Professional Documents

Culture Documents

Katalog

Katalog

Uploaded by

Andhieka Rizky KurniantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Katalog

Katalog

Uploaded by

Andhieka Rizky KurniantoCopyright:

Available Formats

320

HYDRAULIC EXCAVATOR

Engine Power 121 kW (162 hp)

Operating Weight 22 500 kg (49,600 lb)

Cat® C4.4 Engine meets U.S. EPA Tier 4 Final and EU Stage IV emission standards with an aftertreatment system that requires no operator input or downtime.

NEXT GENERATION EXCAVATORS

The new line of Cat® Excavators was designed with a new approach to equipment families that gives you:

+ MORE MODEL OPTIONS

+ MORE STANDARD TECHNOLOGIES

+ MORE PRICE POINTS

Ready to help you make your business stronger, Cat Excavators give you new ways to get the most work

done at the lowest cost—so you put more money in your pocket.

THE NEW THE CAT 320 raises the bar for

efficiency and fuel economy in this

CAT 320

size class. With the industry’s highest

® level of standard factory technology,

a new cab focused on operator comfort

and productivity, plus lower fuel and

maintenance costs, the 320 will set a

new pace for productivity and profit

in your operation.

MOVING THE STANDARD HIGHER

2 320 HYDRAULIC EXCAVATOR

FUEL EFFICIENCY

INCREASE EFFICIENCY SAVINGS ADD UP

UP TO 45% 1

The Cat 320 offers the industry’s highest level of standard SCENARIO:

R

factory-equipped technology, including Cat Grade with 2D,

R YEA Excavators working in a

Grade with Assist and Payload. PE medium-duty

medium duty application,

RN 1,000 hours/year

BU

L

FUE

REDUCE FUEL CONSUMPTION THE ADVANTAGE

UP TO 25% 2

875 GAL | 3312 L

A precise combination of lower engine speed and SAVED!

a large hydraulic pump delivers top performance

while burning less fuel.

W 320

NEW

2,625 GAL | 9938 L

LOWER MAINTENANCE COSTS 320F

3,500 GAL | 13 250 L

UP TO 20% 3

Extended and more synchronized maintenance intervals CALCULATION:

increase uptime and reduce costs compared to the 320F. 320F: NEW 320:

3.5 GAL/HR x 1,000 HR/YR = 3,500 GAL/YR (3.5 GAL/HR x 75%) x 1,000 HR/YR = 2,625 GAL/YR

1 13.25 L/HR x 1000 HR/YR = 13 250 L/YR (13.25 L/HR x 75%) x 1000 HR/YR = 9938 L/YR

Operator efficiency gains compared to traditional grading methods.

2

Compared to the 320F.

3

Cost reduction based on 12,000 hours of operation.

320 HYDRAULIC EXCAVATOR 3

WHAT WOULD YOU DO

STANDARD WITH 4.5 MORE WEEKS?

CAT CONNECT 45 % GAIN WITH TECHNOLOGY

means same amount of work done faster

TECHNOLOGY

GETS JOBS DONE FASTER 4.5 WEEK GAIN

WITH LESS REWORK

0

50

100

150

200

250

300

350

400

Onboard Cat Connect Technology gives you the edge. HOURS

Operators of all experience levels will dig, load and grade PREVIOUS YEAR:

with more confidence, speed and accuracy. The result? USING TRADITIONAL GRADING METHODS

Better productivity and lower costs. 400 hours/year, grading with stakes and checkers

CURRENT YEAR:

USING NEW CAT 320 WITH CAT CONNECT TECHNOLOGY

220 hours/year, with standard Cat Grade

4 320 HYDRAULIC EXCAVATOR

INCREASE EFFICIENCY UP TO 45%

WITH CAT CONNECT TECHNOLOGY

STANDARD, SIMPLE-TO-USE TECHNOLOGIES INCLUDE:

STANDARD CAT GRADE WITH 2D STANDARD CAT GRADE WITH ASSIST

Cat GRADE with 2D helps operators reach grade faster. Operators Automated boom, stick and bucket movements deliver more

cut and fill to exact specifications without overcutting. You can accurate cuts with less effort. The operator simply sets the depth

program up to four of your most commonly used target depth and slope into the monitor and activates single-lever digging.

and slope off sets so you can get to grade with ease—a real time

saver on the job site. Best of all, no grade checkers are needed so

the work area is safer. AVAILABLE OPTIONAL UPGRADES

Cat GRADE with Advanced 2D and Cat GRADE with 3D increase

STANDARD CAT PAYLOAD productivity and expand grading capabilities. GRADE with

Advanced 2D adds in-field design capabilities through an

Cat PAYLOAD technology delivers precise load targets with additional 10-inch (254 mm) high-resolution touchscreen monitor.

on-the-go weighing, which helps prevent over/under-loading GRADE with 3D adds GPS and GLONASS positioning for pinpoint

and maximizes efficiency. Automated tracking helps manage accuracy. Use the excavator’s onboard cell technology to quickly

production and lower cost. connect to 3D services like Trimble Connected Community or

Virtual Reference Station.

320 HYDRAULIC EXCAVATOR 5

REAL-TIME INFORMATION FROM CAT LINK

TAKES THE GUESSWORK OUT OF MANAGING YOUR EQUIPMENT

Cat Link hardware (Product Link™) and software (VisionLink®) work together to put equipment information at your fingertips.

Get real-time access to information on every machine in your fleet on any jobsite—no matter the size of the operation or the

brands of equipment you run.

PRODUCT LINK™

Track asset location, hours, fuel usage, diagnostic codes,

idle time and more to improve your productivity and lower your

operating costs. Cellular connectivity comes standard. Satellite

connectivity is available.

VISIONLINK®

Using the online VisionLink interface, you can see a common,

collective view of your information, making it easier to manage a

mixed fleet and make informed decisions about your equipment.

MY.CAT.COM

You can also access Caterpillar and Cat dealer information at

my.cat.com. My.cat.com gives you access to PM schedules, parts

and service records, warranty coverage and more—with a single

login. Plus, you can link directly to your VisionLink account.

6 320 HYDRAULIC EXCAVATOR

NEW CAB TAKES Sites where excavators typically

work are rugged and challenging.

THE HARD

That’s why it’s important that the

320 cab protects the operator

as much as possible from the

OUT OF WORK

fatigue, stresses, sounds and

temperatures of the job.

NEW SEAT AND JOYSTICK CONSOLE REDUCE FATIGUE

Comfort and efficiency of movement keep operators productive and alert all shift long. The new standard seat is wide and

adjustable for operators of virtually any size. The Deluxe cab package includes a heated air suspension seat; the Premium seat is

both heated and cooled.

320 HYDRAULIC EXCAVATOR 7

TOUCHSCREEN MONITOR

Most machine settings can be controlled

through the high-resolution 10-inch/254 mm

touchscreen monitor. It offers 42 languages

and is easy to reach from the seat—no

twisting or turning.

NEW SMART MODE

The new Smart Mode (one of three power

mode settings) automatically adjusts

engine and hydraulic power for the highest

fuel efficiency—less power for tasks such

as swinging and more power for digging.

CUSTOMIZABLE JOYSTICKS

Joystick function can be customized

through the monitor. Joystick pattern as well

as response can be set to match operator

preference. All preferences are saved with

the operator ID and restored at log in.

KEYLESS PUSH START

The 320 uses a keyless push-button engine

start. This adds security for the machine by

using Operator ID codes to limit and track

machine access. Codes can be entered

manually, via an optional Bluetooth® key

fob or smartphone app.

8 320 HYDRAULIC EXCAVATOR

A QUIET, SAFE WORKSPACE

BUILDS OPERATOR CONFIDENCE

ISO-CERTIFIED ALL-AROUND EASY ACCESS,

ROPS CAB VISIBILITY CONNECTIVITY

The ISO-certified ROPS cab is sound- Standard rearview and right-side-view AND STORAGE

suppressed and sealed. The windows cameras keep operators aware of their

Convenience features include Bluetooth

and lower front profile of the machine surroundings at all times. An optional 360°

integrated radio, USB ports for charging

give outstanding visibility to the work Visibility feature is also available.

and phone connectivity, 12V DC outlets

area without the strain of constantly

and AUX port, storage in rear, overhead

leaning forward.

and console compartments, and cup

and bottle holders.

320 HYDRAULIC EXCAVATOR 9

STAY SAFE EVERY DAY

SAFETY FEATURES

LOOK OUT FOR YOUR PEOPLE FACT:

FALLS

#1 cause of construction

AND YOUR EQUIPMENT accidents: FALLS*

Daily maintenance checks can be performed with 100% of

the points accessible from ground level, making maintenance 49% OF FALLS RESULT

IN SERIOUS INJURY

faster, easier and safer. Checkpoints include the engine oil

dipstick, fuel water separator, fuel tank water and sediment

drains, and cooling system coolant level check. 30% OF FALLS RESULT

IN DEATH

LIFT ASSIST NEW 320

Lift Assist helps you avoid tipping. With visual and auditory alerts,

you’ll know if your load is within the excavator’s safe working

100 GROUND-LEVEL

% MAINTENANCE

HELPS PREVENT FALLS

range limits.

*https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4962179/

10 320 HYDRAULIC EXCAVATOR

PROTECTION IN

ALL DIRECTIONS

E-WALL SWING E-WALL FORWARD E-WALL CAB PROTECTION E-WALL CEILING E-WALL FLOOR

STANDARD 2D E-FENCE TECHNOLOGY

The standard 2D E-fence feature automatically stops excavator motion using boundaries you set in the monitor for the entire working

envelope—above, below, sides and front. E-fence features protect equipment from damage and reduce fines related to zoning or

underground utility damage. Automatic boundaries even help prevent operator fatigue by reducing over-swinging and over-digging.

320 HYDRAULIC EXCAVATOR 11

LOWER MAINTENANCE COSTS

UP TO 20%

With extended and more synchronized maintenance intervals, you STOP LESS. WORK MORE.

get more done at a lower cost compared to the 320F. Consolidated

filter locations make service faster. Hydraulic, air and fuel tank

WITH

TH THE NEW 320, YOU’

YOU’LL

U’LL

L USE

filters have increased capacity and longer life.

66 FEWER FILTERS*

KEY MAINTENANCE COST REDUCTIONS INCLUDE:

EXTENDED INTERVALS INCREASE UPTIME

+ Consolidated filter locations to reduce service time.

+ Multiple oil filters with extended maintenance intervals,

HYDRAULIC

plus a new higher dirt capacity hydraulic filter. RETURN FILTER

1,000 HR DIFFERENCE

TYPE OF SERVICE

+ The new Cat air filter design results in a 100% increase in

FUEL FILTER 500 HR DIFFERENCE

service life compared to our previous filter.

+ Fuel filters are synchronized to be changed at 1,000 hours— AIR FILTER

500 HR DIFFERENCE

CAPACITY

double the interval from the previous filters.

0

500

1,000

1,500

2,000

2,500

3,000

3,500

INTERVAL (HOURS)

NEW CAT 320 CAT 320F

*Based on 12,000 operating hours.

12 320 HYDRAULIC EXCAVATOR

INCREASE YOUR PRODUCTIVITY AND PROFIT

WITH CAT ATTACHMENTS

You can easily expand the performance of your machine by utilizing any of the variety of Cat Attachments.

Each Cat Attachment is designed to fit the weight and horsepower of Cat Excavators for improved

performance, safety and stability.

BUCKETS GRAPPLES HYDRAULIC HAMMERS MULTI-PROCESSORS

QUICK COUPLERS RAKES RIPPERS SECONDARY PULVERIZERS

VIBRATORY PLATE

SHEARS THUMBS COMPACTORS

Did you know you can find your attachments quickly and easily? The excavator’s onboard Bluetooth reader can search for any work

tool equipped with Cat asset tracking devices up to a range of 60 meters (200 feet).

320 HYDRAULIC EXCAVATOR 13

TECHNICAL SPECIFICATIONS

See cat.com for complete specifications.

ENGINE DIMENSIONS

Engine Model Cat C4.4 Boom Reach 5.7 m (18'8")

Engine Power – ISO 9249 121 kW 162 hp Stick Reach 2.9 m (9'6")

Engine Power – ISO 14396 122 kW 164 hp Bucket 1.19 m³ (1.56 yd³)

Bore 105 mm 4 in Shipping Height (top of cab) 2960 mm 9'9"

Stroke 127 mm 5 in Handrail Height 2950 mm 9'9"

Displacement 4.4 L 269 in³ Shipping Length 9530 mm 31'3"

Tail Swing Radius 2830 mm 9'3"

HYDRAULIC SYSTEM

Track Length 4450 mm 14'7"

Main System – Maximum Flow (Implement) 429 L/min 113 gal/min

Length to Center of Rollers 3650 mm 12'0"

Maximum Pressure – Equipment – Normal 35 000 kPa 5,075 psi

Ground Clearance 470 mm 1'7"

Maximum Pressure – 38 000 kPa 5,510 psi

Track Gauge 2380 mm 7'9"

Equipment – Heavy Lift Mode

Transport Width – 600 mm (24") Shoes 2980 mm 9'9"

Maximum Pressure – Travel 34 300 kPa 4,974 psi

Transport Width – 790 mm (31") Shoes 3170 mm 10'5"

Maximum Pressure – Swing 26 800 kPa 3,886 psi

Counterweight Clearance 1050 mm 3'5"

MACHINE WEIGHT

WORKING RANGES AND FORCES

Operating Weight – 790 mm (31") Shoes 22 500 kg 49,600 lb

Boom Reach 5.7 m (18'8")

Reach boom, R2.9 m (9'6") stick, HD 1.19 m³ (1.56 yd³) bucket, 790 mm

(31 in) triple grouser shoes, 4.2 mt (9,300 lb) counterweight. Stick Reach 2.9 m (9'6")

Operating Weight – 600 mm (24") Shoes 21 800 kg 48,100 lb Bucket 1.19 m³ (1.56 yd³)

Reach boom, R2.9 m (9'6") stick, HD 1.19 m³ (1.56 yd³) bucket, 600 mm Maximum Digging Depth 6720 mm 22'1"

(24 in) triple grouser shoes, 4.2 mt (9,300 lb) counterweight. Maximum Reach at Ground Level 9860 mm 32'4"

Maximum Cutting Height 9370 mm 30'9"

SERVICE REFILL CAPACITIES Maximum Loading Height 6490 mm 21'4"

Fuel Tank 345 L 86.6 gal Minimum Loading Height 2170 mm 7'1"

Cooling System 25 L 6.6 gal Maximum Depth Cut for 2440 mm (8'0") 6550 mm 21'6"

Engine Oil 15 L 4.0 gal Level Bottom

Swing Drive (each) 5 L 1.3 gal Maximum Vertical Wall Digging Depth 5190 mm 17'0"

Final Drive (each) 5 L 1.3 gal Bucket Digging Force (ISO) 150 kN 38,811 lbf

Hydraulic System (including tank) 234 L 61.8 gal Stick Digging Force (ISO) 106 kN 23,911 lbf

Hydraulic Tank 115 L 30.4 gal

DEF Tank 39 L 10.3 gal AIR CONDITIONING SYSTEM

The air conditioning system on this machine contains the fluorinated

greenhouse gas refrigerant R134a (Global Warming Potential = 1430).

The system contains 0.9 kg of refrigerant which has a CO2 equivalent

of 1.287 metric tonnes.

CAB FEATURES

FEATURE DESCRIPTION DELUXE PREMIUM

ROPS Standard Sound Suppression

Advanced Sound Suppression

High-Resolution Monitor 254 mm (10 inch) Touchscreen

Keyless Push-to-Start Engine Control

Jog Dial, Shortcut Keys Monitor Control

Air Conditioning Automatic Bi-level

Suspension Seat with Seat Belt Air Adjustable

Automatic

Heated

Heated & Cooled

Console Infinitely Adjustable

Tilt-Up Left Side

Bluetooth Integrated Radio With USB Ports

- standard - not available

14 320 HYDRAULIC EXCAVATOR

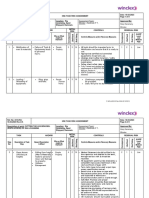

STANDARD & OPTIONAL EQUIPMENT

Standard and optional equipment may vary. Consult your Cat dealer for details.

320 CAB STANDARD OPTIONAL BOOMS AND STICKS STANDARD OPTIONAL

ROPS, standard sound suppression 5.7 m (18'8") reach boom, 2.9 m (9'6") stick

(Deluxe only) 8.85 m (29'0") SLR boom, 6.28 m (20'7")

ROPS, advanced sound suppression SLR stick

(Premium only)

UNDERCARRIAGE AND STRUCTURES STANDARD OPTIONAL

Air-adjustable seat with heat (Deluxe only)

600 mm (24") triple grouser shoes

Auto-adjustable seat with heat and

air ventilation (Premium only) 700 mm (28") triple grouser shoes

High-resolution 254 mm (10 inch) 790 mm (31") triple grouser shoes

LCD touchscreen monitor 900 mm (35") triple grouser shoes

Tie-down points on base frame

CAT CONNECT TECHNOLOGY STANDARD OPTIONAL

4200 kg (9,300 lb) counterweight

Cat Product Link

4700 kg (10,400 lb) counterweight

Cat GRADE with 2D

for SLR boom and stick

Cat GRADE with Advanced 2D

(not available on SLR) ELECTRICAL SYSTEM STANDARD OPTIONAL

Cat GRADE with 3D (not available on SLR) Two 1,000 CCA maintenance-free batteries

Cat GRADE with Assist Programmable time-delay LED

Cat PAYLOAD working lights

2D E-fence LED chassis light, left-hand/right-hand

boom lights, cab lights

Remote Flash capability

Remote Troubleshoot capability SERVICE AND MAINTENANCE STANDARD OPTIONAL

Sampling ports for Scheduled

ENGINE STANDARD OPTIONAL Oil Sampling (S·O·SSM)

Three selectable power modes Ground-level and platform-level

Auto engine idle shutdown engine oil dipsticks

52° C (125° F) high-ambient cooling capacity

SAFETY AND SECURITY STANDARD OPTIONAL

–32° C (–25° F) cold start capability

Rearview camera

Double element air filter with integrated

Right-side-view camera

precleaner

360° Visibility

Reversing electric cooling fans

Lift Assist

Biodiesel capability up to B20

Cat asset tracker

HYDRAULIC SYSTEM STANDARD OPTIONAL Ground-level engine shutoff switch

Boom and stick regeneration circuits Right-hand handrail and hand hold

Boom and stick lowering check valves Signaling/warning horn

Auto hydraulic warm up

Auto two-speed travel

Boom and stick drift reduction valve

Hammer return filter circuit

Advanced Tool Control (two pump, 1

one/two way high-pressure flow)

Medium-pressure circuit

Quick coupler circuit for Cat Pin Grabber 2

1

ANZ and Europe only.

2

Europe only.

Not all features are available in all regions. Please check with your local Cat dealer for specific offering availability in your area.

For additional information, refer to the Technical Specifications brochures for the 320 GC, 320 and 323 models available at www.cat.com or your Cat dealer.

320 HYDRAULIC EXCAVATOR 15

For more complete information on Cat products, dealer services and industry solutions, visit us on the web AEXQ2329-02

at www.cat.com Replaces AEXQ2329-01

Build Number: 07B

© 2019 Caterpillar. All Rights Reserved.

VisionLink is a trademark of Trimble Navigation Limited, registered in the United States and in other countries.

Materials and specifications are subject to change without notice. Featured machines in photos may include

additional equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Yellow”, the “Power Edge”

and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks

of Caterpillar and may not be used without permission.

www.cat.com www.caterpillar.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ZCS300 ManualDocument24 pagesZCS300 ManualFabricio BorgattaNo ratings yet

- 2318-RA 18.03.2023-REV 0A Cutting The Leg Bracing - RIG Rig LovansingDocument9 pages2318-RA 18.03.2023-REV 0A Cutting The Leg Bracing - RIG Rig LovansingHafeez AliNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- IP391 - 2007 - Determination of Aromatic Hydrocarbon Types in Middle Distillates - High Performance Liquid Chromatography Method With Refractive Index Detection (RID)Document12 pagesIP391 - 2007 - Determination of Aromatic Hydrocarbon Types in Middle Distillates - High Performance Liquid Chromatography Method With Refractive Index Detection (RID)Constantinos ChristodoulouNo ratings yet

- Spiral Dynamics Integral 1Document3 pagesSpiral Dynamics Integral 1Wangshosan100% (2)

- Review On Animal Tissues PDFDocument7 pagesReview On Animal Tissues PDFTitiNo ratings yet

- The One Ring™ Character LifepathsDocument10 pagesThe One Ring™ Character LifepathsDave SatterthwaiteNo ratings yet

- Do Dice Play GodDocument6 pagesDo Dice Play Godninafatima allamNo ratings yet

- Control Electrical Appliances Using PCDocument46 pagesControl Electrical Appliances Using PCsumit gandhi100% (1)

- Ijct 1 (5) 305-307Document46 pagesIjct 1 (5) 305-307Anonymous v5uipHNo ratings yet

- 1 Soal PrediksiDocument371 pages1 Soal PrediksiJanuar IrawanNo ratings yet

- Lynyrd Skynyrd - Steve Gaines Equipment HistoryDocument10 pagesLynyrd Skynyrd - Steve Gaines Equipment HistorySean88% (8)

- TP-Link WiFi 6E AXE5400 PCIe WiFi Card - User GuideDocument23 pagesTP-Link WiFi 6E AXE5400 PCIe WiFi Card - User GuidehelpfulNo ratings yet

- XDM 1000Document2 pagesXDM 1000shraddha_karelia5456No ratings yet

- Product Manual For High Strength Deformed Steel Bars and Wires For Concrete Reinforcement ACCORDING TO IS 1786: 2008Document9 pagesProduct Manual For High Strength Deformed Steel Bars and Wires For Concrete Reinforcement ACCORDING TO IS 1786: 2008N.J. PatelNo ratings yet

- Consolidation (2) - 4th SEMDocument3 pagesConsolidation (2) - 4th SEMDipankar NathNo ratings yet

- TLE9 - Q2 - Mod4 Week 8Document24 pagesTLE9 - Q2 - Mod4 Week 8Ceasar Ryan AsuncionNo ratings yet

- Ac BDVDocument12 pagesAc BDVUhhoj JjxhkNo ratings yet

- Learning Plan CLE-9Document5 pagesLearning Plan CLE-9Caren PondoyoNo ratings yet

- Dyna 86l 8086 P Training Development System With LCD PDFDocument1 pageDyna 86l 8086 P Training Development System With LCD PDFSoluchanNo ratings yet

- Lipid Microencapsulation Allows Slow Release of Organic Acids and Natural Identical Flavors Along The Swine Intestine1,2Document8 pagesLipid Microencapsulation Allows Slow Release of Organic Acids and Natural Identical Flavors Along The Swine Intestine1,2ĐêmTrắngNo ratings yet

- Richard Osterlind Mind Mysteries Guide Book 3Document74 pagesRichard Osterlind Mind Mysteries Guide Book 3Vlad George Boancă0% (1)

- GDM 24064 02Document31 pagesGDM 24064 02Fábio Vitor MartinsNo ratings yet

- Task 1 - Pre Knowledge Quiz - CARRODocument15 pagesTask 1 - Pre Knowledge Quiz - CARROClaudia FilipoNo ratings yet

- AdaptiveAndLearningSystems TheoryAndApplications KumpatiSNarendraDocument410 pagesAdaptiveAndLearningSystems TheoryAndApplications KumpatiSNarendraSooperAktifNo ratings yet

- NTN TR73 en P014Document6 pagesNTN TR73 en P014harshal161987No ratings yet

- Department of Education: Learning Activity WorksheetsDocument4 pagesDepartment of Education: Learning Activity WorksheetsARLENE GRACE AVENUENo ratings yet

- Lincoln, Bruce. How To Read A Religious Text - Reflections On Some Passages of The Chandogya UpanisadDocument14 pagesLincoln, Bruce. How To Read A Religious Text - Reflections On Some Passages of The Chandogya UpanisadvkasNo ratings yet

- Specification Sheet NETBOX Profilebox 01Document2 pagesSpecification Sheet NETBOX Profilebox 01Kian Keong YeeNo ratings yet