Professional Documents

Culture Documents

Check Points

Check Points

Uploaded by

MauliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check Points

Check Points

Uploaded by

MauliCopyright:

Available Formats

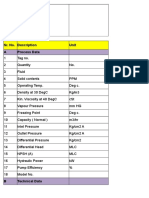

EP 7-1-1

7.7 Nozzles

7.7.8 (*) Unless otherwise specified by the Owner’s Engineer, nozzles NPS 12 inches and smaller

shall have a minimum external projection of 8 inches, and nozzles NPS 14 inches and larger

shall have a minimum projection of 10 inches (all measured on the short side) with the following

additional requirements:

1) If the nozzle is made from pipe and a weld neck flange, the nozzle projection shall be

increased as necessary to permit stud removal from the back side of the flange without

interference from the insulation.

2) If a long weld neck flange or other forged nozzle configuration (i.e. Figure 1, Type 4

integral and Figure 2, Types 1 through 4 integral radiographable) is used, the nozzle

projection shall be increase as necessary to permit stud removal from the back side of the

flange without interference from the insulation provided the resulting projection is within

common commercially available lengths. The vessel fabricator shall identify where “special

orders” would be required and the associated cost. If the resulting nozzle projection

requires “special order” nozzles, the minimum projections specified above shall be used.

7.7.9 Nozzles adjacent to shell girth flanges or horizontal vessel saddles shall be located with

adequate clearance such that bolt tightening equipment can be used on the girth flange bolts.

Adequate clearance in the form of additional saddle height shall be provided such that bolts

between connecting nozzles of stacked heat exchangers can be removed without moving the

heat exchangers.

7.7.6 (*) Nozzle Internal Projections

Unless otherwise specified by the Owner’s Engineer, all nozzles not directly connected to

internals shall be flush with the inside surface of the vessel wall. However, nozzles in portions

of vessels with refractory or linings shall have internal projections such that the nozzle end is

flush with the lining. If retaining rings are used, the nozzle shall have a projection beyond the

lining equal to the thickness of the retaining ring.

[Nozzle internal projection: - Shall be min. 2”]

8.6 Nameplate

8.6.1 All vessels shall be furnished with a stainless steel nameplate. Nameplates shall be installed on

the Manufacturer’s standard nameplate holder of sufficient length to project at least 1 inch

beyond the vessel insulation. The letters and figures shall be at least 5/32 inch high. A drawing

of the nameplate shall be included in the Manufacturer’s vessel drawings.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- RKF 125 Owner ManualDocument15 pagesRKF 125 Owner ManualMohamed ali Ameur67% (3)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Hyster C530a Parts Manual PDFDocument928 pagesHyster C530a Parts Manual PDFEduardo Nuñez83% (6)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Erori dq200Document4 pagesErori dq200Sigismund Beria100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Boq of 100kl Storage TankDocument6 pagesBoq of 100kl Storage TankMauliNo ratings yet

- Pressure: Introduction To Pressure - Psi and Pa - Online Pressure Units ConverterDocument3 pagesPressure: Introduction To Pressure - Psi and Pa - Online Pressure Units ConverterMauliNo ratings yet

- Centrifugal Pump Datasheets 2Document12 pagesCentrifugal Pump Datasheets 2MauliNo ratings yet

- What Is The Relation Between Gauge Pressure Absolute Pressure Atmospheric Pressure and Vacuum Pressure - QuoraDocument3 pagesWhat Is The Relation Between Gauge Pressure Absolute Pressure Atmospheric Pressure and Vacuum Pressure - QuoraMauliNo ratings yet

- Scope of Work Doc-Fire Hydrant SystemDocument2 pagesScope of Work Doc-Fire Hydrant SystemMauliNo ratings yet

- Centrifugal Pump Datasheets 1Document12 pagesCentrifugal Pump Datasheets 1MauliNo ratings yet

- Gear Pump Datasheets 1Document12 pagesGear Pump Datasheets 1MauliNo ratings yet

- Gear Pump Datasheets 2Document12 pagesGear Pump Datasheets 2MauliNo ratings yet

- Boq of 70kl Storage TankDocument10 pagesBoq of 70kl Storage TankMauliNo ratings yet

- Ready Recknor For Vessel CalculationDocument57 pagesReady Recknor For Vessel CalculationMauli100% (1)

- Thermal Aruma Pilot (Tar) Project 18029 Tatweer Petroleum MechanicalDocument2 pagesThermal Aruma Pilot (Tar) Project 18029 Tatweer Petroleum MechanicalMauliNo ratings yet

- Burks Series GNB Centrifugal Pump ManualDocument10 pagesBurks Series GNB Centrifugal Pump ManualAna MoraNo ratings yet

- FinalDocument7 pagesFinalMuralee Dharan PillaiNo ratings yet

- Ho-U Spring Latch Core BarrelDocument1 pageHo-U Spring Latch Core BarrelRossin Hernan Zamora GarciaNo ratings yet

- 701, 702 Oil Burners: Replacement PartsDocument2 pages701, 702 Oil Burners: Replacement PartsHerbert Quispe RjsNo ratings yet

- Sample 7397Document11 pagesSample 7397UdhamNo ratings yet

- WB2630T2 RS2 ExercisesDocument1 pageWB2630T2 RS2 ExercisesMax AdelingNo ratings yet

- Generator Manual: Installation - Operation - MaintenanceDocument66 pagesGenerator Manual: Installation - Operation - MaintenanceJohn Alexander Bonilla AngelNo ratings yet

- PLATE KapalDocument11 pagesPLATE KapalRizal HidayatullahNo ratings yet

- Type 1061 Pneumatic Piston Rotary ActuatorDocument24 pagesType 1061 Pneumatic Piston Rotary ActuatorJesus BolivarNo ratings yet

- Kpijci ft4240Document6 pagesKpijci ft4240HéctorNo ratings yet

- 04 Shallow Foundations 3 - Eccentric LoadingDocument60 pages04 Shallow Foundations 3 - Eccentric LoadingRyan SantosNo ratings yet

- Modern Chap 2Document11 pagesModern Chap 2AMANUEL BABBANo ratings yet

- ACMV Talk 2008 - FinalDocument111 pagesACMV Talk 2008 - FinalFrankie FanNo ratings yet

- Book - Lattice Boltzmann Methods For Shallow Water FlowsDocument117 pagesBook - Lattice Boltzmann Methods For Shallow Water FlowsMauricio Fabian Duque DazaNo ratings yet

- Rele de Proteccion DGPT2 2Document8 pagesRele de Proteccion DGPT2 2WALTERNo ratings yet

- Tai Lieu Thiet Ke Dai RangDocument6 pagesTai Lieu Thiet Ke Dai RangCủa Tôi Thần TuợngNo ratings yet

- Wittenburg Dynamics of Systems of Rigid BodiesDocument223 pagesWittenburg Dynamics of Systems of Rigid Bodiesxogus6216No ratings yet

- Gs 13 Preferred Makes MasterDocument91 pagesGs 13 Preferred Makes Masteronshore purchaseNo ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering Steelraaspoy2007No ratings yet

- CR, Cri, CRN: Safety Instructions and Other Important InformationDocument64 pagesCR, Cri, CRN: Safety Instructions and Other Important InformationNatalja KalarashNo ratings yet

- Homemade Hydraulic Ram Pump For Livestock WaterDocument19 pagesHomemade Hydraulic Ram Pump For Livestock WaterHartoyo Gondomulia100% (1)

- WOMA Technical Data All Pumps en MedidasDocument11 pagesWOMA Technical Data All Pumps en MedidasEd CalheNo ratings yet

- Appendix Five Data On Fracture Toughness and Shock Toughness Fatigue Life Characteristics of Thermal Stability Corrosion Resistance and Castability ofDocument3 pagesAppendix Five Data On Fracture Toughness and Shock Toughness Fatigue Life Characteristics of Thermal Stability Corrosion Resistance and Castability ofChin-Min YangNo ratings yet

- CS, 1134.kit VedaçãoDocument3 pagesCS, 1134.kit VedaçãoGabriel SouzaNo ratings yet

- Economic SectionsDocument13 pagesEconomic SectionsArvin NaborNo ratings yet

- Effect of Silica Particles On Epoxy ResinDocument11 pagesEffect of Silica Particles On Epoxy ResinRaza AliNo ratings yet