Professional Documents

Culture Documents

SECTION 15000 Earthworks: C.R. N - 62618-0 Coepp L - N - EPP/FB/127

SECTION 15000 Earthworks: C.R. N - 62618-0 Coepp L - N - EPP/FB/127

Uploaded by

Henry MalinisCopyright:

Available Formats

You might also like

- Method Statement For Excavation and Backfilling WorksDocument15 pagesMethod Statement For Excavation and Backfilling WorksĐặng Quang Huy100% (6)

- CV-0013-002 - Method Statement For Soil Improvement WorkDocument14 pagesCV-0013-002 - Method Statement For Soil Improvement Work한상호No ratings yet

- Work Procedure For Repair, Revision of Steel Structures & Painting For STB, STG, CCB, WWTB and FWPHDocument14 pagesWork Procedure For Repair, Revision of Steel Structures & Painting For STB, STG, CCB, WWTB and FWPHResearcherNo ratings yet

- Method Statement For Establishment of Site FacilitiesDocument9 pagesMethod Statement For Establishment of Site FacilitiesNaveen GladsonNo ratings yet

- Predictive Modeling Business ReportDocument69 pagesPredictive Modeling Business Reportpreeti100% (3)

- 26071-100-VSC-CV5-00014 - 00A Construction Method Statement For MH & CBDocument82 pages26071-100-VSC-CV5-00014 - 00A Construction Method Statement For MH & CBRezky BaskoroNo ratings yet

- Earthworks PDFDocument5 pagesEarthworks PDFphilipyapNo ratings yet

- Gas Turbine Data Sheet PDFDocument59 pagesGas Turbine Data Sheet PDFajo zinzoNo ratings yet

- MS of Earth Mat Installation - 12-10-2018-SVH-RSDocument25 pagesMS of Earth Mat Installation - 12-10-2018-SVH-RSPankaj Upadhyay100% (1)

- 000-A-Ee-0190470 Rev1 Painting Repair ProcedureDocument34 pages000-A-Ee-0190470 Rev1 Painting Repair Procedureonur gunes100% (2)

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- Ms-07-Method Statement For Earth FillingDocument37 pagesMs-07-Method Statement For Earth FillingAmila Priyadarshana DissanayakeNo ratings yet

- WMS - C&S - 039 - WMS For UPV and Coring TestDocument4 pagesWMS - C&S - 039 - WMS For UPV and Coring TestEchoNo ratings yet

- MS-01-Method Statement For Site EstablishmentDocument26 pagesMS-01-Method Statement For Site EstablishmentAmila Priyadarshana DissanayakeNo ratings yet

- SEP 01 ZAA 1DC 002 Method Statement For Block Work 1Document8 pagesSEP 01 ZAA 1DC 002 Method Statement For Block Work 1usman malik100% (1)

- Docu Ent Sub Ittal Sheet: Qatar Armed Forces Qatar Emiri Corps of EngineeringDocument20 pagesDocu Ent Sub Ittal Sheet: Qatar Armed Forces Qatar Emiri Corps of EngineeringMohameduwais Badurdeen Haqqiyul QadiriNo ratings yet

- Attachment A - Scope of WorkDocument7 pagesAttachment A - Scope of WorkMazhar MahadzirNo ratings yet

- Method Statement of Cable Pulling On Trays, Duct Bank & Cable Trenches - Rev BDocument15 pagesMethod Statement of Cable Pulling On Trays, Duct Bank & Cable Trenches - Rev BDonny Subarja100% (2)

- Method Statement For Bored PilesDocument18 pagesMethod Statement For Bored PilesKaushalye Mahanama Dissanayake100% (3)

- M4 501 01 (R0)Document214 pagesM4 501 01 (R0)ksshashidharNo ratings yet

- 26071-100-VSC-MAH0-40022 - Method Statement For Installation Conduit & Tray Work - 000Document18 pages26071-100-VSC-MAH0-40022 - Method Statement For Installation Conduit & Tray Work - 000ogyrisky100% (1)

- Thissawewa Phase 1Document91 pagesThissawewa Phase 1janithNo ratings yet

- ELT-07-MT-Q-SERV-0001 - Foundation For Truck Loading RackDocument19 pagesELT-07-MT-Q-SERV-0001 - Foundation For Truck Loading RackEl Charasquiada CharroNo ratings yet

- 5779-004-Pvc-W-Specs - 002 - R0Document33 pages5779-004-Pvc-W-Specs - 002 - R0bansalhimanshu07No ratings yet

- Method Statement For Installation of GroundingDocument12 pagesMethod Statement For Installation of GroundingAlvin Jim VillanuevaNo ratings yet

- Section 02300 Earthworks R2Document21 pagesSection 02300 Earthworks R2MØhãmmed ØwięsNo ratings yet

- Cooling Water PumpsDocument143 pagesCooling Water PumpszalabiNo ratings yet

- ROR BQ Arena 2DEC2022 (1) - LatestDocument261 pagesROR BQ Arena 2DEC2022 (1) - LatestJay JayNo ratings yet

- O & M Estimate KC-29 (531+000 To 785+000) 10.2.2022Document465 pagesO & M Estimate KC-29 (531+000 To 785+000) 10.2.2022Muhammad TufailNo ratings yet

- Mas-Rtcf-Ms-El-001-Cable TrayDocument10 pagesMas-Rtcf-Ms-El-001-Cable TrayASHIQUE ZAFARNo ratings yet

- ZWK JSW C Geo 002Document17 pagesZWK JSW C Geo 002bansalhimanshu07No ratings yet

- V-3120-001-A-209-2A Method For Drainage WorkDocument6 pagesV-3120-001-A-209-2A Method For Drainage WorkMajid KhobadNo ratings yet

- ROR BQ Arena 2DEC2022 - LatestDocument196 pagesROR BQ Arena 2DEC2022 - LatestJay JayNo ratings yet

- 26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureDocument25 pages26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureAsril Sang Lentera Senja100% (1)

- SECTION 02 65 00 Underground Storage Tank RemovalDocument8 pagesSECTION 02 65 00 Underground Storage Tank RemovalJuanPaoloYbañezNo ratings yet

- 016 - MS For Full Scale Shear Pad Rev.B - 09 Mar 11Document21 pages016 - MS For Full Scale Shear Pad Rev.B - 09 Mar 11nadraNo ratings yet

- Pressure Grouting Soil Stabilizaion Rev 0Document9 pagesPressure Grouting Soil Stabilizaion Rev 0MohamedOmar83No ratings yet

- Method Statement For Foundation Cm1b 0 SCL Civ Ms 0006 Rev.ADocument127 pagesMethod Statement For Foundation Cm1b 0 SCL Civ Ms 0006 Rev.AMinh HảiNo ratings yet

- No PicDocument36 pagesNo Picapi-3837830No ratings yet

- r2 StadiumDocument69 pagesr2 StadiumRoshan KejariwalNo ratings yet

- Method Statement For Road WorksDocument20 pagesMethod Statement For Road WorksJezrel Gempisao100% (1)

- Saudi Aramco Oil Company: SECTION 02240 Dewatering Part 1 - GeneralDocument4 pagesSaudi Aramco Oil Company: SECTION 02240 Dewatering Part 1 - GeneralPhilip Yap100% (1)

- Secondary IrrigationDocument49 pagesSecondary IrrigationNijasNo ratings yet

- Inspection & Testing Services For Concrete Paving and Earthworks Construction SpecificationDocument11 pagesInspection & Testing Services For Concrete Paving and Earthworks Construction SpecificationJohnny vargas suclupeNo ratings yet

- Mombasa Water Supply and Sanitation Company Limited: Bill of QuantitiesDocument21 pagesMombasa Water Supply and Sanitation Company Limited: Bill of QuantitiesKhairi Ali OmarNo ratings yet

- TOR For Shifting & Extension of Pipeline From Berth2 To 3 For Consultancy WorkDocument14 pagesTOR For Shifting & Extension of Pipeline From Berth2 To 3 For Consultancy WorkSumantra ChattopadhyayNo ratings yet

- SEGS-BHR-CI-AA70-PCD-1042-0 Holiday Testing IFC SignDocument12 pagesSEGS-BHR-CI-AA70-PCD-1042-0 Holiday Testing IFC SignPak WahyuNo ratings yet

- A Con Pro 000 38658 BDocument13 pagesA Con Pro 000 38658 BHussein Adnan FneishNo ratings yet

- QT1 0 Q 030-05-00036 - D - ITP For ESP InstallationDocument26 pagesQT1 0 Q 030-05-00036 - D - ITP For ESP InstallationLâm HuyNo ratings yet

- WRD CSR 2022-23 (Specification)Document973 pagesWRD CSR 2022-23 (Specification)khushal deshmaneNo ratings yet

- Obra C, RFQ For Remaining Boundary Wall Work PC AA SRS (R0, 20220624)Document10 pagesObra C, RFQ For Remaining Boundary Wall Work PC AA SRS (R0, 20220624)ashutoshpathakcivilNo ratings yet

- Method Statement For Drainange Construction Work: Document/Drawing Number: TNEC-STSB-KLIA-CS-MS-013 Revision: ADocument9 pagesMethod Statement For Drainange Construction Work: Document/Drawing Number: TNEC-STSB-KLIA-CS-MS-013 Revision: AAishah AliasNo ratings yet

- BOQ For Vehicles Inspection Lanes 2 - PRICEDDocument67 pagesBOQ For Vehicles Inspection Lanes 2 - PRICEDD A R K S K YNo ratings yet

- MOS - Plumbing and Sanitary Services Rev. 2Document4 pagesMOS - Plumbing and Sanitary Services Rev. 2KAKANo ratings yet

- Technical SpecificationsDocument135 pagesTechnical SpecificationsSrinivasan RajenderanNo ratings yet

- A MTL Pro 000 38673 CDocument21 pagesA MTL Pro 000 38673 CHussein Adnan FneishNo ratings yet

- Working Plan Procedure For GCB and Generator Accessory InstallationDocument38 pagesWorking Plan Procedure For GCB and Generator Accessory InstallationThanh TinhNo ratings yet

- 3045 tsR3Document48 pages3045 tsR3brajesh123No ratings yet

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- SKDDocument5 pagesSKDPaulo VianaNo ratings yet

- Kwasu Solar Load AssessmentDocument7 pagesKwasu Solar Load AssessmentLanre AleNo ratings yet

- CBEprom Data BookDocument65 pagesCBEprom Data BookChelle2100% (2)

- NHMWriter User ManualDocument7 pagesNHMWriter User Manualvelxerox4123No ratings yet

- Canuto v. Mariano G.R. No. L-11346 March 21, 1918Document1 pageCanuto v. Mariano G.R. No. L-11346 March 21, 1918happypammynessNo ratings yet

- Cy17b PH Technical Trial System Protocols v5Document16 pagesCy17b PH Technical Trial System Protocols v5Glenn Cabance LelinaNo ratings yet

- Convolutional Neural Networks in Computer Vision: Jochen LangDocument46 pagesConvolutional Neural Networks in Computer Vision: Jochen LangZichao ZhangNo ratings yet

- VAWA Federalism One-PagerDocument2 pagesVAWA Federalism One-PagerThe National Task Force to End Sexual and Domestic ViolenceNo ratings yet

- Final Paper - Ana Maria PumneaDocument2 pagesFinal Paper - Ana Maria PumneaAnna Pumnea0% (1)

- Underwater Explosive Shock Testing UNDEX CM2000Document11 pagesUnderwater Explosive Shock Testing UNDEX CM2000Maryam RehanNo ratings yet

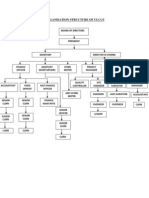

- Organisation Structure of Ulccs: Director in ChargeDocument1 pageOrganisation Structure of Ulccs: Director in ChargeMohamed RiyasNo ratings yet

- ApduDocument1 pageApduMilen MihailovNo ratings yet

- Chapter 8 - Ethnographic ResearchDocument26 pagesChapter 8 - Ethnographic ResearchNoor SalmanNo ratings yet

- q4 MATH-BATCH 3Document2 pagesq4 MATH-BATCH 3Sofia SyNo ratings yet

- Corrective Action PlanDocument3 pagesCorrective Action Plansohail100% (2)

- Steel PuttyDocument1 pageSteel PuttySiva SubramaniNo ratings yet

- Baires Dev PreentrevistaDocument3 pagesBaires Dev PreentrevistaCarlos Gonzalo Maravi ArensNo ratings yet

- Broton V DA Fitzpatrick (Doc 76) Motion To Strike' Delay Tactic. DA Counsel 'Not Ready'Document2 pagesBroton V DA Fitzpatrick (Doc 76) Motion To Strike' Delay Tactic. DA Counsel 'Not Ready'Desiree YaganNo ratings yet

- Automated Packaging Machine Using PLCDocument7 pagesAutomated Packaging Machine Using PLCTimothy FieldsNo ratings yet

- Sojib VaiDocument2 pagesSojib VaiPeash Mredha80% (5)

- Oracle Cloud Infrastructure Developer Exam Questions - Page 2 of 8 - SkillCertProDocument40 pagesOracle Cloud Infrastructure Developer Exam Questions - Page 2 of 8 - SkillCertProSai Aung Hlyan HtetNo ratings yet

- Culinarian CookwareDocument2 pagesCulinarian Cookwarespaw1108100% (1)

- Reaction Paper - Vocation of The Business Leader, A ReflectionDocument2 pagesReaction Paper - Vocation of The Business Leader, A ReflectionDarwyn Mendoza100% (1)

- Valvula Piston Buschjost 86500Document2 pagesValvula Piston Buschjost 86500Base SistemasNo ratings yet

- Asterisk DocumentationDocument34 pagesAsterisk DocumentationSafaa Shaaban50% (2)

- Audit Sur La Restauration Et La Sécurité: Alerte Rouge Dans Les HôpitauxDocument5 pagesAudit Sur La Restauration Et La Sécurité: Alerte Rouge Dans Les HôpitauxL'express Maurice0% (1)

- Neft Terminləri Lüğəti (Azərbaycan, İngilis, Türk, Rus) 1 - FesilDocument307 pagesNeft Terminləri Lüğəti (Azərbaycan, İngilis, Türk, Rus) 1 - FesilMehemmed Alashrafov67% (3)

- Usando MessageBox C BuilderDocument3 pagesUsando MessageBox C BuilderFernando Luiz Do AmaralNo ratings yet

- For Students - AASTU - EMEng-7253 Grade Report (2023)Document1 pageFor Students - AASTU - EMEng-7253 Grade Report (2023)begosew zelalemNo ratings yet

SECTION 15000 Earthworks: C.R. N - 62618-0 Coepp L - N - EPP/FB/127

SECTION 15000 Earthworks: C.R. N - 62618-0 Coepp L - N - EPP/FB/127

Uploaded by

Henry MalinisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SECTION 15000 Earthworks: C.R. N - 62618-0 Coepp L - N - EPP/FB/127

SECTION 15000 Earthworks: C.R. N - 62618-0 Coepp L - N - EPP/FB/127

Uploaded by

Henry MalinisCopyright:

Available Formats

FVB Energy Inc EARTHWORKS

C.R. NO. 62618-0 PAGE 1 (7)

COEPP LIC. NO. EPP/FB/127

SECTION 15000 APRIL 10, 2008

REEF ISLAND REV 0

SECTION 15000

EARTHWORKS

Table of contents

1 PART 1 - GENERAL.....................................................................................................................2

1.1 DESCRIPTION OF WORK ...........................................................................................................2

1.2 QUALITY CONTROL ..................................................................................................................2

1.3 SUBMITTALS ............................................................................................................................2

2 PART 2 - PRODUCTS ..................................................................................................................4

2.1 MATERIALS ..............................................................................................................................4

3 PART 3 - EXECUTION ................................................................................................................5

3.1 PREPARATION ..........................................................................................................................5

City Centre Building 203, Suite 603

Government Road Block 304

P.O. Box 75723

Manama, Kingdom of Bahrain

FVB Energy Inc EARTHWORKS

C.R. NO. 62618-0 PAGE 2 (7)

COEPP LIC. NO. EPP/FB/127

SECTION 15000 APRIL 10, 2008

REEF ISLAND REV 0

PART 1 - GENERAL

1.1 DESCRIPTION OF WORK

This Section covers the earthworks requirements for the construction of the

district cooling piping and associated ducting and concrete structures.

1.2 QUALITY CONTROL

Testing

A. Testing will be undertaken by an independent testing laboratory proposed

by the Contractor and approved by the Owner or his Representative. All

costs for tests shall be borne by the Contractor.

B. The British Standards referred to in this specification are listed below

together with any other references specified.

Standards: BS 1377: 1990 Methods of test for soils for civil

engineering purposes.

C. The Contractor shall have in effect at all times a QA/QC program which

clearly establishes the authority and responsibility of those responsible

for the quality system. Persons performing quality functions shall have

sufficient and well defined authority to enforce quality requirements that

initiate, identify, recommend and provide solutions to quality problems

and verify the effectiveness of the corrective action.

D. The proposed Contractor quality system shall fully satisfy all the

elements of ISO 9001:2000.

E. Implementation of the system shall be in accordance with the

Contractor's quality manual and project specific quality plan, which shall

both, together with all related/referenced procedures, be held and

maintained by the Contractor.

F. The Owner reserves the right to inspect and audit materials and

workmanship at all stages of construction and to witness any or all tests.

1.3 SUBMITTALS

A. Surveying of Site:

1. The Contractor shall, before commencing any excavation or filling,

survey and take levels on the original ground surface, and shall

prepare plans and sections accordingly. The plans and sections shall

truly represent the configuration of the areas in question at the

commencement of work.

B. Excavation, dewatering, shoring and protection

1. The Contractor shall prepare, as soon as possible, information

regarding the intended procedures for excavation, dewatering,

shoring and protection. The information shall include proposed

procedures for recording and monitoring the status of existing

structures and temporary works.

City Centre Building 203, Suite 603

Government Road Block 304

P.O. Box 75723

Manama, Kingdom of Bahrain

FVB Energy Inc EARTHWORKS

C.R. NO. 62618-0 PAGE 3 (7)

COEPP LIC. NO. EPP/FB/127

SECTION 15000 APRIL 10, 2008

REEF ISLAND REV 0

2. The Contractor shall prepare full details of shop drawings and

calculations of all the above procedures before commencing the

excavation.

C. Compaction Trial

1. The Contractor shall carry out compaction trials to assess the

compaction properties of the proposed fill materials and the existing

typical subgrade material. This shall be supplemented by the

necessary laboratory testing. Refer to Part 2 and Part 3 of this

specification for fill material grading, compaction criteria and

laboratory testing.

2. Following completion of the compaction trial and review of

laboratory results, the Contractor shall submit a compaction method

statement. The compaction method statement shall include the

proposed mechanical compaction equipment, number of passes, etc.

D. Test Reports:

1. The Contractor shall keep possession of all laboratory test reports for

all earthwork materials used in the works for inspection by the

Owner’s Representative.

City Centre Building 203, Suite 603

Government Road Block 304

P.O. Box 75723

Manama, Kingdom of Bahrain

FVB Energy Inc EARTHWORKS

C.R. NO. 62618-0 PAGE 4 (7)

COEPP LIC. NO. EPP/FB/127

SECTION 15000 APRIL 10, 2008

REEF ISLAND REV 0

2 PART 2 - PRODUCTS

2.1 MATERIALS

A. Definition and classification of ‘bedding’ material.

1. Bedding is the material within which the district cooling pipes shall

be laid.

2. Bedding material shall be clean sand well worked around the pipe to

a level of 200 mm above the crown and 150 mm below the bottom of

the protective jacket.

3. The bedding material sand shall confirm to the following criteria:

Sieve size Percentage Passing

63 micron 10% max

2.0 mm 60% - 100%

10.0 mm Maximum particle size

Minimum soaked CBR of 25% when compacted to 95% of maximum

dry density (MDD).

Bedding material shall not contain organic material.

B. Definition and classification of ‘backfill’ material.

1. Backfill is the material that shall be placed above the bedding

material up to the roadbed.

2. The backfill material shall be soil material or controlled low

strength material used to fill an excavation.

C. Warning tape for buried pipes.

1. By pipe manufactor provided plastic warning tape with inscription

“District Cooling”.

City Centre Building 203, Suite 603

Government Road Block 304

P.O. Box 75723

Manama, Kingdom of Bahrain

FVB Energy Inc EARTHWORKS

C.R. NO. 62618-0 PAGE 5 (7)

COEPP LIC. NO. EPP/FB/127

SECTION 15000 APRIL 10, 2008

REEF ISLAND REV 0

3 PART 3 - EXECUTION

3.1 PREPARATION

A. Existing Utilities

1. The Contractor is to hand excavate exploratory trenches, plot the

positions of the existing services and submit to the relevant

Authorities for record review. Such services shall be marked by

stakes or appropriate identifications on site. The Contractor shall

also submit his proposals for protecting existing services during

construction.

2. Within the limits of excavation, the Contractor shall remove any

existing piping, cesspits, sub-soil drainage systems, conduit,

manholes and related items which are to be abandoned and plug open

ends with concrete. All services to be abandoned which lie less than

3.0m below the finished ground level are to be removed and taken

for disposal.

B. Excavation, shoring and protection

1. The Contractor shall be fully and solely responsible for the strength

and adequacy of retaining structures, and for the safety and support

of construction, utilities, roads or paving, and for any movement,

settlement or damage thereto. Review by the Owner’s

Representative of shop drawings and calculations shall not imply or

confer the Owner’s Representatives responsibility or liability for

works shown on the shop drawings or in calculations.

2. The Contractor shall also be fully responsible for ensuring that

adequate safety measures are taken to protect site personnel and the

general public from any excavation hazard.

3. The Contractor shall make good at his own expense any damage to

adjacent services or structures that may result from his failure to

provide adequate shoring the excavation process.

C. De-Watering

1. Where the excavation level is below the natural water table and it is

necessary to pump continuously from the excavation or to install a

specialist form of dewatering equipment, around the perimeter of the

site or excavation, the Contractor will be responsible for ensuring

that the equipment installed will allow the excavation and subsequent

construction to be carried out in dry conditions.

2. Continuous or permanent dewatering of the excavation or Site and

the method to be employed shall comply with Codes of Practice and

Local Authority requirements.

3. The water pumped from excavations or well points shall be pumped

to disposal points or sumps as approved by the Local Authority, and

if so required be passed through settling tanks before disposal.

Under no circumstances must water be disposed of in the

Municipality's sewer system.

City Centre Building 203, Suite 603

Government Road Block 304

P.O. Box 75723

Manama, Kingdom of Bahrain

FVB Energy Inc EARTHWORKS

C.R. NO. 62618-0 PAGE 6 (7)

COEPP LIC. NO. EPP/FB/127

SECTION 15000 APRIL 10, 2008

REEF ISLAND REV 0

4. Particular consideration shall be given to the possible effects on the

neighbouring structures of lowering the ground water level. Proper

shoring of the excavation next to the adjacent structures, roads and

walkways, shall be allowed in order to avoid any lateral yield of the

soils, loss of foundation support etc. While the excavation remains

open, settlements and any lateral displacement of these structures,

roads and walkways should be monitored on a daily basis.

5. The Contractor shall make good at his own expense any damage to

services or structures that may result from his dewatering process.

D. Preparation and inspection of excavation subgrade

1. Should the existing sub grade material fail to achieve the specified

compaction criteria, the sub grade material shall be excavated and

replaced by a 300 mm blanket of compacted hardfill material or as

advised by the Owner’s Representative.

2. Irregularities in profile may be made up to an approximate level

grade only after initial preparation of the sub grade as discussed

above.

3. The Owner’s Representative shall review test reports and inspect the

subgrade prior to placement of any fill.

E. Filling of trenches and foundation pits

1. Acceptable fill material shall be as defined within Part 2 of this

specification. Fill material shall be compacted in accordance with

the Contractor’s compaction method statement. Areas of fill shall be

built up over the full trench width. Filling shall be completed in

accordance with the supporting contract drawings.

2. Shoring may be removed as the filling proceeds, except where it is

required by the Contract to be left in position. The removal of such

supports will not relieve the Contractor of his responsibilities for the

stability of the temporary works.

3. Filling requirements for the bedding material are as follows:

• A 150 mm layer of compacted bedding material shall be placed

below the district cooling pipes.

• Filling shall then continue in equal stages at 150 mm layers on

both sides of the district cooling pipes, with particular care given

to compaction of the bedding material at the haunches of the pipe

and the PVC control ducting.

• Bedding material shall extend up to 200 mm above the crown of

the pipe protective jacket.

4. Filling requirements for the backfill material are as follows:

• Backfill material shall be placed in 150 mm layers extending up

to the top of excavation level or as deemed appropriate by the

infrastructure Contractor.

City Centre Building 203, Suite 603

Government Road Block 304

P.O. Box 75723

Manama, Kingdom of Bahrain

FVB Energy Inc EARTHWORKS

C.R. NO. 62618-0 PAGE 7 (7)

COEPP LIC. NO. EPP/FB/127

SECTION 15000 APRIL 10, 2008

REEF ISLAND REV 0

5. Compaction Requirements

• Bedding and backfill material shall be mechanically compacted to at least

95% of maximum dry density (MDD)

6. Testing frequency

• To determine the degree of compaction achieved during construction, the

compacted bedding and backfill material shall be insitu tested for density

and moisture content.

• Testing shall be completed using one of the approved methods detailed in

BS 1377 - Part 9 (sand replacement or nuclear method) at a minimum rate

of 3 tests per 600 square metres for each layer of fill.

• The Contractor shall allow for the cost of all required testing by an

independent laboratory approved by the Employer.

7. The Contractor shall reexcavate and recompact areas of fill that do

not satisfy the required compaction criteria. This shall be completed

under the instruction and supervision of the Owner’s Representative.

F. Fill adjacent to concrete structures

1. The existing subgrade beneath concrete structures shall be prepared

to the criteria detailed in Part 3.D of this specification.

2. Fill material immediately adjacent to concrete structures shall

comply with Part 2 and shall be placed and compacted in accordance

with Part 3 of this specification.

3. When filling against foundations or walls, fill shall be placed evenly

around the structure to prevent eccentric loading. Overstressing of

the structure and damage to the external waterproofing shall be

mitigated through the use of appropriate mechanical compaction

equipment. This shall be approved by the Owner’s Representative.

G. Excavation limits

1. All excavations shall be carried out to the lines and levels in

accordance with the design.

2. If, from any cause whatsoever, excavations other than for concrete

works are carried out beyond their true line and level, the Contractor

shall at his own cost make good to the required line and level with

approved fill material.

H. Slips

1. The Contractor shall make good any damage or defects caused by

slips to any cuttings or excavations and shall do all necessary work to

prevent or remedy the same.

I. Warning tape

1. The tape shall be rolled out along the pipe trench according to the

cross section on the contract drawing.

*** END OF SECTION ***

City Centre Building 203, Suite 603

Government Road Block 304

P.O. Box 75723

Manama, Kingdom of Bahrain

You might also like

- Method Statement For Excavation and Backfilling WorksDocument15 pagesMethod Statement For Excavation and Backfilling WorksĐặng Quang Huy100% (6)

- CV-0013-002 - Method Statement For Soil Improvement WorkDocument14 pagesCV-0013-002 - Method Statement For Soil Improvement Work한상호No ratings yet

- Work Procedure For Repair, Revision of Steel Structures & Painting For STB, STG, CCB, WWTB and FWPHDocument14 pagesWork Procedure For Repair, Revision of Steel Structures & Painting For STB, STG, CCB, WWTB and FWPHResearcherNo ratings yet

- Method Statement For Establishment of Site FacilitiesDocument9 pagesMethod Statement For Establishment of Site FacilitiesNaveen GladsonNo ratings yet

- Predictive Modeling Business ReportDocument69 pagesPredictive Modeling Business Reportpreeti100% (3)

- 26071-100-VSC-CV5-00014 - 00A Construction Method Statement For MH & CBDocument82 pages26071-100-VSC-CV5-00014 - 00A Construction Method Statement For MH & CBRezky BaskoroNo ratings yet

- Earthworks PDFDocument5 pagesEarthworks PDFphilipyapNo ratings yet

- Gas Turbine Data Sheet PDFDocument59 pagesGas Turbine Data Sheet PDFajo zinzoNo ratings yet

- MS of Earth Mat Installation - 12-10-2018-SVH-RSDocument25 pagesMS of Earth Mat Installation - 12-10-2018-SVH-RSPankaj Upadhyay100% (1)

- 000-A-Ee-0190470 Rev1 Painting Repair ProcedureDocument34 pages000-A-Ee-0190470 Rev1 Painting Repair Procedureonur gunes100% (2)

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- Ms-07-Method Statement For Earth FillingDocument37 pagesMs-07-Method Statement For Earth FillingAmila Priyadarshana DissanayakeNo ratings yet

- WMS - C&S - 039 - WMS For UPV and Coring TestDocument4 pagesWMS - C&S - 039 - WMS For UPV and Coring TestEchoNo ratings yet

- MS-01-Method Statement For Site EstablishmentDocument26 pagesMS-01-Method Statement For Site EstablishmentAmila Priyadarshana DissanayakeNo ratings yet

- SEP 01 ZAA 1DC 002 Method Statement For Block Work 1Document8 pagesSEP 01 ZAA 1DC 002 Method Statement For Block Work 1usman malik100% (1)

- Docu Ent Sub Ittal Sheet: Qatar Armed Forces Qatar Emiri Corps of EngineeringDocument20 pagesDocu Ent Sub Ittal Sheet: Qatar Armed Forces Qatar Emiri Corps of EngineeringMohameduwais Badurdeen Haqqiyul QadiriNo ratings yet

- Attachment A - Scope of WorkDocument7 pagesAttachment A - Scope of WorkMazhar MahadzirNo ratings yet

- Method Statement of Cable Pulling On Trays, Duct Bank & Cable Trenches - Rev BDocument15 pagesMethod Statement of Cable Pulling On Trays, Duct Bank & Cable Trenches - Rev BDonny Subarja100% (2)

- Method Statement For Bored PilesDocument18 pagesMethod Statement For Bored PilesKaushalye Mahanama Dissanayake100% (3)

- M4 501 01 (R0)Document214 pagesM4 501 01 (R0)ksshashidharNo ratings yet

- 26071-100-VSC-MAH0-40022 - Method Statement For Installation Conduit & Tray Work - 000Document18 pages26071-100-VSC-MAH0-40022 - Method Statement For Installation Conduit & Tray Work - 000ogyrisky100% (1)

- Thissawewa Phase 1Document91 pagesThissawewa Phase 1janithNo ratings yet

- ELT-07-MT-Q-SERV-0001 - Foundation For Truck Loading RackDocument19 pagesELT-07-MT-Q-SERV-0001 - Foundation For Truck Loading RackEl Charasquiada CharroNo ratings yet

- 5779-004-Pvc-W-Specs - 002 - R0Document33 pages5779-004-Pvc-W-Specs - 002 - R0bansalhimanshu07No ratings yet

- Method Statement For Installation of GroundingDocument12 pagesMethod Statement For Installation of GroundingAlvin Jim VillanuevaNo ratings yet

- Section 02300 Earthworks R2Document21 pagesSection 02300 Earthworks R2MØhãmmed ØwięsNo ratings yet

- Cooling Water PumpsDocument143 pagesCooling Water PumpszalabiNo ratings yet

- ROR BQ Arena 2DEC2022 (1) - LatestDocument261 pagesROR BQ Arena 2DEC2022 (1) - LatestJay JayNo ratings yet

- O & M Estimate KC-29 (531+000 To 785+000) 10.2.2022Document465 pagesO & M Estimate KC-29 (531+000 To 785+000) 10.2.2022Muhammad TufailNo ratings yet

- Mas-Rtcf-Ms-El-001-Cable TrayDocument10 pagesMas-Rtcf-Ms-El-001-Cable TrayASHIQUE ZAFARNo ratings yet

- ZWK JSW C Geo 002Document17 pagesZWK JSW C Geo 002bansalhimanshu07No ratings yet

- V-3120-001-A-209-2A Method For Drainage WorkDocument6 pagesV-3120-001-A-209-2A Method For Drainage WorkMajid KhobadNo ratings yet

- ROR BQ Arena 2DEC2022 - LatestDocument196 pagesROR BQ Arena 2DEC2022 - LatestJay JayNo ratings yet

- 26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureDocument25 pages26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureAsril Sang Lentera Senja100% (1)

- SECTION 02 65 00 Underground Storage Tank RemovalDocument8 pagesSECTION 02 65 00 Underground Storage Tank RemovalJuanPaoloYbañezNo ratings yet

- 016 - MS For Full Scale Shear Pad Rev.B - 09 Mar 11Document21 pages016 - MS For Full Scale Shear Pad Rev.B - 09 Mar 11nadraNo ratings yet

- Pressure Grouting Soil Stabilizaion Rev 0Document9 pagesPressure Grouting Soil Stabilizaion Rev 0MohamedOmar83No ratings yet

- Method Statement For Foundation Cm1b 0 SCL Civ Ms 0006 Rev.ADocument127 pagesMethod Statement For Foundation Cm1b 0 SCL Civ Ms 0006 Rev.AMinh HảiNo ratings yet

- No PicDocument36 pagesNo Picapi-3837830No ratings yet

- r2 StadiumDocument69 pagesr2 StadiumRoshan KejariwalNo ratings yet

- Method Statement For Road WorksDocument20 pagesMethod Statement For Road WorksJezrel Gempisao100% (1)

- Saudi Aramco Oil Company: SECTION 02240 Dewatering Part 1 - GeneralDocument4 pagesSaudi Aramco Oil Company: SECTION 02240 Dewatering Part 1 - GeneralPhilip Yap100% (1)

- Secondary IrrigationDocument49 pagesSecondary IrrigationNijasNo ratings yet

- Inspection & Testing Services For Concrete Paving and Earthworks Construction SpecificationDocument11 pagesInspection & Testing Services For Concrete Paving and Earthworks Construction SpecificationJohnny vargas suclupeNo ratings yet

- Mombasa Water Supply and Sanitation Company Limited: Bill of QuantitiesDocument21 pagesMombasa Water Supply and Sanitation Company Limited: Bill of QuantitiesKhairi Ali OmarNo ratings yet

- TOR For Shifting & Extension of Pipeline From Berth2 To 3 For Consultancy WorkDocument14 pagesTOR For Shifting & Extension of Pipeline From Berth2 To 3 For Consultancy WorkSumantra ChattopadhyayNo ratings yet

- SEGS-BHR-CI-AA70-PCD-1042-0 Holiday Testing IFC SignDocument12 pagesSEGS-BHR-CI-AA70-PCD-1042-0 Holiday Testing IFC SignPak WahyuNo ratings yet

- A Con Pro 000 38658 BDocument13 pagesA Con Pro 000 38658 BHussein Adnan FneishNo ratings yet

- QT1 0 Q 030-05-00036 - D - ITP For ESP InstallationDocument26 pagesQT1 0 Q 030-05-00036 - D - ITP For ESP InstallationLâm HuyNo ratings yet

- WRD CSR 2022-23 (Specification)Document973 pagesWRD CSR 2022-23 (Specification)khushal deshmaneNo ratings yet

- Obra C, RFQ For Remaining Boundary Wall Work PC AA SRS (R0, 20220624)Document10 pagesObra C, RFQ For Remaining Boundary Wall Work PC AA SRS (R0, 20220624)ashutoshpathakcivilNo ratings yet

- Method Statement For Drainange Construction Work: Document/Drawing Number: TNEC-STSB-KLIA-CS-MS-013 Revision: ADocument9 pagesMethod Statement For Drainange Construction Work: Document/Drawing Number: TNEC-STSB-KLIA-CS-MS-013 Revision: AAishah AliasNo ratings yet

- BOQ For Vehicles Inspection Lanes 2 - PRICEDDocument67 pagesBOQ For Vehicles Inspection Lanes 2 - PRICEDD A R K S K YNo ratings yet

- MOS - Plumbing and Sanitary Services Rev. 2Document4 pagesMOS - Plumbing and Sanitary Services Rev. 2KAKANo ratings yet

- Technical SpecificationsDocument135 pagesTechnical SpecificationsSrinivasan RajenderanNo ratings yet

- A MTL Pro 000 38673 CDocument21 pagesA MTL Pro 000 38673 CHussein Adnan FneishNo ratings yet

- Working Plan Procedure For GCB and Generator Accessory InstallationDocument38 pagesWorking Plan Procedure For GCB and Generator Accessory InstallationThanh TinhNo ratings yet

- 3045 tsR3Document48 pages3045 tsR3brajesh123No ratings yet

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- SKDDocument5 pagesSKDPaulo VianaNo ratings yet

- Kwasu Solar Load AssessmentDocument7 pagesKwasu Solar Load AssessmentLanre AleNo ratings yet

- CBEprom Data BookDocument65 pagesCBEprom Data BookChelle2100% (2)

- NHMWriter User ManualDocument7 pagesNHMWriter User Manualvelxerox4123No ratings yet

- Canuto v. Mariano G.R. No. L-11346 March 21, 1918Document1 pageCanuto v. Mariano G.R. No. L-11346 March 21, 1918happypammynessNo ratings yet

- Cy17b PH Technical Trial System Protocols v5Document16 pagesCy17b PH Technical Trial System Protocols v5Glenn Cabance LelinaNo ratings yet

- Convolutional Neural Networks in Computer Vision: Jochen LangDocument46 pagesConvolutional Neural Networks in Computer Vision: Jochen LangZichao ZhangNo ratings yet

- VAWA Federalism One-PagerDocument2 pagesVAWA Federalism One-PagerThe National Task Force to End Sexual and Domestic ViolenceNo ratings yet

- Final Paper - Ana Maria PumneaDocument2 pagesFinal Paper - Ana Maria PumneaAnna Pumnea0% (1)

- Underwater Explosive Shock Testing UNDEX CM2000Document11 pagesUnderwater Explosive Shock Testing UNDEX CM2000Maryam RehanNo ratings yet

- Organisation Structure of Ulccs: Director in ChargeDocument1 pageOrganisation Structure of Ulccs: Director in ChargeMohamed RiyasNo ratings yet

- ApduDocument1 pageApduMilen MihailovNo ratings yet

- Chapter 8 - Ethnographic ResearchDocument26 pagesChapter 8 - Ethnographic ResearchNoor SalmanNo ratings yet

- q4 MATH-BATCH 3Document2 pagesq4 MATH-BATCH 3Sofia SyNo ratings yet

- Corrective Action PlanDocument3 pagesCorrective Action Plansohail100% (2)

- Steel PuttyDocument1 pageSteel PuttySiva SubramaniNo ratings yet

- Baires Dev PreentrevistaDocument3 pagesBaires Dev PreentrevistaCarlos Gonzalo Maravi ArensNo ratings yet

- Broton V DA Fitzpatrick (Doc 76) Motion To Strike' Delay Tactic. DA Counsel 'Not Ready'Document2 pagesBroton V DA Fitzpatrick (Doc 76) Motion To Strike' Delay Tactic. DA Counsel 'Not Ready'Desiree YaganNo ratings yet

- Automated Packaging Machine Using PLCDocument7 pagesAutomated Packaging Machine Using PLCTimothy FieldsNo ratings yet

- Sojib VaiDocument2 pagesSojib VaiPeash Mredha80% (5)

- Oracle Cloud Infrastructure Developer Exam Questions - Page 2 of 8 - SkillCertProDocument40 pagesOracle Cloud Infrastructure Developer Exam Questions - Page 2 of 8 - SkillCertProSai Aung Hlyan HtetNo ratings yet

- Culinarian CookwareDocument2 pagesCulinarian Cookwarespaw1108100% (1)

- Reaction Paper - Vocation of The Business Leader, A ReflectionDocument2 pagesReaction Paper - Vocation of The Business Leader, A ReflectionDarwyn Mendoza100% (1)

- Valvula Piston Buschjost 86500Document2 pagesValvula Piston Buschjost 86500Base SistemasNo ratings yet

- Asterisk DocumentationDocument34 pagesAsterisk DocumentationSafaa Shaaban50% (2)

- Audit Sur La Restauration Et La Sécurité: Alerte Rouge Dans Les HôpitauxDocument5 pagesAudit Sur La Restauration Et La Sécurité: Alerte Rouge Dans Les HôpitauxL'express Maurice0% (1)

- Neft Terminləri Lüğəti (Azərbaycan, İngilis, Türk, Rus) 1 - FesilDocument307 pagesNeft Terminləri Lüğəti (Azərbaycan, İngilis, Türk, Rus) 1 - FesilMehemmed Alashrafov67% (3)

- Usando MessageBox C BuilderDocument3 pagesUsando MessageBox C BuilderFernando Luiz Do AmaralNo ratings yet

- For Students - AASTU - EMEng-7253 Grade Report (2023)Document1 pageFor Students - AASTU - EMEng-7253 Grade Report (2023)begosew zelalemNo ratings yet