Professional Documents

Culture Documents

Construction Methodology For Il Corso

Construction Methodology For Il Corso

Uploaded by

Kinz TanoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction Methodology For Il Corso

Construction Methodology For Il Corso

Uploaded by

Kinz TanoCopyright:

Available Formats

SAFETY UNLOADING, SORTING &

ARRANGEMENT, PROTECTION,

MARIÑAS & CO. BUILDERS, INC ERECTION AND STORAGE OF

MATERIALS WORK METHODOLOGY

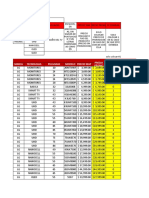

INDEX

CONTENTS PAGE

NO.

INDEX (i)

1.0 PURPOSE 1

2.0 LOCATION OF WORKS 1

3.0 SEQUENCE OF EVENTS 1

4.0 MATERIALS 1

5.0 EQUIPMENT AND TOOLS 1

6.0 SAFETY REQUIREMENTS 2

7.0 RESPONSIBILITIES 2

8.0 WORK PROCEDURE 4

9.0 WORKPLACE, HEALTH & SAFETY 1

MARIÑAS & CO. BUILDERS, INC. – QUALITY ASSURANCE – WORK METHODOLOGY

SAFETY UNLOADING, SORTING &

ARRANGEMENT, PROTECTION,

MARIÑAS & CO. BUILDERS, INC ERECTION AND STORAGE OF

MATERIALS WORK METHODOLOGY

1. PURPOSE

The purpose of this Work Methodology is to define the work operation, quality

control and safety activities involved safely unloading of steel structures, sorting &

arrangement, protection and storage of materials and Erection Steel Structure

including installation and fixing of Roof and Wall Sheets.

2. LOCATION OF WORKS

GTX Terminal Take over Works

IL Corso, SRP, Cebu City

3. SEQUENCE OF EVENTS

This procedure shall apply to all activities and actions undertaking for the following:

Preparation of the site including safety loading, protection, storage materials,

sorting and arrangement

Steel Structure Erection, including Tubular beams, Fascia, C-Purlins, roofings and

Accessories

Concreting and Curing on works upon compaction at SOG, pavement, curb,

asphalt application

4. MATERIALS

All Structural steel works to form a sound and complete structure, consisting of

Tubular steel, steel C-purlins, sagrods threaded w/ washers, THK stiffener plates.

MARIÑAS & CO. BUILDERS, INC. – QUALITY ASSURANCE – WORK METHODOLOGY

SAFETY UNLOADING, SORTING &

ARRANGEMENT, PROTECTION,

MARIÑAS & CO. BUILDERS, INC ERECTION AND STORAGE OF

MATERIALS WORK METHODOLOGY

5. EQUIPMENT AND TOOLS

5.1 Boom Truck

5.2 Jack Hammer

5.3 Welding Machines

5.4 Scaffoldings and Support

5.5 Concrete Cutter

6. SAFETY REQUIREMENTS

6.1 Tools and equipment should be made operational and available for use.

6.2 Continuous monitoring and inspection shall be implemented to detect

and correct unsafe work practices while performing any activities.

6.3 Safety officer shall implement surveillance to help and protect all assigned

workers against exposure to safety hazards.

6.4 All personnel related to work shall wear PPE.

6.5 In case of adverse weather conditions and in poor visibility as

conditions lifting operation will be stopped.

6.6 When working at height, body harness shall be fixed to safety line, fixed on

beams or a rigid steel element.

MARIÑAS & CO. BUILDERS, INC. – QUALITY ASSURANCE – WORK METHODOLOGY

SAFETY UNLOADING, SORTING &

ARRANGEMENT, PROTECTION,

MARIÑAS & CO. BUILDERS, INC ERECTION AND STORAGE OF

MATERIALS WORK METHODOLOGY

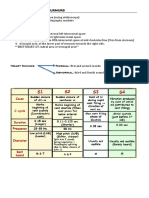

7. RESPONSIBILITIES

7.1 Project Manager

The Project Manager shall be responsible for the overall implementation of this

procedure and execution works in accordance with the requirements.

7.2 Project In-Charge / Site Engr.

The Project In-Charge / Site Engineer shall be responsible in carrying out all the

activities mentioned in this methodology in accordance with the approved

construction drawings.

For the coordination during the execution of this methodology in liaison

with the Consultant during the entire work procedure.

7.3 Safety Officer

The Safety Officer is responsible for monitoring and assessing hazardous and

unsafe situations and developing measures to assure personnel safety.

7.4 QA/QC Engineer

The QA/QC Engineer shall be responsible for monitoring the works, attending

inspections at various stages of the works defined herein, and the efficient

recording and reporting of results.

7.5 Planning Engineer

The Planning Engineer is responsible for planning and coordinating the

materials, plant, equipment and labor for large construction projects.

MARIÑAS & CO. BUILDERS, INC. – QUALITY ASSURANCE – WORK METHODOLOGY

SAFETY UNLOADING, SORTING &

ARRANGEMENT, PROTECTION,

MARIÑAS & CO. BUILDERS, INC ERECTION AND STORAGE OF

MATERIALS WORK METHODOLOGY

8. WORK PROCEDURE

8.1 Safety Unloading

8.1.1. Place the fabricated rigid A-frame beside the truck with container.

8.1.2. Set the rigid A-frame to be the same level or elevation with the truck bed.

8.1.3. Discharge/Sliding tracks are provided in the container for withdrawing the skid.

Remove the discharge/sliding tracks from container.

8.1.4. Align the assembled discharge/sliding track to the inside track. The level of the

discharge/sliding track is the same level with the inside track.

8.1.5. Once the level of inside and discharge/sliding track is aligned, fix the discharge

track to the rigid A-Frame.

8.1.6. Grease the discharge/sliding track. Attach cables(or chains) to the front of the skid

frame, and then attach to the pulling vehicle.

8.1.7. Pull the skid from the container using an even pull speed. Safety should always be

observed. Do not jerk the skid by accelerating discharge vehicle. Cables(or

chains) should always be tight during the entire discharge pull.

8.1.8. After pulling out the contents form inside the container remove the inside tracks

form the container by removing out the fasteners. When the inside track has

been removed from the container closed the door, the container is ready to

returned to the terminal.

MARIÑAS & CO. BUILDERS, INC. – QUALITY ASSURANCE – WORK METHODOLOGY

SAFETY UNLOADING, SORTING &

ARRANGEMENT, PROTECTION,

MARIÑAS & CO. BUILDERS, INC ERECTION AND STORAGE OF

MATERIALS WORK METHODOLOGY

8.2 Sorting & Arrangement

8.2.1. Members should be checked parkmark as packing list enclosed before unloading

for best unloaded positions.

8.2.2. Columns should be arranged closed to their anchor bolt position.

8.2.3. Rafter members should be arranged to ensure easy assembly, movement.

8.2.4. Girts, purlins, eave struts and bracing are divided according to the

8.2.5. requirements of each bay.

8.2.6. Small components (nuts, bolts, clips, fasteners etc.) area stored in a given area

convenient to all parts of the building.

8.3 Protection & Storage of Materials

8.3.1. Choose firmed and dry area for storage.

8.3.2. The material shall be stored above ground level with timber packing. They shall

not be stacked directly on top of each other but must be separated by 50mm

thick timber.

8.3.3. The materials should be placed in minimum 5% slope to avoid water pond.

8.3.4. The materials shall be kept free from dirt, grease, and other foreign materials and

shall be protected from road splash.

8.3.5. Never step on the materials.

8.3.6. All bolts, nuts, washers, screws, small plates and articles generally shall be

suitably packed and identified.

8.3.7. Cover with canvas tarpaulin to protect from rain.

MARIÑAS & CO. BUILDERS, INC. – QUALITY ASSURANCE – WORK METHODOLOGY

SAFETY UNLOADING, SORTING &

ARRANGEMENT, PROTECTION,

MARIÑAS & CO. BUILDERS, INC ERECTION AND STORAGE OF

MATERIALS WORK METHODOLOGY

8.4 Steel Works Preparation

8.4.1 Along Grid Line 1 – 16/ A-B

Applications of rust converter at existing steel tubular columns

Marine Paint Finish Tubular beams divided into equal parts @ 4040mm

O.C and is subjected to change according to tilted columns

C-Purlins divided equally as per span of Tubular Beams

Standing beam metal roofing 1.2mm THK. Long span standing beam

profile roofing system

Steel Tubular Fascia

Downspout painted finish

Bracket light mounted at each column

8.4.2 Along Grid Line 1 – 16/ C-E (Kiosk Area)

Applications of rust converter at existing 200mm diameter steel round

columns

Steel Tubular Cantilevered Beams, spaced @ 2020mm O.C

Bracket mounted lights mounted at each column

C-Purlins divided equally as per span of Tubular Beams

Standing beam metal roofing 1.2mm THK. Long span standing beam

profile roofing system

Steel Tubular Fascia

Downspout painted finish

Bracket light mounted at each column

8.5 Architectural Preparation

8.5.1 Along Gridline T1-T3/TA-TC (Existing public Toilet)

Applications of rust converter at existing steel tubular columns

Preparation for unpolished homogeneous porcelain tiles at both toilets

Toilet partition including accessories (Urinal Partition/ledge and Toilet

partition through Phenolic partition system

Standing Seam pre-painted G.I. Roofing including accessories

Installation of Mirrors, grabrail, doors and windows

Application of Paints

MARIÑAS & CO. BUILDERS, INC. – QUALITY ASSURANCE – WORK METHODOLOGY

SAFETY UNLOADING, SORTING &

ARRANGEMENT, PROTECTION,

MARIÑAS & CO. BUILDERS, INC ERECTION AND STORAGE OF

MATERIALS WORK METHODOLOGY

8.6 Civil Works preparation

Preparation for concreting with 3500 psi at pavement including asphalt

application

Preparation for concreting with 3500 psi at curb including asphalt

application

Preparation for concreting with 3500 psi for slab-on-grade including

asphalt application

Reinforcement Bars preparation and fabrication for concrete manholes

including steel frame/handle

Preparation of concreting of manholes

8.7 Roof Sheeting

8.7.1 Before sheeting, all task below must be completed.

8.7.2 All column base plates must be filled grouting strong enough for support

loading.

8.7.3 Roof sheets lifted on the roof will be arrange to adjacent bays, piled and

tied safely to C purlins before installation.

8.8 Eave Gutter and Downspout

8.8.1 The eave gutter is attached to gutter strap with gutter support and shall be

fixed.

8.8.2 Insert the downspout to the cut valley of the gutter.

MARIÑAS & CO. BUILDERS, INC. – QUALITY ASSURANCE – WORK METHODOLOGY

SAFETY UNLOADING, SORTING &

ARRANGEMENT, PROTECTION,

MARIÑAS & CO. BUILDERS, INC ERECTION AND STORAGE OF

MATERIALS WORK METHODOLOGY

9. WORKPLACE, HEALTH & SAFETY

Health and Safety hazards / Risks associated with the covered by this Work

Methodology are:

Personal Protective Equipment (PPE) such as safety boots and helmet would be

provided with workers. In addition, adequate PPE (e.g. ear and eye protectors)

should also be available for construction work as required.

First Aide Facilities such as first aide box would be made available for in case of

minor injury treatment.

This risk will be reduced by:

Workers used PPE / Gloves / suitable for the work being carried out and as

recommended by the Safety Officer in charge / Engineer in charge.

MARIÑAS & CO. BUILDERS, INC. – QUALITY ASSURANCE – WORK METHODOLOGY

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Standard Welded Wire Mesh For Concrete ReinforcementDocument3 pagesStandard Welded Wire Mesh For Concrete Reinforcementmarksantana100% (2)

- Mariñas & Co.: Builders, IncDocument2 pagesMariñas & Co.: Builders, IncKinz TanoNo ratings yet

- Ricemill S-Curve (Rev 1.6 - Sept 16, 2021)Document2 pagesRicemill S-Curve (Rev 1.6 - Sept 16, 2021)Kinz TanoNo ratings yet

- Amoa Housing Gantt Chart (Rev 1.0 - Sep 20, 2021)Document10 pagesAmoa Housing Gantt Chart (Rev 1.0 - Sep 20, 2021)Kinz TanoNo ratings yet

- Ricemill Executive Summary (Utility Area) (REV 1.0 - Nov 19, 2020)Document1 pageRicemill Executive Summary (Utility Area) (REV 1.0 - Nov 19, 2020)Kinz TanoNo ratings yet

- Silo S-Curve (Rev 1.2-Nov 26, 2020) XDocument1 pageSilo S-Curve (Rev 1.2-Nov 26, 2020) XKinz TanoNo ratings yet

- Silo Executive Summary (REV 1.0 - Nov 26, 2020)Document1 pageSilo Executive Summary (REV 1.0 - Nov 26, 2020)Kinz TanoNo ratings yet

- Holcim Catch Up Plan Rev 1.2Document2 pagesHolcim Catch Up Plan Rev 1.2Kinz TanoNo ratings yet

- Productivity RatiosDocument2,637 pagesProductivity RatiosKinz Tano100% (1)

- Img 20170408 0002Document1 pageImg 20170408 0002Kinz TanoNo ratings yet

- Aquaculture Asia Jan 08Document60 pagesAquaculture Asia Jan 08Nilamdeen Mohamed ZamilNo ratings yet

- NVSM 116 PDFDocument7 pagesNVSM 116 PDF会沢 裕貴No ratings yet

- Marathi - Shri Siddhnath Shikhamani - Abhang GathaDocument88 pagesMarathi - Shri Siddhnath Shikhamani - Abhang GathaVeeresh BTNo ratings yet

- DLL - Science 6 - Q2 - W2Document5 pagesDLL - Science 6 - Q2 - W2Geoffrey Tolentino-Unida100% (1)

- BCC - 1,2 H SPLN 41-4Document1 pageBCC - 1,2 H SPLN 41-4TPNo ratings yet

- STEP 1 Could It Be HIV? STEP 2 Informed Consent and Testing STEP 3 Conveying Test ResultsDocument2 pagesSTEP 1 Could It Be HIV? STEP 2 Informed Consent and Testing STEP 3 Conveying Test ResultsahjkseflhasefNo ratings yet

- Telepathy 101 Primer EnglishDocument285 pagesTelepathy 101 Primer EnglishDavid WalshNo ratings yet

- Non Verbal CommunicationDocument26 pagesNon Verbal Communicationrooroli74No ratings yet

- What Is A Chest X-Ray (Chest Radiography) ?Document5 pagesWhat Is A Chest X-Ray (Chest Radiography) ?shravaniNo ratings yet

- Lynyrd Skynyrd - Steve Gaines Equipment HistoryDocument10 pagesLynyrd Skynyrd - Steve Gaines Equipment HistorySean88% (8)

- Chemical EnergerticsDocument24 pagesChemical EnergerticsAnotidaishe ChakanetsaNo ratings yet

- 1 Soal PrediksiDocument371 pages1 Soal PrediksiJanuar IrawanNo ratings yet

- Analysis Wind Load Uniform Building Clode UbcDocument1 pageAnalysis Wind Load Uniform Building Clode UbcPapatsarsa SrijangNo ratings yet

- 3 Quarter Examination: Technology and Livelihood Education 9 IDocument4 pages3 Quarter Examination: Technology and Livelihood Education 9 IAgp GalvadoresNo ratings yet

- Consolidation (2) - 4th SEMDocument3 pagesConsolidation (2) - 4th SEMDipankar NathNo ratings yet

- U5 SCMDocument48 pagesU5 SCMbhathrinaathan16No ratings yet

- Indian Childhood CirrhosisDocument20 pagesIndian Childhood Cirrhosissubinj_3100% (4)

- Impact of The New ACI 318-14 Confinement Requirements For Special Moment Frame ColumnsDocument2 pagesImpact of The New ACI 318-14 Confinement Requirements For Special Moment Frame ColumnsFWICIPNo ratings yet

- Fundamental Financial Accounting Concepts 9th Edition Edmonds Solutions ManualDocument36 pagesFundamental Financial Accounting Concepts 9th Edition Edmonds Solutions Manualalicenhan5bzm2z100% (33)

- IndonesiaDocument113 pagesIndonesiaLibrary100% (4)

- Security Management Services and Security Culture. I Am Interested in Gaining A MoreDocument1 pageSecurity Management Services and Security Culture. I Am Interested in Gaining A MoreDirgaNo ratings yet

- 7th Heart Sounds and MurmursDocument6 pages7th Heart Sounds and MurmursbabibubeboNo ratings yet

- San Andres Cop Pel 981Document21 pagesSan Andres Cop Pel 981RubenNo ratings yet

- Unit 14 Design of Slender ColumnsDocument32 pagesUnit 14 Design of Slender ColumnsSh Jvon Sh JvonNo ratings yet

- P1662/D8.0, March 2016 - IEEE Draft Recommended Practice For Design and Application of Power Electronics in Electrical Power SystemsDocument63 pagesP1662/D8.0, March 2016 - IEEE Draft Recommended Practice For Design and Application of Power Electronics in Electrical Power SystemsHgoglezNo ratings yet

- TurbineDocument8 pagesTurbineJay Patel100% (1)

- Soal Pas 1 PD 2 - Xii - Bahasa InggrisDocument8 pagesSoal Pas 1 PD 2 - Xii - Bahasa InggrisDita AnugerahNo ratings yet

- Specification Sheet NETBOX Profilebox 01Document2 pagesSpecification Sheet NETBOX Profilebox 01Kian Keong YeeNo ratings yet

- XJ40 1991-92 3,2L 4L Boite Vitesse AutoDocument59 pagesXJ40 1991-92 3,2L 4L Boite Vitesse AutoTACHONNo ratings yet