Professional Documents

Culture Documents

SMP For Slurry Pump

SMP For Slurry Pump

Uploaded by

SonratOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SMP For Slurry Pump

SMP For Slurry Pump

Uploaded by

SonratCopyright:

Available Formats

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 1 of 14

STANDARD MAINTANENCE PROCEDURE

FOR

SLURRY PUMP

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 2 of 14

OBJECTIVE

The purpose of this work instruction is to explain the procedure for carrying out Overhaul of

Slurry Pump.

1. Slurry Pump

The details of the Slurry Pump are as follows

Make: Shijiazhuang Kingda Pump Industries Ltd.; Model:200ZGB; Capacity: 160 cum/hr;

Max Working Pressure: 6kg/sqcm; Head: 60 Meter; Motor Speed: 2950RPM

DETAILED INSTRUCTION

Sr. Activity Responsibility

No.

I Overhaul to be done as per Checklist

Before commencing dismantling operations, ensure that the

1 following tools and tackles are available:

A crane / chain pulley block suitable for handling the weight of

pumping unit.

A selection of ring and open-ended spanners in Metric sizes.

Eyebolts in Metric sizes.

Hardwood and metal packing blocks.

Miscellaneous tools including a set of Allen keys, drills, pin drivers,

files etc.

Extractor / puller for bearing and coupling.

.

After a long service, wear will occur in parts of the pump necessitating

the renewal of the parts. Those most likely to be affected are impeller,

Wear rings, bearings, and sleeves.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 3 of 14

2 Dismantling

1. Before dismantling, make sure the motor is disconnected.

2. The suction and discharge shutoff valves must be closed.

3. The pump casing must have cooled down to ambient

temperature.

4. The pump casing must be empty and not under pressure.

5. Detach all auxiliary supply pipe lines.

6. Remove coupling guard.

7. Remove coupling half from the pump shaft. Refer fig. no. 1

8. Pull out bearing bracket with discharge cover and complete rotor

(assembled unit).

9. If the pump has been in operation for a long time some parts

may be difficult to remove.

In this case use a penetrating oil or suitable pull-off device.

10.Loosen & remove impeller Lock nut.

11.Remove impeller from pump shaft. Refer fig. no. 2

Fig. no. 1: Dismantling the pump

set Fig. no. 2: Removal of Impeller

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 4 of 14

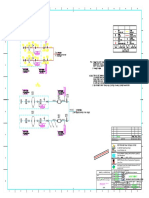

Construction Drawing For Type ZGB Slurry Pump

1. Cover volute plate 2. Impeller 3.volute 4. Frame body 5. Shaft 6. Set nut B 7.

Set nut A 8. Access hole cover 9. Expeller gland 10. Expeller 11. Casing volute

plate 12. Casing 13. Cover

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 5 of 14

Fig. No. 3 : Dismantling the Bearing Unit

Dismantling the Bearing Unit

1. Remove bearing covers and gaskets by unscrewing of hex. Bolt.

Refer fig. no. 3

2. Fasten the bearing unit firmly to the bench vice refer fig. no. 4.

Strike the pump shaft end with a soft hammer. Refer fig. no. 4

3. Fasten the shaft (with bearings) to the bench vice and detach

bearings from shaft with a bearing puller. Refer fig. no. 5

Fig. no. 4 : Dismantling the pump shaft from bearing bracket

Fig. no. 5: Dismantling the bearings from the pump shaft.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 6 of 14

Note: Always replace the bearings once they have been removed from

the shaft with new ones.

Unnecessary removal of the bearings should be avoided because

removal of the bearing can damage it and cause deterioration of the

interference fit. Except where removal is necessary to give access to

the other parts, bearing should be removed only if they need close

inspection. Symptoms, which will indicate the state of bearing, are the

condition of the lubricant, the bearing running temperature, noise level

and vibration during operation.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 7 of 14

Examination of Internal Components :

4 Wearing Rings

The wearing rings have to be replaced when the clearances between

the wearing ring & the impeller, & the Discharge cover exceeds three

times the max. Value as shown in the below table or when the

reduction of efficiency of the pump is noticed.

Note: - In MEGA GC wearing ring is not provided.

Original Clearance on the Diameter

Pump Size Casing Side Impeller Side

Maximum Minimum Maximum Minimum

80-200 0.445 0.33 0.445 0.33

New wearing ring clearances are:-

MEGA GC - 0.5 mm on diameter

MEGA - 0.3 mm on diameter

Shaft Sleeves

Replace shaft sleeve if it is grooved or generally worn.

Impeller

a. Inspect the impeller as follows:

i. Examine the impeller for damage.

ii. For corrosive /erosion pitting.

iii. Cavitations pitting.

iv. Bent or cracked vanes, inlet and outlet vane end wear.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 8 of 14

Any of the above may be repaired, or if damage is extensive, impeller

may need replacement.

b. Around the eye, wearing rings protects the impeller. Examine

around the eye at neck portion for grooving in alignment with

spindle axis; slight grooving is acceptable but deep or profuse

grooving must be remedied by machining the impeller by taking

a polish cut on wearing ring. Spare wear rings are supplied with

excess outside diameter to facilitate machining after fitting. The

wear rings are shrink fitted on impeller neck and are screwed.

c. To check wear, around the impeller neck, use precision

instruments such as outside micrometer to accurately measure

the outside diameter. Measurements should be taken at intervals

around the circumference to check the uneven wear. Differences

between the neck OD and the neck ring ID measured will give us

the clearance between the two. Clearance thus obtained should

not be more than 150% of maximum designed clearance.

Shaft & keys

Shaft should be checked for the trueness, or any other mechanical

damage and corrosion. If the shaft is not true within 0.1 mm TIR, it

should be replaced / repaired. Examine the shaft keys and key ways.

Remove damaged or worn out keys

Bearings

a. Clean all the components using clean white spirit. Do not use

chlorinated solvents such as trichloroethylene and carbon

tetrachloride because they introduce a corrosion risk when used

on ferrous materials.

b. Visually inspect the bearing. The balls, the inner and outer tracks

must all be free from chipping cracks, abrasions or discoloration.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 9 of 14

c. Check that the parts of the cage are firmly fixed together.

d. Visually inspect the bore for any sign of damage. Burrs or any

scratches caused during bearing withdrawal should be carefully

removed by hand application of a fine oilstone, the treatment

being confined to the minimum possible area.

e. Visually inspect the outside diameter for signs of fretting, any

stains may be carefully polished off, but abrasion must be kept

to the absolute minimum that is required, followed by cleaning.

f. Check that bearing rotates freely and smoothly. If there is any

doubt regarding the serviceability of the bearing it should be

replaced.

g. If after inspection, the bearing is reusable, completely coat all

parts with rust preventive oil, working it well into the internal

parts of the bearing. Wrap in clean greaseproof paper and store

until required for replacement or refit on to the spindle if needed.

In case of immediate use, coating of rust preventive oil is not

necessary.

Stuffing box bush

Check bore of stuffing box bush and compare with sleeve

diameter. If "clearance is excessive, the bush should be

renewed.

Note: While assembling stainless steel component, molybdenum-

disulphide paste should be applied to prevent galling / seizure and also

to facilitate easy removal in future.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 10 of 14

1. Vacuum and blow out all cavities of bearing housing.

Bearing Housing

2. Set bearing housing vertical on flange.

3. Press in shaft assembly as shown.

4. Fasten outer bearing cover assembly.

5. Secure inner bearing cover assembly.

6. Fit deflectors at pump side

7. Fit coupling key.

8. Add PVC tape to secure.

9. Place back cover on bench.

10. Insert the packing / logging ring set into this stuffing box.

a. Before repacking, thoroughly clean stuffing box gland, packing

compartment and shaft protection sleeve.

b. Cut the packing ring to correct length and ends at 45º. Ensure

that the packing rings ends come into contact with one another

on fitment.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 11 of 14

5 Reassembly

11. Coat the fits and screw connections with molykote or

similar before reassembly.

12. Check oil seal & o-rings for its damage; replace if

necessary.

13. All gaskets must be renewed; make sure the new ones

have the same thickness as the old ones.

14. Check the shaft with its spacer sleeve / or shaft protection

sleeve (as applicable) for eccentricity, between centers.

Maximum allowable eccentricity is 0.05mm.

15. Fasten the shaft to the bench vice using soft polish sheets

between the vice clamp jaws to avoid damage. Refer fig. no. A.

16. Heat the bearings in the induction heater about 80-90Deg.C

max. and push it on to the shaft. Fig. no. A Allow the bearings to

cool down. Then tap it lightly against the shoulder using suitable

pipe punch.

17. Fit shaft circlip

Shaft assembly Inner Bearing Cover assembly

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 12 of 14

18. Place back cover on bench.

19.Fasten back cover assembly to bearing housing assembly.

20.Rotate shaft & check for rubbing.

21.Fit impeller key tightly and apply.“Locktite” anti seize compound

to shaft.

22.Tap impeller lightly into place.

23.Tighten impeller nut, holding the shaft steady at coupling end.

24.Check operating gap 0.5-1.5 mm.

25. Lightly grease” O” ring & fit.

6. Possible Faults and Removal

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 13 of 14

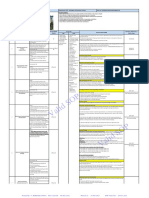

Faults Cause Removal

Air leaking into suction or gland; Seal the leakage;

Pump fails to

discharge any Incorrect direction of pump rotation & impeller worn; Check direction of rotation and

liquid replacing impeller;

Suction pipe blocked Removal blockage.

Gland excessively tightened against packing rings; Loosen gland bolts;

Shaft power Rotating component rubbing on a stationary part; Remove the rubbed parts;

consumption is Bearing is worn; Replace the bearing;

excessive Flow rate is too large; Modify the pump duty and speed;

Misalignment Adjusting drive and pump shaft.

Lubricants too much or less; Lubricating as requirements;

Bearing is over

Containing impurities in the lubricant; Replace new lubricant;

heating

Bearing worn. Replace new bearing.

Misalignment or unparalleled of drive and pump Adjusting drive and pump shaft;

shaft;

Shaft is bent; Replacing shaft;

Bearing has Impeller unbalanced due to wear; Remove rubbing and new Impeller;

short life

Foreign object entered into the bearing or Clean the bearing;

insufficient lubrication;

Incorrect procedure followed in fitting bearings. Replacing or refitting the bearing.

Packing rings are excessive worn; Replace new packing rings;

Excessive

leakage from Shaft sleeve is worn; Replace shaft sleeve;

stuffing box Dirty sealing water. Change clean sealing water.

Bearings worn; Replaced by new bearings;

Impeller unbalanced; Replaced by new impeller;

Pump vibrates

or is noisy Air entered into suction pipe or blocked; Discharge air and remove block;

Flow rate non-uniform and pump not primed Improve on the pump feeding.

REVIEW DATE:-

SMP WILL BE REVIEWED IN EVERY SIX MONTH FROM THE DATE OF ISSUE BASED

ON ACTUAL PROBLEM FACED AND SHALL BE UPDATED ACCORDINGLY.

MECHANICAL MAINTANENCE TEAM WILL VISIT THE EQUIPMENT TWICE IN A WEEK

& IF ANY ABNORMALITY NAMELY (VIBRATION, ABNORMAL SOUND, TEMPERATURE

RISE, BELT TIGHTNESS ETC) OF EQUIPMENT IS OBSERVED AND THEN THE SAME

WILL BE RECTIFIED WITHIN PRESCRIBED TIME PERIOD.

DO’s & DONT’s :

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/SP/01

6 X 600 MW Power Plant

SMP FOR SLURRY PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 14 of 14

DO’s :

1. Ensure relevant equipment/system PTW is available before starting the work.

2. Ensure relevant equipment/system is electrically isolated before starting the work, if applicable.

3. Ensure relevant air/water valves are fully closed for the equipment/system before starting the work.

4. Provide Danger Boards before starting the work involving dismantling of any equipment/system.

5. Ensure proper follow-up of all statutory requirements & hazard norms.

6. Ensure proper follow-up of all plant practices, existing regulations, prescribed procedures & general

safety prior to carry out any work.

7. While replacing any spares/oil, ensure that the same must be as per OEM recommendation.

8. After overhauling of any equipment, ensure proper preservation of spares/oil.

9. Always use the special tools as recommended by OEM for certain equipments like HCSD Pump.

DONT’s :

1. Don’t start the work without presence of Safety Personnel in case fire / other hazards are involved.

2. Don’t use hammer / heating for removing bearings / gears.

3. Don’t use tools & tackles which are not calibrated / certified by relevant authority.

4. Don’t start the work in Pressure Vessels/Pressure Line/Water Line, unless it is completely de-

pressurised.

5. Don’t start the work, especially at height, without proper PPE’s.

6. Don’t start the work, without presence of skilled personnel/expert.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

You might also like

- PMAOPS201 Operate Fluid Flow EquipmentDocument81 pagesPMAOPS201 Operate Fluid Flow EquipmentIntan Siti Hardianti IINo ratings yet

- SOP of Conveyor ReplacementDocument11 pagesSOP of Conveyor ReplacementDwitikrushna Rout100% (1)

- Commissioning Activities - Ball MillDocument10 pagesCommissioning Activities - Ball MillVijay Bhan100% (2)

- ENG SOP 106 - Crusher MaintenanceDocument7 pagesENG SOP 106 - Crusher MaintenanceJohn Lawing100% (3)

- Rod MillDocument9 pagesRod MillupiekupittNo ratings yet

- Sop For Ls CrusherDocument5 pagesSop For Ls CrusherVinod Kumar VermaNo ratings yet

- SOP of Idler ChangeDocument9 pagesSOP of Idler ChangeDwitikrushna RoutNo ratings yet

- SOP For Operation and Cleaning of Conveyer BeltDocument2 pagesSOP For Operation and Cleaning of Conveyer BeltSudheer Nair100% (1)

- Exam Examples Water TreatmentDocument38 pagesExam Examples Water TreatmentBinyam Kebede50% (2)

- SMP For Screw Air Compressor (Transport Air)Document13 pagesSMP For Screw Air Compressor (Transport Air)Sonrat100% (3)

- SMP For For Mill Girth Gear ReplacementDocument3 pagesSMP For For Mill Girth Gear Replacementananthu.uNo ratings yet

- Belt CONVEYOR-FeederDocument7 pagesBelt CONVEYOR-FeederAmit DashNo ratings yet

- Id FanDocument3 pagesId FanKarthi KeyanNo ratings yet

- SOP of Bearing ChangeDocument9 pagesSOP of Bearing ChangeDwitikrushna Rout100% (4)

- 08-SOP For Belt Conveyor 6ABDocument14 pages08-SOP For Belt Conveyor 6ABTamil VananNo ratings yet

- Standard Operating Procedure For (MAINTENANCE SM)Document6 pagesStandard Operating Procedure For (MAINTENANCE SM)JCSNo ratings yet

- 13-SOP For Safe Operation Limestone CrusherDocument2 pages13-SOP For Safe Operation Limestone Crushergothic centuary60% (5)

- Grease Spray System User ManualDocument78 pagesGrease Spray System User ManualDIAGNENo ratings yet

- Risk Assesment Form - Ball MillingDocument6 pagesRisk Assesment Form - Ball Millingbc150100% (1)

- Sop For Oil Purification SystemDocument8 pagesSop For Oil Purification SystemSonrat100% (1)

- Method Improves High-Pressure Settle-Out CalculationsDocument13 pagesMethod Improves High-Pressure Settle-Out CalculationsChem.EnggNo ratings yet

- Kettle Reboiler Mechanical DesignDocument1 pageKettle Reboiler Mechanical DesignNursyarafina Binti Sulaiman100% (1)

- SMP For Pinion Shaft Assembly Replacement of Ball MillDocument2 pagesSMP For Pinion Shaft Assembly Replacement of Ball Millananthu.u100% (1)

- SMP For Agitator (Slurry Sump)Document9 pagesSMP For Agitator (Slurry Sump)SonratNo ratings yet

- SMP For Sealing Water Pump Multi Stage.Document13 pagesSMP For Sealing Water Pump Multi Stage.SonratNo ratings yet

- SMP For Vacuum PumpDocument9 pagesSMP For Vacuum PumpSonratNo ratings yet

- SMP For Supply Water PumpDocument13 pagesSMP For Supply Water PumpSonratNo ratings yet

- SMP For Fluidizing Air BlowerDocument20 pagesSMP For Fluidizing Air BlowerSonrat100% (1)

- 621-CC#09 Idler and Frame ChangingDocument4 pages621-CC#09 Idler and Frame ChangingBuddy Hart100% (1)

- 731-CC-8 Gear Box Oil Seal Changing From Hold Back SideDocument5 pages731-CC-8 Gear Box Oil Seal Changing From Hold Back SideBuddy HartNo ratings yet

- SMP For Pipeline Maintenance at Height: Hindustan Zinc LimitedDocument4 pagesSMP For Pipeline Maintenance at Height: Hindustan Zinc Limitedananthu.u100% (1)

- SOP of Pump Changing JobDocument11 pagesSOP of Pump Changing JobDwitikrushna Rout100% (1)

- 013.0 - 6060 - Central Greasing System - Attachment - CATDocument51 pages013.0 - 6060 - Central Greasing System - Attachment - CAThectorNo ratings yet

- SOP of Conveyor Belt Re-JointingDocument9 pagesSOP of Conveyor Belt Re-JointingDwitikrushna RoutNo ratings yet

- 07-SOP For Belt Conveyor 5ABDocument14 pages07-SOP For Belt Conveyor 5ABTamil Vanan100% (1)

- Sop For Om For Ball MillDocument7 pagesSop For Om For Ball MillvinodsnNo ratings yet

- 615-Hydraulic Pipe Changing of SCR#3Document5 pages615-Hydraulic Pipe Changing of SCR#3Buddy HartNo ratings yet

- Shut-Down Maintenance and Pending Job List: United Cements Pvt. Ltd. Naubise-4, Dhading, NepalDocument20 pagesShut-Down Maintenance and Pending Job List: United Cements Pvt. Ltd. Naubise-4, Dhading, NepalvinodsnNo ratings yet

- Non Availability of Sand Separation: Fabricate New Sand SeparatorDocument2 pagesNon Availability of Sand Separation: Fabricate New Sand Separatorsudhakarrajam2002No ratings yet

- Maintenance Checklist Feed AugerDocument2 pagesMaintenance Checklist Feed Augershamsheer ikramNo ratings yet

- SMP For Grating, Toeguard and Handrail FixingDocument3 pagesSMP For Grating, Toeguard and Handrail Fixingananthu.uNo ratings yet

- Dust CollectorDocument24 pagesDust Collectorafroz ahmedNo ratings yet

- On-Site Emergency Plan: Captive Power Plant Angul, OdishaDocument67 pagesOn-Site Emergency Plan: Captive Power Plant Angul, OdishaANILNo ratings yet

- Hira Ball Mill Line ReplacemenDocument2 pagesHira Ball Mill Line Replacemenananthu.uNo ratings yet

- 628-SCR#2 BUCKET BOLT TIGHTENING and CHANGINGDocument4 pages628-SCR#2 BUCKET BOLT TIGHTENING and CHANGINGBuddy HartNo ratings yet

- SOP-MOD-001 Primary Crushing Plant Operation Version 2 WITHOUT COMMENTDocument3 pagesSOP-MOD-001 Primary Crushing Plant Operation Version 2 WITHOUT COMMENTRuGgED11thNo ratings yet

- DM Plant Operation SopDocument3 pagesDM Plant Operation Sopvel muruganNo ratings yet

- "Centrifuge 101": Bernhard Brauner Josef Göttgens Technical Support Engineers AndritzDocument49 pages"Centrifuge 101": Bernhard Brauner Josef Göttgens Technical Support Engineers AndritzAnuj Gupta100% (2)

- Standard Operating Procedure - Electro Static PrecipitatorDocument3 pagesStandard Operating Procedure - Electro Static PrecipitatorJCSNo ratings yet

- Removal of Mill RejectDocument3 pagesRemoval of Mill Rejectravi singh100% (1)

- SOP - Maintenance of Bag FilterDocument22 pagesSOP - Maintenance of Bag FilterAkash SharmaNo ratings yet

- Mechanical Seal Troubleshooting GuideDocument10 pagesMechanical Seal Troubleshooting Guideempswook100% (2)

- Operation and Maintanance of Conveyor Belt Final 04-10-16Document11 pagesOperation and Maintanance of Conveyor Belt Final 04-10-16Guru Raja Ragavendran NagarajanNo ratings yet

- Sop For Coal Crusher Start Up, Change Over and Shut DownDocument6 pagesSop For Coal Crusher Start Up, Change Over and Shut DownAnbu AyyappanNo ratings yet

- 3.SOP of Pretreatment PlantDocument4 pages3.SOP of Pretreatment PlantBARNALI MUKHERJEE100% (1)

- Sop at Combined MechDocument36 pagesSop at Combined MechVinod Kumar VermaNo ratings yet

- 1 Primary CrusherDocument5 pages1 Primary CrusherDony Edison Gomez0% (1)

- Iron Ore Dressing Plant Auditing - LectureDocument7 pagesIron Ore Dressing Plant Auditing - LectureravibelavadiNo ratings yet

- Roller Chain MaintenanceDocument8 pagesRoller Chain MaintenanceRodrigo SenedezeNo ratings yet

- SOP For Maintenance & Testing of 6.6KV BET-CETDocument2 pagesSOP For Maintenance & Testing of 6.6KV BET-CETArbind NathNo ratings yet

- Predictive Maintenance: 1 Induction FurnaceDocument14 pagesPredictive Maintenance: 1 Induction Furnacenayan vyasNo ratings yet

- Maintenance Component Main Function Level Activity Frequency Line DepartmentDocument7 pagesMaintenance Component Main Function Level Activity Frequency Line DepartmentBarathNo ratings yet

- SMP For Electric Air LockerDocument9 pagesSMP For Electric Air LockerSonratNo ratings yet

- SMP For Dry Ash UnloaderDocument8 pagesSMP For Dry Ash UnloaderSonratNo ratings yet

- OCCW Pump SOP-1Document7 pagesOCCW Pump SOP-1SonratNo ratings yet

- Control Write Up HCSDDocument10 pagesControl Write Up HCSDSonrat100% (1)

- SMP For Fluidizing Air BlowerDocument20 pagesSMP For Fluidizing Air BlowerSonrat100% (1)

- SMP For Dry Ash UnloaderDocument8 pagesSMP For Dry Ash UnloaderSonratNo ratings yet

- SMP For Supply Water PumpDocument13 pagesSMP For Supply Water PumpSonratNo ratings yet

- SMP For Vacuum PumpDocument9 pagesSMP For Vacuum PumpSonratNo ratings yet

- SMP For Sealing Water Pump Multi Stage.Document13 pagesSMP For Sealing Water Pump Multi Stage.SonratNo ratings yet

- Stator CW SOP - Docx-1Document12 pagesStator CW SOP - Docx-1SonratNo ratings yet

- SMP For Agitator (Slurry Sump)Document9 pagesSMP For Agitator (Slurry Sump)SonratNo ratings yet

- Sop For Vent FilterDocument6 pagesSop For Vent FilterSonratNo ratings yet

- ESP-FLD. BLOWER-Model PDFDocument1 pageESP-FLD. BLOWER-Model PDFSonratNo ratings yet

- Turbine Drains SOPDocument6 pagesTurbine Drains SOPSonrat100% (2)

- Pdi EspDocument1 pagePdi EspSonratNo ratings yet

- Buffer Hopper & Air Lock Tank-ModelDocument1 pageBuffer Hopper & Air Lock Tank-ModelSonratNo ratings yet

- Standard Operating Procedure For Hy-Lp Bypass System: ObjectiveDocument8 pagesStandard Operating Procedure For Hy-Lp Bypass System: ObjectiveSonratNo ratings yet

- Silo Blower Compressor ModelDocument1 pageSilo Blower Compressor ModelSonratNo ratings yet

- KSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpDocument6 pagesKSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpSonratNo ratings yet

- Turbine Drains SOPDocument6 pagesTurbine Drains SOPSonrat100% (1)

- Sop For LP PumpDocument5 pagesSop For LP PumpSonratNo ratings yet

- Stator CW SOP-2Document12 pagesStator CW SOP-2SonratNo ratings yet

- State Nodal Officers DS GuidelinesDocument3 pagesState Nodal Officers DS GuidelinesSonratNo ratings yet

- Sop For LP PumpDocument5 pagesSop For LP PumpSonratNo ratings yet

- Salary AnnextureDocument1 pageSalary AnnextureSonratNo ratings yet

- Salary Structure Siddharth KaushikDocument1 pageSalary Structure Siddharth KaushikSonratNo ratings yet

- Seal Oil SopDocument18 pagesSeal Oil SopSonrat100% (2)

- Curriculum Vitae: Nageshwar Prasad RathoreDocument2 pagesCurriculum Vitae: Nageshwar Prasad RathoreSonratNo ratings yet

- SJV-EP-IA-011-VP-003 - DATA SHEET - 190117 - 최종Document15 pagesSJV-EP-IA-011-VP-003 - DATA SHEET - 190117 - 최종Jahangir AlamNo ratings yet

- NG Processing PlantDocument4 pagesNG Processing PlantDanial HazimNo ratings yet

- List of STG ManualsDocument2 pagesList of STG ManualsHarsha Vardhan ReddyNo ratings yet

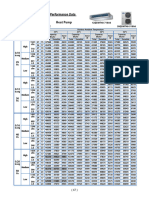

- Ducted Split System 53QDMT48-518A6 Heat Pump 380-415V / 3Ph / 50HzDocument3 pagesDucted Split System 53QDMT48-518A6 Heat Pump 380-415V / 3Ph / 50Hzm.effat3No ratings yet

- UHXDocument14 pagesUHXishu vohraNo ratings yet

- Design of Shell & Tube Heat Exchanger Using SperadsheetDocument47 pagesDesign of Shell & Tube Heat Exchanger Using SperadsheetVirbhadrasinh Puwar100% (15)

- Crack Tip PlasticityDocument2 pagesCrack Tip PlasticitypanbuuNo ratings yet

- Decline and Depletion Rates of Oil ProductionDocument21 pagesDecline and Depletion Rates of Oil ProductionFranck Duprey MvogoNo ratings yet

- Flo Fusion 4000 SLSHDocument1 pageFlo Fusion 4000 SLSHAgustin HaddadNo ratings yet

- Alberta Pressure Equipment Safety RegulationDocument36 pagesAlberta Pressure Equipment Safety Regulationnaismith1No ratings yet

- Standard and Actual Vapor Compression CycleDocument19 pagesStandard and Actual Vapor Compression CycleJB LabraNo ratings yet

- Rating 587 m3h X 90 M - NORM 150-315-200.0kW-3000rpm-380V-3Ph-50HzDocument3 pagesRating 587 m3h X 90 M - NORM 150-315-200.0kW-3000rpm-380V-3Ph-50HzQuynh NguyenNo ratings yet

- Heating Ventilation and Airconditioning SyllabusDocument4 pagesHeating Ventilation and Airconditioning SyllabusCADD LEADERNo ratings yet

- Hydraulic Structures 2020Document382 pagesHydraulic Structures 2020JEMAYER100% (9)

- 7 Design For Static LoadingDocument21 pages7 Design For Static LoadingPRASAD326100% (1)

- Marcet Boiler: Thermodynamics LabDocument5 pagesMarcet Boiler: Thermodynamics LabShiyas Basheer100% (1)

- Scrubber BasicsDocument3 pagesScrubber BasicsherikNo ratings yet

- PSV - Second Term of API FormulaDocument5 pagesPSV - Second Term of API FormuladebjpaulNo ratings yet

- Y22-007 Straight Centrifugal Fan CatalogDocument4 pagesY22-007 Straight Centrifugal Fan CatalogdennyNo ratings yet

- Degrees of Freedm Analysis For Process Control PDFDocument6 pagesDegrees of Freedm Analysis For Process Control PDFsalvatore raffaNo ratings yet

- HYdROGEN FIREDocument2 pagesHYdROGEN FIREVinothen RajNo ratings yet

- 2006249454Document20 pages2006249454sh_nk2010No ratings yet

- Electrical Submersible Pumps 101Document85 pagesElectrical Submersible Pumps 101Anonymous ZSne5ChQNo ratings yet

- Tolerance of Performance Curves According To UNI EN ISO 9906: 2002 NormsDocument2 pagesTolerance of Performance Curves According To UNI EN ISO 9906: 2002 NormsJuan AcostaNo ratings yet

- Chapter 4: Heat SPM 2003, Section A, No. 2 (5 Marks)Document6 pagesChapter 4: Heat SPM 2003, Section A, No. 2 (5 Marks)Angie Kong Su MeiNo ratings yet

- 202104-Chemical Thermodynamics and KineticsDocument8 pages202104-Chemical Thermodynamics and Kineticsmohammed Al-basrawiNo ratings yet