Professional Documents

Culture Documents

BR 1701 PDF

BR 1701 PDF

Uploaded by

destiny2bnCopyright:

Available Formats

You might also like

- OSHA Letter Regarding Kaukauna Mill DeathDocument3 pagesOSHA Letter Regarding Kaukauna Mill DeathFOX 11 NewsNo ratings yet

- Boiler Corrosion MagnetiteDocument14 pagesBoiler Corrosion MagnetiteJakeTheSnake69100% (1)

- Overheating and Fuel Ash Corrosion Failure of Boiler TubeDocument18 pagesOverheating and Fuel Ash Corrosion Failure of Boiler TubeJackSparrow86No ratings yet

- Superheater and Reheater Outlet Header Inspections FailuresDocument65 pagesSuperheater and Reheater Outlet Header Inspections Failureskaruna346No ratings yet

- Relationship Between Microstructure and Ductility of Investment Cast ASTM F-75 Implant AlloyDocument7 pagesRelationship Between Microstructure and Ductility of Investment Cast ASTM F-75 Implant AlloyCatarina Pinto100% (1)

- Certificate of Analysis: National Institute of Standards and TechnologyDocument5 pagesCertificate of Analysis: National Institute of Standards and TechnologyJohn GiannakopoulosNo ratings yet

- Continental-4rev 0302 PDFDocument24 pagesContinental-4rev 0302 PDFLuis Mejia AlbarracinNo ratings yet

- Boiler Life EstimationDocument5 pagesBoiler Life EstimationHalim Selamat100% (1)

- Fatigue CorrosionDocument2 pagesFatigue Corrosionaop10468No ratings yet

- Hot Corrosion Performance of Alloy and Composite CoatingsDocument12 pagesHot Corrosion Performance of Alloy and Composite CoatingsHarkulvinder SinghNo ratings yet

- EPRI Atlas of Steamside Oxide ObservationsDocument12 pagesEPRI Atlas of Steamside Oxide Observationsekrem turan100% (2)

- 1584Document6 pages1584malsttarNo ratings yet

- 58 Weld Repairs - Creep PerformanceDocument21 pages58 Weld Repairs - Creep PerformanceLTE002No ratings yet

- WJ - 1982 - R B Dooley Dissimilar Weld Boiler Tube FailureDocument5 pagesWJ - 1982 - R B Dooley Dissimilar Weld Boiler Tube FailureKuthuraikaranNo ratings yet

- Chapter 14 Boiler System Failures: Deaerator CrackingDocument22 pagesChapter 14 Boiler System Failures: Deaerator CrackingVijay RajaindranNo ratings yet

- Creep - Iwshibli PDFDocument32 pagesCreep - Iwshibli PDFIvanUribeNo ratings yet

- Bor1991 - Effect of Pearlite Banding On Mechanical Properties of Perlitic SteelDocument12 pagesBor1991 - Effect of Pearlite Banding On Mechanical Properties of Perlitic SteelAlejandroAcuñaMaureiraNo ratings yet

- 30 Ncmer037Document16 pages30 Ncmer037Arslan ArshadNo ratings yet

- Status of Advanced Ultra-Supercritical Pulverised Coal Technology - ccc229Document57 pagesStatus of Advanced Ultra-Supercritical Pulverised Coal Technology - ccc229sarangss100% (1)

- ManufProc 4 BulkFormingDocument96 pagesManufProc 4 BulkFormingHannan yusuf KhanNo ratings yet

- Advanced Boiler TubeDocument2 pagesAdvanced Boiler TubeShailendra WaniNo ratings yet

- Limits and State of The Art of The New Creep Resistant SteelsDocument64 pagesLimits and State of The Art of The New Creep Resistant SteelsRené Galbraith BerraNo ratings yet

- Corrosion of Water Walls and Superheaters in Wte MSW PlantsDocument114 pagesCorrosion of Water Walls and Superheaters in Wte MSW Plantsvijay_nani124No ratings yet

- HRSG High Pressure Evaporator Sampling For Internal DepositDocument26 pagesHRSG High Pressure Evaporator Sampling For Internal Depositak_thimiriNo ratings yet

- Corrosion Failures of AISI Type 304 Stainless Steel in A Fertiliser PlantDocument11 pagesCorrosion Failures of AISI Type 304 Stainless Steel in A Fertiliser PlantAndrea CalderaNo ratings yet

- Effect Scale Formation in Boiler Water Wall TubesDocument7 pagesEffect Scale Formation in Boiler Water Wall TubesRishabh ChaureNo ratings yet

- Condition Assessment of BoilerDocument8 pagesCondition Assessment of BoilerEzhil Vendhan PalanisamyNo ratings yet

- Finding The Root Cause of Boiler Tube FailuresDocument17 pagesFinding The Root Cause of Boiler Tube Failuresjgv100% (1)

- State of Maryland Final Report Task Force To Study Pinhole Leaks in Copper PlumbingDocument65 pagesState of Maryland Final Report Task Force To Study Pinhole Leaks in Copper PlumbingSyavash EnshaNo ratings yet

- Bulging Rupture and Caustic Corrosion of A Boiler Tube in A ThermalDocument8 pagesBulging Rupture and Caustic Corrosion of A Boiler Tube in A Thermaladventius S.SNo ratings yet

- Case Study On Copper CorrosionDocument15 pagesCase Study On Copper CorrosionClaudia MmsNo ratings yet

- LABORELEC Conventional Power Plant Materials Course V2 PDFDocument90 pagesLABORELEC Conventional Power Plant Materials Course V2 PDFkatfy1100% (1)

- Feed Water Pipe FailureDocument9 pagesFeed Water Pipe Failuredafteri11No ratings yet

- Boiler MaterialsDocument5 pagesBoiler MaterialsRavi ShankarNo ratings yet

- The Implementation of A Steam Transformer PDFDocument9 pagesThe Implementation of A Steam Transformer PDFASHIL PRABHAKARNo ratings yet

- Condensate in HRSG PDFDocument15 pagesCondensate in HRSG PDFCoalhouse Walker JuniorNo ratings yet

- GSC Steam Turbine CastingsDocument10 pagesGSC Steam Turbine CastingsJozsef Magyari100% (1)

- Waterwall - Fireside CorrosionDocument8 pagesWaterwall - Fireside CorrosionwahonodNo ratings yet

- Boiler Tube Investigation PDFDocument6 pagesBoiler Tube Investigation PDFHussseinmubarkNo ratings yet

- Superheater Corrosion in USC Power PlantDocument136 pagesSuperheater Corrosion in USC Power PlantDanie-Els100% (1)

- V B01B0005B-15GB PDFDocument20 pagesV B01B0005B-15GB PDFनिपुण कुमारNo ratings yet

- Prediction of Oxide Scale Growth in Superheater and Reheater TubesDocument8 pagesPrediction of Oxide Scale Growth in Superheater and Reheater TubesMas ZuhadNo ratings yet

- Mohammad Rasul Ed. Thermal Power Plants Advanced ApplicationsDocument185 pagesMohammad Rasul Ed. Thermal Power Plants Advanced Applicationssurafel amareNo ratings yet

- OsidationDocument49 pagesOsidationSadhasivam VeluNo ratings yet

- 226 Eddystone Station UnitDocument24 pages226 Eddystone Station UnitsbktceNo ratings yet

- Welding Procedures of Turbine Blades by Using ER 309L Austenitic Filler WireDocument8 pagesWelding Procedures of Turbine Blades by Using ER 309L Austenitic Filler Wireeko siswono100% (1)

- BS-EN Comparison ChartDocument14 pagesBS-EN Comparison ChartIan Stewart PorterNo ratings yet

- Cap Boiler ManualDocument43 pagesCap Boiler Manualdnageshm4n244100% (1)

- Fireside Corrosion of Alloys For Combustion Power PlantsDocument11 pagesFireside Corrosion of Alloys For Combustion Power Plantsdealer82No ratings yet

- 07 Thermal StressDocument13 pages07 Thermal StressSundaravathanan ChellappanNo ratings yet

- Astm 4140 PDFDocument3 pagesAstm 4140 PDFRameshNo ratings yet

- BR 170 1Document7 pagesBR 170 1Himanshu ChaturvediNo ratings yet

- SHELL BOILERS - Guidelines For ExaminationDocument28 pagesSHELL BOILERS - Guidelines For ExaminationSH1961100% (1)

- RLA in High Temp Zones of Power Plant ComponentsDocument7 pagesRLA in High Temp Zones of Power Plant ComponentsEzhil Vendhan PalanisamyNo ratings yet

- Safe Remaining Lifetime Assesment of Power Plant Steam BoilersDocument9 pagesSafe Remaining Lifetime Assesment of Power Plant Steam Boilersmuh4iminNo ratings yet

- Strategies For Inspecting Hrsgs in Two-Shift and Low-Load ServiceDocument12 pagesStrategies For Inspecting Hrsgs in Two-Shift and Low-Load ServicevnchromeNo ratings yet

- Case Study - Boiler Condition and Life AssessmentDocument2 pagesCase Study - Boiler Condition and Life AssessmentfelramNo ratings yet

- Early Failure of Waste Heat Boiler and Redesign To Overcome Premature FailureDocument5 pagesEarly Failure of Waste Heat Boiler and Redesign To Overcome Premature FailureEjaj SiddiquiNo ratings yet

- Boiler Tubes Overheating Failures and Actions To Control ThemDocument2 pagesBoiler Tubes Overheating Failures and Actions To Control ThemThanhluan NguyenNo ratings yet

- Coke Drum Monitoring Inspection Assessment and Repair For Service Life Improvement Chadda Foster Wheeler DCU Rio de Janiero 2014Document31 pagesCoke Drum Monitoring Inspection Assessment and Repair For Service Life Improvement Chadda Foster Wheeler DCU Rio de Janiero 2014Piyush PrasadNo ratings yet

- 12 01 01 GL V01 - Commissioning Management GuidelineDocument32 pages12 01 01 GL V01 - Commissioning Management Guidelinedestiny2bn100% (2)

- RAL Code ClassificationDocument8 pagesRAL Code Classificationdestiny2bnNo ratings yet

- Turnover Sub-System ScheduleDocument94 pagesTurnover Sub-System Scheduledestiny2bnNo ratings yet

- How To Read P and IDs PDFDocument62 pagesHow To Read P and IDs PDFdestiny2bnNo ratings yet

- Performance - Test - Codes - C0 - PTC 4.2 PDFDocument27 pagesPerformance - Test - Codes - C0 - PTC 4.2 PDFdestiny2bnNo ratings yet

- Global Blockchain Congress: Consensus 2018Document11 pagesGlobal Blockchain Congress: Consensus 2018destiny2bnNo ratings yet

- ASME ANSI STD PTC 19.3 1974 Temperature Measurement Instruments and Apparatus IDocument141 pagesASME ANSI STD PTC 19.3 1974 Temperature Measurement Instruments and Apparatus Idestiny2bn100% (1)

- Project Finance - Non PDFDocument8 pagesProject Finance - Non PDFdestiny2bnNo ratings yet

- Frame 9FA Erection ProcedureDocument25 pagesFrame 9FA Erection Proceduredestiny2bn93% (15)

- Rita Sixth Edition - PMBOK 4Document548 pagesRita Sixth Edition - PMBOK 4destiny2bnNo ratings yet

- Figs v. My Open Heart - ComplaintDocument30 pagesFigs v. My Open Heart - ComplaintSarah BursteinNo ratings yet

- Synopsis On Study of Debit Card in INDIAN SCENERIODocument5 pagesSynopsis On Study of Debit Card in INDIAN SCENERIOHapi ERNo ratings yet

- Supportand Resistance Trading StrategyDocument10 pagesSupportand Resistance Trading StrategyEng Abdikariim AbdillahiNo ratings yet

- Ranjan Bose Information Theory Coding and Cryptography Solution ManualDocument61 pagesRanjan Bose Information Theory Coding and Cryptography Solution ManualANURAG CHAKRABORTY89% (38)

- Thesis 2Document15 pagesThesis 2El TabianNo ratings yet

- Module-2 Eco-598 ML & AiDocument12 pagesModule-2 Eco-598 ML & AiSoujanya NerlekarNo ratings yet

- The Effects of TikTok Usage On Grade 11 Students of San Fabian National High SchoolDocument16 pagesThe Effects of TikTok Usage On Grade 11 Students of San Fabian National High SchoolKzz PerezNo ratings yet

- Popular CultureDocument2 pagesPopular CultureChloe GuiaoNo ratings yet

- Ielts Speaking Sample Week 8Document8 pagesIelts Speaking Sample Week 8Onyekachi JackNo ratings yet

- Implementing A Risk Management FrameworkDocument51 pagesImplementing A Risk Management FrameworkSayyid ShalahuddinNo ratings yet

- Sampling Unit:: Sampling Theory - Chapter 1 - Introduction - Shalabh, IIT KanpurDocument11 pagesSampling Unit:: Sampling Theory - Chapter 1 - Introduction - Shalabh, IIT KanpurMuskan ManchandaNo ratings yet

- Ms - Shruti Vs Baldev Singh and Others On 23 May, 2017Document8 pagesMs - Shruti Vs Baldev Singh and Others On 23 May, 2017spgkumar7733No ratings yet

- NTA NET Political Science Paper 2 December 2015Document24 pagesNTA NET Political Science Paper 2 December 2015Mohammad Shahbaz KhanNo ratings yet

- QUT Stage2 Document Avijit PaulDocument21 pagesQUT Stage2 Document Avijit PaulAvijit PaulNo ratings yet

- Bose The Untold Story of An Inconvenient NationalistDocument968 pagesBose The Untold Story of An Inconvenient NationalistSumit KhandaitNo ratings yet

- Concepts in Enterprise Resource Planning: Chapter One Business Functions and Business ProcessesDocument48 pagesConcepts in Enterprise Resource Planning: Chapter One Business Functions and Business ProcessesFenri GreenNo ratings yet

- Chapter 11: Radiation: 11.1 Dipole Radiation 11.1.1 What Is Radiation? 11.1.2 Electric Dipole RadiationDocument4 pagesChapter 11: Radiation: 11.1 Dipole Radiation 11.1.1 What Is Radiation? 11.1.2 Electric Dipole RadiationMadhumika ThammaliNo ratings yet

- Kunci Jawaban Pat X Bahasa InggrisDocument5 pagesKunci Jawaban Pat X Bahasa InggrisjuraganshuleeNo ratings yet

- Objectives IPCRF 2021 2022Document19 pagesObjectives IPCRF 2021 2022Melanie Marquez - FernandezNo ratings yet

- Višegrad Genocide, What Is?Document1 pageVišegrad Genocide, What Is?Visegrad GenocideNo ratings yet

- Philippine - Airlines - Inc. - v. - Santos - JR - DigestDocument2 pagesPhilippine - Airlines - Inc. - v. - Santos - JR - DigestAllen Windel BernabeNo ratings yet

- Project Essay FinalDocument5 pagesProject Essay Finalapi-534828614No ratings yet

- Mohamed Bin Zayed Al Nahyan - WikipediaDocument26 pagesMohamed Bin Zayed Al Nahyan - WikipediaJeel VoraNo ratings yet

- 2022 Anatmoy and Physiology Cheat Sheet!Document3 pages2022 Anatmoy and Physiology Cheat Sheet!Estella BrockwellNo ratings yet

- Bearers - Default and DedicatedDocument2 pagesBearers - Default and Dedicatedshaan19No ratings yet

- HGP DLPDocument2 pagesHGP DLPCorona Virus100% (1)

- 2 Faktor-Faktor-Yang-Berhubungan-Dengan-TiDocument9 pages2 Faktor-Faktor-Yang-Berhubungan-Dengan-TiofislinNo ratings yet

- Plaintiffs-Appellants Opening Brief: Ronald Pierce et al vs. Chief Justice Tani Cantil-Sakauye Judicial Council Chair and Steven Jahr Judicial Council Administrative Director - Federal Class Action Lawsuit for Alleged Illegal Use of California Vexatious Litigant Law by Family Court Judges in Child Custody Disputes - Ventura County - Tulare County - Sacramento County - San Mateo County - Santa Clara County - Riverside County - San Francisco County - US District Court for the Northern District of California Judge Jeffrey S. White - US Courts for the Ninth Circuit - 9th Circuit Court of Appeal Class Action for Injunctive and Declaratory ReliefDocument285 pagesPlaintiffs-Appellants Opening Brief: Ronald Pierce et al vs. Chief Justice Tani Cantil-Sakauye Judicial Council Chair and Steven Jahr Judicial Council Administrative Director - Federal Class Action Lawsuit for Alleged Illegal Use of California Vexatious Litigant Law by Family Court Judges in Child Custody Disputes - Ventura County - Tulare County - Sacramento County - San Mateo County - Santa Clara County - Riverside County - San Francisco County - US District Court for the Northern District of California Judge Jeffrey S. White - US Courts for the Ninth Circuit - 9th Circuit Court of Appeal Class Action for Injunctive and Declaratory ReliefCalifornia Judicial Branch News Service - Investigative Reporting Source Material & Story IdeasNo ratings yet

- Maritime LawDocument3 pagesMaritime LawKumar SudarshanNo ratings yet

BR 1701 PDF

BR 1701 PDF

Uploaded by

destiny2bnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BR 1701 PDF

BR 1701 PDF

Uploaded by

destiny2bnCopyright:

Available Formats

Standard Recommendations for Pressure Part

Inspection During a Boiler Life Extension Program

M.N. Hovinga

G.J. Nakoneczny

Babcock & Wilcox

Barberton, Ohio, U.S.A.

Presented to: BR-1701

ICOLM (International Conference on Life Management

and Life Extension of Power Plant)

May 2000

Xi’an, P.R. China

Abstract should be made based on that unit’s history and operating char-

Due to the high costs of new boiler fabrication and erection, acteristics. The more information known about a specific unit,

increasing efforts are being made to extend the life of existing the more a detailed and cost effective inspection plan can be

units. The life extension and reliability of these plants is under- developed.

mined if unscheduled and forced outages occur. Determination

of the pressure parts requiring inspection, type of inspections Inspection Plan

to be performed, and the amount and location of these inspec- The inspection scope depends on several factors such as the

tions has always been a major concern in boiler life extension. boiler design type, design temperatures and pressures, materi-

The complexity of the problem increases when the boiler’s age, als, fuels, age, unit history, as well as future plans and operat-

operating history, and failure history are taken into account. Over ing conditions. B&W follows a multi-level approach in the plan-

the years, The Babcock & Wilcox Company has inspected and ning of the survey scope.

provided life extension recommendations on boilers of every In Level 1 of a Condition Assessment inspection plan, an

style from every manufacturer around the world. These recom- evaluation of the plant’s operating history and review of his-

mendations are based on B&W’s accumulated experience. This torical problem areas is performed. Based on this review, a de-

paper presents Babcock & Wilcox’s approach for the recom- tailed inspection plan is developed and implemented in Level

mendations for boiler pressure part life extension inspection re- 2. Nondestructive examination is then used to evaluate the cur-

quirements to ensure the safe and reliable operation of boilers. rent condition and estimate the remaining life of the inspected

components. After the conclusion of the inspection program,

the results are used in the planning of re-inspection and regular

Introduction preventive maintenance to ensure reliable operation. The inspec-

The goals of today’s condition assessment and life exten- tion is centered around the critical components. Generally, the

sion programs are to increase the availability, efficiency, and critical components are those whose failure will directly affect

reliability of the existing power plants and ensure safe and cost the reliability of the boiler. The critical components can be pri-

effective operation. In planning a condition assessment program, oritized by the impact they have on safety, reliability, and per-

it is important to look at both the operating history and objec- formance. These critical pressure parts include:

tives for the boiler. Presented in the following paper is the pro- ● Drums–steam, lower

gram and methods recommended for the assessment of the boiler ● Headers–both steam and water

pressure parts. The recommendations consider the typical areas ● Tubing–superheater, generating, waterwall, economizer

of concern. However, they are not intended to address every ● Piping–steam and feedwater

boiler or be all inclusive of every problem that may be encoun- ● Deaerator–may have special safety concerns

tered. All inspection plans are unique to the specific unit and ● Attemperators

Babcock & Wilcox 1

The inspection work scope is based on the individual unit’s Hot Side

operating history, failure history, and expected failure mecha- (12 O’Clock Position)

nisms for each critical pressure part.

Following are typical inspection plans for critical pressure

parts. These inspection plans are expected to be altered based

on any additional unit information. Initially a comprehensive

inspection of each pressure component should be made to give

baseline data for future reference. Although expensive and time

consuming, the advantage to this method is that it determines a

time frame when any damage has occurred.

ID Surface

Boiler Drums

Steam drum The steam drum is the most expensive boiler

component and must be included in any comprehensive condi-

tion assessment program. There are two types of steam drums,

the all welded design used predominantly in electric utilities

where the operating pressures exceed 1800 psi (124 bar), and

drums with rolled tubes. Because of its relatively low operating

temperature, the drum is made of carbon steel and is rarely sub-

ject to significant creep damage. Creep is defined as increasing

strain at a constant stress over time. Vernier Scale 1 div. = 0.5 mil 100X

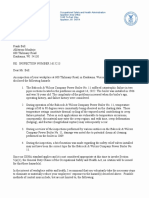

Damage is primarily due to internal metal loss. The causes Fig. 1 Steam side oxide scale on ID surface.

of metal loss include corrosion and oxidation, which can occur

during extended outages, acid attack, oxygen pitting, and chelant Drum Life Assessment In the absence of any significant dam-

attack. Damage can also occur from mechanical and thermal age the drum will normally not be life-limited as it is not sub-

stresses on the drum which concentrate at nozzle and attach- ject to significant creep.

ment welds. These stresses, most often associated with boilers

that are on/off cycled, can result in crack development. Cyclic Boiler Tubing

operation can lead to drum distortion (humping) and can result Boiler tube failures are the primary cause of forced outages.

in concentrated stresses at the major support welds, seam welds, Complete texts are available to address all the problems and

and girth welds. The feedwater penetration area has the great- damage mechanisms that can lead to failures(1) and we have not

est thermal differential because incoming feedwater can be sev- attempted to identify or discuss every damage mechanism in

eral hundred degrees below drum temperature. Based on this, this paper.

these areas should be inspected during any boiler life extension Steam-cooled Steam-cooled tubing is found in the super-

program. heater (high pressure) and reheat superheater. Both components

A problem unique to steam drums with rolled tube seats is have tubes subjected to the effects of metal creep. Because most

tube seat weepage (slight seeping of water through the rolled boilers targeted for condition assessment are at least 20 years

joint). If the leak is not stopped, the joint, with its high residual old, superheaters have become critical assessment components.

stresses from the tube rolling operation, can experience caustic Creep is a function of temperature, stress and operating time.

embrittlement. In addition, the act of eliminating the tube seat The creep life of the superheater tubes is reduced by a higher

leak by repeated tube rolling can overstress the drum shell be- operating temperature and by other damage mechanisms, such

tween tube seats and lead to ligament cracking. as erosion and corrosion, causing tube wall thinning and in-

Lower drum The lower or mud drum is found mostly in in- creased stresses. Excessive stresses associated with thermal

dustrial boilers. Part of the boiler’s water circuit, the lower drum expansion and mechanical loading can also occur, leading to

is not subject to large thermal differentials or mechanical tube cracks and leaks independent of the predicted creep life.

stresses. However, as in steam drums with rolled tubes, seat Over a period of time, superheater tubing exposed to elevated

weepage and excessive stresses from tube rolling can occur. In temperatures experiences an ID oxide growth (Fig. 1). This in-

most cases visual inspection, including fiber optic probe ex- ternal oxide interferes with the cooling effect of the steam flow,

amination of selected tube penetrations, is sufficient. Many causing tube metal temperatures to increase. The resultant in-

lower drums are subject to corrosion of the tube-drum interface crease in temperature will drastically reduce the life of the tube.

on the outside diameter (OD). This area of the drum is inacces- This internal oxide may also exfoliate, causing erosion of valves

sible, therefore inspections are conducted from the inside di- and turbine components. For certain fuels, the life of the super-

ameter (ID) using standard Ultrasonic Thickness Testing (UTT) heater tubing can be greatly reduced by high rates of erosion

and electromagnetic acoustic transducers (EMATs) to check for and corrosion which drives tube degradation more than tem-

cracking and wall thinning. perature and oxide growth. Coal ash corrosion is an example of

Inspection Typical inspections of the drums during a baseline a potentially aggressive damage mechanism.

condition assessment program consist of a thorough visual in- A typical condition assessment inspection of the superheater

spection along with a Wet Fluorescent Magnetic Particle tubing would consist of the following:

(WFMT) inspection of all welded nozzles and attachments. The ● Visual Inspection–A visual inspection will generally find ar-

drum shell ID longitudinal and circumferential welds should be eas of severe erosion, corrosion, thermal shocking or ex-

WFMT and UTT inspected. Selected bore hole ligaments should pansion problems. Visual inspection is also important to iden-

be WFMT inspected. tify failed attachments or rubbing and metal-to-metal wear.

2 Babcock & Wilcox

● Ultrasonic Thickness Inspection–UTT should be per- ● Visual Inspection – A visual inspection will generally find

formed in sootblower lanes and any areas identified by severe erosion, corrosion and thermal shocking, and nu-

visual examination as potential sites of excessive wall loss. merous other problems such as damage from slag falls,

● Internal Oxide Thickness Inspection–Internal oxide thick- local overheat, swelling, etc. Based on the visual inspec-

ness measurements should be taken and remaining creep tion, additional methods may be recommended.

rupture lives calculated for the alloy tube materials in the ● Ultrasonic Thickness Inspection – UTT is by far the most

hottest regions of the superheater and reheater. A large often used inspection method on water-cooled tubes. Ini-

number of inspection locations should be taken on the tially a comprehensive thickness inspection should be per-

initial inspection. Ideally the alloy tube material formed. This results in baseline data that may be com-

(SA213T11, SA 213T22) is tested at location where metal pared to future, limited scope inspections.

temperatures are greatest. A good location is immediately ● EMATS Based Inspection – This form of inspection is

upstream at transition welds to the next grade material. used to locate tube ID under deposit corrosion, pitting or

For example, a good location to test T11 material is im- other tube ID problems such as hydrogen damage. Sys-

mediately upstream of the transition to T22 material. In tems are available for tube thickness mapping(3) and are in

general, the locations are selected based on hottest loca- development for detection of corrosion-fatigue damage.

tion but must also consider accessibility. Future inspec-

tion locations can be reduced based on results of the ini- Tube Life Assessment

tial inspection, history, tube material, dimensional For alloy superheater tubes, life assessment methodologies

changes, and visual inspections. are well established.(4) Tube remaining life can be determined

Water-cooled Water-cooled tubes include those of the econo- using creep rupture properties of materials and life fraction

mizer, boiler bank and furnace. The convection pass sidewall analysis methods. A caution when using these life prediction

and screen tubes may also be water-cooled . These tubes oper- methods is to use the data as a compliment to other data such as

ate at or below saturation temperature and are not subject to tube analysis and failure history. Material creep properties have

significant creep. Modern boilers in electric utilities and many wide variation from heat to heat. Remaining life predictions

industrial plants operate at high pressures. Because these boil- should therefore provide a guideline to help establish trends

ers are not tolerant of water-side deposits, they must be chemi- relative to failures and time of replacement and should not be

cally cleaned periodically, which results in some tube material used as an exact life calculation.

loss. Proper water chemistry control will limit tube inside sur- For low temperature tubing, life prediction is done by com-

face material loss due to ongoing operations and cleaning. The paring wall loss trends to a predetermined flag or replacement

importance of maintaining water quality and keeping ID tube criteria. As a general guideline B&W recommends a flag of 70%

surfaces clean cannot be overly stressed. Extensive damage of original specified wall thickness for water-cooled tubes. For

waterwall circuits has often resulted from excessive deposition damage mechanisms such as hydrogen damage, cracking or cor-

that can lead to aggressive corrosion and hydrogen damage. On rosion-fatigue, no attempt is made to predict life – the goal for

cycling boilers a serious problem has also been corrosion-fa- these tubes is identification of damaged tubes with recommended

tigue damage at lower furnace attachment points such as replacement.

buckstays and windbox attachments. Corrosion fatigue leads to

ID initiated cracking that is very difficult to detect by nonde- Headers

structive methods. Research sponsored by EPRI is currently Headers and their associated problems can be grouped ac-

ongoing to address this NDE need.(2) cording to operating temperature. High temperature steam-car-

Externally, water-cooled tubes are subject to damage. Ero- rying headers are a major concern because they have a finite

sion is most likely to occur on tube surfaces in the boiler or creep life and their replacement cost is high. Lower tempera-

economizer bank from sootblowing or ash particle impingement. ture water- and steam-cooled headers are not susceptible to creep

Erosion of waterwall tubes can also result from sootblower op- but may be damaged by corrosion, erosion, or severe thermal

eration. Corrosion of the water-cooled tubes can result from stresses.

reducing atmospheres associated with mal-distributed burner air High temperature The high temperature headers are the su-

or result from staged combustion on low N0x burner installa- perheater and reheater outlets which operate at a bulk tem-

tions. Some types of coal ash can promote corrosion of waterwall perature of 900F (482C) or higher. Headers operating at high

tubes as well. temperature experience creep under normal conditions. In ad-

Steam- and/or Water-Cooled–External to Setting Of spe- dition to material degradation resulting from creep, high tem-

cial concern are some unique problems that have led to failures perature headers can experience thermal and mechanical fatigue.

of tubing that is outside the boiler settings. These type failures Creep stresses in combination with thermal fatigue stress lead

have a potential for exposing plant personnel to safety hazards. to failure much sooner than those resulting from creep alone.

Examples are supply or riser tubes on units that have had water There are three factors influencing creep fatigue in superheater

chemistry control problems when using chelants. Excessive high temperature headers: combustion, steam flow and boiler

chelant can attack tubing aggressively and lead to thinning and load. Most manufacturers design a boiler with burners arranged

failures. More recently, corrosion-fatigue has been identified in the front and/or rear walls. Heat distribution within the boiler

on older units (>30 years operation) as the root cause mecha- is not uniform: burner inputs can vary, air distribution is not

nism of riser tube failure in the penthouse. In both instances, uniform, and slagging and fouling can occur. The net effect of

whether chelant attack or corrosion-fatigue, the failures tended these combustion parameters is variations in heat input to indi-

to be catastrophic with a large piece of tube rupturing. vidual superheater and reheater tubes. When combined with

A typical condition assessment inspection of water-cooled steam flow differences between tubes within a bank, signifi-

tubes would consist of the following: cant variations in steam temperature entering the header can

Babcock & Wilcox 3

torque plates, and tube stub to header welds. Steam piping flex-

ibility can cause excessive loads to be transmitted to the header

outlet nozzle. These stresses result in externally initiated cracks

at the outlet nozzle to header saddle weld.

Condition assessment of high temperature headers should

include a combination of non-destructive examination (NDE)

techniques that are targeted at the welds where cracks are most

likely to develop:

● Visual Inspection

● Wet Fluorescent Magnetic Particle Inspection–All major

header welds, including the outlet nozzle, torque plates,

support lugs and plates, circumferential girth welds should

be WFMT inspected. Initially, 100% of the tube stub to

header welds should be WFMT inspected. After the

baseline WFMT inspection, future WFMT inspections

may be limited to 10-25% of the tube stub to header welds.

● Ultrasonic angle beam shear wave examination of major

welds–This is particularly important if the header has any

long seam welds. In general, B&W follows EPRI-estab-

lished guidelines for examination of these welds.(5)

● Metallurgical Replication–To examine the header for

creep damage, metallographic replication should be per-

formed. Typically, between 6-12 replicas are taken on the

header tube stubs, header circumferential or longitudinal

pipe welds, and nozzle to header welds. Locations for

replicas are typically in the areas of highest temperature

Fig. 2 Steam temperature variation in a header. or stress.

● Ligament and Bore Hole Inspection–The major cause of

occur (Fig. 2). Changes in boiler load further aggravate the tem-

header end-of-life in the US is creep fatigue. This results

perature difference between the individual tube legs and the bulk

in ligament and bore hole cracking. A total of two to three

header. As boiler load increases, the firing rate must increase to of the hottest or highest stressed areas should be inspected.

maintain pressure. During this transient, the boiler is tempo-

B&W strongly believes that effective bore hole examina-

rarily over-fired to compensate for the increasing steam flow

tion must be preceded by removal of the high tempera-

and decreasing pressure. During load decreases, the firing rate ture oxide. It is important that the base metal of the header

decreases slightly faster than steam flow in the superheater with

be examined for cracking (Fig. 5). B&W developed a

a resulting decrease in tube outlet temperature relative to that

unique process for this inspection which is called the Hone

of the bulk header. As a consequence of these temperature gra- & Glow® exam.

dients, the header experiences localized stresses much greater

Low temperature The low temperature headers are those

than those associated with steam pressure (Fig. 3) and can re-

operating at temperatures below which creep is a consideration.

sult in large ligament cracks (Fig. 4).

These include waterwall headers, economizer inlet and outlet

In addition to the effects of temperature variations, the ex-

ternal stresses associated with header expansion and piping loads

must be evaluated. Header expansion can cause damage on cy-

cling units resulting in fatigue cracks at support attachments,

Stress

(ksi)

22.2

23.5

20.5

17.5

14.5

11.5

8.50

6.00

2.50

-2.50

-6.00

-8.50

-11.5

-14.5

-18.0

-5.47

Fig. 3 Localized stresses due to thermal gradients. Fig. 4 Large ligament cracks on header ID.

4 Babcock & Wilcox

As noted previously, high temperature headers on older units

were typically made of SA335P22 alloys and will eventually

need to be replaced due to reaching their end-of-life. Accurate

quantification of header life is difficult since damage is attrib-

uted to creep fatigue and is driven by locally high stresses, tem-

peratures and cycles that are not readily measured. Software

tools have been developed under projects sponsored by EPRI.

The software BLESS(6) which resulted from this work provides

for prediction of crack initiation as well as crack growth to pre-

dict or quantify life. The difficulty is in accurately defining

operating parameters and material properties. Material sampling

and testing may be necessary to fully implement the analysis

for best results. In general, based on B&W experience, analyti-

cal programs such as BLESS have been used as a tool along

with other data to help make short term decisions for headers

Fig. 5 Header bore hole cracking. that have already experienced significant cracking, i.e. BLESS

can be invaluable to help make a run/repair decision. For most

headers, and superheater inlet and intermediate headers. Any projects, an attempt is not made to quantify remaining life by

damage to the low temperature headers is generally caused by analysis. From empirical experience and re-inspection programs,

corrosion or, in some instances, erosion or thermal fatigue. sufficient data is normally available to make decisions for life

Waterwall headers, found in most electric utility and indus- extension projects. Economic analysis of risk and unavailabil-

trial power generation boilers, are located outside the hostile ity are a key part of this process.

environment of the combustion zone. An exception is the econo-

mizer inlet header; this header is often located in the gas stream Attemperators

and is subject to unique problems associated with cycling. Boil- The attemperator, or desuperheater, is located in the piping

ers that are held overnight in a hot standby condition without of the superheater and is used for steam temperature control.

firing can experience severe damage to the economizer inlet The spray attemperator is the most common type used. In the

header in a very short time. This damage is typically caused by spray unit, high quality water is sprayed directly into the super-

thermal shock. heated steam flow where it vaporizes to cool the steam. The

The magnitude of the thermal shock is a function of the tem- attemperator is typically located in the piping between the pri-

perature differential between the unheated feedwater and the mary superheater outlet header and the secondary superheater

inlet header. It is also a function of water flow, which is usually inlet header. Steam exiting the primary header at temperatures

large because the feedwater piping/valve train is sized for rated of 800 to 900F (427 to 482C) enters the attemperator, where

boiler capacity. The thermal shock is worse near the header relatively cool water [300F (149C)] is sprayed into the steam

feedwater inlet and rapidly decreases as flow passes into the and reduces the temperature to the inlet of the secondary super-

header and tubes. Economizer inlet headers have also experi- heater. Because of the large temperature difference between the

enced damage associated with flow-accelerated corrosion. In steam and spray water, parts of the attemperator experience ther-

general the primary concern with most of the low temperature mal shock each time it is used. Over a period of years this leads

headers is internal and external corrosion, especially during out to thermal fatigue and eventual failure.

of service periods. Condition assessment of the attemperator requires removal

Typical inspections of these headers consist of: of the spray nozzle assembly. The thermal stresses occurring in

● Visual Inspection the attemperator are most damaging at welds, which act as stress

● Wet Fluorescent Magnetic Particle–A WFMT inspection concentrators. The spray head and welds on the nozzle assem-

should be performed on welded attachments, handhole bly are examined visually and by liquid penetrant PT to ensure

plugs, header end plate welds, and 10% of tube to header there are no cracks. With the spray head removed the liner can

welds. be examined with a video or fiber optic probe. For larger

● Video Probe Inspection–An internal visual inspection can attemperators, it may be necessary to remove radiograph plugs

be performed to locate internal problems. before and after the attemperator to better view the critical liner

● UTT–Should visual inspection reveal areas of wall loss welds.

from either corrosion or erosion, then ultrasonic thick-

ness data may be taken to assess header thickness. Attemperator Life Assessment

Spray flow attemperators are critical in the condition assess-

Header Life Assessment ment program since they are in the closed loop of the super-

For low temperature headers, the life is not necessarily fi- heater. Failures in the attemperator can lead to collateral dam-

nite in the normal life spans of the boiler. Replacement of low age in the superheater leading to tube failures. If left undetec-

temperature headers will result from unique damage such as ted over a long period of time, attemperator failures have the

thermal fatigue and cracking. Instances of damage to low tem- potential to lead to piping failure as a result of thermal fatigue.

perature headers are very much dependent on the specific plant In general, the attemperator is treated as a preventive mainte-

and operating history. Low temperature headers are more likely nance item. They should be periodically inspected following 10

to be replaced as part of unit upgrades or as tandem replace- years operation. It is prudent to maintain spares on hand for

ment with other components such as wall panels. eventual replacement of the spray head assembly.

Babcock & Wilcox 5

Piping and Deaerators Assessment programs include NDE to evaluate wall thickness

Main steam and hot reheat piping are regarded as critical in susceptible areas. UTT is the primary NDE method. Key lo-

high energy piping systems in the plant. Because of the operat- cations include flow transitions, such as bends, tees and reduc-

ing temperatures and stresses they are subject to creep damage ers, as well as areas where flow disturbance is possible such as

and must be included in any condition assessment program. at weld backing rings. Any chemical feed injection points are

Seam welded hot reheat piping and seam welds in main steam also susceptible; the downstream piping as well as the location

are of particular concern since the longitudinal seam weld is of the connection is included in the scope of examination. UTT

acted upon by the primary pressure stresses. Catastrophic fail- is performed on a grid that includes the complete circumfer-

ures of long seam welds have occurred in numerous instances ence of the pipe in the area of interest.

and are well documented. Extensive research has been spon- Deaerators, like feedwater piping, were overlooked for many

sored by EPRI and the Materials Property Council and research years. However, catastrophic failure of several DA vessels em-

into more effective inspection methods continues. Full discus- phasized the need to include this component in the boiler island

sion of seam welded piping systems can be found in literature.(5) assessment program. Guidelines for assessment of deaerators

In general, a full volumetric examination of all critical welds is was developed under work sponsored by the National Associa-

mandatory for the high energy piping seam welds and circum- tion of Corrosion Engineers (NACE). NACE Standard RP0590-

ferential welds. Volumetric examination is done by ultrasonic

96 provides a full discussion of the subject. In general, DA prob-

angle beam shear (UTS) wave methods. More recently ultra-

lems and failures are associated with corrosion of internal weld

sonic time-of-flight diffraction (TODF) and focused array trans-

surfaces. The recommended NDE method is Wet Fluorescent

ducers have been used. WFMT, UTT, replication, in-situ mate-

Magnetic Particle Testing to assess internal vessel welds.

rial identification, and dimensional creep swell measurements

are commonly included in the inspection programs.

Low energy piping such as cold reheat piping, and especially

feedwater piping are also subject to degradation and failure. For

Summary

The recommendations listed are a minimum guideline for

cold reheat (CRH) piping, corrosion and fatigue are the primary

mechanisms that can lead to damage. In general, visual inspec- inspecting the critical components of the boiler island. Based

tion and NDE of selected welds, bends, and possibly horizontal on the results of any of the above inspections, or problems en-

runs where water can accumulate, are the focus on CRH piping. countered during the day-to-day boiler operation, additional

NDE includes WFMT, internal video probe if accessible, UTT, inspections may be recommended. These inspections will aid

and UTS. in extending the safe, useful operating life of the boiler. During

The feedwater piping system was overlooked for many years. any outage, either planned or forced, a visual inspection should

Feedwater piping is of particular concern since it is susceptible be performed wherever possible. Regular inspections coupled

to the phenomenon of flow accelerated corrosion (FAC). A full with the appropriate NDE should be performed on a frequent

investigation of flow accelerated corrosion was sponsored by basis and as determined by the re-inspection plan developed

EPRI. (7) Of major concern, FAC of feedwater piping can lead during condition assessment. Due to the wide range of reasons

to wall loss over a large area of the pipe. Failures resulting from that failures may occur in the listed critical components, the

this mechanism tend to be catastrophic since a large area is type and amount of inspection will be determined on a unit-to-

weakened prior to failure. FAC failures pose a safety hazard to unit basis. A thorough initial inspection, followed by frequent

plant personnel. Subsequently, inclusion of this system should location-specific inspection, should result in increased safety,

be given priority in the assessment program of an aging plant. availability, efficiency, and reliability of the unit.

References

1. “Manual for Investigation and Correction of Boiler Tube 5. “Guidelines for The Evaluation of Seam-welded High

Failures,” Report CS-3945, Electric Power Research Institute, Energy Piping,” Report TS-104631, Electric Power Research

Palo Alto, California, April 1985. Institute, Palo Alto, California, January 1995.

2. EPRI Contract WO 4674-01, “Development of NDT Tech- 6. “An Integrated Approach to Life Assessment of Boiler

niques for Detection and Sizing of Corrosion-Fatigue Cracks Pressure Parts, Volume 4: BLESS Code User’s Manual and Life

in Boiler Tubes.” Assessment Guidelines,” Report to Electric Power Research In-

3. Nakoneczny, G., Murphy, R., Tilley, R., “Applications of stitute, Project 2253-10, Palo Alto, California, 1992.

EPRI/B&W Developed EMAT Systems for Assessing Boiler 7. “Flow-Accelerated Corrosion in Power Plants,” Report

Tubes,” ICOLM (International Conference on Life Management TR-106611-R1, Electric Power Research Institute, Palo Alto,

and Life Extension of Power Plant), Xi’an, P.R. China, 2000. California 1998.

4. Wardle, T., “Creep-Rupture Assessment of Superheater

Tubes Using Nondestructive Oxide Thickness Measurements,”

ICOLM, Xi’an, P.R. China, 2000.

6 Babcock & Wilcox

Copyright © 2000 by The Babcock & Wilcox Company,

All rights reserved.

No part of this work may be published, translated or reproduced in any form or by any means, or incorporated into any information retrieval system,

without the written permission of the copyright holder. Permission requests should be addressed to: Market Communications, The Babcock &

Wilcox Company, P.O. Box 351, Barberton, Ohio, U.S.A. 44203-0351.

Disclaimer

Although the information presented in this work is believed to be reliable, this work is published with the understanding that The Babcock & Wilcox

Company and the authors are supplying general information and are not attempting to render or provide engineering or professional services.

Neither The Babcock & Wilcox Company nor any of its employees make any warranty, guarantee, or representation, whether expressed or implied,

with respect to the accuracy, completeness or usefulness of any information, product, process or apparatus discussed in this work; and neither The

Babcock & Wilcox Company nor any of its employees shall be liable for any losses or damages with respect to or resulting from the use of, or the

inability to use, any information, product, process or apparatus discussed in this work.

Babcock & Wilcox 7

You might also like

- OSHA Letter Regarding Kaukauna Mill DeathDocument3 pagesOSHA Letter Regarding Kaukauna Mill DeathFOX 11 NewsNo ratings yet

- Boiler Corrosion MagnetiteDocument14 pagesBoiler Corrosion MagnetiteJakeTheSnake69100% (1)

- Overheating and Fuel Ash Corrosion Failure of Boiler TubeDocument18 pagesOverheating and Fuel Ash Corrosion Failure of Boiler TubeJackSparrow86No ratings yet

- Superheater and Reheater Outlet Header Inspections FailuresDocument65 pagesSuperheater and Reheater Outlet Header Inspections Failureskaruna346No ratings yet

- Relationship Between Microstructure and Ductility of Investment Cast ASTM F-75 Implant AlloyDocument7 pagesRelationship Between Microstructure and Ductility of Investment Cast ASTM F-75 Implant AlloyCatarina Pinto100% (1)

- Certificate of Analysis: National Institute of Standards and TechnologyDocument5 pagesCertificate of Analysis: National Institute of Standards and TechnologyJohn GiannakopoulosNo ratings yet

- Continental-4rev 0302 PDFDocument24 pagesContinental-4rev 0302 PDFLuis Mejia AlbarracinNo ratings yet

- Boiler Life EstimationDocument5 pagesBoiler Life EstimationHalim Selamat100% (1)

- Fatigue CorrosionDocument2 pagesFatigue Corrosionaop10468No ratings yet

- Hot Corrosion Performance of Alloy and Composite CoatingsDocument12 pagesHot Corrosion Performance of Alloy and Composite CoatingsHarkulvinder SinghNo ratings yet

- EPRI Atlas of Steamside Oxide ObservationsDocument12 pagesEPRI Atlas of Steamside Oxide Observationsekrem turan100% (2)

- 1584Document6 pages1584malsttarNo ratings yet

- 58 Weld Repairs - Creep PerformanceDocument21 pages58 Weld Repairs - Creep PerformanceLTE002No ratings yet

- WJ - 1982 - R B Dooley Dissimilar Weld Boiler Tube FailureDocument5 pagesWJ - 1982 - R B Dooley Dissimilar Weld Boiler Tube FailureKuthuraikaranNo ratings yet

- Chapter 14 Boiler System Failures: Deaerator CrackingDocument22 pagesChapter 14 Boiler System Failures: Deaerator CrackingVijay RajaindranNo ratings yet

- Creep - Iwshibli PDFDocument32 pagesCreep - Iwshibli PDFIvanUribeNo ratings yet

- Bor1991 - Effect of Pearlite Banding On Mechanical Properties of Perlitic SteelDocument12 pagesBor1991 - Effect of Pearlite Banding On Mechanical Properties of Perlitic SteelAlejandroAcuñaMaureiraNo ratings yet

- 30 Ncmer037Document16 pages30 Ncmer037Arslan ArshadNo ratings yet

- Status of Advanced Ultra-Supercritical Pulverised Coal Technology - ccc229Document57 pagesStatus of Advanced Ultra-Supercritical Pulverised Coal Technology - ccc229sarangss100% (1)

- ManufProc 4 BulkFormingDocument96 pagesManufProc 4 BulkFormingHannan yusuf KhanNo ratings yet

- Advanced Boiler TubeDocument2 pagesAdvanced Boiler TubeShailendra WaniNo ratings yet

- Limits and State of The Art of The New Creep Resistant SteelsDocument64 pagesLimits and State of The Art of The New Creep Resistant SteelsRené Galbraith BerraNo ratings yet

- Corrosion of Water Walls and Superheaters in Wte MSW PlantsDocument114 pagesCorrosion of Water Walls and Superheaters in Wte MSW Plantsvijay_nani124No ratings yet

- HRSG High Pressure Evaporator Sampling For Internal DepositDocument26 pagesHRSG High Pressure Evaporator Sampling For Internal Depositak_thimiriNo ratings yet

- Corrosion Failures of AISI Type 304 Stainless Steel in A Fertiliser PlantDocument11 pagesCorrosion Failures of AISI Type 304 Stainless Steel in A Fertiliser PlantAndrea CalderaNo ratings yet

- Effect Scale Formation in Boiler Water Wall TubesDocument7 pagesEffect Scale Formation in Boiler Water Wall TubesRishabh ChaureNo ratings yet

- Condition Assessment of BoilerDocument8 pagesCondition Assessment of BoilerEzhil Vendhan PalanisamyNo ratings yet

- Finding The Root Cause of Boiler Tube FailuresDocument17 pagesFinding The Root Cause of Boiler Tube Failuresjgv100% (1)

- State of Maryland Final Report Task Force To Study Pinhole Leaks in Copper PlumbingDocument65 pagesState of Maryland Final Report Task Force To Study Pinhole Leaks in Copper PlumbingSyavash EnshaNo ratings yet

- Bulging Rupture and Caustic Corrosion of A Boiler Tube in A ThermalDocument8 pagesBulging Rupture and Caustic Corrosion of A Boiler Tube in A Thermaladventius S.SNo ratings yet

- Case Study On Copper CorrosionDocument15 pagesCase Study On Copper CorrosionClaudia MmsNo ratings yet

- LABORELEC Conventional Power Plant Materials Course V2 PDFDocument90 pagesLABORELEC Conventional Power Plant Materials Course V2 PDFkatfy1100% (1)

- Feed Water Pipe FailureDocument9 pagesFeed Water Pipe Failuredafteri11No ratings yet

- Boiler MaterialsDocument5 pagesBoiler MaterialsRavi ShankarNo ratings yet

- The Implementation of A Steam Transformer PDFDocument9 pagesThe Implementation of A Steam Transformer PDFASHIL PRABHAKARNo ratings yet

- Condensate in HRSG PDFDocument15 pagesCondensate in HRSG PDFCoalhouse Walker JuniorNo ratings yet

- GSC Steam Turbine CastingsDocument10 pagesGSC Steam Turbine CastingsJozsef Magyari100% (1)

- Waterwall - Fireside CorrosionDocument8 pagesWaterwall - Fireside CorrosionwahonodNo ratings yet

- Boiler Tube Investigation PDFDocument6 pagesBoiler Tube Investigation PDFHussseinmubarkNo ratings yet

- Superheater Corrosion in USC Power PlantDocument136 pagesSuperheater Corrosion in USC Power PlantDanie-Els100% (1)

- V B01B0005B-15GB PDFDocument20 pagesV B01B0005B-15GB PDFनिपुण कुमारNo ratings yet

- Prediction of Oxide Scale Growth in Superheater and Reheater TubesDocument8 pagesPrediction of Oxide Scale Growth in Superheater and Reheater TubesMas ZuhadNo ratings yet

- Mohammad Rasul Ed. Thermal Power Plants Advanced ApplicationsDocument185 pagesMohammad Rasul Ed. Thermal Power Plants Advanced Applicationssurafel amareNo ratings yet

- OsidationDocument49 pagesOsidationSadhasivam VeluNo ratings yet

- 226 Eddystone Station UnitDocument24 pages226 Eddystone Station UnitsbktceNo ratings yet

- Welding Procedures of Turbine Blades by Using ER 309L Austenitic Filler WireDocument8 pagesWelding Procedures of Turbine Blades by Using ER 309L Austenitic Filler Wireeko siswono100% (1)

- BS-EN Comparison ChartDocument14 pagesBS-EN Comparison ChartIan Stewart PorterNo ratings yet

- Cap Boiler ManualDocument43 pagesCap Boiler Manualdnageshm4n244100% (1)

- Fireside Corrosion of Alloys For Combustion Power PlantsDocument11 pagesFireside Corrosion of Alloys For Combustion Power Plantsdealer82No ratings yet

- 07 Thermal StressDocument13 pages07 Thermal StressSundaravathanan ChellappanNo ratings yet

- Astm 4140 PDFDocument3 pagesAstm 4140 PDFRameshNo ratings yet

- BR 170 1Document7 pagesBR 170 1Himanshu ChaturvediNo ratings yet

- SHELL BOILERS - Guidelines For ExaminationDocument28 pagesSHELL BOILERS - Guidelines For ExaminationSH1961100% (1)

- RLA in High Temp Zones of Power Plant ComponentsDocument7 pagesRLA in High Temp Zones of Power Plant ComponentsEzhil Vendhan PalanisamyNo ratings yet

- Safe Remaining Lifetime Assesment of Power Plant Steam BoilersDocument9 pagesSafe Remaining Lifetime Assesment of Power Plant Steam Boilersmuh4iminNo ratings yet

- Strategies For Inspecting Hrsgs in Two-Shift and Low-Load ServiceDocument12 pagesStrategies For Inspecting Hrsgs in Two-Shift and Low-Load ServicevnchromeNo ratings yet

- Case Study - Boiler Condition and Life AssessmentDocument2 pagesCase Study - Boiler Condition and Life AssessmentfelramNo ratings yet

- Early Failure of Waste Heat Boiler and Redesign To Overcome Premature FailureDocument5 pagesEarly Failure of Waste Heat Boiler and Redesign To Overcome Premature FailureEjaj SiddiquiNo ratings yet

- Boiler Tubes Overheating Failures and Actions To Control ThemDocument2 pagesBoiler Tubes Overheating Failures and Actions To Control ThemThanhluan NguyenNo ratings yet

- Coke Drum Monitoring Inspection Assessment and Repair For Service Life Improvement Chadda Foster Wheeler DCU Rio de Janiero 2014Document31 pagesCoke Drum Monitoring Inspection Assessment and Repair For Service Life Improvement Chadda Foster Wheeler DCU Rio de Janiero 2014Piyush PrasadNo ratings yet

- 12 01 01 GL V01 - Commissioning Management GuidelineDocument32 pages12 01 01 GL V01 - Commissioning Management Guidelinedestiny2bn100% (2)

- RAL Code ClassificationDocument8 pagesRAL Code Classificationdestiny2bnNo ratings yet

- Turnover Sub-System ScheduleDocument94 pagesTurnover Sub-System Scheduledestiny2bnNo ratings yet

- How To Read P and IDs PDFDocument62 pagesHow To Read P and IDs PDFdestiny2bnNo ratings yet

- Performance - Test - Codes - C0 - PTC 4.2 PDFDocument27 pagesPerformance - Test - Codes - C0 - PTC 4.2 PDFdestiny2bnNo ratings yet

- Global Blockchain Congress: Consensus 2018Document11 pagesGlobal Blockchain Congress: Consensus 2018destiny2bnNo ratings yet

- ASME ANSI STD PTC 19.3 1974 Temperature Measurement Instruments and Apparatus IDocument141 pagesASME ANSI STD PTC 19.3 1974 Temperature Measurement Instruments and Apparatus Idestiny2bn100% (1)

- Project Finance - Non PDFDocument8 pagesProject Finance - Non PDFdestiny2bnNo ratings yet

- Frame 9FA Erection ProcedureDocument25 pagesFrame 9FA Erection Proceduredestiny2bn93% (15)

- Rita Sixth Edition - PMBOK 4Document548 pagesRita Sixth Edition - PMBOK 4destiny2bnNo ratings yet

- Figs v. My Open Heart - ComplaintDocument30 pagesFigs v. My Open Heart - ComplaintSarah BursteinNo ratings yet

- Synopsis On Study of Debit Card in INDIAN SCENERIODocument5 pagesSynopsis On Study of Debit Card in INDIAN SCENERIOHapi ERNo ratings yet

- Supportand Resistance Trading StrategyDocument10 pagesSupportand Resistance Trading StrategyEng Abdikariim AbdillahiNo ratings yet

- Ranjan Bose Information Theory Coding and Cryptography Solution ManualDocument61 pagesRanjan Bose Information Theory Coding and Cryptography Solution ManualANURAG CHAKRABORTY89% (38)

- Thesis 2Document15 pagesThesis 2El TabianNo ratings yet

- Module-2 Eco-598 ML & AiDocument12 pagesModule-2 Eco-598 ML & AiSoujanya NerlekarNo ratings yet

- The Effects of TikTok Usage On Grade 11 Students of San Fabian National High SchoolDocument16 pagesThe Effects of TikTok Usage On Grade 11 Students of San Fabian National High SchoolKzz PerezNo ratings yet

- Popular CultureDocument2 pagesPopular CultureChloe GuiaoNo ratings yet

- Ielts Speaking Sample Week 8Document8 pagesIelts Speaking Sample Week 8Onyekachi JackNo ratings yet

- Implementing A Risk Management FrameworkDocument51 pagesImplementing A Risk Management FrameworkSayyid ShalahuddinNo ratings yet

- Sampling Unit:: Sampling Theory - Chapter 1 - Introduction - Shalabh, IIT KanpurDocument11 pagesSampling Unit:: Sampling Theory - Chapter 1 - Introduction - Shalabh, IIT KanpurMuskan ManchandaNo ratings yet

- Ms - Shruti Vs Baldev Singh and Others On 23 May, 2017Document8 pagesMs - Shruti Vs Baldev Singh and Others On 23 May, 2017spgkumar7733No ratings yet

- NTA NET Political Science Paper 2 December 2015Document24 pagesNTA NET Political Science Paper 2 December 2015Mohammad Shahbaz KhanNo ratings yet

- QUT Stage2 Document Avijit PaulDocument21 pagesQUT Stage2 Document Avijit PaulAvijit PaulNo ratings yet

- Bose The Untold Story of An Inconvenient NationalistDocument968 pagesBose The Untold Story of An Inconvenient NationalistSumit KhandaitNo ratings yet

- Concepts in Enterprise Resource Planning: Chapter One Business Functions and Business ProcessesDocument48 pagesConcepts in Enterprise Resource Planning: Chapter One Business Functions and Business ProcessesFenri GreenNo ratings yet

- Chapter 11: Radiation: 11.1 Dipole Radiation 11.1.1 What Is Radiation? 11.1.2 Electric Dipole RadiationDocument4 pagesChapter 11: Radiation: 11.1 Dipole Radiation 11.1.1 What Is Radiation? 11.1.2 Electric Dipole RadiationMadhumika ThammaliNo ratings yet

- Kunci Jawaban Pat X Bahasa InggrisDocument5 pagesKunci Jawaban Pat X Bahasa InggrisjuraganshuleeNo ratings yet

- Objectives IPCRF 2021 2022Document19 pagesObjectives IPCRF 2021 2022Melanie Marquez - FernandezNo ratings yet

- Višegrad Genocide, What Is?Document1 pageVišegrad Genocide, What Is?Visegrad GenocideNo ratings yet

- Philippine - Airlines - Inc. - v. - Santos - JR - DigestDocument2 pagesPhilippine - Airlines - Inc. - v. - Santos - JR - DigestAllen Windel BernabeNo ratings yet

- Project Essay FinalDocument5 pagesProject Essay Finalapi-534828614No ratings yet

- Mohamed Bin Zayed Al Nahyan - WikipediaDocument26 pagesMohamed Bin Zayed Al Nahyan - WikipediaJeel VoraNo ratings yet

- 2022 Anatmoy and Physiology Cheat Sheet!Document3 pages2022 Anatmoy and Physiology Cheat Sheet!Estella BrockwellNo ratings yet

- Bearers - Default and DedicatedDocument2 pagesBearers - Default and Dedicatedshaan19No ratings yet

- HGP DLPDocument2 pagesHGP DLPCorona Virus100% (1)

- 2 Faktor-Faktor-Yang-Berhubungan-Dengan-TiDocument9 pages2 Faktor-Faktor-Yang-Berhubungan-Dengan-TiofislinNo ratings yet

- Plaintiffs-Appellants Opening Brief: Ronald Pierce et al vs. Chief Justice Tani Cantil-Sakauye Judicial Council Chair and Steven Jahr Judicial Council Administrative Director - Federal Class Action Lawsuit for Alleged Illegal Use of California Vexatious Litigant Law by Family Court Judges in Child Custody Disputes - Ventura County - Tulare County - Sacramento County - San Mateo County - Santa Clara County - Riverside County - San Francisco County - US District Court for the Northern District of California Judge Jeffrey S. White - US Courts for the Ninth Circuit - 9th Circuit Court of Appeal Class Action for Injunctive and Declaratory ReliefDocument285 pagesPlaintiffs-Appellants Opening Brief: Ronald Pierce et al vs. Chief Justice Tani Cantil-Sakauye Judicial Council Chair and Steven Jahr Judicial Council Administrative Director - Federal Class Action Lawsuit for Alleged Illegal Use of California Vexatious Litigant Law by Family Court Judges in Child Custody Disputes - Ventura County - Tulare County - Sacramento County - San Mateo County - Santa Clara County - Riverside County - San Francisco County - US District Court for the Northern District of California Judge Jeffrey S. White - US Courts for the Ninth Circuit - 9th Circuit Court of Appeal Class Action for Injunctive and Declaratory ReliefCalifornia Judicial Branch News Service - Investigative Reporting Source Material & Story IdeasNo ratings yet

- Maritime LawDocument3 pagesMaritime LawKumar SudarshanNo ratings yet