Professional Documents

Culture Documents

Ba 328 1

Ba 328 1

Uploaded by

ArianeMaeT.Ricabo0 ratings0% found this document useful (0 votes)

9 views1 pageOriginal Title

BA-328-1.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

9 views1 pageBa 328 1

Ba 328 1

Uploaded by

ArianeMaeT.RicaboCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

NAME:

ENUMERATION.

MODIFIED TRUE OR FALSE. 11-12. Benefits of Quality Management Control

1. Quality Manufacturing System (QMS) is a

formalized system that documents processes,

procedures, and responsibilities for achieving

quality policies and objectives. 13-14. 2 Quality Management Principle

2. Progress Flowchart is a graphical representation of

a business process through a flowchart.

3. Quality Management Control isthe application of

the 14 statistical and analytical tools ( 7-QC and 7

SUPP) to monitor process outputs (dependent

Identification:

variables).

_____15. Act of overseeing all activities task

4. Statistical Process Control is the application of the

needed to maintain a desired level of excellence.

same 14 tools to control process inputs

(independent variables). _____16. Developed the zero defect concept and

a prime mover to promote the expansion of the

5. Defect Maps is an advanced attribute module SPC

quality concepts, theories and principles.

Vision Software.

_____17. Are local files recording all the

6. ISO 9001:2000 is used as an aid to help

happenings on the system and it includes

organizations better understand ISO terms and

accessing and deleting.

principles.

_____18. Separation of data into smaller strata

7. Sample Size Determination minimizes the

based on a predetermined set of criteria.

differences among groups by equally distributing

people with particular characteristics among all _____19. Act of choosing the number of

trial arms. observation or replicates to include in a statistical

sample.

8. Six Sigma is a production philosophy that uses

data, processes, and tools to nearly eliminate _____20. Ensure employees are recognized and

defects and bring performance close to perfection. rewarded for bringing challenges in the process to

the forefront.

9. Father of statistical process control and developed

six sigma is Kaoro Ishikawa.

10. Walter Shewart is the father of quality.

You might also like

- The Six Sigma Way Team Fieldbook: An Implementation Guide for Process Improvement TeamsFrom EverandThe Six Sigma Way Team Fieldbook: An Implementation Guide for Process Improvement TeamsRating: 3.5 out of 5 stars3.5/5 (5)

- Computer Aided Audit TechniqueDocument24 pagesComputer Aided Audit TechniqueTeddy HaryadiNo ratings yet

- Client Predictive Analytics Proposal PDFDocument7 pagesClient Predictive Analytics Proposal PDFPeter Karpiuk100% (1)

- The Markstrat.7 Challenge 1 (MS7 SM B2C DG)Document35 pagesThe Markstrat.7 Challenge 1 (MS7 SM B2C DG)MuskaanNo ratings yet

- Herborist CaseDocument7 pagesHerborist CaseRanjani Cool Ranjani0% (1)

- CMM Part3 - CMMIDocument81 pagesCMM Part3 - CMMIgaming zoneNo ratings yet

- Chapter 8 QualityDocument11 pagesChapter 8 QualityMariam HeikalNo ratings yet

- Unit 1 SIADocument68 pagesUnit 1 SIAPHONY BALONEYNo ratings yet

- CMM PDFDocument34 pagesCMM PDFShubham JhaNo ratings yet

- Lean Six Sigma - 20021241093 - 20021241095 - 20021241128 - PPTDocument16 pagesLean Six Sigma - 20021241093 - 20021241095 - 20021241128 - PPTRohit SatijaNo ratings yet

- Lean Six Sigma - 20021241093 - 20021241095 - 20021241128 - PPTDocument16 pagesLean Six Sigma - 20021241093 - 20021241095 - 20021241128 - PPTRohit SatijaNo ratings yet

- 08 Project Quality ManagementDocument46 pages08 Project Quality ManagementsimukondakelvinNo ratings yet

- Six Sigma and Its MethodologyDocument11 pagesSix Sigma and Its Methodologyshreya_sawhneyNo ratings yet

- UCI 202 Topic 7 NotesDocument17 pagesUCI 202 Topic 7 Notesaroridouglas880No ratings yet

- Acquisition, Development and Implementation of Information SystemsDocument32 pagesAcquisition, Development and Implementation of Information SystemsSatrughan ThapaNo ratings yet

- Six SigmaDocument11 pagesSix SigmaHarshaTupakulaNo ratings yet

- Information Technology Project Management, Seventh EditionDocument46 pagesInformation Technology Project Management, Seventh EditionPUise ThitalampoonNo ratings yet

- Maturity Model ResearchDocument9 pagesMaturity Model ResearchJuan Carlos Valencia OsorioNo ratings yet

- Process Improvement and Six Sigma: Managing For Quality and Performance Excellence, 10E, © 2017 Cengage PublishingDocument52 pagesProcess Improvement and Six Sigma: Managing For Quality and Performance Excellence, 10E, © 2017 Cengage PublishingSambil MukwakunguNo ratings yet

- Extra Readings - Lean SystemsDocument6 pagesExtra Readings - Lean Systemsabhinav.k0509No ratings yet

- CS605 Grand Quiz by JunaidDocument16 pagesCS605 Grand Quiz by JunaidtarhumNo ratings yet

- Operations ManagementDocument1 pageOperations ManagementSouravNo ratings yet

- Lect 9 - Lean Sixsigma - Part - IIIDocument46 pagesLect 9 - Lean Sixsigma - Part - IIIlangzayNo ratings yet

- Chapter 1 - Sesi II 2021 2022 - Road Trip Dfc40243Document58 pagesChapter 1 - Sesi II 2021 2022 - Road Trip Dfc40243ShaluNo ratings yet

- ACMP ID-10716-10717-10723-10727-10729 - ST@MPS - Final Report - Quality Framwork For Organization FirmDocument21 pagesACMP ID-10716-10717-10723-10727-10729 - ST@MPS - Final Report - Quality Framwork For Organization FirmAHM Pervej KabirNo ratings yet

- Ch08 PMDocument46 pagesCh08 PMPUise ThitalampoonNo ratings yet

- Stqa 5Document4 pagesStqa 5HarshaaalNo ratings yet

- SE351-Software Construction and Development: Instructor: M. SufianDocument27 pagesSE351-Software Construction and Development: Instructor: M. SufianMuhammad FaisalNo ratings yet

- Software Development Methodologies: PG-DAC March 2022 BatchDocument41 pagesSoftware Development Methodologies: PG-DAC March 2022 BatchAmol PatilNo ratings yet

- Six Sigma Wikipedia Aug 7 2016Document11 pagesSix Sigma Wikipedia Aug 7 2016mizar.g91No ratings yet

- LSS Guide For DummiesDocument25 pagesLSS Guide For DummiesIsabella AvaNo ratings yet

- Chapter 9Document8 pagesChapter 9angelicaNo ratings yet

- K010237 13 - Process - Defs - Develop and Manage Business Capabilities - Oct2019 - v7.2.1 - 2Document29 pagesK010237 13 - Process - Defs - Develop and Manage Business Capabilities - Oct2019 - v7.2.1 - 2nazirkuraNo ratings yet

- Simplifying Six Sigma Methodology Using Shainin D.O.EDocument6 pagesSimplifying Six Sigma Methodology Using Shainin D.O.EVasant bhoknalNo ratings yet

- Chap08 ProjectqualitymanagementDocument30 pagesChap08 Projectqualitymanagementiliya maisarahNo ratings yet

- Se Unit 1.2Document37 pagesSe Unit 1.2Hemanth GoliNo ratings yet

- Six Sigma and Process Improvement: Teaching NotesDocument53 pagesSix Sigma and Process Improvement: Teaching NotesCris Jeriko JimenezNo ratings yet

- A Framework For Improving Key Performance Indicators Using Business Intelligence TechniquesDocument5 pagesA Framework For Improving Key Performance Indicators Using Business Intelligence TechniquesInternational Journal of Innovative Science and Research Technology100% (1)

- PROCESS Improvement Methodologies Are Systematic Approaches and Frameworks Used by Organizations To Enhance Their ProcessesDocument6 pagesPROCESS Improvement Methodologies Are Systematic Approaches and Frameworks Used by Organizations To Enhance Their ProcessesAlojha Mae AbrenicaNo ratings yet

- Information Technology Project Management, Seventh EditionDocument67 pagesInformation Technology Project Management, Seventh EditionزهديابوانسNo ratings yet

- PPTDocument50 pagesPPTNiomi Golrai100% (1)

- Accounting Information System Chapter 20 QuestionsDocument1 pageAccounting Information System Chapter 20 QuestionsAUDEH AHMADNo ratings yet

- Is-6 - 3Document5 pagesIs-6 - 3Ishan MadushankaNo ratings yet

- Software Development ModelsDocument91 pagesSoftware Development ModelsgoshoNo ratings yet

- Project Quality Management: Lec. Muhammad Hasnain Dept. of CE&MDocument20 pagesProject Quality Management: Lec. Muhammad Hasnain Dept. of CE&MhassanNo ratings yet

- LIS AssignmentDocument4 pagesLIS AssignmentReman A. AlingasaNo ratings yet

- Karolina Muszyńska: Based On HTTP://WWW - Csun.edu/ dn58412/IS431/IS431 - SP13.htmlDocument34 pagesKarolina Muszyńska: Based On HTTP://WWW - Csun.edu/ dn58412/IS431/IS431 - SP13.htmlMuhammad SaktoNo ratings yet

- Increased Productivity Through Six Sigma: International Journal of Emerging Technology and Advanced EngineeringDocument6 pagesIncreased Productivity Through Six Sigma: International Journal of Emerging Technology and Advanced EngineeringIrshad AliNo ratings yet

- ISYS6225 - Sesi 13 - LNDocument12 pagesISYS6225 - Sesi 13 - LNAjeng Dyahayu WindaniNo ratings yet

- CH 2Document20 pagesCH 2ARRAHMANNo ratings yet

- SUB158963Document8 pagesSUB158963karen leonNo ratings yet

- Six Sigma Information PDFDocument17 pagesSix Sigma Information PDFFidel AragonNo ratings yet

- Software Engineering Concepts E: FacultyDocument40 pagesSoftware Engineering Concepts E: FacultyAnchalNo ratings yet

- Introduction To Simulation: MS 5225 Business Process Modeling & SimulationDocument43 pagesIntroduction To Simulation: MS 5225 Business Process Modeling & SimulationMatthew ZNo ratings yet

- Documento de DiagramaDocument53 pagesDocumento de DiagramaCris Jeriko JimenezNo ratings yet

- Overview of SDLC: Explain The Process For Auditing System DevelopmentDocument3 pagesOverview of SDLC: Explain The Process For Auditing System Developmentelly-naike nkyaNo ratings yet

- Continuous Improvement Group 8Document18 pagesContinuous Improvement Group 8Hùng Bùi MinhNo ratings yet

- System Development Life Cycle: (SDLC)Document25 pagesSystem Development Life Cycle: (SDLC)Yuni MuhammadNo ratings yet

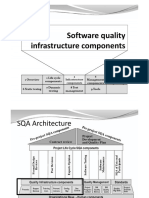

- Chapter 3 - Software Quality Infrastructure ComponentsDocument123 pagesChapter 3 - Software Quality Infrastructure ComponentsLộc TấnNo ratings yet

- Lec 3 - Software Quality Assurance (SQA)Document37 pagesLec 3 - Software Quality Assurance (SQA)Eugene TeyNo ratings yet

- Six Sigma: For Other Uses, See Sigma 6Document14 pagesSix Sigma: For Other Uses, See Sigma 6Edukondalu PentapatiNo ratings yet

- Building Better Policies: The Nuts and Bolts of Monitoring and Evaluation SystemsFrom EverandBuilding Better Policies: The Nuts and Bolts of Monitoring and Evaluation SystemsNo ratings yet

- Assignment 2Document675 pagesAssignment 2ArianeMaeT.RicaboNo ratings yet

- Editha M. Donoso: Personal InformationDocument2 pagesEditha M. Donoso: Personal InformationArianeMaeT.RicaboNo ratings yet

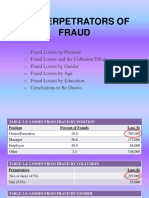

- The Perpetrators of FraudDocument20 pagesThe Perpetrators of FraudArianeMaeT.RicaboNo ratings yet

- Number Messages Handbook 2019Document25 pagesNumber Messages Handbook 2019ArianeMaeT.Ricabo100% (1)

- Ariane BA 328 FinalDocument33 pagesAriane BA 328 FinalArianeMaeT.RicaboNo ratings yet

- Quanta Services Inc. Initiating Coverage ReportDocument12 pagesQuanta Services Inc. Initiating Coverage Reportmikielam23No ratings yet

- The Company Aalen, MapalDocument40 pagesThe Company Aalen, MapalsivanesanmailNo ratings yet

- GeM Suneeta FoundryDocument9 pagesGeM Suneeta FoundryMDL COMMNo ratings yet

- OBLI Chapter 4 - Extinguishment of ObligationDocument16 pagesOBLI Chapter 4 - Extinguishment of ObligationGabby Pundavela100% (2)

- Assignment 2 Asna202309001Document3 pagesAssignment 2 Asna202309001Rameez KhanNo ratings yet

- Aircraft MaintenanceDocument16 pagesAircraft MaintenancebogosilekNo ratings yet

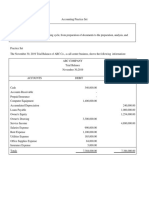

- ABC CompanyDocument11 pagesABC CompanyA DiolataNo ratings yet

- Eoa PDFDocument45 pagesEoa PDFduki banaNo ratings yet

- Synthite-Recipes For SuccessDocument17 pagesSynthite-Recipes For SuccessAbhishek SinghalNo ratings yet

- ECGC Slide ShareDocument17 pagesECGC Slide ShareBiswajit DuttaNo ratings yet

- AutoInvoiceExecution - Auto Invoice Execution ReportDocument97 pagesAutoInvoiceExecution - Auto Invoice Execution Reportahmedmhrous0000No ratings yet

- Analisa Pengaruh Fasilitas Dan Kepuasan Pelanggan Terhadap Loyalitas Pelanggan Menginap Di Mikie Holiday Resort Dan Hotel BerastagiDocument13 pagesAnalisa Pengaruh Fasilitas Dan Kepuasan Pelanggan Terhadap Loyalitas Pelanggan Menginap Di Mikie Holiday Resort Dan Hotel BerastagiAisa WaNo ratings yet

- Adoption Metrics Template 2018Document8 pagesAdoption Metrics Template 2018George Cristian Aquiño HuamanNo ratings yet

- Sap StoDocument7 pagesSap StoPavilion67% (3)

- Market Capitalization (Often Market Cap) Is A Measurement of Size of A Business EnterpriseDocument4 pagesMarket Capitalization (Often Market Cap) Is A Measurement of Size of A Business EnterpriseAnshuman SaikiaNo ratings yet

- IIY 32 RevisedDocument8 pagesIIY 32 RevisedSybroMullisieNo ratings yet

- Global Water Intelligence Media Pack 2015Document22 pagesGlobal Water Intelligence Media Pack 2015GlobalWaterIntelNo ratings yet

- F6 - Taxation BPP Workbook 2021-22Document759 pagesF6 - Taxation BPP Workbook 2021-22AaryanNo ratings yet

- HR List PuneDocument260 pagesHR List PuneSumit Ghosal50% (2)

- Accounting PrinciplesDocument79 pagesAccounting PrinciplesmurugavelsNo ratings yet

- April 22Document48 pagesApril 22fijitimescanadaNo ratings yet

- Erd.2.f.008 Sworn AffidavitDocument2 pagesErd.2.f.008 Sworn Affidavitblueberry712No ratings yet

- DifferentiationDocument9 pagesDifferentiationMohammad RobinNo ratings yet

- Sales Career in ITC - STR 2022-MumbaiDocument2 pagesSales Career in ITC - STR 2022-MumbaiKuhu MiglaniNo ratings yet

- About The BrandDocument19 pagesAbout The Brandguest5624No ratings yet

- Corporate Training Calendar PDFDocument12 pagesCorporate Training Calendar PDFmacsaravanNo ratings yet

- C C & &$ c0cDocument38 pagesC C & &$ c0ckrismmmmNo ratings yet

- REVIEWDocument11 pagesREVIEWROGER DamianNo ratings yet