Professional Documents

Culture Documents

4.5 Bottom Rollers

4.5 Bottom Rollers

Uploaded by

Jhonny Manjarrez0 ratings0% found this document useful (0 votes)

11 views2 pages1. Bottom rollers have lifetime lubrication and generally do not require maintenance until wear limits are reached.

2. The majority of roller leaks are caused by dirt entering through the labyrinth seal and penetrating the duo-cone seals.

3. Loose bottom roller bolts can cause axial forces to transfer to the locking pins, which are not designed for that purpose. The roller can be made operational again by removing it, cleaning it, and refilling it with fresh oil.

Original Description:

Fluk

Original Title

04_05-2471630e

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. Bottom rollers have lifetime lubrication and generally do not require maintenance until wear limits are reached.

2. The majority of roller leaks are caused by dirt entering through the labyrinth seal and penetrating the duo-cone seals.

3. Loose bottom roller bolts can cause axial forces to transfer to the locking pins, which are not designed for that purpose. The roller can be made operational again by removing it, cleaning it, and refilling it with fresh oil.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

11 views2 pages4.5 Bottom Rollers

4.5 Bottom Rollers

Uploaded by

Jhonny Manjarrez1. Bottom rollers have lifetime lubrication and generally do not require maintenance until wear limits are reached.

2. The majority of roller leaks are caused by dirt entering through the labyrinth seal and penetrating the duo-cone seals.

3. Loose bottom roller bolts can cause axial forces to transfer to the locking pins, which are not designed for that purpose. The roller can be made operational again by removing it, cleaning it, and refilling it with fresh oil.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

4.

5 BOTTOM ROLLER

4.5 Bottom rollers

4. Loose bottom roller bolts:

In this case the axial forces are transfered onto

1. Bottom rollers have lifetime lubrication. They do

the locking pins, which are not designed for this

not require any maintenance until the wear lim-

purpose.

its have been reached.

5. The roller can be made fully operational by

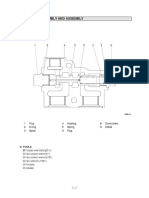

2. The rollers are sealed with duo-cone seals (8).

removing and cleaning it, and then filling it with

Function and assembly of duo-cone seals - see

fresh oil.

chapter 4.11.

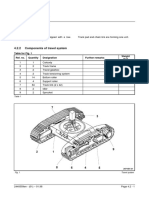

3. The majority of roller leaks is due to dirt that

enters through the labyrinth (see arrow, Fig. 2)

and penetrates into the duo-cone seals.

Components of the bottom roller

Ref. no. Quantity Designation Further remarks Weight

[kg]

1 1 Bottom roller 330

2 2 Support

3 2 Rollpin

4 2 Rollpin

5 1 Plug M 10 / SW 5

6 1 Seal

7 2 Bushing

8 2 Duo-cone seal

9 2 O-Ring 149, 2 x 5,3

10 1 Shaft

11 1 Roller body

2471630en - (00) - 01.97 Page 4.5 - 1

4.5 BOTTOM ROLLER

Fig. 1 Bottom roller 2235011

Fig. 2 Bottom roller 2184683

Page 4.5 - 2 2471630en - (00) - 01.97

You might also like

- Service Manual For Ford Tractor Series 2000, 3000, 4000, 5000, 7000, 3400, 3500, 3550, 4400, 4500, 5500, 5550 Vol. 2Document352 pagesService Manual For Ford Tractor Series 2000, 3000, 4000, 5000, 7000, 3400, 3500, 3550, 4400, 4500, 5500, 5550 Vol. 2Taj Deluria100% (4)

- Sincronizacion de Motores Ssangyong d20dt d27dtDocument4 pagesSincronizacion de Motores Ssangyong d20dt d27dtMynor Witt100% (5)

- 04 - 05-3657707e - Bottom Roller.Document6 pages04 - 05-3657707e - Bottom Roller.Enso RosalesNo ratings yet

- 04 - 06-2803248e - Top Roller.Document4 pages04 - 06-2803248e - Top Roller.Enso RosalesNo ratings yet

- Emco D2000 Swivel PartsDocument2 pagesEmco D2000 Swivel Partsaldo2306No ratings yet

- Group 4 Disassembly and Assembly: 1. Priority ValveDocument38 pagesGroup 4 Disassembly and Assembly: 1. Priority ValveREMZONANo ratings yet

- PartsDocument54 pagesPartsDenis VieiraNo ratings yet

- EASA Essay Technique M7 9 10Document16 pagesEASA Essay Technique M7 9 10Ram C HumagainNo ratings yet

- Mesin RumputDocument32 pagesMesin Rumputaep77No ratings yet

- "Falcon": SeriesDocument8 pages"Falcon": SeriesmarkoNo ratings yet

- Kelly - DE EN - 905 518 1Document18 pagesKelly - DE EN - 905 518 1JORGE BARRERA100% (2)

- sbg2470Document41 pagessbg2470mustafa özkanNo ratings yet

- FR564HR NaDocument22 pagesFR564HR Nausaussr52No ratings yet

- Naf ppt2 Diferential For Camox f175Document40 pagesNaf ppt2 Diferential For Camox f175Marijan LesičakNo ratings yet

- Operating Instuction Front Axle, 5871.197.902Document9 pagesOperating Instuction Front Axle, 5871.197.902Unai Garcia JesusNo ratings yet

- Bomag BMP 8500 Drum Repair OverveiwDocument24 pagesBomag BMP 8500 Drum Repair OverveiwAbdul RehmanNo ratings yet

- Fristam FPE-FPDocument65 pagesFristam FPE-FPJúlia LinoNo ratings yet

- ML Couplings Instruction ManualDocument4 pagesML Couplings Instruction ManualGer BosNo ratings yet

- Chaptr 4 Reslts and DiscussionDocument14 pagesChaptr 4 Reslts and DiscussionirshadNo ratings yet

- Camshaft Wear, CheckDocument6 pagesCamshaft Wear, CheckHamilton MirandaNo ratings yet

- KSB Pump Movi ManualDocument12 pagesKSB Pump Movi ManualVenkat Dora100% (5)

- Front Axle and Reduction DifferentialDocument27 pagesFront Axle and Reduction DifferentialDmitry100% (1)

- Exhaust Valve Roller Guide: S35MC DataDocument6 pagesExhaust Valve Roller Guide: S35MC DatalijinNo ratings yet

- t156 1 Forklift Merlo P35.9ev Oem Service ManualDocument100 pagest156 1 Forklift Merlo P35.9ev Oem Service ManualChomi100% (1)

- MSX125 - 2 - Body Panels - Exhaust System - 4Document10 pagesMSX125 - 2 - Body Panels - Exhaust System - 4camu233No ratings yet

- 7Document20 pages7luis david vela arellanoNo ratings yet

- Group 3 AxleDocument32 pagesGroup 3 AxleSaidi JalelNo ratings yet

- 1986-1988 SuzukiSamurai Clutch ManualDocument10 pages1986-1988 SuzukiSamurai Clutch ManualHatnean CristianNo ratings yet

- Elements of Machine Design (Document8 pagesElements of Machine Design (v.v.ransing22No ratings yet

- HF25Document8 pagesHF25marran almarranyNo ratings yet

- Apltcl040 SGD L-01Document136 pagesApltcl040 SGD L-01Waleed King100% (4)

- Driver and Maintenance Operations TD Steering SystemDocument52 pagesDriver and Maintenance Operations TD Steering SystemmuratNo ratings yet

- CylindersDocument9 pagesCylindersvencyNo ratings yet

- Bearing Assessment For Wartsila 20Document13 pagesBearing Assessment For Wartsila 20magicalseas100% (7)

- DOC022090 - 3-EN - Manutenção Ligação de VigasDocument10 pagesDOC022090 - 3-EN - Manutenção Ligação de VigasmuriloNo ratings yet

- Manual Bomba de Aceite 1701053Document9 pagesManual Bomba de Aceite 1701053ventas freyreNo ratings yet

- HL740 (TM) - 7 5-4Document43 pagesHL740 (TM) - 7 5-4REMZONANo ratings yet

- Engine Bearings DamageDocument65 pagesEngine Bearings Damagealive2flirtNo ratings yet

- Ascensor l10 (Lej-Mm00202)Document11 pagesAscensor l10 (Lej-Mm00202)gui9871No ratings yet

- AkfrontDocument25 pagesAkfrontRicardo VieiraNo ratings yet

- Assembly Drawing & Part ListDocument1 pageAssembly Drawing & Part ListCamila PenhaNo ratings yet

- 08 Jute Drawing IIDocument52 pages08 Jute Drawing IImp.ninfetNo ratings yet

- Group 10 Undercarriage: 1. Track LinkDocument12 pagesGroup 10 Undercarriage: 1. Track LinkJorge Iván Villaseñor LozanoNo ratings yet

- Sincronizacion de Motores Ssangyong d20dt d27dt PDFDocument4 pagesSincronizacion de Motores Ssangyong d20dt d27dt PDFMynor WittNo ratings yet

- Vciom 06062 enDocument4 pagesVciom 06062 enJoeNo ratings yet

- SKFBSSB Catalogue AngularcontactthrustballbearingsforscrewdrivesDocument8 pagesSKFBSSB Catalogue AngularcontactthrustballbearingsforscrewdrivesSuniil AjmeraNo ratings yet

- Double Barrel Service Instructions V2.0 2Document22 pagesDouble Barrel Service Instructions V2.0 2Kleber GarciaNo ratings yet

- Kato 6 Control ValveDocument49 pagesKato 6 Control ValveStormNo ratings yet

- Trunnion Mounted Metal Seated Ball Valve - As Per Shaikh Sir Req.-1Document11 pagesTrunnion Mounted Metal Seated Ball Valve - As Per Shaikh Sir Req.-1demblavalvesltd1989No ratings yet

- Note!: Shock Absorber For Honda ADV150Document8 pagesNote!: Shock Absorber For Honda ADV150AdityaArnasNo ratings yet

- A Complete Guide To Spiratec™ Rotor (Cs41018/Cs41019/Cs41011) & Remote Centrifuge Product Benefits Installation InstructionsDocument7 pagesA Complete Guide To Spiratec™ Rotor (Cs41018/Cs41019/Cs41011) & Remote Centrifuge Product Benefits Installation InstructionsCarlos MeztNo ratings yet

- 10. جنازير ورولاتDocument12 pages10. جنازير ورولاتالمهندسوليدالطويلNo ratings yet

- 215coacoscwlexcmewpatpawwlo22 GBDocument6 pages215coacoscwlexcmewpatpawwlo22 GBImam MuhhudaNo ratings yet

- Wartsila 32 Bearing Assessment PDFDocument8 pagesWartsila 32 Bearing Assessment PDFHeryanto Syam100% (1)

- 3.1training - Manual - TBN Steam Path (Rotor)Document16 pages3.1training - Manual - TBN Steam Path (Rotor)Tung Nguyen100% (1)

- Kobelco 6E - Hyd Motors PDFDocument26 pagesKobelco 6E - Hyd Motors PDFHai VanNo ratings yet

- Aluminum Structures: A Guide to Their Specifications and DesignFrom EverandAluminum Structures: A Guide to Their Specifications and DesignRating: 5 out of 5 stars5/5 (2)

- Mechanics of Optimal Structural Design: Minimum Weight StructuresFrom EverandMechanics of Optimal Structural Design: Minimum Weight StructuresNo ratings yet

- (Dust Suppression SystemDocument4 pages(Dust Suppression SystemJhonny ManjarrezNo ratings yet

- 4.2 Travel System: 4.2.1 GeneralDocument6 pages4.2 Travel System: 4.2.1 GeneralJhonny ManjarrezNo ratings yet

- Pos. 3.2.3.01 Electric Connector AssortmentDocument4 pagesPos. 3.2.3.01 Electric Connector AssortmentJhonny ManjarrezNo ratings yet

- 3.1.1 Foreword: 3.1 TOOLSDocument10 pages3.1.1 Foreword: 3.1 TOOLSJhonny ManjarrezNo ratings yet

- Screws, Fittings, Seals BucyrusDocument16 pagesScrews, Fittings, Seals BucyrusJhonny ManjarrezNo ratings yet