Professional Documents

Culture Documents

Compress Sample: Item Qty Description Material

Compress Sample: Item Qty Description Material

Uploaded by

Sivi NallamothuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compress Sample: Item Qty Description Material

Compress Sample: Item Qty Description Material

Uploaded by

Sivi NallamothuCopyright:

Available Formats

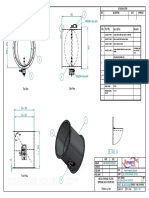

BILL OF MATERIALS

1.68 1.50 R2.50 ITEM QTY DESCRIPTION MATERIAL

D 1.56

1.50 1 1 Shell - 60.00 OD x 0.50 Thk. x 120.00 Long SA-516 70

2.44 R36.00 Head, F&D - 60.00 OD, 1.50 SF, 60.00 ICR, 3.60

1.68 2 2 SA-516 70

3.62 6.00 7.00 IKR, .75 Nom., .68 MAF - Note 12

4.75 2.50 3 2 Flange, RFSO - 150#, 4.00 NPS SA-105

1.625 3.50 .50

D 1.050 4 2 Pipe - Sch. 160, 4.00 NPS SA-106 B

8X .75-10UNC 4.00

1.050 DP 5 1 Coupling, Half - 6000#, 1.00 NPS SA-105

SECTION D-D 8.00 3.75 5.99 7.00

SCALE 1 : 16 6 2 Flange, Pad - 150#, 2.00 NPS SA-240 316

.51 7 1 Manway - 12.00 x 16.00, 3.00 x 1.00 Ring SA-106 B/C

2X 1.00 8 1 Manway - 12.00 x 16.00, 4.00 x 1.00 Ring SA-106 B/C

5.99

60.00 9 4 Leg - W6x15 x 41.75 SA-G40.21 44W

10 4 Pad, Leg - .75 Thk. x 7.00 x 7.00 SA-G40.21 44W

20.00 SECTION E-E

11 2 N3 M1 11 2 Lug, Lifting - .50 Thk. SA-516 70

20.00 19.00 SCALE 1 : 24 12 2 Manway Cover, .25 Thk. (See Note 11/12) SA-516 70

NOTES:

N1 N4

1. All dimensions in inches.

2. All welds shall be neat in appearance, free from slag and other defects.

3. Vessel to be cleaned of scale, oil,weld spatter and all other foreign material,

prior to hydrostatic test.

4. Remove all sharp edges on nozzles (1/8" minimum radius)

5. All nozzles to support nomial loads only.

1 6. Maximum misalignment of butt joints is limited to .25T (Category A, B, C, D

up to 1/2" thick)

7. All fittings conform to B16.9 standards.

120.00 8. All couplings to conform to B16.11 (2011 Add.) standards.

114.00 9. All flanges to conform to B16.5 (2009 Add.)/ B16.47 standards.

162.44 10. Flange bolt holes to straddle natural centre lines.

11. Manway Cover: Clark-Kennedy Co. CRN OH7379.5C

MAWP 150 psi, Max 650 F

12. PFHT on Heads per UCS-79(d)

1/4" M2

12.500 10.00 N5 DESIGN DATA

6.00

Code Design Code: ASME VIII-1 2010 ed. 2011 add.

Seismic Code: IBC 2009, Site E, I 1, Ss .75, S1 .30, R 2

30.000 Wind Code: N/A

9

Design Conditions MAWP - Int / Ext: 150 / 0 psi @ 120 °F

MDMT: -20 °F @ 150 psi

N2 Corrosion Allowance: 0

10 Examination Impact Testing: Exempt per UG-20(f)

E E

Radiography: None

PWHT: None

64.0000 Hydro Test: 195 psi @ 70 °F

Service Fluid: Air / Water

Capacity: 213 cu. ft.

NOZZLE SCHEDULE Weight - Empty: 4900 lb

Weight - Operating: 18000 lb

NOZZLE WELDS FLANGES BOM

Int Ext ITEM # REVISIONS

Mark Size Qty. Service Type 41 42 43 Type SB F1 F2 56.5000

Proj Proj. REV. REVISION HISTORY DATE DRW CHK

N1 4 1 Inlet UW-16.1 (c) .375 - - - 6.00 RFSO .375 .370 .250 3, 4

8x 1.00 0 Release 3/21/2012 TSB LB

Outlet/

N2 4 1

Drain

UW-16.1(c) .375 - - - 6.00 RFSO .375 .370 .250 3, 4 45.0° XYZ Vessel Corp.

N3 1 1 Vent UW-16.1(z-1) .375 - - - - - - - - 5

4x 90.0°

XYZ 123 Basic Street

Seatown, Ontario, Canada

N4 2 1 Process UW-16.1(c) .375 - - - 1.25 - - - - 6 X1Y 2Z3

Certified by

N5 2 1 Process UW-16.1 (c) .375 - - - 1.25 - - - - 6

A XYZ Vessel Corp. Pressure Vessel Engineering, Ltd. www.pveng.com

M1 12x16 1 Manway

UW-16.1 (c) with

inside proj.

.375 - - .75 1.25 - - - - 7, 12 S (Name of Manufacturer) Eng 120 Randall Drive, Suite B

Waterloo, Ontario, Canada

info@pveng.com

Tel. 519-880-9808

UW-16.1 (c) with M 150 psi (kPa) at 120 °F (°C) N2V 1C6 Fax 519-880-9810

M2 12x16 1 Manway .375 - - .50 1.50 - - - - 8, 12 Max. allowable working pressure (MAWP)

inside proj. E Title

- psi (kPa) at - °F (°C)

43

41

W Max. allowable external working pressure

-20 °F (°C) at 150 psi (kPa)

Compress Sample

Typ. Typ. 41 F2 Min. Design Metal Temperature (MDMT)

Nozzle

F1 Size Job ID Drawing No. Revision:

Nozzle

Outside F1

Outside Outside Outside Shell

N-0000

B PVE-6161 PVEdwg-6161-0.1 Compress Sample 0

Shell Manufacturer's serial number Scale Material Sheet

SB ~ 2012 1:1 See BOM 1 OF 1

Typ. Circ. Seam Typ. Long Seam UW-16.1 (c) with CRN Year built This drawing and the information herein is confidential, and must not be reproduced

UW-16.1 (c) inside projection Slip On Flange UW-16.1 (z-1) Coupling or used in any way without the written permission of Pressure Vessel Engineering Ltd.

You might also like

- Drawing Heat Exchanger Assembly Rev 02 PDFDocument9 pagesDrawing Heat Exchanger Assembly Rev 02 PDFDaniel Corredor Gonzalez100% (2)

- Tema Tubesheet Calculation SheetDocument1 pageTema Tubesheet Calculation SheetSanjeev KachharaNo ratings yet

- Sample8 DrawingDocument1 pageSample8 DrawingRam Kumar NNo ratings yet

- Sample3 Drawing PDFDocument2 pagesSample3 Drawing PDFMas Arman TewoNo ratings yet

- Sample13 DrawingDocument2 pagesSample13 DrawingSourav HaitNo ratings yet

- Pveng: Vessel With Large Opening Pve Sample VesselDocument1 pagePveng: Vessel With Large Opening Pve Sample VesselSivateja NallamothuNo ratings yet

- Fab Shop DrawingsDocument14 pagesFab Shop DrawingszainyousafzaiNo ratings yet

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDocument1 pageL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77No ratings yet

- STD-B-002 (Manhole With Davit) - ModelDocument1 pageSTD-B-002 (Manhole With Davit) - ModelRavindra BarangeNo ratings yet

- Drawing Mekanikal SiakDocument20 pagesDrawing Mekanikal SiakDian RoesmanaNo ratings yet

- Detail H Scale 1: 3: Section E-E SCALE 1: 10Document2 pagesDetail H Scale 1: 3: Section E-E SCALE 1: 10Brahamadandi Achyuth KumarNo ratings yet

- S.No. Part No. Description Remarks: 11.5 MM Dia #12 Equal Distance Both Side 550 6 M5X40#4 Allen BoltDocument1 pageS.No. Part No. Description Remarks: 11.5 MM Dia #12 Equal Distance Both Side 550 6 M5X40#4 Allen Boltsabir hussainNo ratings yet

- Heavy Machines (T23J0252A) - Erection DrawingsDocument64 pagesHeavy Machines (T23J0252A) - Erection DrawingsRamiro PerezNo ratings yet

- Sample Seal Pot DWGDocument1 pageSample Seal Pot DWGsandesh sadvilkarNo ratings yet

- Hopper Guide Plate DWG - RDDocument1 pageHopper Guide Plate DWG - RDRaj KumarNo ratings yet

- 2100 S 40534 - 0 PDFDocument1 page2100 S 40534 - 0 PDFstefano.herradaNo ratings yet

- 2294e2 4699 De10 Gad 0006Document1 page2294e2 4699 De10 Gad 0006Issa Med El AbdNo ratings yet

- Asme SawDocument3 pagesAsme Sawhalil ozgunNo ratings yet

- Sand Filter-RwtpDocument6 pagesSand Filter-RwtpAbu SuraisyNo ratings yet

- TK-1560 A&bDocument23 pagesTK-1560 A&bromeo112976No ratings yet

- r1Document3 pagesr1naseema1No ratings yet

- DWG-04.11-ME-011 Pri - Sludge - Pump - Station 3 - 5 (r.6) PDFDocument5 pagesDWG-04.11-ME-011 Pri - Sludge - Pump - Station 3 - 5 (r.6) PDFAhmed HussienNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Murthy GunaNo ratings yet

- 1607 Distillation Reactor As BuiltDocument3 pages1607 Distillation Reactor As BuiltvidyaNo ratings yet

- 660 Gallon TankDocument2 pages660 Gallon Tankleeconner3No ratings yet

- Intercambiador de Calor PDFDocument10 pagesIntercambiador de Calor PDFShalber Jhoel Garcia SaraviaNo ratings yet

- 3147 Hoist r3Document1 page3147 Hoist r3Ade Y SaputraNo ratings yet

- 0602 - 2 - 012 Anchor Bolts PDFDocument2 pages0602 - 2 - 012 Anchor Bolts PDFthesobrevivienteNo ratings yet

- AutoPIPE Vessel GuideDocument5 pagesAutoPIPE Vessel Guidefiuto_rights_1404802No ratings yet

- Kennedy Valve: 3"-12" Oil Cushion Check Valve AssemblyDocument1 pageKennedy Valve: 3"-12" Oil Cushion Check Valve AssemblySamuel Lopez BenitesNo ratings yet

- Calculo de Refuerzos Stub-OnDocument11 pagesCalculo de Refuerzos Stub-OnRoni Oscar Olaza OrtizNo ratings yet

- Mud Agitator Drawing 15KW-Layout1Document1 pageMud Agitator Drawing 15KW-Layout1enuvos engineeringNo ratings yet

- Check Safety Requirements For Clutch Door According To ASMEDocument3 pagesCheck Safety Requirements For Clutch Door According To ASMEtranhonghakd5533No ratings yet

- As Built: Rfso, C/W Dip PipeDocument18 pagesAs Built: Rfso, C/W Dip Piperomeo112976No ratings yet

- Tac4598 - 3350KW - Instruction ManualDocument48 pagesTac4598 - 3350KW - Instruction ManualMiguel Angel RodriguezNo ratings yet

- Shop Drawing Daily Tank 10 Feb 2019-Bottom Plate (1.1)Document1 pageShop Drawing Daily Tank 10 Feb 2019-Bottom Plate (1.1)EnyNo ratings yet

- Bill of Material - 3105538: QTY Description Part No. ItemDocument3 pagesBill of Material - 3105538: QTY Description Part No. ItemluisNo ratings yet

- WEP Standard For Reference OnlyDocument37 pagesWEP Standard For Reference OnlyKiran NikateNo ratings yet

- HeatExchanger DrawingDocument7 pagesHeatExchanger DrawingSivateja Nallamothu100% (1)

- Pbadupws - Nrc.gov Docs ML0731 ML073190432Document57 pagesPbadupws - Nrc.gov Docs ML0731 ML073190432Ashish MahtoNo ratings yet

- Pipe Thread NPT and BSPT Fittings CompatibilityDocument5 pagesPipe Thread NPT and BSPT Fittings CompatibilityEduardoNo ratings yet

- Nalco Idler-S409/1 - 37870/8200004980/IDLERS&ROLLERSDocument2 pagesNalco Idler-S409/1 - 37870/8200004980/IDLERS&ROLLERSAlok NayakNo ratings yet

- TK 1456Document20 pagesTK 1456romeo112976No ratings yet

- Stainless Steel, cf8, cf3, cf8m, cf3m, Ca15, Ca40, 17 - 4, 15 - 5, cd4m 1a, cg8mDocument2 pagesStainless Steel, cf8, cf3, cf8m, cf3m, Ca15, Ca40, 17 - 4, 15 - 5, cd4m 1a, cg8mDewandanuNo ratings yet

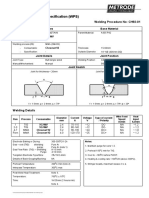

- Welding Procedure Specification (WPS)Document3 pagesWelding Procedure Specification (WPS)Jignasa ShahNo ratings yet

- Dimensions and Weights of Welded and Seamless Wrought Steel Pipe Asme b36.10mDocument77 pagesDimensions and Weights of Welded and Seamless Wrought Steel Pipe Asme b36.10mPablo Cesar PanessoNo ratings yet

- Univeral WPS For Pipe To Plate Fillet Welding (6800009)Document1 pageUniveral WPS For Pipe To Plate Fillet Welding (6800009)Ibrahim shaikNo ratings yet

- Manual de Zaranda Alta Frecuencia Sds38-6mv-5 (Sr4639)Document15 pagesManual de Zaranda Alta Frecuencia Sds38-6mv-5 (Sr4639)victoranticonajicaro100% (1)

- ANSI B36.10 Steel PipesDocument8 pagesANSI B36.10 Steel Pipesphoneme79No ratings yet

- Grating Weight - CalculationDocument1 pageGrating Weight - CalculationMuthuram NNo ratings yet

- SBC (Safety Break-Away Couplings) v140630Document16 pagesSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Details of Star Column Splice ConnectionDocument3 pagesDetails of Star Column Splice ConnectionArun KesbhatNo ratings yet

- Sample2 DrawingDocument1 pageSample2 DrawingSourav HaitNo ratings yet

- Sample2 DrawingDocument1 pageSample2 DrawingganeshNo ratings yet

- Calcs 4Document19 pagesCalcs 4Syariful Maliki NejstaršíNo ratings yet

- Example Vessel Re RatingDocument9 pagesExample Vessel Re RatingRBKUMARNo ratings yet

- Sample4 SpreadsheetDocument21 pagesSample4 SpreadsheetTrishul Nath Pallay100% (1)

- Cartridge Valves For Submarine, Aircraft Carrier Rocket LauncherDocument27 pagesCartridge Valves For Submarine, Aircraft Carrier Rocket LauncherPeter JonesNo ratings yet

- Datasheet Phe OnwjDocument1 pageDatasheet Phe OnwjMamank Ira Sudrajat100% (1)

- PVEclc-6847-0.1 Generic Vessel PDFDocument61 pagesPVEclc-6847-0.1 Generic Vessel PDFKarthik AnandanNo ratings yet

- PlannerDocument36 pagesPlannerFaull JackmanNo ratings yet

- Walworth - V Iron Plug - 2012Document44 pagesWalworth - V Iron Plug - 2012Faull JackmanNo ratings yet

- Model 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesDocument4 pagesModel 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesFaull JackmanNo ratings yet

- FMC - Desairador VerticalDocument4 pagesFMC - Desairador VerticalFaull JackmanNo ratings yet

- Model 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesDocument4 pagesModel 215 Wafer Sphere 3"-12" Digital Control Valve: FeaturesFaull JackmanNo ratings yet

- Pressfit 316 Stainless Steel Pipe SystemDocument12 pagesPressfit 316 Stainless Steel Pipe SystemFaull JackmanNo ratings yet