Professional Documents

Culture Documents

Imotion 3

Imotion 3

Uploaded by

fabioCopyright:

Available Formats

You might also like

- SO5C Repair ManualDocument155 pagesSO5C Repair ManualAung Kham100% (8)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- JCB TRANSMISSION Service Repair Manual PDFDocument13 pagesJCB TRANSMISSION Service Repair Manual PDFmecanikka6romania25% (12)

- Workshop Manual Triumph Speed Triple 1050-3-2005Document379 pagesWorkshop Manual Triumph Speed Triple 1050-3-2005Thunderbird390% (21)

- 2009 2010 Honda Pilot Service ManualDocument3,164 pages2009 2010 Honda Pilot Service Manualtong Saetung100% (1)

- Allison 1000 y 2000Document672 pagesAllison 1000 y 2000Mauricio Gomez Gomez100% (10)

- Minarelli AM6 Engine Workshop Manual PDFDocument35 pagesMinarelli AM6 Engine Workshop Manual PDFAndrás SzántaiNo ratings yet

- FVR FVM Owner ManualDocument472 pagesFVR FVM Owner ManualDo Van DiepNo ratings yet

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- 2019 Linhai 500 D T3 Service ManualDocument291 pages2019 Linhai 500 D T3 Service ManualJason Conerly100% (2)

- Toyota A442F 1992 RM315E Automatic Transmission Repair ManualDocument143 pagesToyota A442F 1992 RM315E Automatic Transmission Repair ManualAndrianjaka andriamanalina100% (2)

- Honda 2003-2009 VTX 1300 PDFDocument506 pagesHonda 2003-2009 VTX 1300 PDFAlfredo Ramirez100% (2)

- Yamaha XVS 1100 Dragstar Manual WWW - Manualedereparatie.info PDFDocument115 pagesYamaha XVS 1100 Dragstar Manual WWW - Manualedereparatie.info PDFSergioPortillaLastarriaNo ratings yet

- Caterpillar Vs JCBDocument32 pagesCaterpillar Vs JCBTomasz Wiatr50% (2)

- LL3014BDocument4 pagesLL3014BKuku BucketNo ratings yet

- Epiroc Drill StringsDocument16 pagesEpiroc Drill StringsCarlos Regaliza100% (1)

- Yamaha XV535Document87 pagesYamaha XV535Cristina GhităNo ratings yet

- Tread ManDocument83 pagesTread ManjbfrankelNo ratings yet

- Caixas Eaton Fuller RoadrangerDocument18 pagesCaixas Eaton Fuller RoadrangerThiago Barroso100% (1)

- Hino Wo6dti ServicemanualDocument10 pagesHino Wo6dti Servicemanualiva100% (61)

- Regal Raptor DAYTONA Euro IV Owner ManualDocument25 pagesRegal Raptor DAYTONA Euro IV Owner ManualKrzysztof Jakiś50% (2)

- Honda Nigthawk PDFDocument198 pagesHonda Nigthawk PDFAngel Orlando Monrroy MéndezNo ratings yet

- Inside Vehiclegeneral MaintenanceDocument4 pagesInside Vehiclegeneral MaintenanceEdson CRNo ratings yet

- XT600E XT500E: Owner'S ManualDocument100 pagesXT600E XT500E: Owner'S ManualVillarroel FrankNo ratings yet

- Symbols Used in This Manual: DangerDocument808 pagesSymbols Used in This Manual: Dangerarif arnestaNo ratings yet

- E60H E75B 75B: Owner'S ManualDocument116 pagesE60H E75B 75B: Owner'S Manualjorge alonsoNo ratings yet

- Yamaha f9.9c Service ManualDocument117 pagesYamaha f9.9c Service Manualweroli9240No ratings yet

- Hyosung GV650 User-ManualDocument76 pagesHyosung GV650 User-Manual19742020No ratings yet

- Service Manual: Spicer Single Drive AxlesDocument44 pagesService Manual: Spicer Single Drive Axlessummoner001100% (1)

- 2021 Yamaha YZ125X Repair ManualDocument268 pages2021 Yamaha YZ125X Repair Manualmotoraksan2No ratings yet

- DM FD0001 03 Eng PDFDocument37 pagesDM FD0001 03 Eng PDFVerna JordanNo ratings yet

- XZ400 (14X) Owners ManualDocument18 pagesXZ400 (14X) Owners ManualRohan SimonNo ratings yet

- Yamaha gp1300r PDFDocument279 pagesYamaha gp1300r PDFАндрей Тепикин100% (1)

- fz6rc Service Manual PDFDocument420 pagesfz6rc Service Manual PDFSusan M. WilliamsNo ratings yet

- 2007 Fz6naDocument538 pages2007 Fz6naRaphael MattosNo ratings yet

- A442f PDFDocument143 pagesA442f PDFSuliz Tiono100% (2)

- Yamaha Outboard 9.9c-15 Owner's ManualDocument96 pagesYamaha Outboard 9.9c-15 Owner's Manualmjavad40001382No ratings yet

- 1st Cover 4th Cover: Owner'S ManualDocument139 pages1st Cover 4th Cover: Owner'S ManualLeon Jaime Velasquez CardenasNo ratings yet

- Vstar xvs650pDocument119 pagesVstar xvs650pArnaldo ArévaloNo ratings yet

- C Eixo4x2 s200 IngDocument12 pagesC Eixo4x2 s200 IngRichard Medrano AlmarazNo ratings yet

- Service Manual: LIT-11616-19-49 3D1-F8197-10Document298 pagesService Manual: LIT-11616-19-49 3D1-F8197-10Phan LamNo ratings yet

- Eng Favero Manu AssiomaDocument56 pagesEng Favero Manu Assiomawarren.nefronNo ratings yet

- SB 10060295 2280Document13 pagesSB 10060295 2280Autotronica ChosicaNo ratings yet

- Assioma User Manual - EN-JA-KODocument56 pagesAssioma User Manual - EN-JA-KOroyNo ratings yet

- Dual Control Lever: User's Manual Regular Inspections Before Riding The BicycleDocument1 pageDual Control Lever: User's Manual Regular Inspections Before Riding The BicyclePrekelNo ratings yet

- Fzs6w-Fz6swc 2007 Levi VDocument394 pagesFzs6w-Fz6swc 2007 Levi VespecialidadmotocicletasNo ratings yet

- S5 Yw04e06ahinodutro PDFDocument130 pagesS5 Yw04e06ahinodutro PDFichan shodiqNo ratings yet

- Suzuki GSX-R1000 A Owner's ManualDocument151 pagesSuzuki GSX-R1000 A Owner's Manualclaudio mateusNo ratings yet

- Owner'S Manual: U.S.A.EditionDocument111 pagesOwner'S Manual: U.S.A.EditionRodrigo PerezNo ratings yet

- MM600D MM700D: Service ManualDocument213 pagesMM600D MM700D: Service ManualTony SleckNo ratings yet

- 2022 - (BEA-28197-E0) - XSR900-MTM890 - Service ManualDocument726 pages2022 - (BEA-28197-E0) - XSR900-MTM890 - Service ManualXuan Truong BuiNo ratings yet

- Fuller Heavy Duty Transmissions TRDR0550: Driver InstructionsDocument36 pagesFuller Heavy Duty Transmissions TRDR0550: Driver InstructionsJ Gabriel S RuanoNo ratings yet

- B3L-28197-20 Yamaha YZF R1 2020 Service Manual EUDocument822 pagesB3L-28197-20 Yamaha YZF R1 2020 Service Manual EURaa Frr100% (1)

- 7281-05-02-01 Air Suspension, Adjustment (Ride Height and Driveline Calculation)Document13 pages7281-05-02-01 Air Suspension, Adjustment (Ride Height and Driveline Calculation)César Arturo Pajuelo EspinozaNo ratings yet

- 06JudyManual EnglishDocument5 pages06JudyManual EnglishilbruthumNo ratings yet

- Essential Scooter Maintenance for the Absolute BeginnerFrom EverandEssential Scooter Maintenance for the Absolute BeginnerNo ratings yet

- School and Metro Bus Driving Skills: Essential Step By Step Guide for Maneuvering Large VehiclesFrom EverandSchool and Metro Bus Driving Skills: Essential Step By Step Guide for Maneuvering Large VehiclesNo ratings yet

- Master the T-CLOCS Pre-Ride Safety Inspection in 15 MinutesFrom EverandMaster the T-CLOCS Pre-Ride Safety Inspection in 15 MinutesNo ratings yet

- P350-El-1305-C - PDT TTDocument9 pagesP350-El-1305-C - PDT TTvigneshwarannnNo ratings yet

- Technologies & Applications: 漢力能源科技股份有限公司 Hanpower Energy Technology Co., LtdDocument34 pagesTechnologies & Applications: 漢力能源科技股份有限公司 Hanpower Energy Technology Co., LtdGiang Nguyễn TrườngNo ratings yet

- Line Driver Type PG: Installation ManualDocument28 pagesLine Driver Type PG: Installation ManualRenny NacarattiNo ratings yet

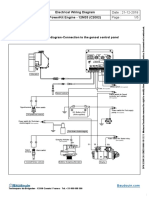

- Electric Wiring Diagram-Connection To The Genset Control PanelDocument5 pagesElectric Wiring Diagram-Connection To The Genset Control PanelAmit Adesh SookunNo ratings yet

- Newlong NP 7ADocument31 pagesNewlong NP 7ALucas TavaresNo ratings yet

- 2x1, 3x1, 4x1 and 5x1: Multisplit Inverter H6 Outdoor Unit MUEX-H6 SeriesDocument7 pages2x1, 3x1, 4x1 and 5x1: Multisplit Inverter H6 Outdoor Unit MUEX-H6 SeriesAbdelbagiNo ratings yet

- Smartpid2000 Module Inside Smart Array ControllerDocument1 pageSmartpid2000 Module Inside Smart Array ControllerSav SashaNo ratings yet

- Shock AbsorbersDocument58 pagesShock AbsorbersKattie ValerioNo ratings yet

- Maintenance Repair Overhaul: Safely To New Horizons Ensuring Your Aircraft Is Ready Whenever Duty CallsDocument10 pagesMaintenance Repair Overhaul: Safely To New Horizons Ensuring Your Aircraft Is Ready Whenever Duty CallsSuryaNo ratings yet

- MB SL55 AMG - pdf-1635604883Document182 pagesMB SL55 AMG - pdf-1635604883Mohamed AhmedNo ratings yet

- Hbka 02Document20 pagesHbka 02Adil AssefNo ratings yet

- Instrumentation and Calibration Lab Proposal SpanishDocument4 pagesInstrumentation and Calibration Lab Proposal SpanishKevin C. UcsmNo ratings yet

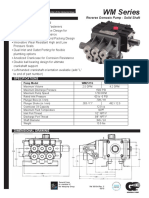

- Bomba WM4215S-PumpDocument3 pagesBomba WM4215S-PumpOscarArturoNo ratings yet

- Hardware (Servers, Nodes & Standalone Computers) : 40-8/2004 (Vol VII)Document38 pagesHardware (Servers, Nodes & Standalone Computers) : 40-8/2004 (Vol VII)PMJAMAKHANDI1No ratings yet

- CALDON LEFM 3xxci Ultrasonic Flowmeters With G3 Transmitters ManualDocument84 pagesCALDON LEFM 3xxci Ultrasonic Flowmeters With G3 Transmitters Manualangel uscangaNo ratings yet

- Ga Drawing 62.5 KvaDocument3 pagesGa Drawing 62.5 KvaHarishkumar TrNo ratings yet

- Bobine Stingere ArcDocument2 pagesBobine Stingere ArcRadu Sergiu CimpanNo ratings yet

- Manual AV110X PDF Engines CoolantDocument8 pagesManual AV110X PDF Engines CoolantBrad BerberNo ratings yet

- 2.wartsila - Rail Valve LeakageDocument15 pages2.wartsila - Rail Valve LeakageSmithmykNo ratings yet

- 25 - Quinte Series EnglishDocument14 pages25 - Quinte Series EnglishJajang NurwandiNo ratings yet

- STD Uei Wheel Loader Weekly Maintenance ChecklistDocument1 pageSTD Uei Wheel Loader Weekly Maintenance Checklistmuhammad lukmanNo ratings yet

- Automotive Sumative TestDocument5 pagesAutomotive Sumative TestRAndy rodelas100% (2)

- ClockworkDocument5 pagesClockworkbernagunduzNo ratings yet

- Getrag En1 PDFDocument6 pagesGetrag En1 PDFJeremías EspinozaNo ratings yet

- Rocky DatasheetDocument2 pagesRocky Datasheetsaikrishna BNo ratings yet

- Electrico Interactivo PDFDocument38 pagesElectrico Interactivo PDFFelipeNicolasSilvaNo ratings yet

- ELAB ManualDocument71 pagesELAB ManualDhamu DharanNo ratings yet

Imotion 3

Imotion 3

Uploaded by

fabioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Imotion 3

Imotion 3

Uploaded by

fabioCopyright:

Available Formats

E

user manual

D

betriebsanleitung

F

notice d’utilisation

Nl

handleiding

Dk

brugsanvisning

Sv

bruksanvisning

DualDrive · December 2002 1

Downloaded from www.Manualslib.com manuals search engine

These instructions contain Please note:

important information about your

SRAM i-MOTION 3 System. Precautionary measures,

which protect from possible

Please take the time to read these accident, injury or danger to

operating instructions carefully. life, or which prevent possible

damage to the bicycle.

Your SRAM i-MOTION 3 System is

almost maintenance-free. Should Special advice to assist in the

you have any queries that are better handling of the opera-

not answered in these operating tion, control, and adjustment

instructions, your qualified bicycle procedures.

specialist will be pleased to help

you.

Have a nice time and enjoy your

SRAM i-MOTION 3.

© Copyright SRAM Corporation 2006

Publ. No. 5300 E/D/F/Nl/Dk/Sv

Information may be enhanced

without prior notice.

Released June 2006

SRAM Technical Documentation,

Schweinfurt/Germany

2 i-MOTION 3 · June 2006

Downloaded from www.Manualslib.com manuals search engine

TA B L E O F C O N T E N T S

THE SRAM i-MOTION 3 SYSTEM 4

OPERATION 5

MAINTENANCE AND CARE

» Gear adjustment 6

» Remove and fit rear wheel 7

» Cleaning and lubrication 10

» Repair work / wear parts 11

A S S E M B LY O F C O M P O N E N T S 12

TECHNICAL DATA 18

i-MOTION 3 · June 2006 3

Downloaded from www.Manualslib.com manuals search engine

THE SRAM i-MOTION 3 SYSTEM

A modern bicycle derailleur should

be sporty, load shiftable, intuitive

to use and durable! With the new

i-MOTION 3, SRAM delivers an

internal gear hub that meets and

exceeds all these requirements!

i-MOTION 3 gear hub

Load shiftable. Light shifting

forces. Shifting during stand-

still is possible: Easy re-start

e.g. at a traffic light.

i-MOTION 3 connecting link

i-MOTION 3 shifter Easy wheel removal:

Intuitive gear indication, high- The gear adjustment remains

quality design. unchanged.

4 i-MOTION 3 · June 2006

Downloaded from www.Manualslib.com manuals search engine

O P E R AT I O N

SHIFTING

Shift gears by turning the 1 E

1 rotating grip.

» You can shift while standing still

or while riding your bicycle.

» When approaching inclines shift

down in good time.

» The smoothest and fastest gear

change happens when changing

gears while pedaling with low

force.

BRAKING

On long and steep downhill roads,

simultaneously use rear and front

brakes to avoid heating up of the

brakes.

Excessive heating of the hub

with the back pedal brake

may result in loss of lubricant and

braking too hard. This will lead to a

trip to the repair shop.

Read the applicable user

manual for each bicycle

equipped with i-BRAKE or band

brakes.

i-MOTION 3 · June 2006 5

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE AND CARE

GEAR ADJUSTMENT

Shift the twist shifter to the

2 3rd gear. 2

The shift cable must be with-

out play in 3rd gear. That

means it must be pulled out of the

hub as far as it will go.

While pulling the plastic re-

3 tainer (1), it should not be pos- 3

sible to pull the shift cable further

out of the hub.

1

– Shift cable has too much play:

Shift the twist shifter to the 1st

gear.

Reduce play of the shift

4 cable by turning the barrel

adjuster (2) at the shifter. 4

– Shift cable is too taut:

The shifter won‘t shift into 3rd

gear or the hub doesn‘t shift in 2

1st gear or will permanently

switch between 1st and 2nd

gear.

Shift the twist shifter to the 1st

gear.

Decrease shift cable ten-

4 sion by turning the barrel

adjuster (2) at the shifter.

» Shift the twist shifter to the 3rd

gear and check again, until there

isn‘t any play in the shift cable.

6 i-MOTION 3 · June 2006

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE AND CARE

REMOVE AND FIT REAR WHEEL

REMOVING THE REAR

WHEEL 5 E

Shift the twist shifter to the 1st

5 gear.

Pull the plastic retainer (1) off

6 the cable stop bracket (2).

Disconnect the shift cable by

7 disengaging the link (3) of the 6

cable nipple (4).

Loosen the axle nuts (5) and 2

8 remove the nuts and the re- 1

taining washers (6) underneath

them.

If applicable, unscrew the frame

clamp connection (7) of the brake

lever. 7

» Remove the rear wheel. 4

3

8 6

i-MOTION 3 · June 2006 7

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE AND CARE

REMOVE AND FIT REAR WHEEL

FITTING THE REAR

WHEEL 9 1

» Place the rear wheel into the rear

frame.

Slide one retaining washer

9 each (1) onto each axle end.

The serrations of the retaining

washer must bear against the

dropout of the frame. 10

Align the cable stop bracket (2) 2

10 parallel to the frame stay (3).

Mount the axle nuts (4) and

11 tighten them alternately with 3

a torque of 30 – 40 Nm (266 – 350

in.lbs.).

11 4

If applicable, mount the brake

12 lever (5) between the two

straps of the frame clamp (6).

The frame clamp must be

seated on the frame with no

play. Use only self-locking nuts!

Tightening torque: 2 – 3 Nm (18 –

27 in.lbs.).

12

6

5

8 i-MOTION 3 · June 2006

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE AND CARE

REMOVE AND FIT REAR WHEEL

Make sure that the shifter is

13 set to the 1st gear. 13 E

Make the cable connection by

14 hooking in the link (7) of the

shift cable to the cable nipple (8)

on the hub.

Slide the plastic retainer (9)

15 completely onto the cable stop 14

bracket (10).

15

10 9

i-MOTION 3 · June 2006 9

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE AND CARE

C L E A N I N G A N D L U B R I C AT I O N

CLEANING

» Your SRAM i-MOTION 3 compo-

nents are well protected from

external evironmental impacts.

However, do not use water under

pressure (such as pressure wash-

ers or water jets) for cleaning to

prevent malfunctions due to water

penetration.

» During the winter season, you

should clean your bicycle in

shorter intervals so that winter

road salt cannot cause any dam-

age.

» Do not use agressive cleaners.

» Clean dirty chains before oiling.

Let cleaner set for only a few

minutes and rinse with water. Do

not oil chain until completely dry.

LUBRICATION

» The rear wheel hub is provided

with permanent lubrication and

maintenance-free under normal

conditions.

» Regular lubrication will extend the

chain's service life.

10 i-MOTION 3 · June 2006

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE AND CARE

REPAIR WORK / WEAR PARTS

REPAIR WORK WEAR PARTS E

Only a qualified bike dealer Brake liners or brake jackets, brake

should perform any necessary cables, shift cables, handlebar

work on the gear hub, shifter, and grips, sprockets, and bike chains

brakes. are wear parts. Please check these

» Unauthorized work on your parts regularly and replace them

i-MOTION 3 system could endan- timely.

ger you and your warranty may

become void.

» Please contact your qualified bike

dealer regarding any questions or

problem you may have.

Back pedal brake

If the back pedal brake is braking

too hard, the brake jacket has to be

lubricated with special grease. This

work must be performed by a quali-

fied bike dealer.

Cable Change

If a cable must be replaced (shifter

cable or brake cable), contact your

qualified dealer.

i-MOTION 3 · June 2006 11

Downloaded from www.Manualslib.com manuals search engine

A S S E M B LY

OF COMPONENTS

A S S E M B LY H U B

» Spoke the hub as normal. 16

1

Set the dust cover (1) onto the

16 driver. The curve must point to

the outside.

Set the sprocket (2) onto the

17 driver.

If an offset sprocket will be used,

mount the sprocket with the curve

17 2

pointing to the outside.

Mount the sprocket retaining

18 ring (3) onto the driver. Check

proper seat of the retaining ring.

Slide the cable stop bracket (4)

19 onto the axle end of the 18 3

sprocket side. Thereafter mount

the washer with rubber insert (5)

to fix the the cable stop bracket.

» Place the rear wheel into the rear

frame.

19

4 5

12 i-MOTION 3 · June 2006

Downloaded from www.Manualslib.com manuals search engine

A S S E M B LY

OF COMPONENTS

Slide one retaining washer

20 each (6) onto each axle end. 20 6

E

The serrations of the retaining

washer must bear against the

dropout of the frame.

Align the cable stop bracket (7)

21 parallel to the frame stay (8).

22

Mount the axle nuts (9) and

tighten them alternately with

21

a torque of 30 – 40 Nm (266 – 350 7

in.lbs.).

If applicable, mount the brake

23 lever (10) between the two 8

straps of the frame clamp (11).

The frame clamp must be

seated on the frame without 22 9

play. Use only self-locking nuts!

Tightening torque: 2 – 3 Nm (18 –

27 in.lbs.).

23

11

10

i-MOTION 3 · June 2006 13

Downloaded from www.Manualslib.com manuals search engine

A S S E M B LY

OF COMPONENTS

A S S E M B LY S H I F T E R

Slide the shifter (1) onto the 24

24 handlebar.

Slide the handlebar grip (2)

25 onto the handlebar.

1

Align the shifter on the han-

26 dlebar grip and position the

shifter according to your needs.

Tighten the clamp bolt (3). 25

2.5 mm Allen wrench, torque 1.7 Nm

(15 in.lbs.).

Never use lubricants or sol-

vents to install handlebar

grips. Handlebar grips provide an 2

axial safety function and may not

become separated from the hand-

lebar.

» Make sure that the shifter and

brake lever function properly and

26

are unobstructed (re-adjust if

needed).

» Never ride without the handlebar

grips. The turning grip of the twist 3 2.5 mm

shifter could become loose. This 1.7 Nm

(15 in.lbs.)

can result in severe injury.

14 i-MOTION 3 · June 2006

Downloaded from www.Manualslib.com manuals search engine

A S S E M B LY

OF COMPONENTS

A S S E M B LY S H I F T

CABLE 27 E

Make sure that the cable

housing length is sufficient to

allow an extreme turning angle.

» Also consider the influence of

adjustable handlebars and stems

on the cable housing length.

27

Fasten the cable housing on

the frame.

28

The cable housing must be

movable at the fastening

points.

» Avoid tight bends when install-

ing the shift cable.

Make sure that the shifter is

28 set to the 1st gear. 29

Make the cable connection by

29 hooking in the link (1) of the

1

shift cable to the cable nipple (2)

on the hub.

2

Slide the plastic retainer (3)

30 completely onto the cable stop

bracket (4). 30

4 3

i-MOTION 3 · June 2006 15

Downloaded from www.Manualslib.com manuals search engine

A S S E M B LY

OF COMPONENTS

GEAR ADJUSTMENT

» Shift the gears up and down re- 31

peatedly before setting the shifter

so that the shift cable can settle.

Shift the twist shifter to the

31 3rd gear.

The shift cable must be with-

out play in 3rd gear. That

means it must be pulled out of the

32

hub as far as it will go.

1

While pulling the plastic re-

32 tainer (1), it should not be pos-

sible to pull the shift cable further

out of the hub.

– Shift cable has too much play:

Shift the twist shifter to the 1st 33

gear.

Reduce play of the shift

33 cable by turning the barrel 2

adjuster (2) at the shifter.

– Shift cable is too taut:

The shifter won‘t shift into 3rd

gear or the hub doesn‘t shift in

1st gear or will permanently

switch between 1st and 2nd

gear.

Shift the twist shifter to the 1st

gear.

Decrease shift cable ten- » Shift the twist shifter to the 3rd

33 sion by turning the barrel gear and check again, until there

adjuster (2) at the shifter. isn‘t any play in the shift cable.

16 i-MOTION 3 · June 2006

Downloaded from www.Manualslib.com manuals search engine

A S S E M B LY

OF COMPONENTS

E

i-MOTION 3 · June 2006 17

Downloaded from www.Manualslib.com manuals search engine

T E C H N I C A L D ATA

GEAR HUB i-MOTION 3 with back pedal brake

Speeds 3

Brake With back pedal brake

Over Locknut Dim., OLD 130 mm

Length, L 168 and 178 mm

Axle

Ends Diameter M 10x1

Dropout Width Dim., A min. 4 mm / max. 8 mm

Holes 28 / 32 / 36

Spoke

Hole Diameter 3.0 mm

Hole Ref. ø, HR 70 mm

Flange Dist. to 1/2 OLD F1 = 27.3 mm / F2 = 27.6 mm

Total Ratio 186 %

Gear jump 1 to 3 36% / 36%

Chainline, CL 44.0 mm (straight spr.) / 40.5 mm (off-set spr.)

Compat- Chain

1

Dimension /2" x 1/8" and 1/2" x 3/32"

Sprocket 16 / 17 / 18 T. (straight) / 19 / 20 / 21 T. (off-set)

ibility

Shifter SRAM i-MOTION 3

Tandem not suitable for tandems and transport bicycles

SHIFTER i-MOTION 3 shifter

Shifter type Twist shifter

Assembly location Right side of handlebar

Gear indication Window

Barrel adjuster Indexed

Clamp diameter 22.3 mm

Straight handlebar ends Length = min. 150 mm

Cable laying Continuous cable housing (pre-assembled)

18 i-MOTION 3 · June 2006

Downloaded from www.Manualslib.com manuals search engine

T E C H N I C A L D ATA

Ø 3.0

Ø 7.3

HR

78

100

M 10x1

3

A

19

CL straight

CL off-set

2.8

F2

OLD

Version with back pedal brake

124.5

L

F1

/ 2 OLD

2.8

1

A

M 10x1

i-MOTION 3 · June 2006 19

Downloaded from www.Manualslib.com manuals search engine

WORLD HEADQUARTERS

Chicago, Illinois U.S.A.

SRAM Corporation

1333 North Kingsbury, 4th floor

Chicago, Illinois 60622

phone: +1-312-664-8800

fax: +1-312-664-8826

EUROPEAN HEADQUARTERS

Amersfoort, The Netherlands

SRAM Europe

Basicweg 12-D

3821 BR Amersfoort

The Netherlands

phone: +31-33-450-6060

fax: +31-33-457-0200

ASIAN HEADQUARTERS

Taichung, Taiwan

SRAM Taiwan

No. 1598-8 Chung Shan Road

Shen Kang Hsiang, Taichung

County 429

Taiwan

phone: +886-4-2561-3678

fax: +886-4-2561-3686

www.sram.com

Downloaded from www.Manualslib.com manuals search engine

You might also like

- SO5C Repair ManualDocument155 pagesSO5C Repair ManualAung Kham100% (8)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- JCB TRANSMISSION Service Repair Manual PDFDocument13 pagesJCB TRANSMISSION Service Repair Manual PDFmecanikka6romania25% (12)

- Workshop Manual Triumph Speed Triple 1050-3-2005Document379 pagesWorkshop Manual Triumph Speed Triple 1050-3-2005Thunderbird390% (21)

- 2009 2010 Honda Pilot Service ManualDocument3,164 pages2009 2010 Honda Pilot Service Manualtong Saetung100% (1)

- Allison 1000 y 2000Document672 pagesAllison 1000 y 2000Mauricio Gomez Gomez100% (10)

- Minarelli AM6 Engine Workshop Manual PDFDocument35 pagesMinarelli AM6 Engine Workshop Manual PDFAndrás SzántaiNo ratings yet

- FVR FVM Owner ManualDocument472 pagesFVR FVM Owner ManualDo Van DiepNo ratings yet

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (17)

- 2019 Linhai 500 D T3 Service ManualDocument291 pages2019 Linhai 500 D T3 Service ManualJason Conerly100% (2)

- Toyota A442F 1992 RM315E Automatic Transmission Repair ManualDocument143 pagesToyota A442F 1992 RM315E Automatic Transmission Repair ManualAndrianjaka andriamanalina100% (2)

- Honda 2003-2009 VTX 1300 PDFDocument506 pagesHonda 2003-2009 VTX 1300 PDFAlfredo Ramirez100% (2)

- Yamaha XVS 1100 Dragstar Manual WWW - Manualedereparatie.info PDFDocument115 pagesYamaha XVS 1100 Dragstar Manual WWW - Manualedereparatie.info PDFSergioPortillaLastarriaNo ratings yet

- Caterpillar Vs JCBDocument32 pagesCaterpillar Vs JCBTomasz Wiatr50% (2)

- LL3014BDocument4 pagesLL3014BKuku BucketNo ratings yet

- Epiroc Drill StringsDocument16 pagesEpiroc Drill StringsCarlos Regaliza100% (1)

- Yamaha XV535Document87 pagesYamaha XV535Cristina GhităNo ratings yet

- Tread ManDocument83 pagesTread ManjbfrankelNo ratings yet

- Caixas Eaton Fuller RoadrangerDocument18 pagesCaixas Eaton Fuller RoadrangerThiago Barroso100% (1)

- Hino Wo6dti ServicemanualDocument10 pagesHino Wo6dti Servicemanualiva100% (61)

- Regal Raptor DAYTONA Euro IV Owner ManualDocument25 pagesRegal Raptor DAYTONA Euro IV Owner ManualKrzysztof Jakiś50% (2)

- Honda Nigthawk PDFDocument198 pagesHonda Nigthawk PDFAngel Orlando Monrroy MéndezNo ratings yet

- Inside Vehiclegeneral MaintenanceDocument4 pagesInside Vehiclegeneral MaintenanceEdson CRNo ratings yet

- XT600E XT500E: Owner'S ManualDocument100 pagesXT600E XT500E: Owner'S ManualVillarroel FrankNo ratings yet

- Symbols Used in This Manual: DangerDocument808 pagesSymbols Used in This Manual: Dangerarif arnestaNo ratings yet

- E60H E75B 75B: Owner'S ManualDocument116 pagesE60H E75B 75B: Owner'S Manualjorge alonsoNo ratings yet

- Yamaha f9.9c Service ManualDocument117 pagesYamaha f9.9c Service Manualweroli9240No ratings yet

- Hyosung GV650 User-ManualDocument76 pagesHyosung GV650 User-Manual19742020No ratings yet

- Service Manual: Spicer Single Drive AxlesDocument44 pagesService Manual: Spicer Single Drive Axlessummoner001100% (1)

- 2021 Yamaha YZ125X Repair ManualDocument268 pages2021 Yamaha YZ125X Repair Manualmotoraksan2No ratings yet

- DM FD0001 03 Eng PDFDocument37 pagesDM FD0001 03 Eng PDFVerna JordanNo ratings yet

- XZ400 (14X) Owners ManualDocument18 pagesXZ400 (14X) Owners ManualRohan SimonNo ratings yet

- Yamaha gp1300r PDFDocument279 pagesYamaha gp1300r PDFАндрей Тепикин100% (1)

- fz6rc Service Manual PDFDocument420 pagesfz6rc Service Manual PDFSusan M. WilliamsNo ratings yet

- 2007 Fz6naDocument538 pages2007 Fz6naRaphael MattosNo ratings yet

- A442f PDFDocument143 pagesA442f PDFSuliz Tiono100% (2)

- Yamaha Outboard 9.9c-15 Owner's ManualDocument96 pagesYamaha Outboard 9.9c-15 Owner's Manualmjavad40001382No ratings yet

- 1st Cover 4th Cover: Owner'S ManualDocument139 pages1st Cover 4th Cover: Owner'S ManualLeon Jaime Velasquez CardenasNo ratings yet

- Vstar xvs650pDocument119 pagesVstar xvs650pArnaldo ArévaloNo ratings yet

- C Eixo4x2 s200 IngDocument12 pagesC Eixo4x2 s200 IngRichard Medrano AlmarazNo ratings yet

- Service Manual: LIT-11616-19-49 3D1-F8197-10Document298 pagesService Manual: LIT-11616-19-49 3D1-F8197-10Phan LamNo ratings yet

- Eng Favero Manu AssiomaDocument56 pagesEng Favero Manu Assiomawarren.nefronNo ratings yet

- SB 10060295 2280Document13 pagesSB 10060295 2280Autotronica ChosicaNo ratings yet

- Assioma User Manual - EN-JA-KODocument56 pagesAssioma User Manual - EN-JA-KOroyNo ratings yet

- Dual Control Lever: User's Manual Regular Inspections Before Riding The BicycleDocument1 pageDual Control Lever: User's Manual Regular Inspections Before Riding The BicyclePrekelNo ratings yet

- Fzs6w-Fz6swc 2007 Levi VDocument394 pagesFzs6w-Fz6swc 2007 Levi VespecialidadmotocicletasNo ratings yet

- S5 Yw04e06ahinodutro PDFDocument130 pagesS5 Yw04e06ahinodutro PDFichan shodiqNo ratings yet

- Suzuki GSX-R1000 A Owner's ManualDocument151 pagesSuzuki GSX-R1000 A Owner's Manualclaudio mateusNo ratings yet

- Owner'S Manual: U.S.A.EditionDocument111 pagesOwner'S Manual: U.S.A.EditionRodrigo PerezNo ratings yet

- MM600D MM700D: Service ManualDocument213 pagesMM600D MM700D: Service ManualTony SleckNo ratings yet

- 2022 - (BEA-28197-E0) - XSR900-MTM890 - Service ManualDocument726 pages2022 - (BEA-28197-E0) - XSR900-MTM890 - Service ManualXuan Truong BuiNo ratings yet

- Fuller Heavy Duty Transmissions TRDR0550: Driver InstructionsDocument36 pagesFuller Heavy Duty Transmissions TRDR0550: Driver InstructionsJ Gabriel S RuanoNo ratings yet

- B3L-28197-20 Yamaha YZF R1 2020 Service Manual EUDocument822 pagesB3L-28197-20 Yamaha YZF R1 2020 Service Manual EURaa Frr100% (1)

- 7281-05-02-01 Air Suspension, Adjustment (Ride Height and Driveline Calculation)Document13 pages7281-05-02-01 Air Suspension, Adjustment (Ride Height and Driveline Calculation)César Arturo Pajuelo EspinozaNo ratings yet

- 06JudyManual EnglishDocument5 pages06JudyManual EnglishilbruthumNo ratings yet

- Essential Scooter Maintenance for the Absolute BeginnerFrom EverandEssential Scooter Maintenance for the Absolute BeginnerNo ratings yet

- School and Metro Bus Driving Skills: Essential Step By Step Guide for Maneuvering Large VehiclesFrom EverandSchool and Metro Bus Driving Skills: Essential Step By Step Guide for Maneuvering Large VehiclesNo ratings yet

- Master the T-CLOCS Pre-Ride Safety Inspection in 15 MinutesFrom EverandMaster the T-CLOCS Pre-Ride Safety Inspection in 15 MinutesNo ratings yet

- P350-El-1305-C - PDT TTDocument9 pagesP350-El-1305-C - PDT TTvigneshwarannnNo ratings yet

- Technologies & Applications: 漢力能源科技股份有限公司 Hanpower Energy Technology Co., LtdDocument34 pagesTechnologies & Applications: 漢力能源科技股份有限公司 Hanpower Energy Technology Co., LtdGiang Nguyễn TrườngNo ratings yet

- Line Driver Type PG: Installation ManualDocument28 pagesLine Driver Type PG: Installation ManualRenny NacarattiNo ratings yet

- Electric Wiring Diagram-Connection To The Genset Control PanelDocument5 pagesElectric Wiring Diagram-Connection To The Genset Control PanelAmit Adesh SookunNo ratings yet

- Newlong NP 7ADocument31 pagesNewlong NP 7ALucas TavaresNo ratings yet

- 2x1, 3x1, 4x1 and 5x1: Multisplit Inverter H6 Outdoor Unit MUEX-H6 SeriesDocument7 pages2x1, 3x1, 4x1 and 5x1: Multisplit Inverter H6 Outdoor Unit MUEX-H6 SeriesAbdelbagiNo ratings yet

- Smartpid2000 Module Inside Smart Array ControllerDocument1 pageSmartpid2000 Module Inside Smart Array ControllerSav SashaNo ratings yet

- Shock AbsorbersDocument58 pagesShock AbsorbersKattie ValerioNo ratings yet

- Maintenance Repair Overhaul: Safely To New Horizons Ensuring Your Aircraft Is Ready Whenever Duty CallsDocument10 pagesMaintenance Repair Overhaul: Safely To New Horizons Ensuring Your Aircraft Is Ready Whenever Duty CallsSuryaNo ratings yet

- MB SL55 AMG - pdf-1635604883Document182 pagesMB SL55 AMG - pdf-1635604883Mohamed AhmedNo ratings yet

- Hbka 02Document20 pagesHbka 02Adil AssefNo ratings yet

- Instrumentation and Calibration Lab Proposal SpanishDocument4 pagesInstrumentation and Calibration Lab Proposal SpanishKevin C. UcsmNo ratings yet

- Bomba WM4215S-PumpDocument3 pagesBomba WM4215S-PumpOscarArturoNo ratings yet

- Hardware (Servers, Nodes & Standalone Computers) : 40-8/2004 (Vol VII)Document38 pagesHardware (Servers, Nodes & Standalone Computers) : 40-8/2004 (Vol VII)PMJAMAKHANDI1No ratings yet

- CALDON LEFM 3xxci Ultrasonic Flowmeters With G3 Transmitters ManualDocument84 pagesCALDON LEFM 3xxci Ultrasonic Flowmeters With G3 Transmitters Manualangel uscangaNo ratings yet

- Ga Drawing 62.5 KvaDocument3 pagesGa Drawing 62.5 KvaHarishkumar TrNo ratings yet

- Bobine Stingere ArcDocument2 pagesBobine Stingere ArcRadu Sergiu CimpanNo ratings yet

- Manual AV110X PDF Engines CoolantDocument8 pagesManual AV110X PDF Engines CoolantBrad BerberNo ratings yet

- 2.wartsila - Rail Valve LeakageDocument15 pages2.wartsila - Rail Valve LeakageSmithmykNo ratings yet

- 25 - Quinte Series EnglishDocument14 pages25 - Quinte Series EnglishJajang NurwandiNo ratings yet

- STD Uei Wheel Loader Weekly Maintenance ChecklistDocument1 pageSTD Uei Wheel Loader Weekly Maintenance Checklistmuhammad lukmanNo ratings yet

- Automotive Sumative TestDocument5 pagesAutomotive Sumative TestRAndy rodelas100% (2)

- ClockworkDocument5 pagesClockworkbernagunduzNo ratings yet

- Getrag En1 PDFDocument6 pagesGetrag En1 PDFJeremías EspinozaNo ratings yet

- Rocky DatasheetDocument2 pagesRocky Datasheetsaikrishna BNo ratings yet

- Electrico Interactivo PDFDocument38 pagesElectrico Interactivo PDFFelipeNicolasSilvaNo ratings yet

- ELAB ManualDocument71 pagesELAB ManualDhamu DharanNo ratings yet