Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

101 viewsFatigue Life Testing of Metal Expansion Joints

Fatigue Life Testing of Metal Expansion Joints

Uploaded by

Virjil AycochoFatigue life testing is a verification of the ability of a bellows to withstand a given number of flexing cycles. This procedure was developed by Macoga Engineered Expansion Joints.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- VibrationControl CATALOGO SOPORTES PDFDocument12 pagesVibrationControl CATALOGO SOPORTES PDFMilena Lemus FonsecaNo ratings yet

- Flanged Basket Strainers IOMDocument4 pagesFlanged Basket Strainers IOMSteve NewmanNo ratings yet

- PADT Webinar Post26 2012 - 04 - 12Document54 pagesPADT Webinar Post26 2012 - 04 - 12Jack FusionNo ratings yet

- Autopipe: Acceptance Test SetDocument185 pagesAutopipe: Acceptance Test SetAob AprilNo ratings yet

- Fatigue Failure Resulting From Variable Loading 1-2Document24 pagesFatigue Failure Resulting From Variable Loading 1-2Rahul Singh100% (1)

- Elevated Temperature Fatigue of Pressure Vessel SteelsDocument6 pagesElevated Temperature Fatigue of Pressure Vessel SteelsJohnNo ratings yet

- TR 110996Document117 pagesTR 110996Subhadip SadhukhanNo ratings yet

- ANSYS Analysis of Single Phase Induction Motor - Hani Aziz AmeenDocument74 pagesANSYS Analysis of Single Phase Induction Motor - Hani Aziz AmeenHani Aziz Ameen50% (2)

- Tubesheet Cladding Baher 1648652344Document3 pagesTubesheet Cladding Baher 1648652344Sapan ShahNo ratings yet

- Density of Materials & Comparison of Ss 304 Vs Ss316LDocument4 pagesDensity of Materials & Comparison of Ss 304 Vs Ss316LShino UlahannanNo ratings yet

- EHB en 9.7-Equivalent-Materials PDFDocument7 pagesEHB en 9.7-Equivalent-Materials PDFArquimedes PerezNo ratings yet

- The Finite Element Method and Applications in Engineering Using Ansys®Document5 pagesThe Finite Element Method and Applications in Engineering Using Ansys®sivaraju22No ratings yet

- Estimation of SIF by Mumerical MethodDocument21 pagesEstimation of SIF by Mumerical Methodworkineh gebeyehuNo ratings yet

- Realiability of Corrosion DeffectsDocument20 pagesRealiability of Corrosion DeffectsJavier Gualdrón PlataNo ratings yet

- Detailed Fea of Locally Thinned Pipe Bends: Usama Abdelsalam & DK VijayDocument9 pagesDetailed Fea of Locally Thinned Pipe Bends: Usama Abdelsalam & DK VijayAnonymous 1hOgJqwZuzNo ratings yet

- Cyclic Symmetry Workbench Version 12Document12 pagesCyclic Symmetry Workbench Version 12Tebong BrowserNo ratings yet

- Structural Analysis and Design of Proces PDFDocument361 pagesStructural Analysis and Design of Proces PDFmarceloNo ratings yet

- Ansys Elements PDFDocument1,401 pagesAnsys Elements PDFprashanthattiNo ratings yet

- MSS SP - 97 - 2019 - Integrally Reinforced Forged Branch Outlet Fittings Socket Welding, Threaded, and Buttwelding EndsDocument4 pagesMSS SP - 97 - 2019 - Integrally Reinforced Forged Branch Outlet Fittings Socket Welding, Threaded, and Buttwelding Endsarnoldbatista55No ratings yet

- Markl SIFs & Asme ViiiDocument3 pagesMarkl SIFs & Asme ViiiDesmond ChangNo ratings yet

- Module 7 Vibration Absorbers Gen - Techn .Data EFBDocument12 pagesModule 7 Vibration Absorbers Gen - Techn .Data EFBRichard PerezNo ratings yet

- IJESH Analysis of Piping System Used in Chemical Plant 80Document7 pagesIJESH Analysis of Piping System Used in Chemical Plant 80pipestress100% (1)

- Nureg 6007Document122 pagesNureg 6007Baher ElsheikhNo ratings yet

- SAPAG Butterfly ValvesDocument22 pagesSAPAG Butterfly ValvespawelzakNo ratings yet

- Pressure Safety Relief Valves Pressure Safety Relief Valves: Technical Bulletin 3 Technical Bulletin 3-IDocument16 pagesPressure Safety Relief Valves Pressure Safety Relief Valves: Technical Bulletin 3 Technical Bulletin 3-Isabi_shiNo ratings yet

- Astm E1049 85 2017Document6 pagesAstm E1049 85 2017Alexandre JesusNo ratings yet

- EQUIPMENT DESIGN by DR NORIN ZAMIAH PDFDocument104 pagesEQUIPMENT DESIGN by DR NORIN ZAMIAH PDFAimanNo ratings yet

- Super Duplex Valve PDFDocument87 pagesSuper Duplex Valve PDFMohamed YousufNo ratings yet

- P91 EnggDocument25 pagesP91 EnggAshwani DograNo ratings yet

- Study On Prefabricated Concrete Beam and Column ConnectionsDocument6 pagesStudy On Prefabricated Concrete Beam and Column ConnectionsreenaNo ratings yet

- PWR Is The Abbreviation For The Pressurized Water ReactorDocument18 pagesPWR Is The Abbreviation For The Pressurized Water Reactorshrishmapaik2070No ratings yet

- Comparative Study EN 13445 / ASME Section VIII Div. 1 & 2Document48 pagesComparative Study EN 13445 / ASME Section VIII Div. 1 & 2Anand PatelNo ratings yet

- S.V Reg. in Asme TDP 1, Asme Sec 1, b31.1Document9 pagesS.V Reg. in Asme TDP 1, Asme Sec 1, b31.1K.S.MAYILVAGHANANNo ratings yet

- W044Rev1 PDFDocument41 pagesW044Rev1 PDFTONNo ratings yet

- 7 Ways To Evaluate FEA AccuracyDocument21 pages7 Ways To Evaluate FEA Accuracyhanson219No ratings yet

- Bellow Design 1Document5 pagesBellow Design 1zingalala100% (2)

- ASME VIII-2 Ed 2023 ExampleDocument7 pagesASME VIII-2 Ed 2023 ExampleLorenzoNo ratings yet

- Nozzle Stiffness and Stress Computation Using A Parametrically Controlled Finite Element Modeling ApproachDocument4 pagesNozzle Stiffness and Stress Computation Using A Parametrically Controlled Finite Element Modeling ApproachkysucoNo ratings yet

- GRI DurlonTechnicalHandbookDocument30 pagesGRI DurlonTechnicalHandbookFrank RamirezNo ratings yet

- Pressure VesselDocument4 pagesPressure VesselDeaz AmbrsNo ratings yet

- Strength of Materials - Statically Indeterminate Beam - Hani Aziz AmeenDocument23 pagesStrength of Materials - Statically Indeterminate Beam - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Diaphragm Seals Application - Operating Principle - Designs: Technical InformationDocument6 pagesDiaphragm Seals Application - Operating Principle - Designs: Technical InformationdleonarenNo ratings yet

- Nozzle StressDocument25 pagesNozzle StressvamsiNo ratings yet

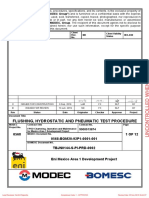

- 0568-Bom20-92p1-0001-001-1-Code-1 Hydro ProcedureDocument12 pages0568-Bom20-92p1-0001-001-1-Code-1 Hydro ProcedureLeilei WangNo ratings yet

- Ver TubagemDocument7 pagesVer TubagemHernâni CruzNo ratings yet

- Barutzki PDFDocument9 pagesBarutzki PDFesutjiadiNo ratings yet

- Dhawi - Reclassification of SRU Equipment To ASME Section VIIIDivision 1 PDFDocument8 pagesDhawi - Reclassification of SRU Equipment To ASME Section VIIIDivision 1 PDFRenan Gustavo PazNo ratings yet

- Victaulic General Catalog G-103Document248 pagesVictaulic General Catalog G-103Muhsen Khan100% (1)

- Nytro® Libra: Property Unit Test Method Specification Limits Typical Data Min Max 1 - FunctionDocument2 pagesNytro® Libra: Property Unit Test Method Specification Limits Typical Data Min Max 1 - FunctionAUFA JAYA PERKASANo ratings yet

- AnsysDocument15 pagesAnsysginupaulNo ratings yet

- B - Lecture10 The Root Locus Rules Automatic Control SystemDocument31 pagesB - Lecture10 The Root Locus Rules Automatic Control SystemAbaziz Mousa OutlawZzNo ratings yet

- Astm A-1005Document6 pagesAstm A-1005dennis_ugarteNo ratings yet

- Design by AnalysisDocument4 pagesDesign by Analysisaandueza_1No ratings yet

- Fatigue Life Testing in Metal Expansion JointsDocument1 pageFatigue Life Testing in Metal Expansion JointsNaresh ANo ratings yet

- Destructive TestingDocument1 pageDestructive TestingSARATH KRISHNAKUMARNo ratings yet

- Results of Very High Cycle Fatigue Tests On Helical Compression SpringsDocument6 pagesResults of Very High Cycle Fatigue Tests On Helical Compression SpringsquratulainNo ratings yet

- Fatigue TestingDocument56 pagesFatigue TestingPrakhar AgrawalNo ratings yet

- IPE 303 Product Design: Chapter 6: Fatigue Failure Resulting From Variable LoadingDocument6 pagesIPE 303 Product Design: Chapter 6: Fatigue Failure Resulting From Variable LoadingRM ShahbabNo ratings yet

- IPE 303 Lecture - 16sept2020Document14 pagesIPE 303 Lecture - 16sept2020RM ShahbabNo ratings yet

- Earthquake isolation method with variable natural frequencyFrom EverandEarthquake isolation method with variable natural frequencyNo ratings yet

- Electrical Double LayerDocument3 pagesElectrical Double LayerDhanvin PrajapatiNo ratings yet

- B271M PDFDocument6 pagesB271M PDFmahantmtechNo ratings yet

- Material Dissimilar JointsDocument7 pagesMaterial Dissimilar JointsPemburu JablayNo ratings yet

- Plates - API-2W Grade 50Document2 pagesPlates - API-2W Grade 50eduardoNo ratings yet

- PM TB Solutions C09Document3 pagesPM TB Solutions C09Vishwajeet Ujhoodha88% (8)

- HW 7Document5 pagesHW 7anonymoussionNo ratings yet

- Exercises 5Document2 pagesExercises 5Jerry CohenNo ratings yet

- Chapter 3 - Surfactant Based Sepn (Lec-5)Document16 pagesChapter 3 - Surfactant Based Sepn (Lec-5)liyou eshetuNo ratings yet

- Ramsden 1903 ProcRoySoc 72, 156-164Document9 pagesRamsden 1903 ProcRoySoc 72, 156-164John TexterNo ratings yet

- Ultrasonic Attenuation As A Measure of Void C o N T e N T in Carbon-Fibre Reinforced PlasticsDocument9 pagesUltrasonic Attenuation As A Measure of Void C o N T e N T in Carbon-Fibre Reinforced PlasticsAbd BaghadNo ratings yet

- Group 5 Sts Chapter 5 Nano World 1Document40 pagesGroup 5 Sts Chapter 5 Nano World 1Kristel May SomeraNo ratings yet

- No.: Wide Flange Crane Bracket Design Page: of Date: LocationDocument13 pagesNo.: Wide Flange Crane Bracket Design Page: of Date: LocationmaheshbandhamNo ratings yet

- Raman Spectral Analysis of Electrophoretically Separated Metallic and Semiconducting Carbon NanotubesDocument4 pagesRaman Spectral Analysis of Electrophoretically Separated Metallic and Semiconducting Carbon NanotubesMarkNo ratings yet

- PrismDocument4 pagesPrismPoorna MathivananNo ratings yet

- Basic Electronics Engineering: Paschimanchal Campus (IOE), PokharaDocument14 pagesBasic Electronics Engineering: Paschimanchal Campus (IOE), PokharaTara Nath PoudelNo ratings yet

- Multiplicity and Statistical Definition of EntropyDocument39 pagesMultiplicity and Statistical Definition of EntropyAggie QuesadaNo ratings yet

- Wear Debris AnalysisDocument2 pagesWear Debris Analysisthoma111sNo ratings yet

- 5-LV Service Drop CablesDocument10 pages5-LV Service Drop CablesapranaguptaNo ratings yet

- Astm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsDocument3 pagesAstm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsSuresh NairNo ratings yet

- Guidance Note: Heritage Railway AssociationDocument23 pagesGuidance Note: Heritage Railway AssociationPaul PridhamNo ratings yet

- Quantum DecoherenceDocument4 pagesQuantum DecoherenceRemigijus Dvaranauskas100% (1)

- The Analysis and Prevention of Failure in Railway AxlesDocument10 pagesThe Analysis and Prevention of Failure in Railway AxlesAnonymous PufNjgNo ratings yet

- Full Beginner's Guide To ESD Protection Circuit Design For PCBDocument12 pagesFull Beginner's Guide To ESD Protection Circuit Design For PCBjackNo ratings yet

- Measurement Systems: Application and Design by Ernest O. DoebelinDocument19 pagesMeasurement Systems: Application and Design by Ernest O. DoebelinAlhji AhmedNo ratings yet

- Technical Tidbits April 2002 - Nickel As A Coating MaterialDocument2 pagesTechnical Tidbits April 2002 - Nickel As A Coating MaterialDavid GillNo ratings yet

- Corrosion FatigueDocument14 pagesCorrosion FatigueAPINo ratings yet

- Dynamic Soil Properties - 6thDocument33 pagesDynamic Soil Properties - 6thAlMahmudNo ratings yet

- Ect 1018 Seers April 2023 f2f CanvasDocument47 pagesEct 1018 Seers April 2023 f2f CanvasJohn Raymund AquinoNo ratings yet

- Curved BeamDocument85 pagesCurved Beampoojasmita14100% (3)

- 2 ULS - Bending With or Without Axial Force (2014) PDFDocument15 pages2 ULS - Bending With or Without Axial Force (2014) PDFLuke LdhNo ratings yet

Fatigue Life Testing of Metal Expansion Joints

Fatigue Life Testing of Metal Expansion Joints

Uploaded by

Virjil Aycocho0 ratings0% found this document useful (0 votes)

101 views1 pageFatigue life testing is a verification of the ability of a bellows to withstand a given number of flexing cycles. This procedure was developed by Macoga Engineered Expansion Joints.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFatigue life testing is a verification of the ability of a bellows to withstand a given number of flexing cycles. This procedure was developed by Macoga Engineered Expansion Joints.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

101 views1 pageFatigue Life Testing of Metal Expansion Joints

Fatigue Life Testing of Metal Expansion Joints

Uploaded by

Virjil AycochoFatigue life testing is a verification of the ability of a bellows to withstand a given number of flexing cycles. This procedure was developed by Macoga Engineered Expansion Joints.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

FATIGUE LIFE TESTING

METAL EXPANSION JOINTS MACOGA

bkdfkbboba=bum^kpflk glfkqp

Excessive cycle life requirements will not

Fatigue Life Testing necessarily ensure desired results. An overly

conservative estimate of cycles is not

Fatigue life testing is a verification of the ability of recommended because it will tend to increase the

a bellows to withstand a given number of flexing number of corrugations and will lead to a bellows

cycles. more prone to squirm.

The Expansion Joint is placed on a test machine Fatigue life depends on the maximum stress range

and allowed to cycle continually until the bellows to which the bellows is submitted during each

fails. complete operational cycle. The stress range due

to deflection generally affects the fatigue more

Fatigue life testing will render the Expansion Joint than the stress range due to static or variable

or at least the bellows unsuitable for installation pressure.

in an operating system and therefor this test

must be performed on a prototype Expansion Accordingly, the cycles to fatigue will be reduced if

Joint. A prototype Expansion Joint is defined as the deflection is increased and vice versa.

one having the same pressure and temperature

rating as production models, identical diameter, In addition to the shape of the corrugations, the

height, pitch, and general shape of the fatigue life is affected by the type of material and

convolution, the thickness and type of bellows the manufacturing process. The cold work

materials, bellows reinforcement, method of hardening of austenitic steel for instance, induced

manufacture, and maximum movement per during the forming process of the corrugations,

convolution. generally improves the fatigue life.

MACOGA performs fatigue testing at constant

pressure or at varying pressure. This latter

condition more closely approximates the service

to which the Expansion Joint will be subjected.

It is acceptable to cycle test at room temperature

any Expansion Joint which will be furnished for

operating temperatures up to the active creep

range. For Expansion Joints operating above this

range, consideration should be given to testing at

elevated temperatures.

With all other shape factors remaining constant,

cycle life will generally increase with diameter;

for prototype testing, it may be acceptable to

cycle test the smallest size Expansion Joint being

furnished for a given series for identical service

condition.

Fatigue life expectancy

The fatigue life of a metal joint is affected by

many factors such as temperature, pressure,

movement, vibration and how the joint was

initially designed. Typically, metal joints have a

defined cycle or fatigue life that can be calculated.

j^`ld^=pK^K=

iÉáê~=ëLåK=NRSUM=lêÇÉåÉë=i~=`çêì¥~I=pé~áå=qÉäW=HPQ=VUN=SU=MM=MM==

ïïïKã~ÅçÖ~KÅçã macoga@macoga.com

You might also like

- VibrationControl CATALOGO SOPORTES PDFDocument12 pagesVibrationControl CATALOGO SOPORTES PDFMilena Lemus FonsecaNo ratings yet

- Flanged Basket Strainers IOMDocument4 pagesFlanged Basket Strainers IOMSteve NewmanNo ratings yet

- PADT Webinar Post26 2012 - 04 - 12Document54 pagesPADT Webinar Post26 2012 - 04 - 12Jack FusionNo ratings yet

- Autopipe: Acceptance Test SetDocument185 pagesAutopipe: Acceptance Test SetAob AprilNo ratings yet

- Fatigue Failure Resulting From Variable Loading 1-2Document24 pagesFatigue Failure Resulting From Variable Loading 1-2Rahul Singh100% (1)

- Elevated Temperature Fatigue of Pressure Vessel SteelsDocument6 pagesElevated Temperature Fatigue of Pressure Vessel SteelsJohnNo ratings yet

- TR 110996Document117 pagesTR 110996Subhadip SadhukhanNo ratings yet

- ANSYS Analysis of Single Phase Induction Motor - Hani Aziz AmeenDocument74 pagesANSYS Analysis of Single Phase Induction Motor - Hani Aziz AmeenHani Aziz Ameen50% (2)

- Tubesheet Cladding Baher 1648652344Document3 pagesTubesheet Cladding Baher 1648652344Sapan ShahNo ratings yet

- Density of Materials & Comparison of Ss 304 Vs Ss316LDocument4 pagesDensity of Materials & Comparison of Ss 304 Vs Ss316LShino UlahannanNo ratings yet

- EHB en 9.7-Equivalent-Materials PDFDocument7 pagesEHB en 9.7-Equivalent-Materials PDFArquimedes PerezNo ratings yet

- The Finite Element Method and Applications in Engineering Using Ansys®Document5 pagesThe Finite Element Method and Applications in Engineering Using Ansys®sivaraju22No ratings yet

- Estimation of SIF by Mumerical MethodDocument21 pagesEstimation of SIF by Mumerical Methodworkineh gebeyehuNo ratings yet

- Realiability of Corrosion DeffectsDocument20 pagesRealiability of Corrosion DeffectsJavier Gualdrón PlataNo ratings yet

- Detailed Fea of Locally Thinned Pipe Bends: Usama Abdelsalam & DK VijayDocument9 pagesDetailed Fea of Locally Thinned Pipe Bends: Usama Abdelsalam & DK VijayAnonymous 1hOgJqwZuzNo ratings yet

- Cyclic Symmetry Workbench Version 12Document12 pagesCyclic Symmetry Workbench Version 12Tebong BrowserNo ratings yet

- Structural Analysis and Design of Proces PDFDocument361 pagesStructural Analysis and Design of Proces PDFmarceloNo ratings yet

- Ansys Elements PDFDocument1,401 pagesAnsys Elements PDFprashanthattiNo ratings yet

- MSS SP - 97 - 2019 - Integrally Reinforced Forged Branch Outlet Fittings Socket Welding, Threaded, and Buttwelding EndsDocument4 pagesMSS SP - 97 - 2019 - Integrally Reinforced Forged Branch Outlet Fittings Socket Welding, Threaded, and Buttwelding Endsarnoldbatista55No ratings yet

- Markl SIFs & Asme ViiiDocument3 pagesMarkl SIFs & Asme ViiiDesmond ChangNo ratings yet

- Module 7 Vibration Absorbers Gen - Techn .Data EFBDocument12 pagesModule 7 Vibration Absorbers Gen - Techn .Data EFBRichard PerezNo ratings yet

- IJESH Analysis of Piping System Used in Chemical Plant 80Document7 pagesIJESH Analysis of Piping System Used in Chemical Plant 80pipestress100% (1)

- Nureg 6007Document122 pagesNureg 6007Baher ElsheikhNo ratings yet

- SAPAG Butterfly ValvesDocument22 pagesSAPAG Butterfly ValvespawelzakNo ratings yet

- Pressure Safety Relief Valves Pressure Safety Relief Valves: Technical Bulletin 3 Technical Bulletin 3-IDocument16 pagesPressure Safety Relief Valves Pressure Safety Relief Valves: Technical Bulletin 3 Technical Bulletin 3-Isabi_shiNo ratings yet

- Astm E1049 85 2017Document6 pagesAstm E1049 85 2017Alexandre JesusNo ratings yet

- EQUIPMENT DESIGN by DR NORIN ZAMIAH PDFDocument104 pagesEQUIPMENT DESIGN by DR NORIN ZAMIAH PDFAimanNo ratings yet

- Super Duplex Valve PDFDocument87 pagesSuper Duplex Valve PDFMohamed YousufNo ratings yet

- P91 EnggDocument25 pagesP91 EnggAshwani DograNo ratings yet

- Study On Prefabricated Concrete Beam and Column ConnectionsDocument6 pagesStudy On Prefabricated Concrete Beam and Column ConnectionsreenaNo ratings yet

- PWR Is The Abbreviation For The Pressurized Water ReactorDocument18 pagesPWR Is The Abbreviation For The Pressurized Water Reactorshrishmapaik2070No ratings yet

- Comparative Study EN 13445 / ASME Section VIII Div. 1 & 2Document48 pagesComparative Study EN 13445 / ASME Section VIII Div. 1 & 2Anand PatelNo ratings yet

- S.V Reg. in Asme TDP 1, Asme Sec 1, b31.1Document9 pagesS.V Reg. in Asme TDP 1, Asme Sec 1, b31.1K.S.MAYILVAGHANANNo ratings yet

- W044Rev1 PDFDocument41 pagesW044Rev1 PDFTONNo ratings yet

- 7 Ways To Evaluate FEA AccuracyDocument21 pages7 Ways To Evaluate FEA Accuracyhanson219No ratings yet

- Bellow Design 1Document5 pagesBellow Design 1zingalala100% (2)

- ASME VIII-2 Ed 2023 ExampleDocument7 pagesASME VIII-2 Ed 2023 ExampleLorenzoNo ratings yet

- Nozzle Stiffness and Stress Computation Using A Parametrically Controlled Finite Element Modeling ApproachDocument4 pagesNozzle Stiffness and Stress Computation Using A Parametrically Controlled Finite Element Modeling ApproachkysucoNo ratings yet

- GRI DurlonTechnicalHandbookDocument30 pagesGRI DurlonTechnicalHandbookFrank RamirezNo ratings yet

- Pressure VesselDocument4 pagesPressure VesselDeaz AmbrsNo ratings yet

- Strength of Materials - Statically Indeterminate Beam - Hani Aziz AmeenDocument23 pagesStrength of Materials - Statically Indeterminate Beam - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Diaphragm Seals Application - Operating Principle - Designs: Technical InformationDocument6 pagesDiaphragm Seals Application - Operating Principle - Designs: Technical InformationdleonarenNo ratings yet

- Nozzle StressDocument25 pagesNozzle StressvamsiNo ratings yet

- 0568-Bom20-92p1-0001-001-1-Code-1 Hydro ProcedureDocument12 pages0568-Bom20-92p1-0001-001-1-Code-1 Hydro ProcedureLeilei WangNo ratings yet

- Ver TubagemDocument7 pagesVer TubagemHernâni CruzNo ratings yet

- Barutzki PDFDocument9 pagesBarutzki PDFesutjiadiNo ratings yet

- Dhawi - Reclassification of SRU Equipment To ASME Section VIIIDivision 1 PDFDocument8 pagesDhawi - Reclassification of SRU Equipment To ASME Section VIIIDivision 1 PDFRenan Gustavo PazNo ratings yet

- Victaulic General Catalog G-103Document248 pagesVictaulic General Catalog G-103Muhsen Khan100% (1)

- Nytro® Libra: Property Unit Test Method Specification Limits Typical Data Min Max 1 - FunctionDocument2 pagesNytro® Libra: Property Unit Test Method Specification Limits Typical Data Min Max 1 - FunctionAUFA JAYA PERKASANo ratings yet

- AnsysDocument15 pagesAnsysginupaulNo ratings yet

- B - Lecture10 The Root Locus Rules Automatic Control SystemDocument31 pagesB - Lecture10 The Root Locus Rules Automatic Control SystemAbaziz Mousa OutlawZzNo ratings yet

- Astm A-1005Document6 pagesAstm A-1005dennis_ugarteNo ratings yet

- Design by AnalysisDocument4 pagesDesign by Analysisaandueza_1No ratings yet

- Fatigue Life Testing in Metal Expansion JointsDocument1 pageFatigue Life Testing in Metal Expansion JointsNaresh ANo ratings yet

- Destructive TestingDocument1 pageDestructive TestingSARATH KRISHNAKUMARNo ratings yet

- Results of Very High Cycle Fatigue Tests On Helical Compression SpringsDocument6 pagesResults of Very High Cycle Fatigue Tests On Helical Compression SpringsquratulainNo ratings yet

- Fatigue TestingDocument56 pagesFatigue TestingPrakhar AgrawalNo ratings yet

- IPE 303 Product Design: Chapter 6: Fatigue Failure Resulting From Variable LoadingDocument6 pagesIPE 303 Product Design: Chapter 6: Fatigue Failure Resulting From Variable LoadingRM ShahbabNo ratings yet

- IPE 303 Lecture - 16sept2020Document14 pagesIPE 303 Lecture - 16sept2020RM ShahbabNo ratings yet

- Earthquake isolation method with variable natural frequencyFrom EverandEarthquake isolation method with variable natural frequencyNo ratings yet

- Electrical Double LayerDocument3 pagesElectrical Double LayerDhanvin PrajapatiNo ratings yet

- B271M PDFDocument6 pagesB271M PDFmahantmtechNo ratings yet

- Material Dissimilar JointsDocument7 pagesMaterial Dissimilar JointsPemburu JablayNo ratings yet

- Plates - API-2W Grade 50Document2 pagesPlates - API-2W Grade 50eduardoNo ratings yet

- PM TB Solutions C09Document3 pagesPM TB Solutions C09Vishwajeet Ujhoodha88% (8)

- HW 7Document5 pagesHW 7anonymoussionNo ratings yet

- Exercises 5Document2 pagesExercises 5Jerry CohenNo ratings yet

- Chapter 3 - Surfactant Based Sepn (Lec-5)Document16 pagesChapter 3 - Surfactant Based Sepn (Lec-5)liyou eshetuNo ratings yet

- Ramsden 1903 ProcRoySoc 72, 156-164Document9 pagesRamsden 1903 ProcRoySoc 72, 156-164John TexterNo ratings yet

- Ultrasonic Attenuation As A Measure of Void C o N T e N T in Carbon-Fibre Reinforced PlasticsDocument9 pagesUltrasonic Attenuation As A Measure of Void C o N T e N T in Carbon-Fibre Reinforced PlasticsAbd BaghadNo ratings yet

- Group 5 Sts Chapter 5 Nano World 1Document40 pagesGroup 5 Sts Chapter 5 Nano World 1Kristel May SomeraNo ratings yet

- No.: Wide Flange Crane Bracket Design Page: of Date: LocationDocument13 pagesNo.: Wide Flange Crane Bracket Design Page: of Date: LocationmaheshbandhamNo ratings yet

- Raman Spectral Analysis of Electrophoretically Separated Metallic and Semiconducting Carbon NanotubesDocument4 pagesRaman Spectral Analysis of Electrophoretically Separated Metallic and Semiconducting Carbon NanotubesMarkNo ratings yet

- PrismDocument4 pagesPrismPoorna MathivananNo ratings yet

- Basic Electronics Engineering: Paschimanchal Campus (IOE), PokharaDocument14 pagesBasic Electronics Engineering: Paschimanchal Campus (IOE), PokharaTara Nath PoudelNo ratings yet

- Multiplicity and Statistical Definition of EntropyDocument39 pagesMultiplicity and Statistical Definition of EntropyAggie QuesadaNo ratings yet

- Wear Debris AnalysisDocument2 pagesWear Debris Analysisthoma111sNo ratings yet

- 5-LV Service Drop CablesDocument10 pages5-LV Service Drop CablesapranaguptaNo ratings yet

- Astm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsDocument3 pagesAstm A 829 - SAE 4140 / SAE 4142: CR Mo-Alloyed Vacuum Degassed SteelsSuresh NairNo ratings yet

- Guidance Note: Heritage Railway AssociationDocument23 pagesGuidance Note: Heritage Railway AssociationPaul PridhamNo ratings yet

- Quantum DecoherenceDocument4 pagesQuantum DecoherenceRemigijus Dvaranauskas100% (1)

- The Analysis and Prevention of Failure in Railway AxlesDocument10 pagesThe Analysis and Prevention of Failure in Railway AxlesAnonymous PufNjgNo ratings yet

- Full Beginner's Guide To ESD Protection Circuit Design For PCBDocument12 pagesFull Beginner's Guide To ESD Protection Circuit Design For PCBjackNo ratings yet

- Measurement Systems: Application and Design by Ernest O. DoebelinDocument19 pagesMeasurement Systems: Application and Design by Ernest O. DoebelinAlhji AhmedNo ratings yet

- Technical Tidbits April 2002 - Nickel As A Coating MaterialDocument2 pagesTechnical Tidbits April 2002 - Nickel As A Coating MaterialDavid GillNo ratings yet

- Corrosion FatigueDocument14 pagesCorrosion FatigueAPINo ratings yet

- Dynamic Soil Properties - 6thDocument33 pagesDynamic Soil Properties - 6thAlMahmudNo ratings yet

- Ect 1018 Seers April 2023 f2f CanvasDocument47 pagesEct 1018 Seers April 2023 f2f CanvasJohn Raymund AquinoNo ratings yet

- Curved BeamDocument85 pagesCurved Beampoojasmita14100% (3)

- 2 ULS - Bending With or Without Axial Force (2014) PDFDocument15 pages2 ULS - Bending With or Without Axial Force (2014) PDFLuke LdhNo ratings yet