed for new tube insertion.

After 25% tube insertion, for remaining tubes removal the same sequence (25-

50%) will follow until 100% achieve in order to facilitate proper tube insertion

through baffles.

After all tube removal, the face area of tube sheet will be thoroughly cleaned and

offer for inspection. The dust or any residues which may fall into the shell inside or

tube fin area will be removed by using industrial vacuum machine.

AMCOG-DOC-18-02, Rev.01 Page 7 of 13

10.2 Adjustment of expansion Torque

Reduction range of tube wall thickness for heavy expansion shall not exceed 6% to

8% of tube thickness & % expansion shall be max 8% (heavy expansion), as

specified in the approved drawings. Light expansion % shall be max. 3%.

The reduction in thickness is controlled with the adjustment of the expansion

torque.

The expansion length is specified (Para.9, Details of Exchanger for Re-Tubing) for

each type heat exchanger.(for expansion sequence, see 10.3)

The differential expansion will be achieved by controlling the torque given by

01

wattage reading on the torque control.

Light expansion is just closing the clearance but heavy expansion is to have the

tube to forced and embedded into the tube sheet. Light expansion is normally 0-

3% (Min. 2-3% to be considered) where as heavy expansion is 6-8%.

Start at a lower testing of the torque and check inside diameter of tube for %

expansion.

Repeat the operation till the correct dimension as per approved drawing is

achieved.

The unit is now ready for complete use. This torque setting gives uniform tube

expanding.

After expanding of each tube the expander rotates in opposite direction which

facilitates easy removal of the expander.

10.3 Expansion Procedure for the re-Tubing of C3 Condenser 25-E-0609A/B/C/D

& C3 Sub Cooler 25-E-0610 (At workshop-Salwa)

Receive the exchangers and new tubes at AMC/Designated workshop.

Arrange all exchanger’s so that all the activities can be performed simultaneously.

The exchanger will be inspected by AMC QC Inspector after receipt and inspection

report shall be prepared.

Preparatory activities such as scaffolding, removal of end blinds and rest shelter

preparation etc.

01

QA/QC inspection to be carried out after removal of end cover.

Offer to QG QC for the internal inspection after tube removal.

Offer QG QC for tube projection and alignment checking before performing

expansion. As per drawing 3mm projection is required at both inlet and outlet side.

After clearance from QG QC about tube alignment and projection, start expansion

from both inlet and outlet side. Arrange the tube expander at both sides of the

exchanger. (Using one set expander at any one side of exchanger for expansion is

not allowed in order to achieve the sequence and integrity from both inlet and

AMCOG-DOC-18-02, Rev.01 Page 8 of 13

outlet side. During expansion, exchanger both side should possess with correct

tube expander)

Tube expanders must be greased (Special tubes expander grease entirely soluble in

water).

Roll expands about 6%-8% of the tubes in the heavy expansion area of the tube

sheet on the inlet side (The tubes flash with the tube sheet surface). And Roll

expands about 0-3% (Min. 2-3% to be considered) of the tubes in the light

expansion area of the tube sheet.

Roll expands the same tubes in the outlet side tube sheet for both light and heavy

expansion.

During Expansion, it will be done in two different ways at both the end of the

exchanger tube sheet, at one end (inlet side) first heavy expansion (@6%) to be

carried out and then light expansion (@3%) to be done this will enable the flow

of thinning material to the free end and at then at the opposite end (outlet side)

first light expansion(@3%) will be done which will lock the tube and then heavy

expansion(@6%) will be carried out.

Complete the expansion by expanding tubes one after another.

The projection length of outlet side tubes, which are out of the tolerance indicated

on the drawing, shall be trimmed of.

Tube expansion measurement to be taken at the beginning of each shift to ensure

01

that the procedure is followed to capture appropriately.

11.0 INSPECTION & TESTING

Inspection: 01

The equipment must be offered to QG QC for inspection of expanded joint after

every 25% of tube expansion. The frequency must be repeated at all stages of

expansion.

Record all dimensions and readings (in Attachment-1) for % of expansion

calculation.

Record the dimensions of tube before and after expansion by using bore dial gauge

randomly. (Min. 5% of tubes considered for taking reading after every 25% tube

expansion cycle).

Take reading for both inlet and outlet side for each heavy and light expansion

length and record both readings separately to calculate the % of wall thickness

reduction for both heavy and light expansion.

Calculate and compare the values with mockup test values (of pull-out tested

tubes values) and compare if any values are below required limit. If minimum

required % not achieved, reroll the joint again to achieve required value.

AMCOG-DOC-18-02, Rev.01 Page 9 of 13

Testing:

The integrity of the expansion joint will be tested through shell side hydro test. (Refer hydro

test procedure (AMCOG-QAQC-HYDRO-18-002) for more details.)

11.1 Calculation of Expansion %:

To assure a proper tube joint, the tube wall is reduced to a predetermined

percentage. This is done by the following steps:

Measure the tube hole ID in the Tube Sheet = A.

Measure the tube OD = B.

Calculate clearance, T = A – B.

Use tube gauge to measure ID of the tube before rolling = C.

Roll the tube and measure actual ID of tube after rolling with tube gauge as “Da”

Calculate the actual percentage of wall reduction as

%R = ((Da - (T+C)) / (B-C)) x 100

Since the amount of wall reduction greatly determines the quality of the tube joint,

it is important to arrive the % required prior to tube rolling. This technique is used

to set torque of the rolling devices. The following % reductions are recommended

to achieve a proper tube joint (Mechanical Joint).

Tube Material - Carbon Steel, SA 179

01

Heavy Expansion - 6 to 8 % & Light Expansion - 3%

Check that the expansion is within the recommended range. Torque setting may be

gradually changed to achieve the proper expansion ratio. Later use the same

torque value for rolling the rest of the tubes.

Use suitable lubricant for rolling.

In case tube is under rolled i.e. tube is not expanded to fill the tube sheet hole and

proper amount of wall reduction is not obtained then reroll using the next higher

size roller. Take care not to over roll as that can do damage to T/S.

AMCOG-DOC-18-02, Rev.01 Page 10 of 13

Following are the figures of tools which are involved in the job

Torque Controller

MAKE: Make - Tritorc/Equivalent, Model- TCW

01

AMCOG-DOC-18-02, Rev.01 Page 11 of 13

Tube Expander

Make - Tritorc/Equivalent, Model- TM8

Tube Expander/Roller

Make - Tritorc/Equivalent, Model- T824

AMCOG-DOC-18-02, Rev.01 Page 12 of 13

Attachment-1 01

EXPANSION REPORT

PROJECT : RE-TUBING OF FRESH COOLING WATER EXCHANGER

REF.CODE/SPECIFICATION : ASME Sec VIII Div.1/ASME

EXCHANGER TAG. 25-E0609A/B/C/D & 25-0610 Sec IX /TEMA R, API 660

JOB NUMBER : LTC/C/MNT/3164-A/17 REPORT NO :

EXPANSION DETAILS :- After every 25% tube expansion (Approx. 1600 tubes) *

EXCHANGER SIDE :- INLET/OUTLET

EXPANSION TYPE : HEAVY/LIGHT

EXCHNAGER TAG NO. Date :-

Tube sheet hole Clearance

Tube No. Tube OD(B) Tube ID (C) After rolling (Da) (T+C) (B-C) Reduction R% =

ID(A) (T)=(AB)

((Da(T+C))/(B-C)x100

PREPARED BY AL MUFTAH QA/QC QATAR GAS

Name :

Designation :

Signature :

Date :

*25% cycle will repeat until complete tube get expanded.

AMCOG-DOC-18-02, Rev.01 Page 13 of 13

You might also like

- PayslipDocument1 pagePayslipAshish Agarwal67% (3)

- INTERNAL INSTALLATION MANUAL DRP001-PUC-SUL-V99-135CZ-101-0001 内件Document119 pagesINTERNAL INSTALLATION MANUAL DRP001-PUC-SUL-V99-135CZ-101-0001 内件alhad.ma100% (3)

- Hydro Test Procedure For Heat ExchangerDocument2 pagesHydro Test Procedure For Heat Exchangerbabmech600791% (11)

- Tuning Guide Peug. 206 2.0L HDI EDC15C2 90cv - 120HP by J-SkyDocument6 pagesTuning Guide Peug. 206 2.0L HDI EDC15C2 90cv - 120HP by J-Skyzo68No ratings yet

- Reformer Tube Replacement - RFQDocument4 pagesReformer Tube Replacement - RFQChinmay FakeNo ratings yet

- Method Statement For RetubingDocument4 pagesMethod Statement For RetubingJeffrey78% (9)

- Procedure For Tubing & ExpansionDocument6 pagesProcedure For Tubing & ExpansionBoby ThomasNo ratings yet

- STS Qac Sop 002 Heat Exchanger Retubing ProcedureDocument4 pagesSTS Qac Sop 002 Heat Exchanger Retubing Proceduremohd as shahiddin jafri50% (2)

- ITP (Test Procedure) PDFDocument2 pagesITP (Test Procedure) PDFkrishnit100% (1)

- Insulation ProceduresDocument8 pagesInsulation ProceduresMark Darrel AranasNo ratings yet

- Leak Testing MethodologiesDocument9 pagesLeak Testing MethodologiesPin SantosNo ratings yet

- Pneumatic Test ProcedureDocument12 pagesPneumatic Test ProcedurePower Power100% (4)

- Flange Weld Build UpDocument3 pagesFlange Weld Build UpMohd Shafuaaz KassimNo ratings yet

- Pressure Vessel Repair ProcedureDocument2 pagesPressure Vessel Repair ProcedureMohamad Arraj75% (8)

- Raindrop Technique How ToDocument6 pagesRaindrop Technique How Toapi-251091141100% (2)

- B.6.23 - STD SPECS - For Plum Concrete & Plum MasonaryDocument3 pagesB.6.23 - STD SPECS - For Plum Concrete & Plum MasonaryBijay Krishna Das100% (3)

- CHE Retubing ReportDocument29 pagesCHE Retubing ReportRajesh KtrNo ratings yet

- Gas Exchanger RetubingDocument15 pagesGas Exchanger Retubinghamal.w757No ratings yet

- Maintaining and Repairing Heat Exchanger TubesDocument14 pagesMaintaining and Repairing Heat Exchanger TubesMicheal Brooks100% (1)

- Tube Expansion ProcedureDocument3 pagesTube Expansion Procedurerudi 01100% (1)

- HIRAC For Project Retubing ACHEDocument2 pagesHIRAC For Project Retubing ACHEragilNo ratings yet

- U BundleDocument16 pagesU BundleWael ElAriny100% (1)

- Floating Head Heat Exchanger Maintenance PDFDocument15 pagesFloating Head Heat Exchanger Maintenance PDFAdilMunirNo ratings yet

- ITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CDocument2 pagesITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CAmel Rayhan Aira100% (5)

- Air Cooler MaintenanceDocument13 pagesAir Cooler Maintenancemostafa_1000No ratings yet

- Heat Exchanger InspectionDocument9 pagesHeat Exchanger Inspectionpstechnical_43312697No ratings yet

- Failure Analysis of Heat Exchngers: An Approach and Case StudiesDocument51 pagesFailure Analysis of Heat Exchngers: An Approach and Case Studiessathish69100% (5)

- Floating Head Heat Exchanger MaintenanceDocument15 pagesFloating Head Heat Exchanger MaintenanceSriKakarlapudi100% (2)

- Cleaning of Heat ExchangersDocument22 pagesCleaning of Heat ExchangersFareed Alam0% (1)

- Third Party Procedure For Heat Exchanger TestingDocument10 pagesThird Party Procedure For Heat Exchanger TestingVarun MalhotraNo ratings yet

- Installation Procedure For Air Heater CoolerDocument4 pagesInstallation Procedure For Air Heater CoolerRachel FloresNo ratings yet

- STS QAC SOP 008 Tube Plugging ProcedureDocument7 pagesSTS QAC SOP 008 Tube Plugging Proceduremohd as shahiddin jafriNo ratings yet

- Heat Exchanger Tube Bundle InspectionDocument3 pagesHeat Exchanger Tube Bundle InspectionVenkatesh Natla100% (4)

- Expansion Joints For HRSG BoilersDocument12 pagesExpansion Joints For HRSG BoilersBruhaspathy KatikaneniNo ratings yet

- Catalyst Loading by Dense Method Multi Bed Reactor Inert AtmosphereDocument7 pagesCatalyst Loading by Dense Method Multi Bed Reactor Inert Atmospherevishal bailur100% (1)

- Heat Exchanger Tube Material SpecificationsDocument2 pagesHeat Exchanger Tube Material SpecificationssdrtfgNo ratings yet

- Air Cooler Cleaning TechniqueDocument4 pagesAir Cooler Cleaning Techniquedinakaranpatel100% (1)

- IONE-AA00-MS-MS-0013 WMS For Air Cooler InstallationDocument18 pagesIONE-AA00-MS-MS-0013 WMS For Air Cooler InstallationYusufNo ratings yet

- Replacement of Lip Seal Gasket For Heat ExchangerDocument10 pagesReplacement of Lip Seal Gasket For Heat ExchangerBESTIN67% (3)

- Guide For ASME AUDIT - 2018: Table - U3 Mandatory Appendix 43 UG-20 (F)Document1 pageGuide For ASME AUDIT - 2018: Table - U3 Mandatory Appendix 43 UG-20 (F)anon_673643629No ratings yet

- Header Plug Seal Weld ProcedureDocument2 pagesHeader Plug Seal Weld ProcedureMohd Shafuaaz KassimNo ratings yet

- Tube Removal Catalog Web ELLIOTDocument24 pagesTube Removal Catalog Web ELLIOTJose Luis RattiaNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Furnace Dryout SAIC-N-2030 25-May-05 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Furnace Dryout SAIC-N-2030 25-May-05 MechAnonymous S9qBDVky0% (1)

- Fix Tube Sheet Heat Exchanger MaintenanceDocument10 pagesFix Tube Sheet Heat Exchanger MaintenanceKarthik MadhuNo ratings yet

- Cleaning Balls PDFDocument8 pagesCleaning Balls PDFAlexandruNicolaNo ratings yet

- Post Weld Treatment Procedure For Piping Spools (Abj) KN Rev-2Document15 pagesPost Weld Treatment Procedure For Piping Spools (Abj) KN Rev-2williamsenNo ratings yet

- Floating Head Heat Exchanger Hydrotest ProcedureDocument15 pagesFloating Head Heat Exchanger Hydrotest ProcedureDoğuhan DenizgezNo ratings yet

- Report Lube Oil FlushingDocument10 pagesReport Lube Oil Flushingmohan_krishna372No ratings yet

- 16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Document28 pages16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Fauzan Rusmayadi Reharder100% (1)

- Hot Oil Flushing Procedure For Mechanical Package PDFDocument20 pagesHot Oil Flushing Procedure For Mechanical Package PDFLeo Sembiring0% (1)

- Heat Exchanger InspectionDocument27 pagesHeat Exchanger Inspectionglazetm100% (23)

- Nesl Training ManualDocument91 pagesNesl Training ManualSOUMYA DEEP CHATTERJEENo ratings yet

- Plug Process Repair Heat Exchangers PDFDocument6 pagesPlug Process Repair Heat Exchangers PDFJOÃO CARLOS SILVANo ratings yet

- Pipe Bend Procedure SA-4200-70621Document7 pagesPipe Bend Procedure SA-4200-70621mohd as shahiddin jafri100% (1)

- Report No. TA-V-1456Document2 pagesReport No. TA-V-1456u04ajf3No ratings yet

- SRV Detaisl Awa Salawas PDFDocument222 pagesSRV Detaisl Awa Salawas PDFdiwakarngm100% (1)

- 001.17066.000010 - DR016 - Rev 02 - ADocument36 pages001.17066.000010 - DR016 - Rev 02 - Ayifei.zhuNo ratings yet

- DDDDocument7 pagesDDDmohd as shahiddin jafriNo ratings yet

- 8188-MD-FEA-RFQ-001 Rev-0Document24 pages8188-MD-FEA-RFQ-001 Rev-0sridharNo ratings yet

- HIC & SSC Test ProcedureDocument32 pagesHIC & SSC Test ProcedureMohamed FarisNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument52 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesAsif ChougleNo ratings yet

- MST Installation of WEHOLITE Pipe - Stormwater - FinalDocument13 pagesMST Installation of WEHOLITE Pipe - Stormwater - FinalShahzaib ShahidNo ratings yet

- Piping Typical Installation DrawingsDocument51 pagesPiping Typical Installation DrawingsNguyen Anh Tung100% (3)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Find Me Phoenix Book 6 Stacey Kennedy Full ChapterDocument67 pagesFind Me Phoenix Book 6 Stacey Kennedy Full Chaptercatherine.anderegg828100% (21)

- Suntrust VeronaDocument12 pagesSuntrust Veronalyanca majanNo ratings yet

- Turbine-Less Ducted Fan Jet Engine: Subsonic PropulsionDocument25 pagesTurbine-Less Ducted Fan Jet Engine: Subsonic PropulsionزهديابوانسNo ratings yet

- Remarks:: Republic of The Philippines City of General SantosDocument1 pageRemarks:: Republic of The Philippines City of General SantosThe MatrixNo ratings yet

- Abyssinian Ground HornbillDocument4 pagesAbyssinian Ground HornbillEmilio Lecaros BustamanteNo ratings yet

- Health The Basics 11th Edition Donatelle Test BankDocument19 pagesHealth The Basics 11th Edition Donatelle Test BankJosephWilliamsinaom100% (6)

- Drainage Below GroundDocument5 pagesDrainage Below GroundmisharyNo ratings yet

- Vision PT 365 Culture 2021 (WWW - Upscpdf.com)Document51 pagesVision PT 365 Culture 2021 (WWW - Upscpdf.com)Swati YadavNo ratings yet

- g8 With Answer SheetDocument4 pagesg8 With Answer SheetMICHAEL REYESNo ratings yet

- Sebp7383 05 00 Allcd - 9Document837 pagesSebp7383 05 00 Allcd - 9Roland Culla100% (1)

- Characterising Roof Ventilators: P 2 A Q CDocument4 pagesCharacterising Roof Ventilators: P 2 A Q CDhirendra Singh RathoreNo ratings yet

- Hayden Esterak Resume 1Document1 pageHayden Esterak Resume 1api-666885986No ratings yet

- GACAL vs. PALDocument2 pagesGACAL vs. PALKathleen Valencia100% (1)

- Channel DecisionsDocument30 pagesChannel Decisionsuzmatabassum1996No ratings yet

- Power Electronics ProjectDocument38 pagesPower Electronics Projectvishwatheja198950% (2)

- Summary of Current Charges (RS) : Talk To Us SMSDocument13 pagesSummary of Current Charges (RS) : Talk To Us SMSBrandon FloresNo ratings yet

- Written RequestDocument2 pagesWritten Requestcarvazro100% (1)

- 9de13c0f0c009828f703d0103efa820b.xlsDocument70 pages9de13c0f0c009828f703d0103efa820b.xlsPreeti JaiswalNo ratings yet

- Chapter 3 InternetDocument33 pagesChapter 3 InternetJeanette LynnNo ratings yet

- Cost FM Sample PaperDocument6 pagesCost FM Sample PapercacmacsNo ratings yet

- Practice Questions: Musculoskeletal SystemDocument4 pagesPractice Questions: Musculoskeletal SystemSali IqraNo ratings yet

- Sir Syed University of Engineering & Technology.: OGDCL Internship Report 2021Document16 pagesSir Syed University of Engineering & Technology.: OGDCL Internship Report 2021Aisha KhanNo ratings yet

- Biomedx Workshop AgendaDocument6 pagesBiomedx Workshop AgendabiomedxNo ratings yet

- MIL SyllabusDocument15 pagesMIL SyllabusChristopher PilotinNo ratings yet

- Money Exchange: Materials/Equipment You Would NeedDocument7 pagesMoney Exchange: Materials/Equipment You Would NeedEsther Joy PerezNo ratings yet

- Jamboree GRE StudyPlan PDFDocument3 pagesJamboree GRE StudyPlan PDFMd Minhaj Ahmed AhmedNo ratings yet