Professional Documents

Culture Documents

Unit V Pavement Design

Unit V Pavement Design

Uploaded by

Siva PrasadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unit V Pavement Design

Unit V Pavement Design

Uploaded by

Siva PrasadCopyright:

Available Formats

UNIT V

PAVEMENT DESIGN

PAVEMENT

Pavement is the durable surface material laid down on an area intended to sustain

vehicular load or foot traffic, such as a road or walkway.

REQUIREMENTS OF A PAVEMENT

An ideal pavement should meet the following requirements:

Sufficient thickness to distribute the wheel load stresses to a safe value on the sub-

grade soil,

Structurally strong to withstand all types of stresses imposed upon it,

Adequate coefficient of friction to prevent skidding of vehicles,

Smooth surface to provide comfort to road users even at high speed.

Produce least noise from moving vehicles,

Dust proof surface so that traffic safety is not impaired by reducing visibility

Impervious surface, so that sub-grade soil is well protected, and

Long design life with low maintenance cost.

TYPES OF PAVEMENTS

Based on the structural behaviour, pavements are generally classified into two categories:

1. Flexible Pavements

2. Rigid Pavements

FLEXIBLE PAVEMENTS

1. Flexible pavements are those, which on the whole have low or negligible flexural

strength and are rather flexible in their structural action under the loads.

2. A typical flexible pavement consists of four components

i. Soil sub grade iii. Base course

ii. Sub-base course iv. Surface course

Flexible pavements will transmit wheel load stresses to the lower layers by grain-to-

grain transfer through the points of contact in the granular structure.

The wheel load acting on the pavement will be distributed to a wider area, and the

stress decreases with the depth.

Taking advantage of these stress distribution characteristic, flexible pavements

normally has many layers. Hence, the design of flexible pavement uses the concept of

layered system.

Based on this, flexible pavement may be constructed in a number of layers and the top

layer has to be of best quality to sustain maximum compressive stress, in addition to

wear and tear.

The lower layers will experience lesser magnitude of stress and low quality material

can be used.

5. PAVEMENT DESIGN ( TE-1) Page 1

Flexible pavements are constructed using bituminous materials. These can be either in

the form of surface treatments (such as bituminous surface treatments generally found

on low volume roads) or, asphalt concrete

surface courses (generally used on high

volume roads such as national highways).

Flexible pavement layers reflect the

deformation of the lower layers on to the

surface layer (e.g., if there is any undulation

in sub-grade then it will be transferred to the

surface layer). In the case of flexible

pavement, the design is based on overall

performance of flexible pavement, and the

stresses produced should be kept well below

the allowable stresses of each pavement

layer.

RIGID PAVEMENTS

Rigid pavements have sufficient flexural strength to transmit the wheel load stresses

to a wider area below.

A typical cross section of the rigid pavement is shown in Figure 19:3. Compared to

flexible pavement, rigid pavements are placed either directly on the prepared sub-

grade or on a single layer of granular or stabilized material.

Since there is only one layer of material between the concrete and the sub-grade, this

layer can be called as base or sub-base course.

In rigid pavement, load is distributed by the slab action, and the pavement behaves

like an elastic plate resting on a viscous medium (Figure).

Rigid pavements are constructed by Portland cement concrete (PCC) and should be

analyzed by plate theory instead of layer theory, assuming an elastic plate resting on

viscous foundation.

Plate theory is a simplified version of layer theory that assumes the concrete slab as a

medium thick plate which is plane before loading and to remain plane after loading.

5. PAVEMENT DESIGN ( TE-1) Page 2

Bending of the slab due to wheel load and temperature variation and the resulting

tensile and flexural stress.

SEMI RGIGD PAVEMENTS

When bonded materials like the pozzolanic concrete (lime-flyash-aggregate mix), lean

cement concrete or soil-cement are used in the base course or sub-base course layer,

the pavement layer has considerably higher flexural strength than the common

flexible pavement layers.

However these bonded materials do not possess as much flexural strength as the

cement concrete pavements. Therefore when this intermediate class of materials used

in the base or sub-base course layer of the pavements, they are called semi-rigid

pavements.

This third category of semi-rigid pavements are either designed as flexible pavements

with some correction factors to find the thickness requirements based on experience,

or by using a new design approach.

These semi-rigid pavement materials have low resistance to impact and abrasion and

therefore are usually provided with flexible pavement surface course.

COMPARISON OF FLEXIBLE PAVEMENT & RIGID PAVEMENT

FLEXIBLE PAVEMENT RIGID PAVEMENT

1. Have low flexural strength 1. Have more flexural strength

2. Load is transferred by grain to 2. No such phenomenon of

grain contact grain to grain load transfer

3. Surfacing cannot be laid exists

directly on the sub grade but a 3. Surfacing can be directly laid

sub base is needed on the sub grade

4. No thermal stresses are 4. Thermal stresses are induced

induced 5. Expansion joints are needed

5. expansion joints are not needed 6. Design life 20-30 years

6. Design life 10-15 years 7. Initial cost of construction is

7. Initial cost of construction is high

low 8. Less maintenance cost

8. Maintenance cost is high 9. Road cannot be used until 14

9. Road can be used for traffic days of curing

within 24 hours 10. No Damage by Oils and

10. Damaged by Oils and Certain other chemicals

Chemicals

5. PAVEMENT DESIGN ( TE-1) Page 3

FUNCTIONS OF PAVEMENT COMPONENTS

SOIL SUBGRADE

The soil subgrade is a layer of natural soil prepared to receive the layers of pavements

materials placed over it.

The loads on the pavement are ultimately received by the soil subgrade for dispersion

to the earth mass. It is essential that at no time, the soil subgrade is overstressed.

It is desirable that at least top 50 cm layer of the subgrade soil is well compacted

under controlled of optimum moisture content and maximum density.

The common strength tests for the evaluation of soil subgrade are

California bearing ratio test

California resistance value test

Tri axial compression test and

Plate bearing test

5. PAVEMENT DESIGN ( TE-1) Page 4

SUB BASE COURSE

It is the layer of locally available material laid over the subgrade. Materials used may be

sand, gravel, rubble stabilized soil. etc

It functions primarily as structural support but it can also help:

1. Minimize the intrusion of fines from the sub-grade into the pavement structure.

2. Improve drainage.

3. Minimize frost action damage.

4. Provide a working platform for construction.

5. The sub base generally consists of lower quality materials than the base course

but better than the sub-grade soils.

BASE COURSE

It is the layer between sub base and wearing course.

It is made of good materials like Hard Broken Granite metal and well compacted.

It is important structural component and should be strong enough to bear the road

traffic load

Functions of base course

1. To prevent horizontal shear stresses and vertical pressure produced by moving

or standing wheel load

2. To provide density and resistance to weathering

3. Distribution of higher wheel load pressure.

WEARING COURSE

The top most layer of the pavement

The purpose of the wearing course is to give a smooth riding surface that is dense. It

resists pressure exerted by tyres and takes up wear and tear due to the traffic.

Wearing course also offers a water tight layer against the surface water inflation.

In flexible pavement, normally a bituminous surfacing is used as a wearing course. In

rigid pavements the cement concrete acts like a base course as well as wearing course.

The type of surface depends upon the availability of materials, plants and equipments

and upon the magnitude of surface loads.

5. PAVEMENT DESIGN ( TE-1) Page 5

DESIGN FACTORS

The various factors to be considered for the design of pavements are given below.

1. Design wheel load

2. Subgrade soil

3. Climatic factors

4. Pavement component materials

5. Environmental factors

6. Special factors in the design of different types of pavements.

1. DESIGN WHEEL LOADS

The various wheel load factors to be considered in pavement design are:

A. Maximum Wheel load

The wheel load configurations are important to know the way in which the loads of a

given vehicle are applied on the pavement surface.

For highways the maximum legal axle load as specified by Indian Road Congress is

8170 kg with a maximum equivalent single wheel load of 4085 kg. Total load

influences the quality of surface course.

The magnitude of the vertical pressure at any depth of soil subgrade mass depends

upon the surface pressure as well as on the total load.

The equation for vertical stress computations under a uniformly distributed circular

load based on Boussineq’s theory given by: a2

σz = Vertical pressure, p = wheel load, z = depth at which the stress is calculating,

a = radius of the wheel base

B. Contact pressure

The influence of tyre pressure is predominating in the upper layers. At a greater depth

the effect of type pressure diminishes and the total load exhibits a considerable

influence on the vertical stress magnitudes.

Tyre pressure of high magnitudes therefore demand high quality of materials in upper

layers in pavements.

The stresses on the pavement surface under the steel tyre wheels of bullock carts are

very high. This demands use of very strong and hard aggregate for the wearing

surface of the pavement.

Generally the wheel load is assumed to be distributed over a circular area. But by

measurement of the imprints of tyres with different load and inflation pressures, it is

seen that contact area in many cases are elliptical.

5. PAVEMENT DESIGN ( TE-1) Page 6

C. Equivalent single wheel load.

To carry maximum load within the specified limit and to carry greater load, dual

wheel, or dual tandem assembly is often used. Equivalent single wheel load (ESWL)

is the single wheel load having the same contact pressure, which produces same value

of maximum stress, deflection, tensile stress or contact pressure at the desired depth.

The procedure of finding the ESWL for equal stress criteria is provided below. This is

a semi-rational method, known as Boyd and Foster method, based on the following

assumptions:

Equalancy concept is based on equal stress;

contact area is circular;

Influence angle is 45o; and

Soil medium is elastic, homogeneous, and isotropic half space.

The ESWL is given by:

Where P is the wheel load, S is the centre to centre distance between the two wheels,

d is the clear distance between two wheels, and z is the desired depth.

D. Repetition of loads

The deformation of pavement or subgrade due to a single application of wheel load

may be small. But due to repeated application of the load there would be increased

magnitude of plastic and elastic deformations and the accumulated unrecovered or

permanent deformations may even result in pavement failure.

5. PAVEMENT DESIGN ( TE-1) Page 7

It is required to carry out traffic surveys for accounting the factor of repetitions for

wheel loads in the design of pavement. Such data collected are converted to some

constant equivalent wheel loads.

Traffic composition in India is of mixed type and it is essential for design purposes to

convert the various wheel loads to one single standard wheel load.

Equivalent wheel load is as single load equivalent to the repeated applications of any

particular wheel load on a pavement which requires the same thickness and strength

of pavements.

If the pavement structure fails with N1 number of repetitions of P1 kg load and

similarly if N2 number of repetitions of p2 kg load can also cause failure of the same

pavement surface, then P1N1 and P2N2 are considered equivalent.

2. Subgrade soil

The properties of the subgrade are important in deciding the thickness

requirements of pavements.

A subgrade with lower stability requires thicker pavement to protect it from the

traffic loads. The variations in stability and volume of the subgrade soil with

moisture changes are to be studies as these properties are dependent on the soil

characteristics.

The stress strain behaviour of the soil under static and repeated loads has also

significance.

Apart from the design, the pavement performance to a great extent depends on the

subgrade soil properties and the drainage.

3. Climatic factors

The climatic variations cause following major effects.

(a) Variation in moisture condition

The surface water during rains may enter the subgrade either through the pavement

edges or through the pavement itself, if it is porous.

The subgrade moisture variation depends on fluctuations of ground water table. The

moisture movement in subgrade is also caused by capillary action and vapour

movements. However, high moisture variations could be controlled by providing

suitable surface and sub-surface drainage system.

The stability of most of the subgrade soils are decreased under adverse moisture

conditions.

Presence of soil fraction with high plasticity will result in variations in volume

(swelling and shrinkage) with variation in water content.

(b) Frost action

Frost action refers to the adverse effective due to frost heave, frost melting and thaw

and the alternate cycles of freezing and thawing. The frost action in general includes

all effects associated with freezing temperature on pavement performance.

5. PAVEMENT DESIGN ( TE-1) Page 8

The held water in subgrade soil forms ice crystals at some spots if the freezing

temperatures continue for a certain period. The ice crystals grow further in size if

there is a continuous supply of water due to capillary action and the depressed

temperature continues. This result in raising of portion of the pavement structure

known as frost heave.

Subsequent increase in temperature would result in melting or thawing of the frozen

ice crystals and soften the road bed. The load carrying capacity of the subgrade is

considerably decreased at this stage due to the voids created by the melted ice crystals

and the excessive water trapped in the thawed soil below the pavement.

Under heavy traffic, the pavement would deflect excessively causing progressive

failure due to decreased load carrying capacity of the subgrade.

(c) Variation in temperature.

Wide variation in temperature due to climatic changes may cause damaging effects in

some pavements. Temperature stresses of high magnitude are induced in cement

concrete pavements due to daily variations in temperature and consequent warping of

the pavement.

Bituminous pavement become soft in hot weather and brittle in very cold weather

4. Pavement component materials

For, design purposes, it is required that the various pavement materials are assigned

strength parameters suitable to the design method employed for the purpose.

The general strength values evaluated are:

i. California Bearing Ratio (CBR) value

ii. Elastic Modulii

Depending upon the design methods, the elastic modulli of different pavement

materials are evaluated. Mainly Plate bearing test is employed for this purpose.

Further modulus elasticity or modulus of deformation of highway materials may

be determined from tri axial compression test.

5. Environmental factors

The environmental factors such as height of embankment and its foundation details,

depth of cutting, depth of water table, etc. affect the performance of pavements.

The choice of bituminous binder and the performance of the bituminous pavements

depend on the variations in pavement temperature with the seasons in the region.

The warping stresses in rigid pavements depend on the daily variations in temperature

in the region and in the maximum difference in temperature between the top and

bottom of the pavement slab.

6. Special factors in the design of different types of pavements.

In the case of semi-rigid pavement materials, the formation of shrinkage cracks,

pattern and the mode of propagation and the fatigue behaviour under such adverse

conditions of hair cracks are to be studied before arriving at a rational method of

design for the semi-rigid pavements.

5. PAVEMENT DESIGN ( TE-1) Page 9

GROUP INDEX METHOD OF FLEXIBLE PAVEMENT DESIGN

Group Index method of flexible pavement design is an empirical method which is

based on the physical properties of the soil sub-grade.

Determination of Group Index Value of Soil Sub grade:

Group Index is a number assigned

to the soil based on its physical

properties like particle size, Liquid

limit and plastic limit. It varies from

a value of 0 to 20, lower the value

higher is the quality of the sub-

grade and greater the value, poor is

the sub-grade.

By sieve analysis test we can

determine Group index value of soil

sub grade from below equation

GI = 0.2a + 0.005 ac + 0.01bd

Where,

a= percentage of soil passing 0.074 mm sieve in excess of 35 per cent, not exceeding

75.

b= percentage of soil passing 0.074 mm sieve in excess of 15 per cent, not exceeding

55.

c = Liquid limit in per cent in excess of 40.

d= Plasticity index in excess of 10.

DATA REQUIRED FOR FLEXIBLE PAVEMENT DESIGN

1. Group index of soil subgrade

Group index value range of different soils is given below

For good soil – 0 to 1

For fair soil – 2 to 4

For poor soil – 5 to 9

For very poor soil – 10 to 20

2. Traffic volume

It is the measure of Annual average daily traffic, peak-hour traffic. It is denominated

by commercial vehicles/day or CVPD.

It is classified in three categories. Based on number of vehicles per day.

If no. of vehicles per days is

<50 – light traffic

50-300 – medium traffic

>300 – Heavy traffic

5. PAVEMENT DESIGN ( TE-1) Page 10

FLEXIBLE PAVEMENT DESIGN PROCEDURE:

Before going to design the pavement we must know the structure of flexible pavement

Calculation total thickness (T):

From the below chart for given group index of soil subgrade and traffic volume value

select appropriate thick curve value of “combined thickness of surface, base and sub-

base line” which will give the total thickness of pavement.

(Note: thick line indicates the total thickness value and the dotted line indicates

thickness of surface and base)

Calculation thickness of sub-base course (tsb):

From the below chart for given group index of soil subgrade select appropriate curve

value of “thickness of sub base only” which will give the thickness of the sub-base

course.

The curve highlighted in below diagram

5. PAVEMENT DESIGN ( TE-1) Page 11

Calculation of thickness of base and surface course (tb & ts):

Thickness of surface and base course = total thickness – sub-base thickness = T – tsb

The combined value of thickness of base and surface course can be found out from

above chart form dotted curve with the help of group index value and traffic volume.

Or otherwise assume the thickness of surface course (t s) = 5 cm

Then we can easily calculate the value of thickness of the base course, Tb = T-tsb-ts

Cross section of flexible pavement:

The group index method is essentially an empirical method based on the physical

properties of the subgrade soil and it does not consider the strength characteristics of

soil and is therefore open to question regarding its reliability.

DESIGN METHODS-CBR METHOD, (AS PER IRC 37-2002)

Design procedure

Based on the performance of existing designs and using analytical approach, simple

design charts and a catalogue of pavement designs are added in the code.

The pavement designs are given for subgrade CBR values ranging from 2% to 10% and

design traffic ranging from 1 msa to 150 msa for an average annual pavement temperature

of 35 C.

The later thicknesses obtained from the analysis have been slightly modified to adapt the

designs to stage construction. Using the following simple input parameters, appropriate

designs could be chosen for the given traffic and soil strength.

Design traffic in terms of cumulative number of standard axles; and CBR value of

subgrade.

DESIGN TRAFFIC

The method considers traffic in terms of the cumulative number of standard axles (8160 kg)

to be carried by the pavement during the design life. This requires the following information:

1. Initial traffic in terms of CVPD (Commercial Vehicles Per Day)

2. Traffic growth rate during the design life

3. Design life in number of years

4. Vehicle damage factor (VDF)

5. Distribution of commercial traffic over the carriage way.

5. PAVEMENT DESIGN ( TE-1) Page 12

INITIAL TRAFFIC

Initial traffic is determined in terms of commercial vehicles per day (CVPD). For the

structural design of the pavement only commercial vehicles are considered assuming laden

weight of three tonnes or more and their axle loading will be considered. Estimate of the

initial daily average traffic flow for any road should normally be based on 7-day 24-hour

classified traffic counts (ADT). In case of new roads, traffic estimates can be made on the

basis of potential land use and traffic on existing routes in the area.

TRAFFIC GROWTH RATE

Traffic growth rates can be estimated (i) by studying the past trends of traffic growth, and (ii)

by establishing econometric models. If adequate data is not available, it is recommended that

an average annual growth rate of 7.5 percent may be adopted.

DESIGN LIFE

For the purpose of the pavement design, the design life is defined in terms of the cumulative

number of standard axles that can be carried before strengthening of the pavement is

necessary. It is recommended that pavements for arterial roads like NH, SH should be

designed for a life of 15 years, EH and urban roads for 20 years and other categories of roads

for 10 to 15 years.

VEHICLE DAMAGE FACTOR

The vehicle damage factor (VDF) is a multiplier for converting the number of commercial

vehicles of different axle loads and axle configurations to the number of standard axle-load

repetitions. It is defined as equivalent number of standard axles per commercial vehicle. The

VDF varies with the axle configuration, axle loading, terrain, type of road, and from region to

region. The axle load equivalency factors are used to convert different axle load repetitions

into equivalent standard axle load repetitions. For these equivalency factors refer IRC:37-

2001. The exact VDF values are arrived after extensive field surveys.

VEHICLE DISTRIBUTION

A realistic assessment of distribution of commercial traffic by direction and by lane is

necessary as it directly affects the total equivalent standard axle load application used in the

design. Until reliable data is available, the following distribution may be assumed.

Single lane roads: Traffic tends to be more channelized on single roads than two lane

roads and to allow for this concentration of wheel load repetitions, the design should

be based on total number of commercial vehicles in both directions.

Two-lane single carriageway roads: The design should be based on 75 % of the

commercial vehicles in both directions.

Four-lane single carriageway roads: The design should be based on 40 % of the total

number of commercial vehicles in both directions.

Dual carriageway roads: For the design of dual two-lane carriageway roads should be

based on 75 % of the number of commercial vehicles in each direction. For dual

5. PAVEMENT DESIGN ( TE-1) Page 13

three-lane carriageway and dual four-lane carriageway the distribution factor will be

60 % and 45 % respectively.

COMPUTATION OF TRAFFIC (N)

PAVEMENT THICKNESS DESIGN CHARTS

For the design of pavements to carry traffic in the range of 1 to 10 msa, use chart 1 and for

traffic in the range 10 to 150 msa, use chart 2 of IRC:37 2001. The design curves relate

pavement thickness to the cumulative number of standard axles to be carried over the design

life for different sub-grade CBR values ranging from 2 % to 10 %. The design charts will

give the total thickness of the pavement for the above inputs. The total thickness consists of

granular sub-base, granular base and bituminous surfacing. The individual layers are

designed based on the recommendations given below and the subsequent tables.

5. PAVEMENT DESIGN ( TE-1) Page 14

PAVEMENT DESIGN CATALOGUE

Plate 1 – Recommended Design for Traffic Range 1 -10 msa

DESIGN OF RIGID PAVEMENTS

MODULUS OF SUB-GRADE REACTION

Westergaard considered the rigid pavement slab as a thin elastic plate resting on soil

sub-grade, which is assumed as a dense liquid. The upward reaction is assumed to be

proportional to the deflection.

Base on this assumption, Westergaard defined a modulus of sub-grade reaction K in

kg/cm3 given by K = p/Δ where K = p/Δ is the displacement level taken as 0.125 cm

and p is the pressure sustained by the rigid plate of 75 cm diameter at a deflection of

0.125 cm.

RELATIVE STIFFNESS OF SLAB DUE TO SUB GRADE

A certain degree of resistance to slab deflection is offered by the sub-grade. The sub-

grade deformation is same as the slab deflection. Hence the slab deflection is direct

measurement of the magnitude of the sub-grade pressure.

This pressure deformation characteristic of rigid pavement lead Westergaard, to

define the term radius of relative stiffness l in cm is given

Where E is the modulus of elasticity of cement concrete in kg/cm2 (3.0 x 105), µ is the

Poisson's ratio of concrete (0.15), h is the slab thickness in cm and K is the modulus

of sub-grade reaction.

5. PAVEMENT DESIGN ( TE-1) Page 15

CRITICAL LOAD POSITIONS

Since the pavement slab has definite length and width, either the character or the

intensity of maximum stress induced by the application of a given traffic load is

dependent on the location of the load on the pavement surface.

There are three typical locations namely the interior, edge and corner, where differing

conditions of slab continuity exist. These locations are termed as critical load

positions.

(a) Interior Loading: When load is applied in the interior of the slab surface at any place

remote from all edges.

(b) Edge Loading: When load is applied on an edge of the slab at any place remote from

a corner.

(c) Corner Loading: When the centre of load application is located on the bisector of the

corner angle formed by two intersecting edges of the slab, and loaded area is at the

corner touching the two corner edges.

EQUIVALENT RADIUS OF RESISTING SECTION

When the interior point is loaded, only a small area of the pavement is resisting the

bending moment of the plate.

Where a is the radius of the wheel load distribution in cm and h is the slab thickness

in cm.

STRESSES IN RIGID PAVEMENTS

WHEEL LOAD STRESSES - WESTERGAARD'S STRESS EQUATION

The cement concrete slab is assumed to be homogeneous and to have uniform elastic

properties with vertical sub-grade reaction being proportional to the direction.

Westergaard developed relationships for the stress at interior, edge and corner

regions, denoted as σi; σe; σc in kg/cm2 respectively.

5. PAVEMENT DESIGN ( TE-1) Page 16

TEMPERATURE STRESSES

Temperature stresses are developed in cement concrete pavement due to variation in

slab temperature. This is caused by

Daily variation resulting in a temperature gradient across the thickness of the

slab results in warping stresses.

Seasonal variation resulting in overall change in the slab temperature results in

frictional stresses.

WARPING STRESS

Whenever the top and bottom surfaces of a concrete pavement simultaneously possess

different temperatures, the slab tends to warp downward or upward inducing warping

stresses.

The differences in temperature between the top and bottom of the slab depend mainly

on the slab thickness and the climatic conditions of the region.

The warping stress at the interior, edge and corner regions, denoted as σti; σte; σtc in

kg/cm2 respectively and

Where

E = Modulus of elasticity of concrete in kg/cm2 (3 X105)

ϵ = Thermal coefficient of concrete per oC (1x10-7)

t = Temperature difference between the top and bottom of the slab

Cx and Cy are the coefficient based on Lx/l in the desired direction and Ly/l

right angle to the desired direction

µ = Poisson's ration (0.15),

a = Radius of the contact area and l is the radius of the relative stiffness.

FRICTIONAL STRESSES

Due to uniform temperature rise and fall in the cement concrete slab, there is an

overall expansion and contraction of the slab. Since the slab is in contact with soil sub

grade or the sub-base, the slab movements are restrained due to the friction between

the bottom layer of the pavement and the soil layer.

The frictional resistance therefore tends to prevents the movements there by inducing

the frictional stress in the bottom fibre of the cement concrete pavement.

The frictional stress σf in kg/cm2 is given by the equation

5. PAVEMENT DESIGN ( TE-1) Page 17

Where W is the unit weight of concrete in kg/cm2 (2400), f is the coefficient of sub

grade friction (1.5) and L is the length of the slab in meters.

COMBINATION OF STRESSES

It is necessary to consider the conditions under which the various stresses in cement

concrete pavements would combine to give the most critical combinations.

The following conditions are considered to provide the critical combinations

(i) During summer: The critical combinations at interior and edge region during mid

day occur when the slab tends to warp downwards. During this period maximum

tensile stress is develop at the bottom fibre due to warping and this is cumulative with

the tensile stress due to the loading. However the frictional stress is compressive

during expansion. The load stress at edge region is higher than the interior

Summer, mid-day: The critical stress is for edge region given by

σcritical = σe + σte - σf

(ii) During winter: The critical combination of stresses at the above regions occurs at the

bottom fibre when the slab contracts and the slab warp downward during the mid day.

The frictional stress is tensile during contraction.

Winter, mid-day: The critical combination of stress is for the edge region given

by σcritical = σe + σte + σf

(iii)Mid Nights: At corner region, the critical combination occurs at the top fibre of the

slab, when the slab warps upwards during mid nights. There is no frictional stress at

the corner region.

Mid-nights: The critical combination of stress is for the corner region given by

σcritical = σc + σtc

DESIGN OF JOINTS INCEMENT CONCRETE PAVEMENTS

Various types o joints provided in cement concrete pavements to reduce the

temperature stresses are expansion joint, contraction joints and warping stresses

If expansion and contraction joints are properly designed and constructed, there is no

need of providing warping joints, in addition.

Expansion joint spacing is designed based on the maximum temperature variation

expected and the width of joint.

The contraction joint spacing design is governed by the anticipated frictional

resistance and allowable tensile stresses in concrete during the initial curing period, or

the amount of reinforcement, if any.

The spacing between the expansion joints is so adjusted that the contraction joints

have equal spacing.

5. PAVEMENT DESIGN ( TE-1) Page 18

EXPANSION JOINTS

The width or gap in expansion joint depends upon the length of slab. Greater the

distance between the expansion joints, the greater is the width required of the gap for

expansion.

The use of the wide expansion joint space should be avoided as it would be difficult to

keep them properly filled in when the gap widens during the winter season.

The purpose of the expansion joint is to allow the expansion of the pavement due to

rise in temperature with respect to

construction temperature.

The design consideration are:

Provided along the longitudinal

direction,

Design involves finding the joint

spacing for a given expansion joint

thickness (say 2.5 cm specified by

IRC) subjected to some maximum

spacing (say 140 as per IRC)

CONTRACTION JOINT

The purpose of the contraction joint is to allow the contraction of the slab due to fall

in slab temperature below the construction temperature. The design considerations

are:

The movement is restricted by the sub-grade friction

Design involves the length of the slab given by:

Where, Sc is the allowable stress in tension in cement concrete and is taken as 0.8

kg/cm2, W is the unit weight of the concrete which can be taken as 2400 kg/cm3 and f

is the coefficient of sub-grade friction which can be taken as 1.5.

Steel reinforcements can be use, however with a maximum spacing of 4.5 m as per

IRC.

5. PAVEMENT DESIGN ( TE-1) Page 19

DESIGN OF DOWEL BARS

The purpose of the dowel bar is to effectively transfer the load between two concrete

slabs and to keep the two slabs in same height.

The dowel bars are provided in the direction of the traffic (longitudinal). The design

considerations are:

Mild steel rounded bars,

bonded on one side and free on other side

Bradbury's analysis: Bradbury's analysis gives load transfer capacity of single dowel bar

in shear, bending and bearing as follows:

where,

P = Load transfer capacity of a single dowel bar in shear s, bending f and bearing

b, d is the diameter of the bar in cm,

Ld =Length of the embedment of dowel bar in cm,

Δ = Joint width in cm,

Fs; Ff; Fb are the permissible stress in shear, bending and bearing for the dowel bar

in kg/cm2.

DESIGN PROCEDURE

Step 1 Find the length of the dowel bar embedded in slab L d

Step 2 Find the load transfer capacities Ps, Pf , and Pb of single dowel bar with the Ld

Step 3 Assume load capacity of dowel bar is 40 percent wheel load, find the load capacity

factor f as

5. PAVEMENT DESIGN ( TE-1) Page 20

Step 4 Spacing of the dowel bars:

Effective distance up to which effective load transfer take place is given by 1.8 l,

where l is the radius of relative stiffness.

Assume a linear variation of capacity factor of 1.0 under load to 0 at 1.8 l.

Assume dowel spacing and find the capacity factor of the above spacing.

Actual capacity factor should be greater than the required capacity factor.

If not, do one more iteration with new spacing.

DESIGN OF TIE BARS.

In contrast to dowel bars, tie bars are not load transfer devices, but serve as a means to

tie two slabs.

They are provided across longitudinal joints.

Hence tie bars must be deformed or hooked and must be firmly anchored into the

concrete to function properly. They are smaller than dowel bars and placed at large

intervals.

Step 1 Diameter and spacing: The diameter and the spacing are first found out by equating

the total sub-grade friction to the total tensile stress for a unit length (one meter).

Hence the area of steel per one meter in cm2 is given by:

Where,

b =Width of the pavement panel in m,

h = Depth of the pavement in cm,

W = Unit weight of the concrete (assume 2400 kg/cm2),

f = Coefficient of friction (assume .5),

Ss = Allowable working tensile stress in steel (assume 1750 kg/cm2).

Assume 0.8 to 1.5 cm Ø bars for the design.

Step 2 Length of the tie bar: Length of the tie bar is twice the length needed to develop

bond stress equal to the working tensile stress and is given by:

Where,

d =Diameter of the bar,

Ss =Allowable tensile stress in kg/cm2,

Sb = is the allowable bond stress and can be assumed for plain and

deformed bars respectively as 17.5 and 24.6 kg/cm2.

5. PAVEMENT DESIGN ( TE-1) Page 21

You might also like

- Group 4 PresentationDocument96 pagesGroup 4 PresentationClarenz BragaNo ratings yet

- Irrigation Engineering Principles: Version 2 CE IIT, KharagpurDocument27 pagesIrrigation Engineering Principles: Version 2 CE IIT, KharagpurSiva PrasadNo ratings yet

- Long Span Structures - SalahuddinDocument15 pagesLong Span Structures - SalahuddinSalahuddin ShaikhNo ratings yet

- Introduction To Pavement DesignDocument7 pagesIntroduction To Pavement DesignPrabhakar Kumar BarnwalNo ratings yet

- Pavement DesignDocument18 pagesPavement DesignTjandra LiemNo ratings yet

- Pavement DesignDocument18 pagesPavement DesignTjandra LiemNo ratings yet

- Lec 8 Pavement DesignDocument87 pagesLec 8 Pavement DesignBernard de VeraNo ratings yet

- Lec 8 Pavement DesignDocument87 pagesLec 8 Pavement DesignMay de Vera100% (1)

- Unit2 - Lecture1 CIV241Document64 pagesUnit2 - Lecture1 CIV241Soumya MishraNo ratings yet

- Pavement Design (15cv833)Document90 pagesPavement Design (15cv833)Pavan kashappagoudarNo ratings yet

- Pavement DesignDocument20 pagesPavement DesignHanamant HunashikattiNo ratings yet

- Lecture 1 Cce 2424 Pavement Design and ConstructionDocument18 pagesLecture 1 Cce 2424 Pavement Design and Constructionmotanyadebra11No ratings yet

- Flexible PavementsDocument13 pagesFlexible PavementsAhmad NajiNo ratings yet

- Pavement DesignDocument7 pagesPavement DesignvictorNo ratings yet

- Introduction To Pavement DesignDocument1 pageIntroduction To Pavement DesignZharif ZubirNo ratings yet

- Introduction To Pavement DesignDocument12 pagesIntroduction To Pavement DesignVijay KumarNo ratings yet

- Definition of PavementDocument7 pagesDefinition of PavementSujon AhmmedNo ratings yet

- Introduction To Pavement DesignDocument11 pagesIntroduction To Pavement DesignChris EminentNo ratings yet

- Chapter OneDocument28 pagesChapter Onemure YusufNo ratings yet

- General IntroductionDocument12 pagesGeneral IntroductionKanimozhi SNo ratings yet

- Lecture 1 Introduction To Highway Pavement Construction 25.072023Document37 pagesLecture 1 Introduction To Highway Pavement Construction 25.072023Timothy MagikaNo ratings yet

- High Way - Ass.1docxDocument11 pagesHigh Way - Ass.1docxMekuannint DemekeNo ratings yet

- Introduction To Pavement DesignDocument23 pagesIntroduction To Pavement DesignDaniel Berhane100% (1)

- An Overview To The Construction of Road PavementsDocument21 pagesAn Overview To The Construction of Road PavementsliuhoyinNo ratings yet

- 15cv833-Pavement DesignDocument90 pages15cv833-Pavement DesignMEHRAN KAPRANo ratings yet

- IntroductionDocument55 pagesIntroductionketanbaghel66No ratings yet

- Chapter 1Document10 pagesChapter 1Nalina Amith VijayanandNo ratings yet

- Pavements: Types of PavementDocument8 pagesPavements: Types of PavementKing RickNo ratings yet

- 1610546775introduction To Pavement Structure DesignDocument12 pages1610546775introduction To Pavement Structure DesignSasultan UltansasNo ratings yet

- Introduction To Pavement DesignDocument17 pagesIntroduction To Pavement Designmvap2856No ratings yet

- Structural Design of HighwayDocument19 pagesStructural Design of Highwayبلسم محمود شاكرNo ratings yet

- Desirable Characteristics: Module 1: Introduction Introduction To Pavement DesignDocument21 pagesDesirable Characteristics: Module 1: Introduction Introduction To Pavement DesignBharath SpidyNo ratings yet

- Introduction To Pavement Design Lecture Notes in Transportation Systems Engineering 3 August 2009Document12 pagesIntroduction To Pavement Design Lecture Notes in Transportation Systems Engineering 3 August 2009Shreenidhi HariharanNo ratings yet

- Chapter OneDocument17 pagesChapter OneAlemayehu MitekuNo ratings yet

- UNIT-1 Factors Affecting Pavement Design: 1.2 Types of PavementsDocument11 pagesUNIT-1 Factors Affecting Pavement Design: 1.2 Types of PavementsJemson VictorioNo ratings yet

- Types of PavementsDocument17 pagesTypes of PavementsPereira KastroNo ratings yet

- Module-1 Types of Pavements & Load Distribution UpdatedDocument12 pagesModule-1 Types of Pavements & Load Distribution UpdatedHuzaifa ZafarNo ratings yet

- Highway and Pavement ConstructionDocument35 pagesHighway and Pavement ConstructionCherylNo ratings yet

- Road StructureDocument10 pagesRoad StructureMohammed NawzanNo ratings yet

- Pavement DesignDocument12 pagesPavement DesignTarun KumarNo ratings yet

- Transport Assignment 2Document37 pagesTransport Assignment 2Animesh MishraNo ratings yet

- Basics of Pavement, MMHDocument19 pagesBasics of Pavement, MMHMd Mehedi HasnatNo ratings yet

- Design of Pavement Structure-Odd 2015 - Print 01Document11 pagesDesign of Pavement Structure-Odd 2015 - Print 01BISUNo ratings yet

- Difference Between Flexible Pavement and Rigid PavementDocument7 pagesDifference Between Flexible Pavement and Rigid PavementAbdul RehmanNo ratings yet

- Topic:-Flexible Pavement: By: AMIT KumarDocument10 pagesTopic:-Flexible Pavement: By: AMIT Kumarpkgoyal1983No ratings yet

- Sci 1610Document76 pagesSci 1610Omkar Gadage PatilNo ratings yet

- Highway ConstructionDocument80 pagesHighway Constructionsarat100% (1)

- Highway Engineering Lab Assignment#03Document73 pagesHighway Engineering Lab Assignment#03tayyabNo ratings yet

- Design of Flexible PavementDocument81 pagesDesign of Flexible PavementAnonymous UncXDPRy100% (1)

- Chapter One: School of Civil and Environmental Engineering 2018/19Document11 pagesChapter One: School of Civil and Environmental Engineering 2018/19xan pitchuNo ratings yet

- Pavement Materials and Design: by Eng. Ra'Id ArrhaibehDocument207 pagesPavement Materials and Design: by Eng. Ra'Id ArrhaibehEilmohNo ratings yet

- Unit III - Design of Flexible and Rigid PavementsDocument13 pagesUnit III - Design of Flexible and Rigid PavementsKandasamy AsohanNo ratings yet

- Comparative Study Between Flexible and Rigid Pavement: Fariha Azad Anika 1018042305Document7 pagesComparative Study Between Flexible and Rigid Pavement: Fariha Azad Anika 1018042305Fariha AzadNo ratings yet

- Pavement Design: Submitted To:-Submitted By: - Kapil Sharma Akshay Kumar 1102800003Document14 pagesPavement Design: Submitted To:-Submitted By: - Kapil Sharma Akshay Kumar 1102800003vishal banaNo ratings yet

- Pavement Design: Balona, Christian Abell Bedis, John Robert Laguna, Nelmar Quismundo, Lester Voluntad, Nolfredo JRDocument52 pagesPavement Design: Balona, Christian Abell Bedis, John Robert Laguna, Nelmar Quismundo, Lester Voluntad, Nolfredo JRJessa LatosaNo ratings yet

- Mizan Tepi University: Collage of Engineering and TechnologyDocument18 pagesMizan Tepi University: Collage of Engineering and TechnologyANDLENATUNo ratings yet

- Topic:-: Pavement DesignDocument59 pagesTopic:-: Pavement DesignMalik ZainNo ratings yet

- Report On ENGINEERING COMPARISON BETWEEN FLEXIBLE AND RIGID PAVEMENTDocument35 pagesReport On ENGINEERING COMPARISON BETWEEN FLEXIBLE AND RIGID PAVEMENTTahmidul Islam FarabiNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Caution: We Don'T Have Branches Anywhere in India: Sri Guru RaghavendraDocument8 pagesCaution: We Don'T Have Branches Anywhere in India: Sri Guru RaghavendraSiva PrasadNo ratings yet

- BankingDocument83 pagesBankingSiva PrasadNo ratings yet

- Wa0005Document23 pagesWa0005Siva PrasadNo ratings yet

- SVR Engineering College: (Approved by AICTE New Delhi, Affiliated by JNT University, Anantapuramu)Document1 pageSVR Engineering College: (Approved by AICTE New Delhi, Affiliated by JNT University, Anantapuramu)Siva PrasadNo ratings yet

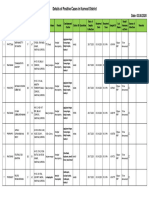

- 06.08.2020-1757 Positive Cases Submitted To State For Announcment On 07.08.2020Document95 pages06.08.2020-1757 Positive Cases Submitted To State For Announcment On 07.08.2020Siva Prasad0% (1)

- Wa0004Document17 pagesWa0004Siva PrasadNo ratings yet

- 03.08.2020 - 0319 CasesDocument41 pages03.08.2020 - 0319 CasesSiva PrasadNo ratings yet

- S V C E: A Technical Seminar Report OnDocument20 pagesS V C E: A Technical Seminar Report OnSiva PrasadNo ratings yet

- NandyalDocument16 pagesNandyalSiva PrasadNo ratings yet

- Piano Key Spillway For DamsDocument22 pagesPiano Key Spillway For DamsSiva PrasadNo ratings yet

- Drought Prone AreasDocument6 pagesDrought Prone AreasSiva PrasadNo ratings yet

- 11 Hydrology PDFDocument1 page11 Hydrology PDFSiva PrasadNo ratings yet

- 2 PPT 1 Design ConceptsDocument33 pages2 PPT 1 Design ConceptsLuis Hernán Guillén CardonaNo ratings yet

- RCD2Document59 pagesRCD2Bobby AguilarNo ratings yet

- An Analytical Study On Rotational Capacity of Beam Column Joints in Unit Modular FramesDocument4 pagesAn Analytical Study On Rotational Capacity of Beam Column Joints in Unit Modular Frameszhang zhaoboNo ratings yet

- ThesisBlandon Jan2008 PDFDocument418 pagesThesisBlandon Jan2008 PDFTheo Alejandro Rojas VivarNo ratings yet

- Foot Over Bridge First Review PKPDocument25 pagesFoot Over Bridge First Review PKPpandianNo ratings yet

- Construction Logbook Sheet San Jose (MARASIGAN POULTRY)Document162 pagesConstruction Logbook Sheet San Jose (MARASIGAN POULTRY)Czari MuñozNo ratings yet

- EG-A-415E Roofing Wall Cladding Rev 3Document12 pagesEG-A-415E Roofing Wall Cladding Rev 3Vicente Aparecido Pineda Ferrari Jr.No ratings yet

- 3 Jet GroutingDocument5 pages3 Jet GroutingshubhamNo ratings yet

- Subterranean Termites - A Handbook For HomeownersDocument54 pagesSubterranean Termites - A Handbook For Homeownersjerrymakilan100% (1)

- Water Tower Inspection ReportDocument8 pagesWater Tower Inspection ReportKevinSeanHeldNo ratings yet

- Wondwossen KifleDocument97 pagesWondwossen KifleIyaadanNo ratings yet

- Hydrogen Induced Cracking TestDocument2 pagesHydrogen Induced Cracking TestJayeshNo ratings yet

- BS 6100 5 3 PDFDocument12 pagesBS 6100 5 3 PDFShaik AbdullaNo ratings yet

- Cat Acvbr9000Document16 pagesCat Acvbr9000gazwang478No ratings yet

- Fire Resistant Data CablesDocument44 pagesFire Resistant Data Cablesrose chenNo ratings yet

- Building PermitDocument4 pagesBuilding Permitlayaljamal2No ratings yet

- Best Interior Architects in Kolkata PDF DownloadDocument1 pageBest Interior Architects in Kolkata PDF DownloadArsh KrishNo ratings yet

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetGaona industrial PetroleroNo ratings yet

- PC - Print - 11-11-22 AmDocument7 pagesPC - Print - 11-11-22 AmTheo AnggaraNo ratings yet

- Concrete Mix Design STFA 09 06 2009Document20 pagesConcrete Mix Design STFA 09 06 2009Ahmet ÖzdenNo ratings yet

- FI-200w Tunel FagorDocument24 pagesFI-200w Tunel Fagoro.m.martin81gmail.comNo ratings yet

- Simply Supported Reinforced Concrete Beam Analysis and Design (ACI 318-14)Document33 pagesSimply Supported Reinforced Concrete Beam Analysis and Design (ACI 318-14)Anonymous ARMtmNKL100% (1)

- Eco Living Japan - ARQUILIBROS - AL PDFDocument241 pagesEco Living Japan - ARQUILIBROS - AL PDFKev Ruiz100% (2)

- JOINTSDocument4 pagesJOINTSSceva AquilaNo ratings yet

- Sl. No. Description of Equipment Equipment Code Air CompressorDocument17 pagesSl. No. Description of Equipment Equipment Code Air CompressorsivathegrateNo ratings yet

- Wk6 Application of Hydrology 20224Document37 pagesWk6 Application of Hydrology 20224DEBRA DEIRDRE S. ONONG DEBRA DEIRDRE S. ONONGNo ratings yet

- D10 Handbook of Stormwater Drainage DesignDocument59 pagesD10 Handbook of Stormwater Drainage DesignAnonymous WqYvpVd100% (3)

- Stress-Strain Model of Unconfined and Confined Concrete and Stress-Block ParametersDocument112 pagesStress-Strain Model of Unconfined and Confined Concrete and Stress-Block ParametersGabrielaSanMartínNo ratings yet