Professional Documents

Culture Documents

Page 53 Missing

Page 53 Missing

Uploaded by

Janita SiddiquiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Page 53 Missing

Page 53 Missing

Uploaded by

Janita SiddiquiCopyright:

Available Formats

PROCEDURE

a) - FOR MATERIALS HAVING SOFTENING POINTS 80°C OR BELOW

Assemble the apparatus with the rings, ASTM Thermometer 15 °C or I5 °F, and

ball centering guides in position and fill the bath with freshly boiled water to a

depth of not less than 102mm and not more than 108mm. Maintain the bath

temperature at 5 ± 1°C for 15 min, placing the test container in ice water if

necessary. Using forceps, place a ball, previously adjusted to the bath temperature,

in each ball-centering guide.

Apply heat in such a manner that the temperature of the liquid is raised 5°C/min.

Avoid the effect of drafts, using shields if necessary. (Rigid adherence to the

prescribed rate of heating is absolutely essential for reproducibility of results.

Either a gas burner or electric heater may be used; however, the latter must be of

the low-lag, variable output type to maintain the necessary rate of heating.)

The rate of rise of temperature shall be uniform and shall not be averaged over the

period of the test. The maximum permissible variation of any 1-mm period after

the first 3 mm shall be ± 0.5°C. Reject all tests in which the rate of rise does not

fall within these limits.

Record for each ring and ball the temperature shown by the thermometer at the

instant the specimen surrounding the ball touches the bottom plate. Make no

correction for the emergent stem of the thermometer. If the difference between the

values obtained in the duplicate determinations exceeds 1°C repeat the test.

b) - FOR MATERIALS HAVING SOFTENING POINTS ABOVE 80°C

Follow the same procedure as described above, except use USP glycerin

instead of water and use ASTM Thermometer l6°C or 16°F. The starting

temperature of the glycerin bath shall be 32°C.

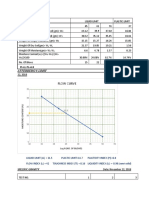

OBSERVATIONS & RESULTS

SOFTENING POINT MEAN

Sr. #

(°C) (°C)

COMMENTS

Page 53 of 53

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Job 5Document10 pagesJob 5Janita SiddiquiNo ratings yet

- End Conditions Weight of Colum (Grame) Width B (MM) Thickness T (MM) Length L (MM)Document6 pagesEnd Conditions Weight of Colum (Grame) Width B (MM) Thickness T (MM) Length L (MM)Janita SiddiquiNo ratings yet

- Job 9Document3 pagesJob 9Janita SiddiquiNo ratings yet

- Lab CompilationDocument11 pagesLab CompilationJanita SiddiquiNo ratings yet

- LAB TestsDocument35 pagesLAB TestsJanita SiddiquiNo ratings yet

- Report GeoDocument24 pagesReport GeoJanita SiddiquiNo ratings yet

- Visit To Construction Ste: 2016-CIV-16 2016-CIV-18 2016-CIV-31 2016-CIV-55Document5 pagesVisit To Construction Ste: 2016-CIV-16 2016-CIV-18 2016-CIV-31 2016-CIV-55Janita SiddiquiNo ratings yet

- Time Inflow (Q) Area of flow (A) Depth (y) Kr Width (b) Ry Velocit y Sr q q weeks m /sec m m m m m m/sec ton/sec/m kg/sec 26 − 0.25 ρDocument8 pagesTime Inflow (Q) Area of flow (A) Depth (y) Kr Width (b) Ry Velocit y Sr q q weeks m /sec m m m m m m/sec ton/sec/m kg/sec 26 − 0.25 ρJanita SiddiquiNo ratings yet

- Wind RoseDocument2 pagesWind RoseJanita SiddiquiNo ratings yet

- Time Inflow (Q) Area of flow (A) Depth (y) Kr Width (b) Ry Velocit y Sr q q weeks m /sec m m m m m m/sec ton/sec/m kg/sec 26 − 0.25 ρDocument8 pagesTime Inflow (Q) Area of flow (A) Depth (y) Kr Width (b) Ry Velocit y Sr q q weeks m /sec m m m m m m/sec ton/sec/m kg/sec 26 − 0.25 ρJanita SiddiquiNo ratings yet

- 2 Fluid Statics PDFDocument1 page2 Fluid Statics PDFJanita SiddiquiNo ratings yet

- TITLE: Graph Between Moisture Content and Depth: CommentsDocument3 pagesTITLE: Graph Between Moisture Content and Depth: CommentsJanita SiddiquiNo ratings yet

- Perspective of Pakistan On SDG Goal 16Document22 pagesPerspective of Pakistan On SDG Goal 16Janita SiddiquiNo ratings yet