Professional Documents

Culture Documents

Bioburden Test

Bioburden Test

Uploaded by

Mujeeb Ullah KhanCopyright:

Available Formats

You might also like

- Environmental Monitoring Incubation Conditions - JustificationDocument4 pagesEnvironmental Monitoring Incubation Conditions - Justificationveerreddy_157808No ratings yet

- Mercedes-Benz Sprinter Engine TypesDocument2 pagesMercedes-Benz Sprinter Engine TypesJack Norhy100% (1)

- SOP On Calculation of YieldsDocument2 pagesSOP On Calculation of YieldsYousif100% (1)

- Sterility Test Validation ProtocolDocument6 pagesSterility Test Validation ProtocolԼուսինե Հովսեփյան100% (2)

- VAL-020 Procedure For Cleaning Validation SampleDocument3 pagesVAL-020 Procedure For Cleaning Validation SampleVizit31No ratings yet

- Title SOP Incubator Operation QC 047 01Document12 pagesTitle SOP Incubator Operation QC 047 01aKureishiNo ratings yet

- Band 6 Eit ExampleDocument37 pagesBand 6 Eit Exampleapi-294518117100% (1)

- Calibration and Applications For Temperature Sensors Using LabViewDocument8 pagesCalibration and Applications For Temperature Sensors Using LabViewpkNo ratings yet

- СОП - media - fill Micro LaboratoryDocument7 pagesСОП - media - fill Micro LaboratoryMykolaNo ratings yet

- MICLAB 060 SampleDocument7 pagesMICLAB 060 SampleVizit31No ratings yet

- MICLAB 110 Microbiology Laboratory Investigation and Retest Procedure For Atypical Results PDFDocument4 pagesMICLAB 110 Microbiology Laboratory Investigation and Retest Procedure For Atypical Results PDFalnzeer omerNo ratings yet

- MICLAB 055 Sample 2Document4 pagesMICLAB 055 Sample 2Vizit31No ratings yet

- Validation Protocol For Disinfectant Efficacy ValidationDocument12 pagesValidation Protocol For Disinfectant Efficacy ValidationMubarak PatelNo ratings yet

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- Sterlity Validation (Membrane Filtration Method) in Pharmaceuticals - Pharmaceutical GuidelinesDocument4 pagesSterlity Validation (Membrane Filtration Method) in Pharmaceuticals - Pharmaceutical GuidelinesDucNo ratings yet

- Bioburden ALERT Levels PDFDocument17 pagesBioburden ALERT Levels PDFRudhy21No ratings yet

- Bioburden TestingDocument5 pagesBioburden TestingApar Dholakia100% (1)

- Validation of IncubatorsDocument4 pagesValidation of Incubatorsltrevino100No ratings yet

- VAL-090 Equipment Validation Guideline SampleDocument2 pagesVAL-090 Equipment Validation Guideline SampleVizit31No ratings yet

- Settle AIr Plate TechniqueDocument10 pagesSettle AIr Plate Techniquehoookooo100% (3)

- DHS ValidationDocument7 pagesDHS Validationmuna82dasNo ratings yet

- SOP For Testing of Compressed Air and Nitrogen Gas For Viable Count - Pharmaceutical GuidelinesDocument2 pagesSOP For Testing of Compressed Air and Nitrogen Gas For Viable Count - Pharmaceutical GuidelinesAnonymous FZs3yBHh7No ratings yet

- SOP Aseptic Filling PDFDocument6 pagesSOP Aseptic Filling PDFSandraNo ratings yet

- VAL-095 Facility and Utility Validation Guideline SampleDocument1 pageVAL-095 Facility and Utility Validation Guideline SampleVizit31No ratings yet

- SOP For Sampling and Testing Schedule of Water For Injection and Clean Steam - Pharmaceutical GuidelinesDocument2 pagesSOP For Sampling and Testing Schedule of Water For Injection and Clean Steam - Pharmaceutical GuidelinesASHOK KUMAR LENKA100% (1)

- Pantoprazole 40mg InjectionDocument36 pagesPantoprazole 40mg Injectiondaizhussain004No ratings yet

- Dirty-Hold Time Effect On The CleaningDocument6 pagesDirty-Hold Time Effect On The CleaningOmar FaruqNo ratings yet

- Dynamic Pass BoxDocument3 pagesDynamic Pass BoxMd.Tareque AbdullahNo ratings yet

- Clean RoomDocument19 pagesClean Roomhouas menasriaNo ratings yet

- Disinfectant ValidationDocument8 pagesDisinfectant ValidationSiva SubrahmanyamNo ratings yet

- Qualification Procedure For Vial Washing Machine - Pharmaceutical GuidelinesDocument1 pageQualification Procedure For Vial Washing Machine - Pharmaceutical GuidelinesAli Goutas50% (2)

- LAL Test - Lonza - 00190169 - enDocument20 pagesLAL Test - Lonza - 00190169 - enPaolo PiccoliniNo ratings yet

- MICRO 4 SOP For Microbial Monitoring in Drain Point of Pharmaceutical Manufacturing SitesDocument2 pagesMICRO 4 SOP For Microbial Monitoring in Drain Point of Pharmaceutical Manufacturing SitesAjesh Tk100% (1)

- Microbiological Test of Medical DevicesDocument5 pagesMicrobiological Test of Medical Devicesbijendra_sinhaNo ratings yet

- Validation of Sterilization: GMP and Qa Class: BDocument50 pagesValidation of Sterilization: GMP and Qa Class: BHikmah Purnama AzaniNo ratings yet

- Procedure For Environmental Monitoring by Settle Plate MethodDocument2 pagesProcedure For Environmental Monitoring by Settle Plate Methodejazmaqsood100% (1)

- Sterlity Validation (Membrane Filtration Method) in Pharmaceuticals - Pharmaceutical GuidelinesDocument4 pagesSterlity Validation (Membrane Filtration Method) in Pharmaceuticals - Pharmaceutical GuidelinesASHOK KUMAR LENKANo ratings yet

- Compressed Air Testing ProcedureDocument5 pagesCompressed Air Testing ProcedureroopadharNo ratings yet

- Cleaning Validation Life Cycle: October 2020Document16 pagesCleaning Validation Life Cycle: October 2020rouss1906100% (2)

- Cleaning Validation Protocol PDFDocument17 pagesCleaning Validation Protocol PDFhauvu100% (1)

- Autoclave Validation PresentationDocument17 pagesAutoclave Validation PresentationprakhyaatNo ratings yet

- Microbial Limit Test Validation ProtocolDocument12 pagesMicrobial Limit Test Validation ProtocolMubarak Patel100% (2)

- Establishing A Complete Set of Target, Alert, and Action Limits For Microbial Counts in Purified WaterDocument8 pagesEstablishing A Complete Set of Target, Alert, and Action Limits For Microbial Counts in Purified WaterSagi Nguyen100% (2)

- Protocol For Process Validation of Cefowin Cefotaxime 1000mgDocument31 pagesProtocol For Process Validation of Cefowin Cefotaxime 1000mgShafaq ALI100% (2)

- Disinfection ValidationDocument25 pagesDisinfection ValidationSumitNo ratings yet

- Annex4-TRS992 Hold Time Study GuidelineDocument8 pagesAnnex4-TRS992 Hold Time Study Guidelinensk79in@gmail.com100% (1)

- What Are The Key Benefits of Validation?Document6 pagesWhat Are The Key Benefits of Validation?siva sankarNo ratings yet

- Checklist of Validation of Dy Heat SterilizerDocument8 pagesChecklist of Validation of Dy Heat Sterilizersami2210No ratings yet

- Lifecycle Approach To Cleaning ValidationDocument60 pagesLifecycle Approach To Cleaning Validational68130No ratings yet

- Equipment Logbook 2 2Document7 pagesEquipment Logbook 2 2Belazouz BoualemNo ratings yet

- SOP For Fumigation in Microbiology Lab - Pharmaceutical GuidelinesDocument1 pageSOP For Fumigation in Microbiology Lab - Pharmaceutical GuidelinesranaNo ratings yet

- Microbial Testing in Support of Aseptic ProcessingDocument6 pagesMicrobial Testing in Support of Aseptic ProcessingmeghanalandeNo ratings yet

- Hold Time Protocol FinalDocument20 pagesHold Time Protocol FinalSolomon0% (1)

- Procedure For Media-Fill Simulation of Aseptic TechniqueDocument5 pagesProcedure For Media-Fill Simulation of Aseptic Techniquelimiyanto100% (1)

- Validation of Sterilization of AutoclavesDocument15 pagesValidation of Sterilization of AutoclavesErich Hermann Günther Molina100% (3)

- Worst Case SelectionDocument3 pagesWorst Case SelectionPrince MoniNo ratings yet

- Microbial Limit TestDocument29 pagesMicrobial Limit TestJai MurugeshNo ratings yet

- Cleaning Validation Rinsing TesDocument5 pagesCleaning Validation Rinsing TesUrsula HilleNo ratings yet

- Production of Plasma Proteins for Therapeutic UseFrom EverandProduction of Plasma Proteins for Therapeutic UseRating: 3 out of 5 stars3/5 (5)

- SC-HM910 - HM810 (sm-RQZM0167) PDFDocument104 pagesSC-HM910 - HM810 (sm-RQZM0167) PDFJory2005No ratings yet

- 2022 Fenix Product CatalogDocument62 pages2022 Fenix Product CatalogsachinumaryeNo ratings yet

- GVC Ths. Nguy ễn Minh Đạo Bm Cnpm - Khoa Cntt - Đhspkt Tp.HcmDocument76 pagesGVC Ths. Nguy ễn Minh Đạo Bm Cnpm - Khoa Cntt - Đhspkt Tp.HcmĐinhĐạiĐồngNo ratings yet

- The Best Way To Solve The World's Environmental Problems Is To Increase The Cost of Fuel. To What Extend Do You Agree or DisagreeDocument2 pagesThe Best Way To Solve The World's Environmental Problems Is To Increase The Cost of Fuel. To What Extend Do You Agree or DisagreeJagpreet Singh RandhawaNo ratings yet

- Jeff Sly - Case Study Nagios at Nu SkinDocument58 pagesJeff Sly - Case Study Nagios at Nu Skinkrovidiprasanna0% (1)

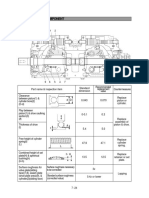

- Weaving Loom Parts Catalogue Tsudakoma Water Jet SDocument15 pagesWeaving Loom Parts Catalogue Tsudakoma Water Jet SRavi Kumar100% (1)

- Resume PDFDocument3 pagesResume PDFAnonymous B0j7sQNo ratings yet

- Imaginative Toys - OM Case StudyDocument2 pagesImaginative Toys - OM Case Studysheika_11100% (2)

- LSPB Trajectory Planning Design For The ModularDocument4 pagesLSPB Trajectory Planning Design For The ModularbasantsahuNo ratings yet

- Zipcar - Final CompressedDocument19 pagesZipcar - Final CompressedYovantioTriPutraNo ratings yet

- Turbomachinery: Fluid Mechanics: Fundamentals and ApplicationsDocument86 pagesTurbomachinery: Fluid Mechanics: Fundamentals and ApplicationsBabita GuptaNo ratings yet

- Hamworthy Compressor ManualDocument5 pagesHamworthy Compressor ManualDastan0% (1)

- Section12 Needle ValvesDocument16 pagesSection12 Needle ValvesHENRY LLOFREL CORREA LOPEZNo ratings yet

- Vlsi Design of Amba Based Ahb2apb BridgeDocument12 pagesVlsi Design of Amba Based Ahb2apb BridgeAnonymous e4UpOQEPNo ratings yet

- Manual On Quality Assurance For KhadiDocument189 pagesManual On Quality Assurance For KhadiManas DasNo ratings yet

- Demo KaleidoscopeDocument3 pagesDemo KaleidoscopeTracy Lloyd MaaghopNo ratings yet

- Ramjets & Pulse JetsDocument10 pagesRamjets & Pulse JetsInterogator5No ratings yet

- SimulationDocument32 pagesSimulationRufus Raj100% (2)

- Lesson Plan DraftDocument3 pagesLesson Plan Draftapi-266453331No ratings yet

- JHD162A LCD CodeDocument3 pagesJHD162A LCD CodeAnkit Daftery100% (3)

- Mks - TksDocument12 pagesMks - TksNguyen Duong HieuNo ratings yet

- Albena Yaneva, Actor-network-Theory Approach To The Archaeology of Contemporary ArchitectureDocument33 pagesAlbena Yaneva, Actor-network-Theory Approach To The Archaeology of Contemporary ArchitectureAdeena MeyNo ratings yet

- Cost Estimation of Residential Electrical WiringDocument5 pagesCost Estimation of Residential Electrical WiringVikas VijayaraghavanNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpHậu MinhNo ratings yet

- Da-6000ss (60H 110V)Document15 pagesDa-6000ss (60H 110V)Geiler Benitez PiñaNo ratings yet

- Cable Accessories: Systems, IncDocument4 pagesCable Accessories: Systems, IncLuis MurilloNo ratings yet

- Slva372b Basic Calculation of A Boost Converter's Power StageDocument9 pagesSlva372b Basic Calculation of A Boost Converter's Power StagericardoszfNo ratings yet

Bioburden Test

Bioburden Test

Uploaded by

Mujeeb Ullah KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bioburden Test

Bioburden Test

Uploaded by

Mujeeb Ullah KhanCopyright:

Available Formats

Standard Operating Procedure

Title: Microbiological Evaluation of Bioburdens, Non-Sterile Products and Raw

Materials

______________________________________________________________________________________

Related Documents

MICLAB 065 Determination of Heat Resistance of Spore Forming Organisms

MICLAB 060 Micro Laboratory Procedure for Sterility Testing

MICLAB 070 Identification of Micro organisms to Genus and Species Level

MICLAB 095 Sterile Sampling Procedure for Microbiology Laboratory

EHS Statement

Correct Aseptic technique must be used when performing any Microbiological procedures.

Safety glasses and gloves are to be worn when using IPA/Solvent.

All testing must be preformed within a LAF cabinet.

Table of Contents

1 Equipment preperation For Non-sterile testing: 2

2 Procedure 3

3 Bulk Solution Bioburden (BSB) Samples 3

4 Filled Container Bioburdens (FCB) 4

5 Raw Material Bioburdens, (RMB) 4

6 Surgical Face Masks 4

7 Isopropyl Alcohol (70% IPA) 4

8 Speciation Procedures for Organisms found in Non-Sterile Products and Raw Materials 5

9 Out-of-Specification Procedures for Non-Sterile Products and Raw Materials 6

10 Retest and Repeat Procedures for Non-Sterile Products and Raw Materials 9

11 Summary of Changes 9

1 Equipment preperation For Non-sterile testing:

1.1 Assemble filtration units together.

1.2 Place 6 filtration units in a dacron bag, place autoclave tape with Date Autoclaved on the tied

section.

1.3 Place 6 forceps inside individual test tubes, then place the 6 filled test tubes inside a

Sterilope bags, seal by folding over twice and applying autoclave tape. Add the Number and

Item and Date Autoclaved on the front of the bag.

1.4 Follow the above procedure for preparation of spoons and scissors.

1.5 Place the wrapped bags of forceps, scissors and spoons into the wire rack for the autoclave.

1.6 Autoclave the items in laboratory autoclave.

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 2 of 9

Standard Operating Procedure

Title: Microbiological Evaluation of Bioburdens, Non-Sterile Products and Raw

Materials

______________________________________________________________________________________

If count obtained is over the Alert Level of 100 and less than 200 colonies, conduct a

Gram stain on different types of colonies present.

If count obtained is over 200 colonies and not countable a retest is to be performed.

Gram stain is required on the original sample, which is over the Alert Level.

If any Gram negative rods are present, identify for conformance. Record all results

in log book.

If a retest is required, apply the same test method to the original sample using 10mL

and 1mL volumes so that an exact count is obtained.

If a re-retest is required apply the same test method to the original sample using

volume less than 1ml, i.e. 0.5ml and 0.1ml as to obtain a count.

After reading and recording the result in the log book, the BSB bottles can be

cleaned out of the refrigerator,

OR either retested.

Every 6 months, graphical representations of Bioburden results are to be printed and

stored in the Bioburden Reports File.

If the Bioburden is more than alert level, inform the Microbiology Manager who will

decide if any additional testing of the product is required, e.g. LAL Pyrogen test. The

reason for release is to be added in the ‘Comments’ section of the log book.

4 Filled Container Bioburdens (FCB)

4.1 Example-Prior to Autoclaving

All batches manufactured are to be sampled for Filled Container Bioburden testing.

4.1.1 Predetermined units are to be randomly selected immediately prior to the autoclaving

of the final load. These samples are to be labelled “Bioburden” and placed into a

plastic bag and delivered to the Micro. Lab. (see MICLAB 095).

4.1.2 Aseptically pool specified amount from each of the units into a sterile Membrane

Filtration unit and filter through a 0.45µ membrane filter and wash with sterile

Peptone Water. Transfer the filter into a sterile petri-dish containing an absorbent

filter pad moistened with Tryptone Soy Broth.

4.1.3 Incubate at 30-35°C for 5 days under humid conditions. If any colonies are present

Gram stain & record the morphological and microscopic appearance. If any Gram-

positive or negative rods are present, identify further.

4.1.4 Record the results in the log book. Specify Alert and action limits.

5 Raw Material Bioburdens, (RMB)

Sterile operator’s sample raw material for microbiological analysis and the samples are either

delivered directly to the laboratory or placed into the micro sample cabinet within production.

6 Surgical Face Masks

Every batch of Face Masks purchased must be examined for microbiological status prior to use. On

delivery of every batch, 5 boxes of facemasks will be randomly sampled by the Warehouse Sampling

staff, and delivered to the Microbiology Laboratory. Test as per Raw Material Specification and test

method.

7 Isopropyl Alcohol (70% IPA)

Isopropyl Alcohol is routinely used throughout the Microbiology Laboratory. The Production Services

team prepares the 70% IPA. A sample from each new keg is to be aseptically sampled into a sterile

100ml bottle and sent to the Micro Lab for testing,

The following method is used for IPA samples and all growth is to be evaluated:

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 4 of 9

Standard Operating Procedure

Title: Microbiological Evaluation of Bioburdens, Non-Sterile Products and Raw

Materials

______________________________________________________________________________________

Correct collection, storage and preparation of test sample and collection vessel.

Correct set-up of test equipment.

Correct method used for test.

Completed Training records.

Expiry of consumables and equipment observed.

Media stasis satisfactory.

Correct incubation conditions of test.

Observations made during test procedure.

All calculations checked.

All test control results, where relevant, are satisfactory.

Review of other test results for the test session, to determine a trend.

The above items must be clearly addressed in the DR for OOS results

9.2.2 Phase 2 investigations involve a thorough systematic analysis of the incident, to

determine the root cause for the OOS result. Phase 2 investigations are to be

tailored for each incident to reflect the significance of meeting or exceeding either the

ALERT or ACTION Levels.

9.3 Phase 2 Investigation Responses

9.3.1 Determine if the alert excursion is to become an action level excursion that requires

upgrading the notification to an action level based on the following criteria:

9.3.2 Three alert/action level excursions from the same sterile area on the same day.

10.3.3 The minimum requirements for most situations are listed as below, this list is by no

means exhaustive and specialist assistance from departments other than

Microbiology should be utilised in the investigation.

10.3.4 All affected departments will perform their part of the investigation, carry out

corrective actions and findings of the investigation.

9.4 OOS Bulk Solution Bioburden

9.4.1 Alert Level

Results obtained over the alert level require the following actions

Gram stain

Further identification as outlined in section 9 ‘Specification Procedures for

Organisms found in Non-Sterile Products and Raw Materials’

9.4.2 Action Level (In addition to alert level requirements)

Results obtained over the action Level require the following details

Results of any material used to manufacture the batch e.g. WFI & raw materials

Sterilisation of vessels (SIP)

Cleaning records for vessels (CIP)

Review of other test results to determine a trend.

Environmental conditions conform

CAPA recommendations

9.5 OOS Filled Container Bioburden

9.5.1 Alert Level

Results obtained over the alert level require the following actions

Gram stain

Further identification as outlined in section 9 ‘Specification Procedures for

Organisms found in Non-Sterile Products and Raw Materials’

D-values where applicable.

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 7 of 9

Standard Operating Procedure

Title: Microbiological Evaluation of Bioburdens, Non-Sterile Products and Raw

Materials

______________________________________________________________________________________

9.8.2 Action Level (In addition to alert level requirements)

Results obtained over the action Level require the following details

Additional testing may be required.

Put masks on hold and hold an investigation meeting.

Contact supplier.

9.9 OOS IPA

9.9.1 Alert Level

Gram stain

Further identification as outlined in section 9 ‘Specification Procedures for

Organisms found in Non-Sterile Products and Raw Materials’

9.9.2 Action Level (In addition to alert level requirements)

Results obtained over the action Level require the following details

Additional testing may be required.

Contact immediately to ensure IPA is not distributed to production.

Contact immediately to resample the batch.

10 Retest and Repeat Procedures for Non-Sterile Products and Raw Materials

10.1 Repeat Procedures

A test may be repeated when the initial test has been invalidated due to an error in the

procedure (including equipment, Technician, etc).

10.2 Retest Procedures

Where the number of micro-organisms in the Non-sterile product or Raw Material detected in

the Microbial Limit Test is over the ALERT LEVEL for that material, a retest on the

Non-Sterile product or Raw Material in question should be carried out. The retest involves

repeating the Microbial Limit Test in triplicate, for both Limit and Presence testing. If after

retesting the product or raw material three times the number of micro-organisms is still over

the ALERT LEVEL the situation is to be evaluated by the Microbiology Manager.

Note:

If there is not a sufficient quantity remaining from the original sample for either repeat test or

the re-test, new samples should be acquired by randomly sampling throughout the batch.

11 Summary of Changes

Version # Revision History

MICLAB 075 New

Copyright©www.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 9 of 9

You might also like

- Environmental Monitoring Incubation Conditions - JustificationDocument4 pagesEnvironmental Monitoring Incubation Conditions - Justificationveerreddy_157808No ratings yet

- Mercedes-Benz Sprinter Engine TypesDocument2 pagesMercedes-Benz Sprinter Engine TypesJack Norhy100% (1)

- SOP On Calculation of YieldsDocument2 pagesSOP On Calculation of YieldsYousif100% (1)

- Sterility Test Validation ProtocolDocument6 pagesSterility Test Validation ProtocolԼուսինե Հովսեփյան100% (2)

- VAL-020 Procedure For Cleaning Validation SampleDocument3 pagesVAL-020 Procedure For Cleaning Validation SampleVizit31No ratings yet

- Title SOP Incubator Operation QC 047 01Document12 pagesTitle SOP Incubator Operation QC 047 01aKureishiNo ratings yet

- Band 6 Eit ExampleDocument37 pagesBand 6 Eit Exampleapi-294518117100% (1)

- Calibration and Applications For Temperature Sensors Using LabViewDocument8 pagesCalibration and Applications For Temperature Sensors Using LabViewpkNo ratings yet

- СОП - media - fill Micro LaboratoryDocument7 pagesСОП - media - fill Micro LaboratoryMykolaNo ratings yet

- MICLAB 060 SampleDocument7 pagesMICLAB 060 SampleVizit31No ratings yet

- MICLAB 110 Microbiology Laboratory Investigation and Retest Procedure For Atypical Results PDFDocument4 pagesMICLAB 110 Microbiology Laboratory Investigation and Retest Procedure For Atypical Results PDFalnzeer omerNo ratings yet

- MICLAB 055 Sample 2Document4 pagesMICLAB 055 Sample 2Vizit31No ratings yet

- Validation Protocol For Disinfectant Efficacy ValidationDocument12 pagesValidation Protocol For Disinfectant Efficacy ValidationMubarak PatelNo ratings yet

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- Sterlity Validation (Membrane Filtration Method) in Pharmaceuticals - Pharmaceutical GuidelinesDocument4 pagesSterlity Validation (Membrane Filtration Method) in Pharmaceuticals - Pharmaceutical GuidelinesDucNo ratings yet

- Bioburden ALERT Levels PDFDocument17 pagesBioburden ALERT Levels PDFRudhy21No ratings yet

- Bioburden TestingDocument5 pagesBioburden TestingApar Dholakia100% (1)

- Validation of IncubatorsDocument4 pagesValidation of Incubatorsltrevino100No ratings yet

- VAL-090 Equipment Validation Guideline SampleDocument2 pagesVAL-090 Equipment Validation Guideline SampleVizit31No ratings yet

- Settle AIr Plate TechniqueDocument10 pagesSettle AIr Plate Techniquehoookooo100% (3)

- DHS ValidationDocument7 pagesDHS Validationmuna82dasNo ratings yet

- SOP For Testing of Compressed Air and Nitrogen Gas For Viable Count - Pharmaceutical GuidelinesDocument2 pagesSOP For Testing of Compressed Air and Nitrogen Gas For Viable Count - Pharmaceutical GuidelinesAnonymous FZs3yBHh7No ratings yet

- SOP Aseptic Filling PDFDocument6 pagesSOP Aseptic Filling PDFSandraNo ratings yet

- VAL-095 Facility and Utility Validation Guideline SampleDocument1 pageVAL-095 Facility and Utility Validation Guideline SampleVizit31No ratings yet

- SOP For Sampling and Testing Schedule of Water For Injection and Clean Steam - Pharmaceutical GuidelinesDocument2 pagesSOP For Sampling and Testing Schedule of Water For Injection and Clean Steam - Pharmaceutical GuidelinesASHOK KUMAR LENKA100% (1)

- Pantoprazole 40mg InjectionDocument36 pagesPantoprazole 40mg Injectiondaizhussain004No ratings yet

- Dirty-Hold Time Effect On The CleaningDocument6 pagesDirty-Hold Time Effect On The CleaningOmar FaruqNo ratings yet

- Dynamic Pass BoxDocument3 pagesDynamic Pass BoxMd.Tareque AbdullahNo ratings yet

- Clean RoomDocument19 pagesClean Roomhouas menasriaNo ratings yet

- Disinfectant ValidationDocument8 pagesDisinfectant ValidationSiva SubrahmanyamNo ratings yet

- Qualification Procedure For Vial Washing Machine - Pharmaceutical GuidelinesDocument1 pageQualification Procedure For Vial Washing Machine - Pharmaceutical GuidelinesAli Goutas50% (2)

- LAL Test - Lonza - 00190169 - enDocument20 pagesLAL Test - Lonza - 00190169 - enPaolo PiccoliniNo ratings yet

- MICRO 4 SOP For Microbial Monitoring in Drain Point of Pharmaceutical Manufacturing SitesDocument2 pagesMICRO 4 SOP For Microbial Monitoring in Drain Point of Pharmaceutical Manufacturing SitesAjesh Tk100% (1)

- Microbiological Test of Medical DevicesDocument5 pagesMicrobiological Test of Medical Devicesbijendra_sinhaNo ratings yet

- Validation of Sterilization: GMP and Qa Class: BDocument50 pagesValidation of Sterilization: GMP and Qa Class: BHikmah Purnama AzaniNo ratings yet

- Procedure For Environmental Monitoring by Settle Plate MethodDocument2 pagesProcedure For Environmental Monitoring by Settle Plate Methodejazmaqsood100% (1)

- Sterlity Validation (Membrane Filtration Method) in Pharmaceuticals - Pharmaceutical GuidelinesDocument4 pagesSterlity Validation (Membrane Filtration Method) in Pharmaceuticals - Pharmaceutical GuidelinesASHOK KUMAR LENKANo ratings yet

- Compressed Air Testing ProcedureDocument5 pagesCompressed Air Testing ProcedureroopadharNo ratings yet

- Cleaning Validation Life Cycle: October 2020Document16 pagesCleaning Validation Life Cycle: October 2020rouss1906100% (2)

- Cleaning Validation Protocol PDFDocument17 pagesCleaning Validation Protocol PDFhauvu100% (1)

- Autoclave Validation PresentationDocument17 pagesAutoclave Validation PresentationprakhyaatNo ratings yet

- Microbial Limit Test Validation ProtocolDocument12 pagesMicrobial Limit Test Validation ProtocolMubarak Patel100% (2)

- Establishing A Complete Set of Target, Alert, and Action Limits For Microbial Counts in Purified WaterDocument8 pagesEstablishing A Complete Set of Target, Alert, and Action Limits For Microbial Counts in Purified WaterSagi Nguyen100% (2)

- Protocol For Process Validation of Cefowin Cefotaxime 1000mgDocument31 pagesProtocol For Process Validation of Cefowin Cefotaxime 1000mgShafaq ALI100% (2)

- Disinfection ValidationDocument25 pagesDisinfection ValidationSumitNo ratings yet

- Annex4-TRS992 Hold Time Study GuidelineDocument8 pagesAnnex4-TRS992 Hold Time Study Guidelinensk79in@gmail.com100% (1)

- What Are The Key Benefits of Validation?Document6 pagesWhat Are The Key Benefits of Validation?siva sankarNo ratings yet

- Checklist of Validation of Dy Heat SterilizerDocument8 pagesChecklist of Validation of Dy Heat Sterilizersami2210No ratings yet

- Lifecycle Approach To Cleaning ValidationDocument60 pagesLifecycle Approach To Cleaning Validational68130No ratings yet

- Equipment Logbook 2 2Document7 pagesEquipment Logbook 2 2Belazouz BoualemNo ratings yet

- SOP For Fumigation in Microbiology Lab - Pharmaceutical GuidelinesDocument1 pageSOP For Fumigation in Microbiology Lab - Pharmaceutical GuidelinesranaNo ratings yet

- Microbial Testing in Support of Aseptic ProcessingDocument6 pagesMicrobial Testing in Support of Aseptic ProcessingmeghanalandeNo ratings yet

- Hold Time Protocol FinalDocument20 pagesHold Time Protocol FinalSolomon0% (1)

- Procedure For Media-Fill Simulation of Aseptic TechniqueDocument5 pagesProcedure For Media-Fill Simulation of Aseptic Techniquelimiyanto100% (1)

- Validation of Sterilization of AutoclavesDocument15 pagesValidation of Sterilization of AutoclavesErich Hermann Günther Molina100% (3)

- Worst Case SelectionDocument3 pagesWorst Case SelectionPrince MoniNo ratings yet

- Microbial Limit TestDocument29 pagesMicrobial Limit TestJai MurugeshNo ratings yet

- Cleaning Validation Rinsing TesDocument5 pagesCleaning Validation Rinsing TesUrsula HilleNo ratings yet

- Production of Plasma Proteins for Therapeutic UseFrom EverandProduction of Plasma Proteins for Therapeutic UseRating: 3 out of 5 stars3/5 (5)

- SC-HM910 - HM810 (sm-RQZM0167) PDFDocument104 pagesSC-HM910 - HM810 (sm-RQZM0167) PDFJory2005No ratings yet

- 2022 Fenix Product CatalogDocument62 pages2022 Fenix Product CatalogsachinumaryeNo ratings yet

- GVC Ths. Nguy ễn Minh Đạo Bm Cnpm - Khoa Cntt - Đhspkt Tp.HcmDocument76 pagesGVC Ths. Nguy ễn Minh Đạo Bm Cnpm - Khoa Cntt - Đhspkt Tp.HcmĐinhĐạiĐồngNo ratings yet

- The Best Way To Solve The World's Environmental Problems Is To Increase The Cost of Fuel. To What Extend Do You Agree or DisagreeDocument2 pagesThe Best Way To Solve The World's Environmental Problems Is To Increase The Cost of Fuel. To What Extend Do You Agree or DisagreeJagpreet Singh RandhawaNo ratings yet

- Jeff Sly - Case Study Nagios at Nu SkinDocument58 pagesJeff Sly - Case Study Nagios at Nu Skinkrovidiprasanna0% (1)

- Weaving Loom Parts Catalogue Tsudakoma Water Jet SDocument15 pagesWeaving Loom Parts Catalogue Tsudakoma Water Jet SRavi Kumar100% (1)

- Resume PDFDocument3 pagesResume PDFAnonymous B0j7sQNo ratings yet

- Imaginative Toys - OM Case StudyDocument2 pagesImaginative Toys - OM Case Studysheika_11100% (2)

- LSPB Trajectory Planning Design For The ModularDocument4 pagesLSPB Trajectory Planning Design For The ModularbasantsahuNo ratings yet

- Zipcar - Final CompressedDocument19 pagesZipcar - Final CompressedYovantioTriPutraNo ratings yet

- Turbomachinery: Fluid Mechanics: Fundamentals and ApplicationsDocument86 pagesTurbomachinery: Fluid Mechanics: Fundamentals and ApplicationsBabita GuptaNo ratings yet

- Hamworthy Compressor ManualDocument5 pagesHamworthy Compressor ManualDastan0% (1)

- Section12 Needle ValvesDocument16 pagesSection12 Needle ValvesHENRY LLOFREL CORREA LOPEZNo ratings yet

- Vlsi Design of Amba Based Ahb2apb BridgeDocument12 pagesVlsi Design of Amba Based Ahb2apb BridgeAnonymous e4UpOQEPNo ratings yet

- Manual On Quality Assurance For KhadiDocument189 pagesManual On Quality Assurance For KhadiManas DasNo ratings yet

- Demo KaleidoscopeDocument3 pagesDemo KaleidoscopeTracy Lloyd MaaghopNo ratings yet

- Ramjets & Pulse JetsDocument10 pagesRamjets & Pulse JetsInterogator5No ratings yet

- SimulationDocument32 pagesSimulationRufus Raj100% (2)

- Lesson Plan DraftDocument3 pagesLesson Plan Draftapi-266453331No ratings yet

- JHD162A LCD CodeDocument3 pagesJHD162A LCD CodeAnkit Daftery100% (3)

- Mks - TksDocument12 pagesMks - TksNguyen Duong HieuNo ratings yet

- Albena Yaneva, Actor-network-Theory Approach To The Archaeology of Contemporary ArchitectureDocument33 pagesAlbena Yaneva, Actor-network-Theory Approach To The Archaeology of Contemporary ArchitectureAdeena MeyNo ratings yet

- Cost Estimation of Residential Electrical WiringDocument5 pagesCost Estimation of Residential Electrical WiringVikas VijayaraghavanNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpHậu MinhNo ratings yet

- Da-6000ss (60H 110V)Document15 pagesDa-6000ss (60H 110V)Geiler Benitez PiñaNo ratings yet

- Cable Accessories: Systems, IncDocument4 pagesCable Accessories: Systems, IncLuis MurilloNo ratings yet

- Slva372b Basic Calculation of A Boost Converter's Power StageDocument9 pagesSlva372b Basic Calculation of A Boost Converter's Power StagericardoszfNo ratings yet