Professional Documents

Culture Documents

Air Leak Detector

Air Leak Detector

Uploaded by

VickyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Leak Detector

Air Leak Detector

Uploaded by

VickyCopyright:

Available Formats

AIR LEAK DETECTOR

SYNOPSIS

Air leak detector is a project to intimate the alarm signal when there are any

leakages in the tank. The field of mechanical engineering has a theme word called

“CHANGE” as its backbone. The new technological advancements and the needs of

people have made us think about this project.

In a process industry pressure is an important parameter. Particularly pneumatic

pressure is a very important parameter. By using the pneumatic pressure controller, we

can save the power consumed by the industries too. Normally in the industries, there are

high pressure is somewhat low (say around 30 to 40 mbar) the required pressure is

depends upon the process presently we are working with the machine. If there are any

chances of air leakages from the tank due to the high pressure, at that time in our project

is used to intimate the leakages.

INTRODUCTION

This is an era of automation where it is broadly defined as replacement of manual

effort by mechanical power in all degrees of automation. The operation remains an

essential part of the system although with changing demands on physical input as the

degree of mechanization is increased.

Degrees of automation are of two types, viz.

Full automation.

Semi automation.

In semi automation a combination of manual effort and mechanical power is required

whereas in full automation human participation is very negligible.

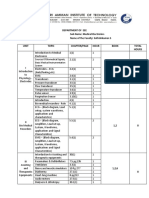

BLOCK DIAGRAM

SENSOR RELAY

MICROCONTROLLER

UNIT

ALARM

LCD DISPLAY

WORKING PRINCIPLE

The pressure sensor senses the pressure leakage of the air tank. This sensing signal

is given to the microcontroller unit. When there is no leakage in the tank, there is no

signal given to the microcontroller unit.

In our 12 volt power supply is used. The power supply output is given to the

control unit. Control unit having three relays, they are connected to the alarm unit.

Initially the pressure is set with the help of the variable resistance. The pressure leakages

of the tank is sensed by the pressure sensor and this control signal is given to the

microcontroller unit

ADVANTAGES

Simple in construction

This system is noiseless in operation

It is portable, so it can be transferred easily from one place to other place

Maintenance cost is low

The LCD display monitors the current status.

DISADVANTAGES

Initial cost is high

APPLICATION

Home

Industries

Meeting hall

Seminar hall

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- An Efficient Regenerative Braking System Based On Battery Supercapacitor For Electric Hybrid and Plug-In Hybrid Electric Vehicles With BLDC MotorDocument15 pagesAn Efficient Regenerative Braking System Based On Battery Supercapacitor For Electric Hybrid and Plug-In Hybrid Electric Vehicles With BLDC MotorsathishNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- A Novel Single-Input Dual-Output ThreeLevel DC-DC ConverterDocument11 pagesA Novel Single-Input Dual-Output ThreeLevel DC-DC ConvertersathishNo ratings yet

- Suresh 2019Document20 pagesSuresh 2019sathishNo ratings yet

- Applied SciencesDocument18 pagesApplied SciencessathishNo ratings yet

- Sliding Mode Control Based On Fractional Order Calculus For DC-DC ConvertersDocument15 pagesSliding Mode Control Based On Fractional Order Calculus For DC-DC ConverterssathishNo ratings yet

- Emperor Penguins ColonyDocument16 pagesEmperor Penguins ColonysathishNo ratings yet

- 6.fabrication of Pedal Operating Podride CarDocument2 pages6.fabrication of Pedal Operating Podride CarsathishNo ratings yet

- Chakrabarti 2019Document46 pagesChakrabarti 2019sathishNo ratings yet

- Applied Sciences: Artificial Intelligence-Based Controller For DC-DC Flyback ConverterDocument22 pagesApplied Sciences: Artificial Intelligence-Based Controller For DC-DC Flyback Convertersathish100% (1)

- Droop Control of Bi-Directional DC-DC Converter For Improved Voltage Regulation and Load Sharing in DC MicrogridDocument16 pagesDroop Control of Bi-Directional DC-DC Converter For Improved Voltage Regulation and Load Sharing in DC MicrogridsathishNo ratings yet

- 1.fabrication of Borewell Pipe Removing MachineDocument2 pages1.fabrication of Borewell Pipe Removing MachinesathishNo ratings yet

- Research Article: Fuzzy Second-Order Sliding Mode Control Design For A Two-Cell DC-DC ConverterDocument9 pagesResearch Article: Fuzzy Second-Order Sliding Mode Control Design For A Two-Cell DC-DC ConvertersathishNo ratings yet

- Sazz ConverterDocument251 pagesSazz ConvertersathishNo ratings yet

- Journal of King Saud University - Engineering Sciences: Montadher S. Shaker, Asaad A. KraidiDocument7 pagesJournal of King Saud University - Engineering Sciences: Montadher S. Shaker, Asaad A. KraidisathishNo ratings yet

- 12.design and Fabrication of Manual Mixer Grinder MachineDocument2 pages12.design and Fabrication of Manual Mixer Grinder MachinesathishNo ratings yet

- 11.fabrication of Bike TrolleyDocument1 page11.fabrication of Bike TrolleysathishNo ratings yet

- Electric BikeDocument20 pagesElectric Bikesathish100% (1)

- 7.fabrication of Adaptive Cruise ControlDocument2 pages7.fabrication of Adaptive Cruise ControlsathishNo ratings yet

- M15 1 2 7 2014 PDFDocument8 pagesM15 1 2 7 2014 PDFsathishNo ratings yet

- A 97.0% Maximum Efficiency, Fast Response, Low Voltage Ripple KY Boost Converter For Photovoltaic ApplicationDocument5 pagesA 97.0% Maximum Efficiency, Fast Response, Low Voltage Ripple KY Boost Converter For Photovoltaic ApplicationsathishNo ratings yet

- Sources of Biomedical Signals, Basic Medical Instrumentation SystemDocument2 pagesSources of Biomedical Signals, Basic Medical Instrumentation SystemsathishNo ratings yet

- DAC Makes Controller Programmable: Programmble Voltage, Programmable Controller, Dynamic Voltage, Core VoltageDocument4 pagesDAC Makes Controller Programmable: Programmble Voltage, Programmable Controller, Dynamic Voltage, Core VoltageJonathan JaegerNo ratings yet

- SDH Principle Curriculum: The Principle Is Divided Into 4 PartsDocument119 pagesSDH Principle Curriculum: The Principle Is Divided Into 4 PartsFahadKh100% (1)

- Armored VehiclesDocument20 pagesArmored VehiclesSerOs9No ratings yet

- Data SheetDocument1 pageData SheetPanagos PanagiotisNo ratings yet

- THZ PaperDocument9 pagesTHZ PaperKrishna PrasadNo ratings yet

- Wireless Network Absolute Beginner's GuideDocument11 pagesWireless Network Absolute Beginner's GuideAndriamahefamanana Onja TantelyNo ratings yet

- Calibration RigDocument5 pagesCalibration RigBijoy AyyagariNo ratings yet

- KPAV125Document183 pagesKPAV125Hana TruongNo ratings yet

- Some Investigations On The Corrosion of IronDocument6 pagesSome Investigations On The Corrosion of IronHannah MercadoNo ratings yet

- Kaw2002 010CDocument6 pagesKaw2002 010CapacheminxNo ratings yet

- GE 489 ManualDocument314 pagesGE 489 ManualNav Kalidas100% (1)

- Sixth Sense TechnologyDocument26 pagesSixth Sense Technologyharisri269No ratings yet

- RedHawk GPS ManualDocument146 pagesRedHawk GPS ManualThulasi ReddyNo ratings yet

- Lightning Discharge and Fundamentals of Lightning ProtectionDocument10 pagesLightning Discharge and Fundamentals of Lightning ProtectionMellina LisboaNo ratings yet

- Noise Reduction Rating Calculation MethodDocument11 pagesNoise Reduction Rating Calculation Methodmrizalygani99No ratings yet

- CH 1Document171 pagesCH 1temamNo ratings yet

- MODULE 3 (B) : Domestic WiringDocument70 pagesMODULE 3 (B) : Domestic WiringBOBAN05No ratings yet

- Fact Sheet DPR6000B enDocument2 pagesFact Sheet DPR6000B enMudhi putraNo ratings yet

- Bid DocumentDocument74 pagesBid DocumentShaswat DubeyNo ratings yet

- Tidubv4a PDFDocument31 pagesTidubv4a PDFStef GaudreauNo ratings yet

- Memo2team2 2Document2 pagesMemo2team2 2api-345931616No ratings yet

- Procedures For Replacing Nodes and Adding Nodes To Existing SVC Clusters V3R5Document14 pagesProcedures For Replacing Nodes and Adding Nodes To Existing SVC Clusters V3R5BogdanNo ratings yet

- GTP - 5 Mva - 66 - 6.6 KV - Octc - 18.05.19Document1 pageGTP - 5 Mva - 66 - 6.6 KV - Octc - 18.05.19Electrical RadicalNo ratings yet

- Kelompok Teknik Audio VideoDocument1 pageKelompok Teknik Audio VideoMoch SuhermanNo ratings yet

- W Section 1 Mma Welding Saf Fro General Catalogue68475045296859596Document8 pagesW Section 1 Mma Welding Saf Fro General Catalogue68475045296859596sarahrouNo ratings yet

- Assignment 1 AESDocument6 pagesAssignment 1 AESnjnvsrNo ratings yet

- PageFlip Cicada User GuideDocument29 pagesPageFlip Cicada User GuideDave JohnsonNo ratings yet

- Basic Electronics Objective Type QuestionsDocument3 pagesBasic Electronics Objective Type QuestionsParames WaranNo ratings yet

- SIEPAN 8PU Low Voltage Switchboards Technology by SiemensDocument4 pagesSIEPAN 8PU Low Voltage Switchboards Technology by SiemensaayushNo ratings yet

- 5 MARKS QUESTIONS Final PDFDocument5 pages5 MARKS QUESTIONS Final PDFAditya KinariwalaNo ratings yet