Professional Documents

Culture Documents

Goktepe 2006

Goktepe 2006

Uploaded by

salmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Goktepe 2006

Goktepe 2006

Uploaded by

salmaCopyright:

Available Formats

Textile Research Journal Article

A Comparison of Compact Yarn Properties

Produced on Different Systems

1

Fatma Göktepe , Demet

Abstract It is well known that yarn produced using Yilmaz and Özer Göktepe

the compact spinning technique, which has been Textile Engineering Department, The University

introduced as one of the best spinning inno-vations of

of Suleyman Demirel, Isparta, Turkey

this century, has superior yarn structure and quality,

especially in terms of hairiness and strength. However,

there are different compact spin-ning systems on the

market from different manu-facturers and information

concerning the favorable and unfavorable properties of

each would be of great interest. In this study, we

compared the prop-erties of yarn spun on the three main

compact spinning systems commonly used today. To

main-tain impartiality it was preferable to refer to these

three systems as system A, system B, and system C

instead of using their trade names. It was found that

system B seemed to be more suitable for finer yarns

whereas system A generally gave better results for

medium to coarse counts.

Key words compact yarn spinning systems, yarn

hairiness, yarn properties

There are a number of new systems offered to tackle the There are studies comparing compact yarn structure with

current yarn quality/production speed problem on conven- conventional ring spun yarns, and the greater even-ness of

tional ring systems and compact yarn spinning is one of these. structure and reduced hairiness of compact yarns is well

Although this system uses the major components of a known [1–3]. Furthermore, because of this structure, greater

conventional ring spinning system, it is also considered to be strength, evenness and elongation properties have been

a new spinning system by some researchers [1, 2]. reported by several researchers [1–7]. On the other hand,

Today, there are a number of designs offered by differ-ent some investigations have indicated that the same strength, and

machine manufacturers, but they all use the same prin-ciple, therefore higher productivity, can be achieved with lower

namely condensing the fibrous strand at the end of the draft twist values [1–3, 8–10]. Krifa and Hequet defined the

region pneumatically. The main compact spin-ning machine necessary fiber properties for this system [11] and Mahmood

producers available today are Zinser by Air-Com-Tex 700 et al. studied the effect of spinning parame-ters on yarn

(CompACT3), Rieter by K44 (Com4) and Suessen by Elite. hairiness [12].

However, some other companies such as Cognetex and Both yarn structure and the performance of compact yarns

Officine Gaudino have recently introduced their own designs in downstream processes have been investigated and the

to the market. benefits of compact yarn in winding, sizing, singe-ing,

Although, the compact system was first introduced at doubling, weaving, and knitting have been reported

ITMA 1995, most of the subsequent publications in this field

derive from the compact spinning system manufacturers or

the institutions involved in developing the system, and inde- 1 Corresponding author: fax: + 90 246 237 08 59; e-mail: fgok-

pendent studies, although needed, are very limited. tepe@mmf.sdu.edu.tr

Textile Research Journal Vol 76(3): 226–234 DOI: 10.1177/0040517506061241 www.trj.sagepub.com © 2006 SAGE Publications

Figures 6, 7 appear in color online: http://trj.sagepub.com

Downloaded from trj.sagepub.com at Karolinska Institutets Universitetsbibliotek on May 24, 2015

A Comparison of Compact Yarn Properties Produced on Different Systems F. Göktepe et al. 227

TRJ

in some studies. Dash et al. studied their performance in

winding [4] and Krifa et al. compared the performance of ring

Material and Methods

spun and compact yarns spun from various staple lengths of

fibers [5]. Artzt indicated the advantage of this system for

Compact Yarn Spinning Systems Used

combed yarns [13] and Behera et al. studied the performance In this study, the three different systems most commonly in

of compact yarns in weaving [14]. use today in short staple spinning mills were compared. The

In his study, Hechtl produced worsted yarn on a com-pact basic principles of these three systems (named as sys-tem A,

spinning system and compared its properties with con- B, and C, respectively in this paper) are shown in Figures 1–3.

ventional yarns [9]. Artzt, on the other hand, reported that this

system was also advantageous for man-made fiber spinning System A has a perforated apron which follows just after

[13]. the classical 3 over 3 drafting rollers (Figure 1). One of the

However, Cheng and Yu criticised the compact spin-ning typical properties of this system is its perforated apron

system, suggesting that it was only effective for yarns finer situated at the top and an air current created under-neath. In

1

than Ne 60 and that it required higher investment and system A, the delivery top roller (4 ) and perfo-rated apron

maintenance costs [2]. Similarly, Oxenham reported that for are the condensing components and are called the

of similar reasons the system was still not widely accepted in “compacting element”. After drafting, the fiber bundle is

the USA [6]. 1 2

sucked through the slot in the H –H region by air suc-tion

Nikolic et al. reported another interesting study in which after leaving the front rollers. The perforated apron has pores

they compared the properties of cotton and cotton/ polyester and the forms of these pores are in the order elliptical pores

blended compact yarn spun on the Elite Fiomax E1 machine followed by circular ones.

of Suessen and Air-Com-Tex 700 of Zinser On the other hand system B, which is shown schematically

[15]. However their study did not compare these two com- in Figure 2, uses a perforated drum rather than an apron.

pacting systems but instead focused on a comparison of Inside the perforated drum, there is a stationary drum hav-ing

compact yarns with conventional yarns. a slot in direction of fiber flow so that an extra transverse

In all the studies mentioned above, the main interest was force could be applied onto the yarn. Fibers are caught by the

on the superior yarn and fabric properties of com-pact yarns air current in the perforated drum soon after they leave the nip

1 2

as well as their running performance in down-stream point (3–3 ) until they reach the nip point (3–3 ). The air

processes in comparison with the conventional yarns. current influences the fibers to pass along the slot

However, we believe a comparison of the differ-ent systems (S) and therefore the fibers are condensed by means of the

currently in common use in the world would be a valuable aerodynamic forces caused by the air current.

contribution to the decision-makers in the short-staple The third system, system C has a perforated apron simi-lar

spinning industry, and so the present study compared the to the system A, but this is situated at the bottom part of the

properties of compact ring spun yarns made from the same drafting system (Figure 3). Underneath this apron, there is a

raw material but spun on different systems. grooved tube (S) to facilitate the condensing process. This

tube has a small slot beginning from the nip line of

Figure 1 The basic principle of system A.

Downloaded from trj.sagepub.com at Karolinska Institutets Universitetsbibliotek on May 24, 2015

TRJ 228 Textile Research Journal 76(3)

Figure 2 The basic principle of

system B.

Figure 3 The basic principle of system C.

1

front rollers (S ) and ending at the delivery nip line formed by Yarn Production

4

the delivery top roller (S ). The form of the groove changes

We produced 100% cotton combed compact yarns of Ne 20/1,

according to yarn count and raw material. The condensing

Ne 30/1 and Ne 41/1 on each system. This count range was

zone consists of a grooved tube (S), lattice apron and the

chosen since it covers the majority of the yarn pro-duced

delivery top roller (4). Drafted fibers pass to the condensing

zone and are held on the surface of the perforated apron although the compact system is mainly designed for finer

firmly. The fibers are seized by the air current and transported counts.

1 4 It was necessary to use different roving for Ne 41 to be

from the S end to the S end of the suction slot.

able to produce the yarn count range required without any

difficulty. Therefore the yarns of Ne 20 and Ne 30 were

produced from Agean cotton of Ne 0.85 rovings whereas

Downloaded from trj.sagepub.com at Karolinska Institutets Universitetsbibliotek on May 24, 2015

A Comparison of Compact Yarn Properties Produced on Different Systems F. Göktepe et al. 229

TRJ

the yarns of Ne 41 were produced from Greek cotton of Ne

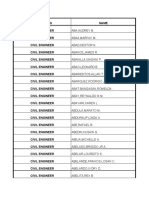

Table 1 The fiber properties.

1.0 roving count.

For yarn production, the yarn preparation processes were Properties Mean values

followed closely. During yarn spinning, the same rov-ings Agean cotton Greek cotton

were fed in the same order to the spindles of each of the

different compact yarn spinning machines to eliminate any Staple Length (mm) 30.1 28.2

Micronaire 4.6 4.2

variation between roving bobbins. On each machine, the same

U.I. 85.6 82.6

10 spindles were also used during the production of different Strength (g/tex) 30.6 27.9

yarn counts to eliminate any possible variation between Breaking Elongation (%) 6.7 11.6

spindles. SFI 7.3 6.9

In addition, all yarn samples were produced with the same +b 8.0 7.6

spinning parameters, namely the same twist multi-plier, draft Rd 76.5 74.85

and spindle speed, etc. We also tried to use same traveler for CG 31–2 41–1

each, but there had to be slight differ-ences in travelers SCI 153 128.6

because of the differences between ring diameters and profiles

of the three compact spin-ning machines. However, the most

suitable traveler types having similar wire profile and shape was used [16–18]. However, when we examined the test

were chosen by fol-lowing the manufacturer’s results, it was found that the highest hairiness values occurred

recommendations to provide the highest performance for each with system C although the traveler used for this count at

ring profile and yarn count. In terms of traveler number, system C was the heaviest. Similarly, the lowest hairiness

similar numbers were used during the production of Ne 20 results were obtained at system A for Ne 41 although the

and Ne 30 counts, but for Ne 41 yarn, there were differences lightest traveler was used there. As a result, the effect of the

as the lightest traveler was used for System A whereas the traveler weight for Ne 41 seemed to be insignificant.

heavi-est one was used for System C. As it is well known, the

yarn hairiness values decrease as the heavier traveler The fiber properties and spinning parameters are given in

Tables 1 and 2, respectively.

Table 2 Spinning particulars.

System A System B System C

Roving count 0.85

Twist (t/m) 628

αe 3.6

Spindle speed (rpm) 12.000

Ne 20

Take-up speed (m/min.) 19 19 19

Traveler EL1 Hf 1/0 C1 UL Udr 1/0 C1 LM Udr 1/0

Ring diameter (mm) 38 (Elliptic) 40 (Titan) 40 (Titan)

Break draft 1.18 1.14 1.16

Draft Total 23.5 23.8 23.4

Roving count 0.85

Twist (t/m) 843

αe 3.9

Spindle speed (rpm) 15.000

Ne 30

Take-up speed (m/min.) 17.8 17.8 18.5

Traveler EL1 Hf 5/0 C1 EL Udr 4/0 C1 LM Udr 5/0

Ring diameter (mm) 38 (Elliptic) 40 (Titan) 40 (Titan)

Break draft 1.18 1.14 1.16

Draft Total 35.3 35.6 34.9

Roving count 1.0

Twist (t/m) 918

αe 3.56

Spindle speed (rpm) 15.500

Ne 41

Take-up speed (m/min.) 16.8 16.8 17

Traveler EL1 Hf 4/0 C1 EL Udr 6/0 C1 LM Udr 7/0

Ring diameter (mm) 38 (Elliptic) 40 (Titan) 40 (Titan)

Break draft 1.19 1.14 1.16

Draft Total 40.7 41.0 40.5

Downloaded from trj.sagepub.com at Karolinska Institutets Universitetsbibliotek on May 24, 2015

TRJ 230 Textile Research Journal 76(3)

Yarn Tests

To minimize any possible variation, we used 10 spindles side

by side on each compact spinning machine and obtained

samples following two consecutive doffings from each

spindle. As a result, 20 bobbins from each compact spinning

machine for each yarn count were available to determine their

properties.

The yarn tests were carried out on Uster Tester 4, Uster

Tensorapid and Zweigle G566 testers by feeding bobbins of

each system in the same order to the test-ers. Twenty bobbins

were tested for each system yielding the average values of 20

test results for each property. The tests were carried out under

standard atmospheric conditions and the samples were

conditioned for a mini-mum of 24 hours before the tests. All Figure 5 Zweigle hairiness (S3) values.

the tests were car-ried out on the same testers and the test

results were analysed statistically to determine any significant

differ-ences [19].

the suction is through narrower grooves situated under-neath

the perforated drum and lattice apron, respectively (Figure 6).

Results and Discussion 1

In system A, the roller 4 has a larger diameter in com-

1

parison with the roller 3 (Figure 1) leading to a slight draft in

this condensing region. However, at system B and C, there is

Yarn Hairiness Results no such draft in this region. The combined effect of air

The Uster hairiness (H) and Zweigle S3 results are given in suction through the perforated apron and such a draft

(max.1.04) in system A might lead to much better fiber

Figures 4 and 5. The test results show that system A had the

control and binding into the yarn body, and therefore reduced

lowest hairiness in terms of both Uster H and Zweigle S3

hairiness. These aspects indicate that system A works more

value in comparison with the other two systems for all yarn

effectively in terms of reducing hairiness for this range of

counts we produced. The reason for this might be the different yarn counts because the condensing power may be stronger

design and construction of the systems. In system A, the air than that of systems B and C. As reported by the

suction is performed over a larger area under-neath the manufacturers, system A has a maximum suction of 3430 Pa

perforated apron. However, in systems B and C whereas systems B and C have 686 and 3000 Pa suction,

respectively.

System B appeared to yield the highest H and S3 values

for Ne 20, but this trend changed for Ne 30 and Ne 41 as

system C had the highest values. This is in agreement with the

earlier study of Cheng and Yu [2] as system B was reported to

having quite weak fiber control and therefore poorer fiber

properties for coarse yarns.

On the other hand, yarns produced on system C had the

higher variation in hairiness values. The high CV% of hair-

iness of these yarns has a negative effect on subsequent

processes. This might lead to the conclusion that fiber con-trol

by the compacting action of this system was not very constant

and stable because of the lattice apron design. The surface of

this apron has a porous structure like a net, causing fiber

deposition and blockage at the surface from time to time as

observed during production. However, in system B there was

an air guide element (Figure 7) pro-tecting the pores of the

steel drum from fiber/dust block-age. Similarly there was also

no blockage in system A since the air suction is at the top

Figure 4 Uster Hairiness (H) values. through a single line of pores (Figure 8).

Downloaded from trj.sagepub.com at Karolinska Institutets Universitetsbibliotek on May 24, 2015

A Comparison of Compact Yarn Properties Produced on Different Systems F. Göktepe et al. 231 TRJ

Figure 6 Different designs of suction slots in three systems. (1), (2), (3):, suction slots.

Figure 7 Air guide element of system B. Figure 8 Perforated apron of system A.

Yarn Irregularity Results

On the other hand, the reason for the unsatisfactory results

Irregularity test results are given in Figure 9. The test results with system B for Ne 20 and Ne 30 might perhaps be the

show that statistically the system A had the best irregularity weak compacting power of this system for the medium to

for Ne 20 and Ne 30, whereas system B had the best value for coarse counts, as similar results have been reported earlier

Ne 41. Clearly, system C had the worst irreg-ularity results as [2]. System A had worse irregularity values for Ne 41 yarn in

well as the highest variation for all yarn counts we applied. A comparison with the system B. This can be explained by the

possible explanation for that might be the weak fiber control level of suction power, as it might be higher than the ideal

by system C due to the blockage of fibers underneath the value for Ne 41, although optimum for Ne 20 and Ne 30

perforated apron, as sometimes observed, leading to unstable yarns for system A.

compacting power and there-fore uncontrolled spinning

during production.

Downloaded from trj.sagepub.com at Karolinska Institutets Universitetsbibliotek on May 24, 2015

TRJ 232 Textile Research Journal 76(3)

Figure 11 Thick place values.

Figure 9 Irregularity values.

When the neps values shown in Figure 12 are exam-ined,

system A appeared to have the lowest value for Ne 20 and Ne

30. However, there was no statistically sig-nificant difference

between the three systems for Ne 20, although, on the other

Yarn Imperfection Results

hand, system B gave the best values for Ne 41.

The test results for thin places, thick places and neps are

shown in Figures 10–12. The results above also reveal some limitations for these

Similar to the irregularity results, system A appears to have systems in general. In system B, the power of the suction

given the best values for Ne 20 and 30 whereas system B gave effect may not be strong enough as the distance between the

the best values for Ne 41 (Figure 10). However, no apron nip line (R) and the front roller nip line is longer than

statistically significant difference was found between the test that of the conventional ring spinning drafting system

results of systems A and B for Ne 30 and Ne 41. On the other [2] (Figure 2) and this distance can not be reduced further

hand, the yarn produced on system C had the highest variation because of the large diameter of the perforated drum. Fib-ers

for thin places. that are shorter than this distance could not be drafted

When thick place values were analysed (Figure 11), the properly and this situation may cause increased yarn faults.

results were quite similar to the above findings. Earlier findings such as the increased number of thick

Figure 10 Thin place values. Figure 12 Neps values.

Downloaded from trj.sagepub.com at Karolinska Institutets Universitetsbibliotek on May 24, 2015

A Comparison of Compact Yarn Properties Produced on Different Systems F. Göktepe et al. 233

TRJ

Figure 13 Yarn tenacity values. Figure 14 Yarn breaking elongation values.

places and neps for compact yarns confirm this point [2, 7]. Conclusions

Consequently, this restricts the raw material properties used in

this system and therefore this system seems to be more

suitable for processing longer cotton fibers, i.e finer yarns. This study was carried out to determine the significant dif-

ferences in yarn properties obtained by the most common

In system A, on the other hand, the design of condens-ing compact yarn spinning systems used today.

zone, especially the distance between the nip points of the In terms of hairiness, system A had the lowest Uster

rollers in the condensing zone (Figure 1) may restrict work hairiness (H) and S3 values for all yarns in comparison with

with longer staple fibers and so it might be a problem to work the other two systems because of the system design. Inter-

with longer staples, i.e. finer yarns, with this sys-tem. estingly, in general we observed the highest variations with

system C. This is attributed to the blockage due to fiber and

dust observed under the perforated apron, which therefore

caused a continuous change in the condensing area leading

Yarn Tenacity and Breaking unstable fiber control in the condensing zone.

The test results of irregularity, thin/thick place, neps and

Elongation Results

tenacity show that, in general systems A and B led to better

Tenacity and breaking elongation test results are shown in yarn properties in comparison with system C. For Ne 20 and

Figures 13 and 14. Ne 30, the best irregularity values were obtained by system A

Similar to the previous findings, system A appeared to give whereas for the finest yarn we produced (Ne 41), system B

the highest tenacity in comparison with the other two systems gave the best irregularity. The better results obtained by

for Ne 20 and 30 yarns whereas system B gave the highest system A with Ne 20 and Ne 30 made us consider that the

tenacity for Ne 41. However, all the yarns pro-duced by drafting system design might be more suitable with this

system C had the lowest tenacity of all in parallel to the trend system for these count ranges. However, for finer yarns such

in irregularity results. The same trend was observed for as Ne 41 that was produced here, sys-tem B was superior.

breaking elongation values. With system B, yarns that had the Therefore it was concluded that system B has a less effective

highest breaking elongation values were obtained. The reason fiber control for coarse to medium counts in comparison with

for this might be that there was no transverse draft in system system A and when the yarn became coarser, the number of

B and also the vacuum effect seems to be weaker as explained fibers in the yarn cross-sec-tion increased and the condensing

in the section on yarn hairiness results above. Therefore, the power of system B may not be strong enough to grasp all the

degree of paralleli-zation of the fibers in the yarn structure fibers effectively. In addition, the distance between the apron

might be lower than other systems causing higher breaking nip line and the front nip line is longer than that of the

elongation. Of course, a further detailed yarn structure conventional ring spinning drafting system, which made the

analysis is needed to confirm these comments. yarn irregularity and imperfections results poorer.

Downloaded from trj.sagepub.com at Karolinska Institutets Universitetsbibliotek on May 24, 2015

TRJ 234 Textile Research Journal 76(3)

On the other hand, system B led to the best values in terms 8. Clapp, D. M., Suessen Elite Compact Ring Spinning Evaluation,

th

of breaking elongation, possibly because of there was no in “14 EFS System Conference,” Fiber Processing Research

transverse draft in system B, and also because of the weaker Report, Report Number 2001–1 (FLP-00-234), Cotton Incor-

vacuum effect. Therefore, the degree of paral-lelization of the porated, North Carolina, USA pp. 161–168, (2001).

9. Hechtl, R., Compact Spinning System-An Opportunity For

fibers in the yarn structure might be lower than that of other

Improving The Ring Spinning Process, Melliand English 77(4),

systems, causing higher breaking elonga-tion. Of course, a 37–38 (1996).

further detailed yarn structure analysis is needed to confirm 10. Krifa, M. and Ethridge, D., Compact Ring Spun Yarns: An

this comment. Examination of Some Productivity Issues, Textile Topics, 2003–

Consequently, system B seems to be more suitable for 2, 2–8 (2003).

finer yarns whereas system A gave better results for medium 11. Krifa, M. and Hequet, E., Interaction Between Cotton Fiber

to coarse counts, i.e. Ne 20 and Ne 30, because of the designs Characteristics and Spinning Process: Conventional Vs. Com-

of the condensing zone and the condensing power. System C pact Ring Spinning, in Beltwide Cotton Conferences, January 6–

seemed to give unsatisfactory results for all the yarn counts 10, Nashville, National Cotton Council of America, Memphis,

TN, USA, 1978–1982, (2003).

produced here because of the weak fiber con-trol and the fiber

12. Mahmood, N., Jamil, N. A., Nawaz, S. M., and Saleem, M. S.,

blockage problem. Technological Studies On Compact (K-44) Versus Ring (G-33)

Spinning With Reference To Yarn Hairiness, Pakistan Textile J.

July, 53–56 (2003).

Literature Cited 13. Artzt, P., Specific Technological Aspects Of The Compact Spin-

ning Process, in “Proceedings of International Isparta Textile

1. Artzt, P., The Special Structure of Compact Yarns-Advantages In Congress,” Istek 2003 Suleyman Demirel University Isparata

Downstream Processing, ITB Yarn And Fabric Forming, No 2, Turkey, 22–23 May, pp. 51–80, (2003).

41–48, (1997). 14. Behera, B. K., Hari, P. K., and Ghosh, S., Weavability Of

2. Cheng, K. P. S., and Yu, C., A Study Of Compact Spun Yarns, Compact Yarn, Melliand International, 9, 311–314 (2003).

Textile Res. J. 73(4), 345–349 (2003). 15. Nikolic, M., Stjepanovic, Z., Lesjak F., and Stritof, A., Com-pact

3. Stalder, H., Ring Spinning Advance, Textile Asia, March, 43– Spinning For Improved Quality Of Ring-Spun Yarns, J. Fibres

46 (2000). & Textiles Eastern Eur. 11(4), 43 (2003).

4. Dash, J. R., Ishtiaque, S. M., and Alagirusamy, R., Properties And 16. Kadoglu, H., Üreyen, M. E., Çelik, P., and Yildirim, D., Pamuk

Processibility Of Compact Yarns, Indian J. Fibre & Textile Res. Ipliklerinde Tüylülügün Nedenleri ve Azaltilma Olanaklari

27(4), 362–368 (2002). Üzerine Bir Çalisma, Tübitak Tekstil Araþtirma Merkezi, Project

5. Krifa, M., Hequet, E., and Ethridge D., Compact Spinning: New No: TAM 2002–06, Turkey, (2004).

Potential For Short Staple Cottons, Textile Topics 2002–2, 2–8 17. Kumar, G.V., and Zacharia, J., Study on Ring Yarn Hairiness with

(2002). Special Reference to the Effect of BTRA Ring Cleaner-cum-

6. Oxenham, W., Trends In Yarn Production – A New Twist, in Lubricant, BTRA-Scan 28(3), 6–9 (1997).

“Proceedings of International Isparta Textile Congress,” Istek 18. Usta, I., and Canoglu, S., Influence of Ring Traveller Weight and

2003 Suleyman Demirel University Isparata Turkey, 22–23 May, Coating on Hairiness of Acrylic Yarns, J. Fibres & Textiles

pp. 26–50, (2003). Eastern Eur. October/December, 20–24 (2002).

7. Ömeroglu, S., Kompakt Iplikçilik Sisteminde Üretilen Iplik-lerin 19. Yilmaz, D., Farkli Kompakt Ring Iplik Egirme Sistemlerinin ve

Yapisal Özellikleri ve Bazi Üretim Parametrelerinin Etkileri Elde Edilen Ipliklerin Özelliklerinin Karþilaþtirilmasi, Süley-

Üzerine Bir Arastirma, Uludag University, PhD The-sis, Bursa, man Demirel University, MSc Thesis, Isparta, Turkey, (2004).

Turkey, (2002).

Downloaded from trj.sagepub.com at Karolinska Institutets Universitetsbibliotek on May 24, 2015

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AI523 Data Sheet, 2, en USDocument12 pagesAI523 Data Sheet, 2, en USJozz LivelyNo ratings yet

- Aba, AudrDocument162 pagesAba, AudrRenuka TekumudiNo ratings yet

- CURSO: Ingles II DOCENTE: Sandra Melissa Manrique (AC-S17) Week 17-Task: Assignment - Final Assignment Part IDocument3 pagesCURSO: Ingles II DOCENTE: Sandra Melissa Manrique (AC-S17) Week 17-Task: Assignment - Final Assignment Part Imaria cecilia ojeda garciaNo ratings yet

- KBI - Group 2 - Community Mapping (RRA & PRA)Document13 pagesKBI - Group 2 - Community Mapping (RRA & PRA)Yudha OkpriandaNo ratings yet

- Dhuvarageesh VaasthuDocument100 pagesDhuvarageesh VaasthuKs SenthilKumarNo ratings yet

- Project of SecurityDocument9 pagesProject of SecurityBerehe GezuNo ratings yet

- Math 7-Q4-Module-3Document16 pagesMath 7-Q4-Module-3Peterson Dela Cruz Enriquez33% (3)

- Ishan Parmar - Performance MarketingDocument2 pagesIshan Parmar - Performance MarketingVaibhav RaghuvanshiNo ratings yet

- CHAP 2 - Diode Applications-Clippers ClampersDocument33 pagesCHAP 2 - Diode Applications-Clippers Clampersksreddy2002No ratings yet

- Kono Subarashii Sekai Ni Shukufuku Wo! Volume 2 PDFDocument198 pagesKono Subarashii Sekai Ni Shukufuku Wo! Volume 2 PDFRokhi NNo ratings yet

- Perancangan Sistem OperasiDocument48 pagesPerancangan Sistem OperasiZulfikar YahyaNo ratings yet

- Biography of Francisco ArcellanaDocument4 pagesBiography of Francisco ArcellanabooboothefoolNo ratings yet

- Listeria Monocytogenes and Other Listeria Species PDFDocument27 pagesListeria Monocytogenes and Other Listeria Species PDFkurniawan0031No ratings yet

- BOSCH 01 Family OriginsDocument7 pagesBOSCH 01 Family OriginsAntonela ElenaNo ratings yet

- Title: Investigation of Agriculture Related Problems of Rural Women in District LayyahDocument10 pagesTitle: Investigation of Agriculture Related Problems of Rural Women in District LayyahMuhammad Asim Hafeez ThindNo ratings yet

- Analisis de La Termodinamica Del Salado de QuesoDocument9 pagesAnalisis de La Termodinamica Del Salado de QuesoJeam Danny Rodriguez CalvoNo ratings yet

- Slice: Safety Data SheetDocument7 pagesSlice: Safety Data Sheetzubair1951No ratings yet

- IC Residential Renovation Timeline Template 8531 V1Document38 pagesIC Residential Renovation Timeline Template 8531 V1Bobby QaziNo ratings yet

- TW316 PresentationDocument26 pagesTW316 PresentationCherylNo ratings yet

- Sustainable DevelopmentDocument11 pagesSustainable DevelopmentrcayNo ratings yet

- Problem 1Document8 pagesProblem 1KyleRhayneDiazCaliwagNo ratings yet

- Hanumad Gita: by Devi Sita To HanumanDocument6 pagesHanumad Gita: by Devi Sita To HanumanbalayogivNo ratings yet

- 51125-07 Vevo LAB User Manual 1.1Document694 pages51125-07 Vevo LAB User Manual 1.1Leon PalomeraNo ratings yet

- Hussain 62692Document3 pagesHussain 62692Hussain - حسينNo ratings yet

- Private Moralities in The Public Sphere - Democratization, Islam, and Gender in IndonesiaDocument13 pagesPrivate Moralities in The Public Sphere - Democratization, Islam, and Gender in IndonesiaKenny MNo ratings yet

- CORDILLERADocument27 pagesCORDILLERAmaria kyla andradeNo ratings yet

- Chapter 6 Consumption and SavingsDocument1 pageChapter 6 Consumption and SavingsEnter any name or emailNo ratings yet

- Final 3.2sedimentary RocksDocument49 pagesFinal 3.2sedimentary RocksErich IsnainNo ratings yet

- Behavioral Finance AssignmentDocument8 pagesBehavioral Finance Assignmentthulli06No ratings yet

- Rubric For Group WorkDocument1 pageRubric For Group WorkAlven ReyNo ratings yet