Professional Documents

Culture Documents

2 PDF

2 PDF

Uploaded by

Louielah Jeanne CeballosCopyright:

Available Formats

You might also like

- Automatic Voltage Regulators: SpecificationsDocument4 pagesAutomatic Voltage Regulators: SpecificationsArman Haq100% (9)

- Visual Inspection - Sample Report For Spherical VesselDocument8 pagesVisual Inspection - Sample Report For Spherical Vesselkamal90% (10)

- Thresher-Literature ReviewDocument37 pagesThresher-Literature ReviewAdil Khawaja80% (5)

- Din en 1011-2Document58 pagesDin en 1011-2mohamed ahmed100% (3)

- Ee4302 Ca1Document51 pagesEe4302 Ca1Norul Ashikin NorzainNo ratings yet

- International Journal of Engineering Research and Development (IJERD)Document9 pagesInternational Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- 51 Ijasroct201751Document10 pages51 Ijasroct201751TJPRC PublicationsNo ratings yet

- Testings, Results & Analysis of Payback Period of Portable Organic Waste Chopping Machine To Obtain CompostDocument7 pagesTestings, Results & Analysis of Payback Period of Portable Organic Waste Chopping Machine To Obtain CompostIJSTENo ratings yet

- Integration of The Grinding Function With A Cereal Thresher For The Recovery of Crop Residues in CompostingDocument13 pagesIntegration of The Grinding Function With A Cereal Thresher For The Recovery of Crop Residues in CompostingIJAR JOURNALNo ratings yet

- Design and Development of Rotary Power Weeder: International Journal of Current Microbiology and Applied SciencesDocument6 pagesDesign and Development of Rotary Power Weeder: International Journal of Current Microbiology and Applied SciencesGurkanwal Singh ThindNo ratings yet

- 2019 - Evaluation of Cutting Blades Impact On Productivity and Performance of Sugar Cane Harvesting MachineDocument6 pages2019 - Evaluation of Cutting Blades Impact On Productivity and Performance of Sugar Cane Harvesting MachineRAFAEL JIMENEZ ORTIZNo ratings yet

- Iarjset Ncdmete7Document4 pagesIarjset Ncdmete7Sweaten PRemNo ratings yet

- Pod Shelling Machines - A ReviewDocument6 pagesPod Shelling Machines - A ReviewTJPRC PublicationsNo ratings yet

- Jsaer2015 02 03 01 08Document8 pagesJsaer2015 02 03 01 08jsaereditorNo ratings yet

- Study of The Performance of The Most Widely Used Shredders For Crops Residues in EgyptDocument19 pagesStudy of The Performance of The Most Widely Used Shredders For Crops Residues in EgyptIbraheem KhressNo ratings yet

- Weeder pdf33Document8 pagesWeeder pdf33Anonymous 1MgSpwNo ratings yet

- 446 Article p75Document12 pages446 Article p75sayyed KNo ratings yet

- Performance Evaluation and Modification of Shredder Cutting MechanismDocument16 pagesPerformance Evaluation and Modification of Shredder Cutting MechanismTJPRC PublicationsNo ratings yet

- Iarjset Ncdmete7Document4 pagesIarjset Ncdmete7venkatesaperumal eNo ratings yet

- ZJAR - Volume 43 - Issue 4 - Pages 1289-1299Document11 pagesZJAR - Volume 43 - Issue 4 - Pages 1289-1299KamekazeNo ratings yet

- Development and Evaluation of Multi Millet ThresherDocument10 pagesDevelopment and Evaluation of Multi Millet Thresherberihu tesfayNo ratings yet

- Juxtaposition of Push-Type Wheel Hoe To Evaluate Its Weeding Coherence and Impair On EggplantDocument9 pagesJuxtaposition of Push-Type Wheel Hoe To Evaluate Its Weeding Coherence and Impair On EggplantIJRASETPublicationsNo ratings yet

- Development and Evaluation of A Rotary Power WeederDocument13 pagesDevelopment and Evaluation of A Rotary Power WeederKaran KoshtiNo ratings yet

- Performance Evaluation of Two Planter Makes As Affected by Forward SpeedsDocument7 pagesPerformance Evaluation of Two Planter Makes As Affected by Forward SpeedsaymanNo ratings yet

- Manjeet PreM Et Al 1Document8 pagesManjeet PreM Et Al 1Prem Ranjan MehtaNo ratings yet

- Development and Evaluation of Self-Propelled Cono Weeder For Rice Cultivation in VertisolDocument7 pagesDevelopment and Evaluation of Self-Propelled Cono Weeder For Rice Cultivation in VertisolSapuniiNo ratings yet

- ScreeningDocument16 pagesScreeningMohammed AlnasharNo ratings yet

- Development and Ergonomic Evaluation of Manual Weeder RAJVIR YADAVDocument9 pagesDevelopment and Ergonomic Evaluation of Manual Weeder RAJVIR YADAVSapuniiNo ratings yet

- Report of Project 1Document9 pagesReport of Project 1Murari KrishnaNo ratings yet

- SimulationDocument13 pagesSimulationGojjam LibayNo ratings yet

- IJASR - Performance Studies On Power Operated Chaff Cutter PDFDocument8 pagesIJASR - Performance Studies On Power Operated Chaff Cutter PDFAnonymous pxdbBLu100% (3)

- Design and Development of Cassava Planting MachineDocument6 pagesDesign and Development of Cassava Planting Machinejohn lester benignoNo ratings yet

- Prototype Grading Cereal CorpsDocument16 pagesPrototype Grading Cereal Corpstaufiq hidNo ratings yet

- Development of Solar Powered Knapsack Sprayer: Indian Journal of Agricultural Sciences April 2018Document10 pagesDevelopment of Solar Powered Knapsack Sprayer: Indian Journal of Agricultural Sciences April 2018Siva RajNo ratings yet

- Development of Multinozzle Pesticides Sprayer PumpDocument5 pagesDevelopment of Multinozzle Pesticides Sprayer PumpTania JohnsonNo ratings yet

- Ijirt144400 PaperDocument5 pagesIjirt144400 Paperhadush gebreNo ratings yet

- Design and Structural Analysis of Weed Removing Machine Fitted With Rotovator Blade in Glory Lily PlantDocument7 pagesDesign and Structural Analysis of Weed Removing Machine Fitted With Rotovator Blade in Glory Lily PlantvenkatNo ratings yet

- Effect of Disc and Tilt Angles of Disc PDocument12 pagesEffect of Disc and Tilt Angles of Disc PMuhammad DennyNo ratings yet

- Solar Pesticide SprayerDocument6 pagesSolar Pesticide SprayerShobhit SinghNo ratings yet

- Plant Power ShredderDocument27 pagesPlant Power ShredderDanica Joyce DayritNo ratings yet

- 2 50 1583903003 1ijasrapr20201Document8 pages2 50 1583903003 1ijasrapr20201TJPRC PublicationsNo ratings yet

- 2 50 1583903003 1ijasrapr20201Document8 pages2 50 1583903003 1ijasrapr20201TJPRC PublicationsNo ratings yet

- IJRAR23B4373Document6 pagesIJRAR23B4373KARTIK KANAWADENo ratings yet

- Design and Experimental Evaluation of A Form TrimmDocument13 pagesDesign and Experimental Evaluation of A Form Trimmالأردني JordanianNo ratings yet

- Ijasr - Performance Evaluation of Tractor Operated PDFDocument10 pagesIjasr - Performance Evaluation of Tractor Operated PDFAnonymous dbnms1yNo ratings yet

- Development A Feeding Mechanism of Chopper For Chopping Sugarcane BagasseDocument19 pagesDevelopment A Feeding Mechanism of Chopper For Chopping Sugarcane BagassedansihNo ratings yet

- 16 23yonasmulatuDocument9 pages16 23yonasmulatuELMER DELOSSANTOSNo ratings yet

- Design and Performance Evaluation of A Screw Press Separator For Separating Dairy Cattle ManureDocument10 pagesDesign and Performance Evaluation of A Screw Press Separator For Separating Dairy Cattle ManureDaniel SouzaNo ratings yet

- N RavikumaretalDocument14 pagesN RavikumaretalPrashant NaleNo ratings yet

- Rice TresherDocument11 pagesRice TresherGerry100% (1)

- N K DhruweetalDocument6 pagesN K DhruweetalZIGAMENo ratings yet

- Field Capacity and Efficiency of A Turmeric Rhizome Planter in Response To Machine Speeds and Some Selected Crop ParametersDocument5 pagesField Capacity and Efficiency of A Turmeric Rhizome Planter in Response To Machine Speeds and Some Selected Crop ParametersVishal SaravananNo ratings yet

- Development and Performance Evaluation of Lucerne Harvesting MachineDocument10 pagesDevelopment and Performance Evaluation of Lucerne Harvesting MachineIJRASETPublicationsNo ratings yet

- Potato Grader CIGR2019Document8 pagesPotato Grader CIGR2019Munnaf M AbdulNo ratings yet

- Design and Fabrication of Sugarcane Cutting Machine For Cane-Can Industry, NagpurDocument2 pagesDesign and Fabrication of Sugarcane Cutting Machine For Cane-Can Industry, NagpurSaiNo ratings yet

- Conceptual Design and Development of Shredding Machine For Agricultural WasteDocument7 pagesConceptual Design and Development of Shredding Machine For Agricultural WasteVJ CarbonellNo ratings yet

- AssignmentDocument6 pagesAssignmentJudyNo ratings yet

- Performance Characteristics of A CoconutDocument14 pagesPerformance Characteristics of A CoconutNeil TaneoNo ratings yet

- 710-File Utama Naskah-1439-2-10-20180214Document7 pages710-File Utama Naskah-1439-2-10-20180214ISLAM INDAH DAMAINo ratings yet

- 1-8 Mohammed TemamDocument8 pages1-8 Mohammed TemamAddisalem MesfinNo ratings yet

- Development of A Portable Pneumatic Grain Broadcasting Unit: Ahmad, M. CDocument8 pagesDevelopment of A Portable Pneumatic Grain Broadcasting Unit: Ahmad, M. CMariana VictoriaNo ratings yet

- Seed Growing 1Document18 pagesSeed Growing 1Sandeep ArduNo ratings yet

- Farm Machinery and Equipment : Improving Productivity in the FieldFrom EverandFarm Machinery and Equipment : Improving Productivity in the FieldNo ratings yet

- The Machinery of Hay Harvesting - With Information on the Equipment and Methods Mowing, Raking and BailingFrom EverandThe Machinery of Hay Harvesting - With Information on the Equipment and Methods Mowing, Raking and BailingNo ratings yet

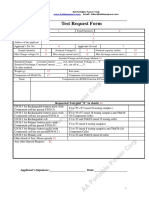

- Test Request Form: Requested Test (Put "X" To Check)Document2 pagesTest Request Form: Requested Test (Put "X" To Check)Claudia Lizeth Chacon PedrazaNo ratings yet

- BV Guide Windfarm Project CertificationDocument108 pagesBV Guide Windfarm Project CertificationCyprian Cypu100% (1)

- Carriage of MaterialDocument7 pagesCarriage of MaterialDigvijay SinghNo ratings yet

- METRO Member Directory and Delivery Roster - Spring 2012Document42 pagesMETRO Member Directory and Delivery Roster - Spring 2012Metropolitan New York Library Council (METRO)No ratings yet

- Indra GanesanDocument89 pagesIndra GanesanShanmugam BalasubramaniamNo ratings yet

- Electrical Crimping Tool PDFDocument2 pagesElectrical Crimping Tool PDFbaolifengNo ratings yet

- DO s2019 011Document131 pagesDO s2019 011Jerome GliponeoNo ratings yet

- ApprovedVendorList Civil 24012018Document48 pagesApprovedVendorList Civil 24012018amandeepNo ratings yet

- International RoamingDocument25 pagesInternational RoamingAbu Bakir Akhter75% (4)

- Translating English-IndonesiaDocument6 pagesTranslating English-IndonesiaefaNo ratings yet

- Sequential TimerDocument4 pagesSequential Timerprasad mdvNo ratings yet

- Study and Operation of Tempering ProcessDocument11 pagesStudy and Operation of Tempering ProcessMostafizur Rahman SobujNo ratings yet

- Document Tabs For Application in DepEdDocument1 pageDocument Tabs For Application in DepEdLea Jane Ilagan Razona100% (3)

- HW 3Document4 pagesHW 3Alwyn KalapuracanNo ratings yet

- Asha Sharma ResumeDocument3 pagesAsha Sharma ResumeRachit SharmaNo ratings yet

- Intrusion Detection System Using Multivariate Control Chart Hotelling's T Based On PCADocument7 pagesIntrusion Detection System Using Multivariate Control Chart Hotelling's T Based On PCARumaisa KrubaNo ratings yet

- Erp Construction Industry PDFDocument2 pagesErp Construction Industry PDFTroyNo ratings yet

- CaseHard 17CrNiMo6Document2 pagesCaseHard 17CrNiMo6Francisco Botelho Carlos100% (1)

- Vaddl 12: Pressure Relief ValvesDocument2 pagesVaddl 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Propeler Shaft Survey Extension - Preventive Maintenance (1) 4Document8 pagesPropeler Shaft Survey Extension - Preventive Maintenance (1) 4Frano GrifiNo ratings yet

- HAWC2 Course: Lesson 3: Aerodynamic Modeling and Implementation in Hawc2Document52 pagesHAWC2 Course: Lesson 3: Aerodynamic Modeling and Implementation in Hawc2Mahmoud MoussaNo ratings yet

- CAT 2023 Composite Score and Calls Predictor - AmiyaDocument69 pagesCAT 2023 Composite Score and Calls Predictor - AmiyaHarsimran SinghNo ratings yet

- Optical Character Recognition Research: IndexDocument6 pagesOptical Character Recognition Research: IndexPhi Thiện HồNo ratings yet

- 1DV2 (1K1DV450E1) T115SEC Vega ForceDocument58 pages1DV2 (1K1DV450E1) T115SEC Vega ForceGAYLE GONo ratings yet

- Maersk DelivererDocument12 pagesMaersk DelivererNoor HadiNo ratings yet

- Brand Management of HULDocument76 pagesBrand Management of HULMohammed Yunus100% (1)

2 PDF

2 PDF

Uploaded by

Louielah Jeanne CeballosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 PDF

2 PDF

Uploaded by

Louielah Jeanne CeballosCopyright:

Available Formats

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 10, October 2016 ISSN 2319 - 4847

SHREDDING EFFICIENCY OF

AGRICULTURAL CROP SHREDDER AS

INFLUENCED BY FORWARD SPEED OF

OPERATION, NUMBER OF BLADES AND

PERIPHERAL VELOCITY

N.Sridhar1 , Dr. A .Surendrakumar 2

1

Research scholar, Dept. of Farm Machinery and Power, AEC &RI, Kumulur, Trichy- 621 712, Tamil Nadu Agricultural

University, India.

2

Professor , Agricultural Machinery Research Centre, TNAU, Coimbatore- 641 003, Tamil Nadu Agricultural University,

India.

ABSTRACT

In India, annually 500 million tons of crop residues are produced, out which 81-141 million tons of residues are burned in the field.

Burning of crop residues, which causes environmental pollution as well as loss of plant nutrients like N, P, K and S. Therefore,

appropriate management of crop residues assumes a great significance. Shredders are used widely and their performance study is

an important factor for wide scale adoption. Hence, the present investigation was taken up to assess the shredding efficiency of

agricultural crop shredders as influenced by operational parameters. A total number of 81 field experiments were conducted in

cotton field. The influence of the selected level of variability of three levels of operational speed (viz. 2, 3 and 5 km hr-1), three

levels of peripheral velocity (viz. 18.75, 24.27 and 27.80 ms-1) and three levels of number of blades (viz. 2, 4 and 6) on the

shredding efficiency of an experimental shredder, in terms of length of cut of the stalk were investigated. Increase in peripheral

velocity from 18.75 to 27.80 ms-1, number of blades from 2 to 6 and reducing the forward speed of operation from 5 to 2 km hr-1

resulted in decreased length of cut. Six numbers of blades with 2 km hr -1 forward speed of operation and 27.80 ms-1 peripheral

velocity recorded the lowest value of length of cut at the highest per cent in selected different scale level L1= 18.30, L2=23. 66,

L3=30. 98, L4= 22.09 and L5= 4.97 per cent respectively.

Key words: Number of blades, Forward speed, Peripheral velocity, Shredding efficiency.

1. INTRODUCTION

The annual production of crop residues approximately is 500 Mt in India (MNRE, 2009). There is a large variability in

crop residues generation and their use, depending on the cropping intensity, productivity and crops grown in different

states of India. The amount of crop residue, which does not have any identifiable end use is either left in the fields to rot

or is burnt away, is termed as Surplus Biomass. The estimated total crop residue surplus in India is 84-141 Mt yr-1,

where cereals and fiber crops contribute 58 per cent and 23 per cent, respectively. Remaining 19 per cent is from

sugarcane, pulses, oilseeds and other crops (Management of Crop Residue NAAS, India). Burning of crop residues

causes environmental pollution which is hazardous to human health and also produces greenhouse gases causing global

warming and results in loss of plant nutrients like N, P, K and S adverse impacts on soil properties and wastage of

valuable crop residues. The root sections decompose slower than other plant parts and the equipment for disposal of

cotton residue should include provision for reducing it to a length of 8 to 15 cm and burying it in depth of 10 cm

(Cowlick et al., 1971). The crop residues improve the soil fertility by improving nutrient availability and enriching the

organic matter content of soil. Sorghum stubble incorporation in the soil added 6.06 kg ha -1 of N, 2.6 kg ha-1 of P and

9.5 kg ha-1 of K (Shanmugasundaram et al., 1975). In India, crop residues are removed by manual uprooting or cutting

the stalks which is highly labor intensive. Shredders are mostly suggested for shredding the crop residues and their

performance study is an important factor for wide scale adoption. Hence, the type of shredding mechanism should be

selected based on the efficiency in terms of finished dimensions of the stalk required for incorporation in the soil to

facilitate quick decomposition. A rotary cutter is an implement in the mechanization chain of crop production. After

harvesting the crop, these machines cut the stalk and distribute them on the field surface. The rotary cutter consists of

blades pivoted horizontally on a vertical shaft and moves forward on the field. They are simple and sturdy in

construction, with less wearing parts and, therefore, the frictional power loss is minimized (Guzel and Zeren, 1990).

Volume 5, Issue 10, October 2016 Page 129

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 10, October 2016 ISSN 2319 - 4847

Hence, a study to assess the performance of shredders was contemplated. Keeping the above facts in view, the present

investigation entitled “To assess the shredding efficiency of shredders as influenced by operational parameters” was

taken up with following specific objectives.

To identify the influence of selected variable on shredding efficiency.

To optimize the selected variable for suggesting the future development of the new unit.

2. MATERIALS AND METHODS

The efficiency of a shredder is the ability to cut the crops/straw/stalk into very small pieces. The shredder performance

depends mainly on the number of rotating blades, peripheral velocity, and forward speed of operation.

2.1. Selected level of variables on length of cut

In the field test, the effect of peripheral velocity of rotary impact cutter blade, forward speed operation and the number

of blades on length of cut of crop stem at different scale levels was investigated. For achieving maximum shredding

efficiencies of crop stalk the following variables were selected for the investigation.

i. Peripheral velocity (V)

ii. Forward speed of operation (S)

iii. Number of blades (N)

2.1.1. Peripheral velocity (V)

The quality of the cut crop stem is highly influenced by the peripheral velocity of the blade. Peripheral velocity of the

blade is an important parameter in cutting and shredding operation. The rotary cutter is an implement in the

mechanization chain of cotton production. After harvesting the cotton, these machines cut the cotton stalk and

distribute them on the field surface. The evaluation of rotary cutters with the peripheral velocity of the blade ranged

between 800 to 1000 rpm was done by Guzel and Zeren, 1990. Hence, peripheral velocity of cutter blade of shredder

viz., 18.75, 24.27 and 27.80 ms-1 was selected for the investigation.

2.1.2. Forward speed of operation (S)

The efficiency of the machines depends upon the removed plant, plant condition (density and moisture content),

machine type and forward speed. The field efficiency decreases by increasing forward speed, so the field efficiency is

the ratio of the productivity of machine under field conditions to the theoretical maximum productivity. The shredder

machine is recommended to be used in removing residues of both cotton and sunflower stalks, while a self-propelled

harvester is recommended in removing rice straw. The shredder machine was recommended for removing residues of

corn stalks at forward speeds between 2 to 4 km h-1 and similarly 3 to 5 km h-1 forward speed was recommended for

self-propelled harvester for removing barley straw (Eltarhunyl .M.M. and Fouda, 2007). Hence, three levels of forward

speed of operation viz., 2, 3 and 5 km h-1 were selected for the investigation.

2.1.3. Number of blades

The length of cut of crop stem is highly influenced by a number of blades in the shredder unit. Number of blades is also

one of the important parameters in cutting and shredding operation. Hence, number of cutter blade of shredder viz., 2,

4, 6 were selected for the investigation.

2.2. Field experiments

A total number of 81 experiments were conducted in a cotton field in the department of cotton, TNAU, Coimbatore

with selected level variables as shown in Plate 2.1.

Volume 5, Issue 10, October 2016 Page 130

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 10, October 2016 ISSN 2319 - 4847

Plate 2.1a View of the trial field before shredding

Plate 2.1b View of the trial field during the operation

Plate 2.1c View of the trial field after shredding Plate 2.1d View of the trial field after shredding

Plate 2.1.Field experiments of shredder with selected levels of variables

After the completion of shredding, the sample was collected randomly in from the field. The collected samples were

analyzed several times to separate shredding crop residues into five categories by scale (referred to Luis et al. 1993)

according to their length of cut off the stem ( L1 = 0 -5 cm, L2= 5-10 cm, L3= 10-15 cm, L4= 15- 20 cm, L5= >20 cm)

as shown in Plate 2.2.

Volume 5, Issue 10, October 2016 Page 131

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 10, October 2016 ISSN 2319 - 4847

Plate 2.2a Length of cut of crop stem Plate 2.2b Length of cut of crop stem

at 0 to 5 cm at 5 to 10 cm

Plate 2.2c Length of cut of crop stem Plate 2.2d Length of cut of crop stem

at 10 to 15 cm at 15 to 20 cm

Plate.2.2. Length of cut of shredded cotton stem by prototype at different sieve levels

The values of finished dimensions of cotton stalks in terms of length of cut were recorded for all treatments. The effect

of selected levels of variables on finishing dimensions of the cotton stalk in terms of length of cut was analyzed.

Volume 5, Issue 10, October 2016 Page 132

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 10, October 2016 ISSN 2319 - 4847

3. RESULTS AND DISCUSSION

In this chapter, the effect of peripheral velocity of the rotary cutter blade, forward speed of operation and number of

blades on length of cut of crop stem by using different scale level is presented. The optimization of the selected

variables for achieving the best performance of crop stem shredding in terms of minimum length of cut of crop stem

with impact type rotary cutter shredder is presented.

3.1. Effects of selected variables on length of cut

The influence of selected level of variables on length of cut of agricultural crop stems with impact type rotary cutter

shredders is discussed below.

3.1.1. Effect of peripheral velocity (V) on length of cut at 2 (N1) number of blade with different forward speed of

operation (S)

The relationship between the length of cut and the peripheral velocity for the 2 number of blades with different levels

of forward speed of operation is depicted in Fig. 3.1.

Forward speed of operation 2 km h-1

Forward speed of operation 3 km h-1

Volume 5, Issue 10, October 2016 Page 133

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 10, October 2016 ISSN 2319 - 4847

Forward speed of operation 5 km h-1

Fig.3.1 Effect of peripheral velocity (V) on length of cut at 2 (N1) number of blade with different forward speed of

operation (S)

An increase in peripheral velocity from 18.75 to 27.80 ms-1 resulted in decreased length of cut. It is evident that at

lower peripheral velocity, the length of cut of cotton stems decreases. This might be due to fact that at lower peripheral

velocity of rotary cutter blade, the impact of blade was too less to fail the stem cutting and hence energy requirement is

increased. At higher velocities, the increase in the cutting energy may be owing to the kinetic energy imparted by the

cutter blade to the separate parts of the stem after cutting (Yiliep et al., 2005; Prasad and Gupta, 1975 Manjeet Singh et

al., 1998; T.Senthilkumar et.al., 2004.).The lowest value of length of cut was observed at the shredder with 2 (N1)

numbers of blades, 2 km h-1 forward speed of operation and 27.800 ms-1 (V3) peripheral velocity.

3.1.2. Effect of peripheral velocity (V) on length of cut at 4 (N2) number of blade with different forward speed of

operation (S)

The effect of peripheral velocity (V) of cutter blade on length of cut at 2 (S1), 3 (S2) and 5 (S3) kmh-1 forward speed of

operation with 4 number of blades in cotton crop field is shown in Fig 3.2

The trend of increase in peripheral velocity from V1 to V3 resulted in decreased length of cut at varies scale level (L1to

L5) with different operational speed at 2 (S1), 3 (S2) and 5 kmh-1 respectively.

Forward speed of operation 2 km h-1

Volume 5, Issue 10, October 2016 Page 134

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 10, October 2016 ISSN 2319 - 4847

Forward speed of operation 3 km h-1

Forward speed of operation 5 km h-1

Figure.3.2 Effect of peripheral velocity (V) on length of cut at 4 (N2) number of blade with different forward speed

of operation (S)

3.1.3. Effect of peripheral velocity (V) on length of cut at 6 (N2) number of blade with different forward speed of

operation (S)

An increase in peripheral velocity from 18.75 to 27.80 ms-1 resulted in decreased length of cut. The above result was in

conformity with the findings of Manjeet Singh et al., (1998). The lowest value of length of cut at the highest per cent in

selected different scale level L1= 18.30, L2=23. 66, L3=30. 98, L4= 22.09 and L5= 4.97 per cent, respectively occurs

with 6 numbers of blades, 2 km h-1 forward speed of operation and 27.80 ms-1 peripheral velocity as shown in Fig.

3.3

A 6 number of blade with 2 km hr -1 forward speed of operation and V3 level of peripheral velocity combination

recorded lowest value of length of cut when compared with other combinations. In the case of number of blades, 6

blades with S1 operating speed and 27.80 ms-1 peripheral velocity recorded lowest value of length of cut. Increase in

number of blade with reduction of operating speed resulted in increased length of cut for all the levels of peripheral

velocity.

3.2 Optimization of levels of variables with experimental agricultural crop shredder

The selected levels of variables were optimized for achieving the best performance of cutter blade in terms of minimum

length of cut at all selected levels of scale.

The treatment combination of S1N3V3 yielded the minimum length of cut shredded crop stem at maximum per cent in

all levels of scale was L1= 18.30, L2=23.66, L3=30.98, L4= 22.09 and L5= 4.97 per cent respectively.

Volume 5, Issue 10, October 2016 Page 135

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 10, October 2016 ISSN 2319 - 4847

Forward speed of operation 2 km h-1

Forward speed of operation 3 km h-1

Forward speed of operation 5 km h-1

Figure.3.3 Effect of peripheral velocity (V) on length of cut at 6 (N3) number of blade with different forward speed of

operation (S)

Volume 5, Issue 10, October 2016 Page 136

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 5, Issue 10, October 2016 ISSN 2319 - 4847

4. CONCLUSION

Increase in peripheral velocity and number of blades from 18.75 to 27.80 ms-1, 2 to 6 and reducing forward speed of

operation from 5 to 2 km h-1 resulted in decreased length of cut. The lowest value of length of cut of stem at high

percentage in different scale level was L1= 18.30, L2=23.66, L3=30.98, L4= 22.09 and L5= 4.97 per cent was observed

in the shredder with 6 number of blades, 2 km h -1 operational speed and 28.60 ms-1 peripheral velocity.

REFERENCES

[1]. Cowlick, R.F., J.W.Jones and F.E.Fulgham 1971. Crop residues disposal-tillage-planting, Transaction of ASAE,

14 (1): 114-120.

[2]. Eltarhuny M. M., T. Fouda.2007. Utilization of self-propelled harvester and shredder machines for removing some

field crop residues. Training High Institute, Farm Mechanisation Department, Libya.

[3]. Guzel, E. and Zeren, Y. 1990. The theory of free cutting and its application on cotton stalk. Agricultural

Mechanization in Asia, Africa and Latin America, 21: 55-56.

[4]. Luis, F.C.; G. M. Savage; L. L. Eggerth and G. G. Clarence 1993.Composting and Recycling Municipal Solid

Waste. Lewis Pub.London. P: 453-468.

[5]. Manjeet Singh, S.S. Ahuja and V.K. Sharma 1998. Selected design and operational parameters of serrated tooth-

type bruising mechanism of a straw combine. Agricultural Mechanization in Asia Africa and Latin America, 29

(3).

[6]. MNRE (Ministry of New and Renewable Energy Resources) 2009. Govt.of India, New Delhi.

www.mnre.gov.in/biomassrsources.

[7]. Prasad,J. and C.P. Gupta. 1975. Mechanical properties of maize stalk as related to harvesting. J.of Agric. Eng. Res.

[8]. Senthilkumar, T. 2004. Investigation on development of a tractor operated cotton stalk shredder cum insitu

applicator as influenced by crop, machine and operational parameters PhD Thesis. Department of farm Machinery,

Tamil Nadu Agricultural University, Coimbatore, India.

[9]. Shanmugasundram, V.S., N. Arunachalam, C. Rangasamy, A.Gopalswamy, N.Durairaj and Y.B. Morachan. 1975.

The role of crop residues to meet the fertilizer shortage. Madras agric. J., 62 (6): 353-355.

[10]. Yiliep, Y.D. and U.S. Mohammed, 2005.Effect of knife velocity on cutting energy and efficiency during impact

cutting of sorghum stalk. The E-Journal of CIGR, Vol. VII: Manuscript PM 05004.

Volume 5, Issue 10, October 2016 Page 137

You might also like

- Automatic Voltage Regulators: SpecificationsDocument4 pagesAutomatic Voltage Regulators: SpecificationsArman Haq100% (9)

- Visual Inspection - Sample Report For Spherical VesselDocument8 pagesVisual Inspection - Sample Report For Spherical Vesselkamal90% (10)

- Thresher-Literature ReviewDocument37 pagesThresher-Literature ReviewAdil Khawaja80% (5)

- Din en 1011-2Document58 pagesDin en 1011-2mohamed ahmed100% (3)

- Ee4302 Ca1Document51 pagesEe4302 Ca1Norul Ashikin NorzainNo ratings yet

- International Journal of Engineering Research and Development (IJERD)Document9 pagesInternational Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- 51 Ijasroct201751Document10 pages51 Ijasroct201751TJPRC PublicationsNo ratings yet

- Testings, Results & Analysis of Payback Period of Portable Organic Waste Chopping Machine To Obtain CompostDocument7 pagesTestings, Results & Analysis of Payback Period of Portable Organic Waste Chopping Machine To Obtain CompostIJSTENo ratings yet

- Integration of The Grinding Function With A Cereal Thresher For The Recovery of Crop Residues in CompostingDocument13 pagesIntegration of The Grinding Function With A Cereal Thresher For The Recovery of Crop Residues in CompostingIJAR JOURNALNo ratings yet

- Design and Development of Rotary Power Weeder: International Journal of Current Microbiology and Applied SciencesDocument6 pagesDesign and Development of Rotary Power Weeder: International Journal of Current Microbiology and Applied SciencesGurkanwal Singh ThindNo ratings yet

- 2019 - Evaluation of Cutting Blades Impact On Productivity and Performance of Sugar Cane Harvesting MachineDocument6 pages2019 - Evaluation of Cutting Blades Impact On Productivity and Performance of Sugar Cane Harvesting MachineRAFAEL JIMENEZ ORTIZNo ratings yet

- Iarjset Ncdmete7Document4 pagesIarjset Ncdmete7Sweaten PRemNo ratings yet

- Pod Shelling Machines - A ReviewDocument6 pagesPod Shelling Machines - A ReviewTJPRC PublicationsNo ratings yet

- Jsaer2015 02 03 01 08Document8 pagesJsaer2015 02 03 01 08jsaereditorNo ratings yet

- Study of The Performance of The Most Widely Used Shredders For Crops Residues in EgyptDocument19 pagesStudy of The Performance of The Most Widely Used Shredders For Crops Residues in EgyptIbraheem KhressNo ratings yet

- Weeder pdf33Document8 pagesWeeder pdf33Anonymous 1MgSpwNo ratings yet

- 446 Article p75Document12 pages446 Article p75sayyed KNo ratings yet

- Performance Evaluation and Modification of Shredder Cutting MechanismDocument16 pagesPerformance Evaluation and Modification of Shredder Cutting MechanismTJPRC PublicationsNo ratings yet

- Iarjset Ncdmete7Document4 pagesIarjset Ncdmete7venkatesaperumal eNo ratings yet

- ZJAR - Volume 43 - Issue 4 - Pages 1289-1299Document11 pagesZJAR - Volume 43 - Issue 4 - Pages 1289-1299KamekazeNo ratings yet

- Development and Evaluation of Multi Millet ThresherDocument10 pagesDevelopment and Evaluation of Multi Millet Thresherberihu tesfayNo ratings yet

- Juxtaposition of Push-Type Wheel Hoe To Evaluate Its Weeding Coherence and Impair On EggplantDocument9 pagesJuxtaposition of Push-Type Wheel Hoe To Evaluate Its Weeding Coherence and Impair On EggplantIJRASETPublicationsNo ratings yet

- Development and Evaluation of A Rotary Power WeederDocument13 pagesDevelopment and Evaluation of A Rotary Power WeederKaran KoshtiNo ratings yet

- Performance Evaluation of Two Planter Makes As Affected by Forward SpeedsDocument7 pagesPerformance Evaluation of Two Planter Makes As Affected by Forward SpeedsaymanNo ratings yet

- Manjeet PreM Et Al 1Document8 pagesManjeet PreM Et Al 1Prem Ranjan MehtaNo ratings yet

- Development and Evaluation of Self-Propelled Cono Weeder For Rice Cultivation in VertisolDocument7 pagesDevelopment and Evaluation of Self-Propelled Cono Weeder For Rice Cultivation in VertisolSapuniiNo ratings yet

- ScreeningDocument16 pagesScreeningMohammed AlnasharNo ratings yet

- Development and Ergonomic Evaluation of Manual Weeder RAJVIR YADAVDocument9 pagesDevelopment and Ergonomic Evaluation of Manual Weeder RAJVIR YADAVSapuniiNo ratings yet

- Report of Project 1Document9 pagesReport of Project 1Murari KrishnaNo ratings yet

- SimulationDocument13 pagesSimulationGojjam LibayNo ratings yet

- IJASR - Performance Studies On Power Operated Chaff Cutter PDFDocument8 pagesIJASR - Performance Studies On Power Operated Chaff Cutter PDFAnonymous pxdbBLu100% (3)

- Design and Development of Cassava Planting MachineDocument6 pagesDesign and Development of Cassava Planting Machinejohn lester benignoNo ratings yet

- Prototype Grading Cereal CorpsDocument16 pagesPrototype Grading Cereal Corpstaufiq hidNo ratings yet

- Development of Solar Powered Knapsack Sprayer: Indian Journal of Agricultural Sciences April 2018Document10 pagesDevelopment of Solar Powered Knapsack Sprayer: Indian Journal of Agricultural Sciences April 2018Siva RajNo ratings yet

- Development of Multinozzle Pesticides Sprayer PumpDocument5 pagesDevelopment of Multinozzle Pesticides Sprayer PumpTania JohnsonNo ratings yet

- Ijirt144400 PaperDocument5 pagesIjirt144400 Paperhadush gebreNo ratings yet

- Design and Structural Analysis of Weed Removing Machine Fitted With Rotovator Blade in Glory Lily PlantDocument7 pagesDesign and Structural Analysis of Weed Removing Machine Fitted With Rotovator Blade in Glory Lily PlantvenkatNo ratings yet

- Effect of Disc and Tilt Angles of Disc PDocument12 pagesEffect of Disc and Tilt Angles of Disc PMuhammad DennyNo ratings yet

- Solar Pesticide SprayerDocument6 pagesSolar Pesticide SprayerShobhit SinghNo ratings yet

- Plant Power ShredderDocument27 pagesPlant Power ShredderDanica Joyce DayritNo ratings yet

- 2 50 1583903003 1ijasrapr20201Document8 pages2 50 1583903003 1ijasrapr20201TJPRC PublicationsNo ratings yet

- 2 50 1583903003 1ijasrapr20201Document8 pages2 50 1583903003 1ijasrapr20201TJPRC PublicationsNo ratings yet

- IJRAR23B4373Document6 pagesIJRAR23B4373KARTIK KANAWADENo ratings yet

- Design and Experimental Evaluation of A Form TrimmDocument13 pagesDesign and Experimental Evaluation of A Form Trimmالأردني JordanianNo ratings yet

- Ijasr - Performance Evaluation of Tractor Operated PDFDocument10 pagesIjasr - Performance Evaluation of Tractor Operated PDFAnonymous dbnms1yNo ratings yet

- Development A Feeding Mechanism of Chopper For Chopping Sugarcane BagasseDocument19 pagesDevelopment A Feeding Mechanism of Chopper For Chopping Sugarcane BagassedansihNo ratings yet

- 16 23yonasmulatuDocument9 pages16 23yonasmulatuELMER DELOSSANTOSNo ratings yet

- Design and Performance Evaluation of A Screw Press Separator For Separating Dairy Cattle ManureDocument10 pagesDesign and Performance Evaluation of A Screw Press Separator For Separating Dairy Cattle ManureDaniel SouzaNo ratings yet

- N RavikumaretalDocument14 pagesN RavikumaretalPrashant NaleNo ratings yet

- Rice TresherDocument11 pagesRice TresherGerry100% (1)

- N K DhruweetalDocument6 pagesN K DhruweetalZIGAMENo ratings yet

- Field Capacity and Efficiency of A Turmeric Rhizome Planter in Response To Machine Speeds and Some Selected Crop ParametersDocument5 pagesField Capacity and Efficiency of A Turmeric Rhizome Planter in Response To Machine Speeds and Some Selected Crop ParametersVishal SaravananNo ratings yet

- Development and Performance Evaluation of Lucerne Harvesting MachineDocument10 pagesDevelopment and Performance Evaluation of Lucerne Harvesting MachineIJRASETPublicationsNo ratings yet

- Potato Grader CIGR2019Document8 pagesPotato Grader CIGR2019Munnaf M AbdulNo ratings yet

- Design and Fabrication of Sugarcane Cutting Machine For Cane-Can Industry, NagpurDocument2 pagesDesign and Fabrication of Sugarcane Cutting Machine For Cane-Can Industry, NagpurSaiNo ratings yet

- Conceptual Design and Development of Shredding Machine For Agricultural WasteDocument7 pagesConceptual Design and Development of Shredding Machine For Agricultural WasteVJ CarbonellNo ratings yet

- AssignmentDocument6 pagesAssignmentJudyNo ratings yet

- Performance Characteristics of A CoconutDocument14 pagesPerformance Characteristics of A CoconutNeil TaneoNo ratings yet

- 710-File Utama Naskah-1439-2-10-20180214Document7 pages710-File Utama Naskah-1439-2-10-20180214ISLAM INDAH DAMAINo ratings yet

- 1-8 Mohammed TemamDocument8 pages1-8 Mohammed TemamAddisalem MesfinNo ratings yet

- Development of A Portable Pneumatic Grain Broadcasting Unit: Ahmad, M. CDocument8 pagesDevelopment of A Portable Pneumatic Grain Broadcasting Unit: Ahmad, M. CMariana VictoriaNo ratings yet

- Seed Growing 1Document18 pagesSeed Growing 1Sandeep ArduNo ratings yet

- Farm Machinery and Equipment : Improving Productivity in the FieldFrom EverandFarm Machinery and Equipment : Improving Productivity in the FieldNo ratings yet

- The Machinery of Hay Harvesting - With Information on the Equipment and Methods Mowing, Raking and BailingFrom EverandThe Machinery of Hay Harvesting - With Information on the Equipment and Methods Mowing, Raking and BailingNo ratings yet

- Test Request Form: Requested Test (Put "X" To Check)Document2 pagesTest Request Form: Requested Test (Put "X" To Check)Claudia Lizeth Chacon PedrazaNo ratings yet

- BV Guide Windfarm Project CertificationDocument108 pagesBV Guide Windfarm Project CertificationCyprian Cypu100% (1)

- Carriage of MaterialDocument7 pagesCarriage of MaterialDigvijay SinghNo ratings yet

- METRO Member Directory and Delivery Roster - Spring 2012Document42 pagesMETRO Member Directory and Delivery Roster - Spring 2012Metropolitan New York Library Council (METRO)No ratings yet

- Indra GanesanDocument89 pagesIndra GanesanShanmugam BalasubramaniamNo ratings yet

- Electrical Crimping Tool PDFDocument2 pagesElectrical Crimping Tool PDFbaolifengNo ratings yet

- DO s2019 011Document131 pagesDO s2019 011Jerome GliponeoNo ratings yet

- ApprovedVendorList Civil 24012018Document48 pagesApprovedVendorList Civil 24012018amandeepNo ratings yet

- International RoamingDocument25 pagesInternational RoamingAbu Bakir Akhter75% (4)

- Translating English-IndonesiaDocument6 pagesTranslating English-IndonesiaefaNo ratings yet

- Sequential TimerDocument4 pagesSequential Timerprasad mdvNo ratings yet

- Study and Operation of Tempering ProcessDocument11 pagesStudy and Operation of Tempering ProcessMostafizur Rahman SobujNo ratings yet

- Document Tabs For Application in DepEdDocument1 pageDocument Tabs For Application in DepEdLea Jane Ilagan Razona100% (3)

- HW 3Document4 pagesHW 3Alwyn KalapuracanNo ratings yet

- Asha Sharma ResumeDocument3 pagesAsha Sharma ResumeRachit SharmaNo ratings yet

- Intrusion Detection System Using Multivariate Control Chart Hotelling's T Based On PCADocument7 pagesIntrusion Detection System Using Multivariate Control Chart Hotelling's T Based On PCARumaisa KrubaNo ratings yet

- Erp Construction Industry PDFDocument2 pagesErp Construction Industry PDFTroyNo ratings yet

- CaseHard 17CrNiMo6Document2 pagesCaseHard 17CrNiMo6Francisco Botelho Carlos100% (1)

- Vaddl 12: Pressure Relief ValvesDocument2 pagesVaddl 12: Pressure Relief ValvesSachin RamadasanNo ratings yet

- Propeler Shaft Survey Extension - Preventive Maintenance (1) 4Document8 pagesPropeler Shaft Survey Extension - Preventive Maintenance (1) 4Frano GrifiNo ratings yet

- HAWC2 Course: Lesson 3: Aerodynamic Modeling and Implementation in Hawc2Document52 pagesHAWC2 Course: Lesson 3: Aerodynamic Modeling and Implementation in Hawc2Mahmoud MoussaNo ratings yet

- CAT 2023 Composite Score and Calls Predictor - AmiyaDocument69 pagesCAT 2023 Composite Score and Calls Predictor - AmiyaHarsimran SinghNo ratings yet

- Optical Character Recognition Research: IndexDocument6 pagesOptical Character Recognition Research: IndexPhi Thiện HồNo ratings yet

- 1DV2 (1K1DV450E1) T115SEC Vega ForceDocument58 pages1DV2 (1K1DV450E1) T115SEC Vega ForceGAYLE GONo ratings yet

- Maersk DelivererDocument12 pagesMaersk DelivererNoor HadiNo ratings yet

- Brand Management of HULDocument76 pagesBrand Management of HULMohammed Yunus100% (1)