Professional Documents

Culture Documents

Section 9 Maintenance Welding

Section 9 Maintenance Welding

Uploaded by

Miguel Rodriguez0 ratings0% found this document useful (0 votes)

69 views4 pagespala p&h

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpala p&h

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

69 views4 pagesSection 9 Maintenance Welding

Section 9 Maintenance Welding

Uploaded by

Miguel Rodriguezpala p&h

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

SECTION IX

MAINTENANCE WELDING

GENERAL

‘This section covers repair welding proceduresthat have not

‘been covered in tho specific section of the manual desig:

ated for the item being repaired. Included is Harnisch:

foger Corporation Field Repair Welding Recommendations

a8 to oper preheat and weld information.

REPAIR AND WELDING PROCEDURE

The following is a summary of practices that shoutd be em

ployed when making any structural repair, This procedure

‘dows not apply to any welding of the manganese racking to

the dippat handle bottom plate, dipper lip. propel dive

tumbler or crawier shoe.

1. Cleaning - Remove all mill seale, dint. grease and any

other contaminants from the area that is to be repaired.

Atter cleaning, the entire area should be checked witha dye

enetrant or any other moans of magnetic particle inspec:

von to determing the extant of eracking.

2, Grinding ~ Grind the weld surtoce te getitsmooth andes

Feasonably level as possible so that there are no areas for

trapping slag during tha welding eperation

3. Preheating - Depending upon tne alloy, always preheat

‘and maintain « temperature of at least 200°F in the weld

‘ment during welding, The entire structure usually doosn’t

eating, but fan the heat around with atarch to

cover the adjacent areas, Qbtain @ reasonable amount of

soaking heat for 3 inches towach side of the weld joint, At.

dhe

inches, a 200°F indicating crayon should melt

4 Rod — Wher preheat tamparature ig resched, bagin

Welding immediately. Use low hydrogen siectrodes of a

Qood quality. Uniass extremaly high strength is a must, the

best general recommendation is to weld both joining sur-

faces of the prepared joint with AWS E-7018 low hydrogen

slectrodes. The rod must be new and elean,

elore using the electrodes, they should be baked at 700°F

for @ period of on6 hour to assure dryness and then held in

hot boxes of holding ovens st 200°F until used. Any elec-

trode exposed t0 air for aver two Hours should be rebskod

before use,

5. Buttering - Use the stringet bead technique with no

weaving. Weld only the sides, Put a single layer af weld

‘metal on each side! the weld joint. This layer shoulda p-

proximately 3/32 inch to 1/8 inch thick. The bottom or root

‘of the joint should be epan far enough that the joint is not

Joined when the buttering passes are made. The buttering

‘Weld passes should extend up over the top edge of the joint

‘and onto the surtace of the plate for eppraximately ¥/4inch

‘oh e8eh Side of the joint

6, Peaning - The first two passes put into the root of the

‘weld should not be poened. These passes must be thor-

‘oughly cleaned, This should give approximately 1/2 inch

thickness of weld, All passes of the weld trom there to the:

final pass or layers must be paened with a well rounded

chisel

Figure 9-1, Weld Cress Sections

o4

SECTION IX

NOTE

‘Take care to avaid overweld. The weld deposit should

bbe above the original thickness of the plate and then

‘ground flush. On joint welds the deposits should be

‘well blended. Whanavor possible,

‘made in the tlat position. Refer 10

typical weld joint cross sections with the weld

sequence.

7. Cooling ~ Protect the weld area trom rapid cooling. Pro-

vide an ares free of wind and drafts 1a ensure slew even

cooling of the weld matorial

8. Finishing - Grind and blond the wold eseners to elimin.

ate sharp notches and severe corners.

9. Air-arcing - Preheat the material t0200°F. Limit the

moval of material toa maximum of 3/16 inch depth per are

MAINTENANCE WELDING

pass. After air-arcing, a dyepenetrant shouldagainbe used

to ussure that the erack has been complatoly removad.

‘Air-arcing should be to the full hickness of the plate, Toas=

‘sure that a full thickness welt is employed, a back-up bar

should be placed under the crack to be welded. The arc

(groove should be ground out by the use of a hand grinder to

‘depth of 1/32 inch to remove all carbon deposits latt by

the air-arcing operation,

REPAIR WELDING RECOMMENDATIONS

‘The following table provides weld information specifically,

designed for all field rework. This table provides the P&H

‘Material Specification Numbers, the Spacifieation Rete

‘ence. the P&H Weid Symbols used on the drawings, the

AWS Weld Rod Classification and the Recommended Mini-

mum Prohoat required in throw categorin

Table 8-1, Field Repair Welding Recommendations:

PBN Pan | AWS

cer as en ae Rlscommandad Minimum Prehant

Spee 'S.- Gant Stee! Symbo! | fication] 374 Inch and Under [7/8 inch to 2 inch] Over @ Inch

1 | CS - Med carton Ww fevae | ror aie | 200%F( S80 | S00-F IARC)

2 | CS ~ Med carbon Wy [e-toore} —ao0eF (tage) | do0eF 208%) | S00 (260°C)

6 | cs-camo nH Jegors] —eooF(areec) | oom (aztec) | e00% (427°C),

7 | GS — AUST. MN (Hodtieta) aa | e307 70°F ( 21°C), 20°F 21°C) | 70°F 21°C)

8 | CS — Low Carbon Ww fevore | 70°F; 210) 70°F ( 21¢C) | 70°F! 21°C),

nn | Gs «mimo nN Jesoore| —soorr (rag) | 00°F (zo8"c) | soo-F 280°C)

13 | CS —NICRMO Consul 7OOeF (37186) | BOO |A27eC)

18 | CS —NLCR.MO Welding 50°F 28°C) | 600°F(318°C)

19 | CS-NLCRMO Engineer 00°F 260°) | ss0°F izeerc) | eo0%F (316°C)

20 | CS-cAMO.8 500% (260%) | SOF (2marc) | BOO (a16eC)

21 | CS. Low Carbon MH Jeors | 20°F) sq | asorF(I2zt°G) | aoorFII8a"C)

22 | ES-NLCR-MO Consult Welding S00 260%) | BOO 318%) | 7OO%R(I7I¢C)

23 | CS-NbCRMO Engineer 00°F (260°C) | GOO"F (318°C) | 700°F (371°C)

BO | Steet Carbon Pinte Hi w fe: 70°F | 24°C) | soos, Sach

80 | Stal KSLA mw [eso | 70°F) 21%cy 70°F | 21e¢) | 100°R( 38°C)

97 | Steal - HR, Alloy nH Jerore | stor izaec) | enor iaia'c) | z00°F(a71°<)

100 | Stoel - Carb, Pate H Jevoe| ori arc) | 150F1 Ba°cs | 250° 121°C)

108 | 86204 Carburized Steet Beezo | 200° 93°q | somF {149°C | 00°F 208°C)

1064 | AGA1 SLA [Tri Ton Type) wero | ror, zie) | ¥E0%F| Bares | 200%; 93%C)

108 | Alloy Steet Abcasson nw [evs | asorr 77°C) | 00° (208c)

105 | Nevabioy 135 HR [eros | soo-r iso | ss0°F 288%)

112 | 4340 Alioy Stoat E.aaso | sooeriat6°c} | TOF ITIP)

113 | 1080 1A. Carbon Bars [E7018 | soo zeorc) | Gooreiatercy | 700°F(971"C)

119 40H Alley Steal CF & [E4130 | S00°F (260°C) | Goo" 16) | 700% a7I°C)

120 | 4142-87-50 Alloy Svee! [e130 | sooF (260°C) | soorFiat6%e) | 7oOrF (371°C)

121. | 41308 Alloy Stee! p [eaizo| soor tage) | 80H (179%¢) | dooHe oa%cy

123, | 1010 Carbon Steet nw fev | 70°F) 21°c) TO"R( 21°C) | OFC 2V*C1

125. | 12L14 CF Stoel feo | y0F\ 21°c) 70°F, 21%) | Fore, 2b"C)

126 | 117 CF Steal mw [evo] — 70°F) 2190 7o%r | 21°C) | NOOPFE JBeCI

127 | 118 GF steel wu [eros | ror) 210 Tore( 21%) | 10°F 38°C)

128 | 1045 CF Stes! w | &7018 | so0er rao8rc) | sa0%F 260°C) | 6OO% (916%CI

129 | 1020HA Su nH fevoie| 70°F) 21°C) TO"F( 21°C) | 1O0°FE 38°C)

190 | 1035 HA Steet H [e718 | — 200°F( sec) | soOrF (149° ¢) | doorF 204°C)

131 | 1040 HR Seaat W [e7ors | goer iraarc) | Aare 20aecy | soorF 260°C)

132 | 1065 WA Steet H [e-vore| a00°Fir4aq | a00*F 20arcr | soorF r2eorc)

133 | M27 Elec Snaet Stee) 4 [E701 70°F ( 29°C)

134 | Steet Back Pine n feos | 70°F, 21-0)

138 | 1015 Carbon Stee! HR H [erota| — 70°F( 21°C)

139 | 4:36 Carbon Stee! 1. 4 fevors| yore 21°C

140 | 4439 Alloy Tubing Ne toors| soner (aor

92

MAINTENANCE WELDING

Table

SECTION IX

‘1. Field Repair Welding Recommendations (Cont,)

ran Pan

Mast ‘Spee. Reterance aid

Spee. C8. = Cant Stool Symbol 3/4 Inch and Under |7/8 tneh ta 2 inch] Over 2 inch

1141 Cold Drawn Str Rat " soorr iiagrcy | 400% (aor) | soomF 260°C)

1148 Cold Drawn Sir Ret " soorrirasrc | aoorr zone) | sooraeero)

1018 Seamless Tobing 4 TOF ( 28C

43204 Bars ond Biles x soorrias | asorei177°C) | 400% 208°C)

ER Stamoing Swe! " 70°F | 21

OMB Cold Fished " sor (asec) | 400F p08rc) | soo AsO"

HSLA Struct Shapes " yor zee | 180%) s8rcr | 25GRNZITC

4182.47.51 HR Alloy " s0orF @eorc: | eporeane%c | 700%FI37N°C)

1015 Welded Tubing * POF (21°C

Inger iron * Tork ( 21°C)

303 Stainless AK 20°F ( 21°C)

ingen iron ©. Fin " Torr 21¢C

1053 Steel HA Bars 4 aoorr otc) | 500° (260%) | soo%e a16°C)

1070 HR. Stool " soovF sore; | 60" (318°C) | TOO II7N¢CI

A514 HSLA T) Type " Tore aire | ¥50°F\ orc | Z00°FI 83°C)

Hye Tubing

1095 HT High Carton ” soorr atsrer | 700% (a7¥een | soorr 427°C)

Carbon Scwel Expanded i Room Temp

2:36 HR. Carbon ™ TOF ao) TorF( 24°C) | 1SOrFH ere)

Golanised Poe * TOF 21H

Low Carton * Dorr 20°C

Gold Oran Totieg . ror aver

Buck Pee x aon Teme

1080 Seamiess HR. Pe me soorritaac) | 400"F oars

Steet Carbon Plate we TOE, 21%) | ABO; BHC | ao0HRHNABHC

4.26 Stroctural Tubing K vo-F 200

4190 Steet HA r soorriasch | asorr irre | soo'rrosc)

Steet HHT K sour 38°C) | 200%: 93ecs | 30orFNA9"C)

Steet HAN T " wore sercr | 200%; 93°c) | aoorFHa8"C)

NOMA Steel HA Carton Pr K corr aoarcy | poor aeo'c) | woorR TEC

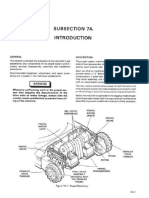

GARBODY INSPECTION & REPAIR

‘The carbody should be Inspected on # routine schedule for

fatigue cracks as shown on Figure 9-2. If any cracks are

found on the carbody structure they should be weld rer

paired as described in the Repair and Woiding procedure,

Prior to making any inspection in the carbody,

the power must ba secured and the tall cable

must be disconnected from the axcavator to

Prevent the possibility of death or injury of per-

sonnel if they accidentally contact the high

voltage collectors.

93

SECTION IX

|AINTENANCE WELDING

POINT 1: WELD AROUND POINT 4: WELDS

‘CENTER HUB ‘ON GUSSETS

POINT 2: WELDS. POINT 5: HOLES IN

BOTTOM PLATE

TOP view BOTTOM VIEW

POINT 6: WELD AROUND

POINT 3: HOLES Tus SECTION

IN REAR PLATE

REAR VIEW

NOTE: IT IS SUGGESTED THAT THE

AREAS SHOWN BE PERIODICALLY

CHECKED FOR CRACKS SO THAT

REPAIRS CAN BE MADE IF NECESSARY

Figure 9-2. Carbody Inspection Paints

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Esquema Hidráulico AtualizadoDocument3 pagesEsquema Hidráulico AtualizadoMiguel RodriguezNo ratings yet

- 13 - Drive Controller - Operation ManualDocument14 pages13 - Drive Controller - Operation ManualMiguel RodriguezNo ratings yet

- NDT-PQ PDFDocument7 pagesNDT-PQ PDFMiguel RodriguezNo ratings yet

- Diagrama de Bloque de 4 Zonas PDFDocument1 pageDiagrama de Bloque de 4 Zonas PDFMiguel RodriguezNo ratings yet

- 3 Zone Lincoln PDFDocument1 page3 Zone Lincoln PDFMiguel RodriguezNo ratings yet

- Nondestructive Test Procedure: Acceptance Criteria For Nondestructive Testing of P&H ProductDocument3 pagesNondestructive Test Procedure: Acceptance Criteria For Nondestructive Testing of P&H ProductMiguel RodriguezNo ratings yet

- 014 CAT-6060 AC 60Hz E-Drive CAMP + SIL + BCS4 FS Legend H-Schematic Canada No New AvailableDocument13 pages014 CAT-6060 AC 60Hz E-Drive CAMP + SIL + BCS4 FS Legend H-Schematic Canada No New AvailableMiguel RodriguezNo ratings yet

- Manufacturing Operating Procedure: Appendix "B" Deviation Requests (MRB)Document3 pagesManufacturing Operating Procedure: Appendix "B" Deviation Requests (MRB)Miguel RodriguezNo ratings yet

- Diagrama de Bloque de 3 Zonas PDFDocument1 pageDiagrama de Bloque de 3 Zonas PDFMiguel RodriguezNo ratings yet

- Nondestructive Test Procedure: Acceptance Criteria For Nondestructive Testing of P&H ProductDocument3 pagesNondestructive Test Procedure: Acceptance Criteria For Nondestructive Testing of P&H ProductMiguel RodriguezNo ratings yet

- Manufacturing Operating Procedure: Recommended Filler Material and Preheat/Interpass TemperaturesDocument5 pagesManufacturing Operating Procedure: Recommended Filler Material and Preheat/Interpass TemperaturesMiguel Rodriguez100% (1)

- 004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFDocument12 pages004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFMiguel RodriguezNo ratings yet

- Section 4 Hoist SystemDocument32 pagesSection 4 Hoist SystemMiguel RodriguezNo ratings yet

- Extension - Cable Grease SystemDocument3 pagesExtension - Cable Grease SystemMiguel RodriguezNo ratings yet

- Table of Contents:: User InstructionsDocument2 pagesTable of Contents:: User InstructionsMiguel RodriguezNo ratings yet

- Section 7 Propel SystemDocument50 pagesSection 7 Propel SystemMiguel RodriguezNo ratings yet

- Bronze Bushing Shrinkage On Diameter PDFDocument1 pageBronze Bushing Shrinkage On Diameter PDFMiguel RodriguezNo ratings yet

- Tarjetas 2800XPBDocument3 pagesTarjetas 2800XPBMiguel RodriguezNo ratings yet

- Bypass Kit Hoist FilterDocument2 pagesBypass Kit Hoist FilterMiguel RodriguezNo ratings yet

- Section 3 Swing SystemDocument35 pagesSection 3 Swing SystemMiguel RodriguezNo ratings yet

- NPR & Kits PDFDocument11 pagesNPR & Kits PDFMiguel RodriguezNo ratings yet

- Section 10 LubricationDocument16 pagesSection 10 LubricationMiguel RodriguezNo ratings yet

- Sis Web User Guide v3-5-1Document60 pagesSis Web User Guide v3-5-1Miguel RodriguezNo ratings yet

- Service Technician Workbench: What's New in 2004BDocument53 pagesService Technician Workbench: What's New in 2004BMiguel RodriguezNo ratings yet