Professional Documents

Culture Documents

3 - AAAC-Tech. Spec

3 - AAAC-Tech. Spec

Uploaded by

Sumit TyagiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 - AAAC-Tech. Spec

3 - AAAC-Tech. Spec

Uploaded by

Sumit TyagiCopyright:

Available Formats

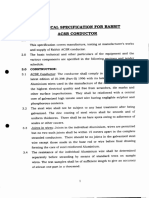

TECHNICAL SPECIFICATION FOR ALL ALUMINIUM STRANDED ALLOY

CONDUCTORS (AAAC)

[1] SCOPE:

This specification covers details of All Aluminium Alloy Conductor (AAAC) for use on

overhead lines. The sizes of the conductor cover under this specification are as under:

1 Code Name AAAC Weasel AAAC Rabbit AAAC Dog.

2 Size 7/2.5 mm 7/3.15mm 7/4.26 mm

3 area in mm2 34 mm2 55 mm2 100 mm2

[2] APPLICABLE STANDARDS:

Unless otherwise specified in the specification, the conductor shall comply with IS-398

(Part-IV)/1994 with latest amendment if any & REC Specification 33/1984 (Revised

March-2000).

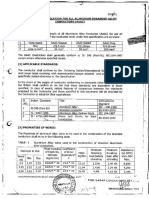

[3] PROPERTIES OF WIRES:

The Properties of aluminum alloy wires to be used in the construction of the stranded

conductors shall be as in the following table.

TABLE - I Aluminium Alloy wires used in the construction of stranded Aluminium

alloy conductors.

Minimum Resistance (at

Cross Sectional

Diameter in mm Mass breaking 20ºC) ohm

area of wire

Kg/Km load after /KM

(nominal dia.)

Nominal Min. Max stranding Max.

2.5 2.47 2.53 4.909 mm2 13.25 1.44 KN 6.845

3.15 3.12 3.18 7.793 mm2 21.04 2.29 KN 4.290

4.26 4.22 4.30 14.253 mm2 38.48 4.18 KN 2.345

[4] PROPERTIES OF CONDUCTORS:

The properties of stranded all aluminum alloy conductors of various sizes shall be as in

the following table.

TABLE- II ALL ALUMINIUM ALLOY CONDUCTORS (AAAC)

approx. Calculated Approx.

Nominal Strands & Sectional approx.

overall resistance at breaking

alloy area wire dia. Area mass

dia. 20ºC (max) load.

sq. mm mm sq. mm mm Kg/KM Ohm/KM KN

34 7/2.5 34.36 7.5 94.00 0.990 10.11

55 7/3.15 54.55 9.45 149.2 0.621 16.03

100 7/4.26 99.77 12.78 272.86 0.339 29.26

DGVCL/SP/CPP/ 16-17/10075/34-55-100 mm2 AAAC/Tech. Spec. >P 1/7

[5] FREEDOM FROM DEFECTS:

The wire shall be smooth and free from all imperfections like, spills, splits & scratches.

[6] MATERIAL:

The conductor shall be constructed of heat treated Aluminium Magnesium silicon alloy

wires having composition appropriate to the mechanical and electrical properties

specified in IS-398 (Part IV)/1994 and this specification.

[7] JOINTS IN WIRES:

There shall be no joint in any wire of a stranded conductor containing seven wires,

except those made in the base rod or wire before final drawing.

[8]STRANDING:

8.1 The wires used in the construction of a stranded conductor shall before stranding

satisfy all the relevant requirements of this specification.

8.2 The lay ratio shall be minimum 10 and maximum 14.

8.3 The outer layer shall be right handed. The wires in layer shall be evenly and

closely stranded.

[9] STANDARD LENGTH:

9.1The stranded All Aluminium Alloy Conductor shall be supplied in standard lengths of

(a) 2000 meters for 34 mm2 & 55 mm2 and (b) 1100 meters for 100 mm2 sizes.

9.2 The tolerance for standard length shall be +/- 5% (five percent).

9.3 Supply of short length shall not be less than 50% of the standard length. Also such

random / short length shall not exceed 5% (five percent) of the ordered quantity.

In any one drum, maximum three random lengths shall be permissible.

[10] INSPECTION OF CONDUCTORS.

The supplier shall offer the material for inspection in lots as and when ready with him.

The Purchaser shall arrange for inspection of each lot of material as early as possible

within 15 days from the date of receipt of intimation. The lot offered shall not be

dispatched by the supplier without having it inspected and tested by the Purchaser’s

inspector or issue of waiver of inspection by the Purchaser.

The acceptance tests on samples drawn from the offered lot for each size by the

Purchaser’s Inspector, as per sampling plan specified in the relevant Indian Standards,

shall be carried out at the works of the supplier at their cost. The testing instruments

should be in working condition and duly calibrated either by the original manufacturer

of the instruments or by any NABL approved testing agency. Copies of the calibration

certificates shall be made available to the inspector.

DGVCL/SP/CPP/ 16-17/10075/34-55-100 mm2 AAAC/Tech. Spec. >P 2/7

The offered lot will be accepted only after samples selected for tests are found to pass

all the acceptance test, In case of failure of sample in any test, procedure as per

clause no. 13 of IS 398 (part-IV) 1994 will be applicable.

One Conductor drum for any one size shall be taken up for verification of actual length

measurements. This shall form part of inspection for each and every lot offered for

inspection by the manufacturer.

[11] ROUTINE TESTS:

Routine tests on samples of individual wires shall be taken before stranding by supplier.

A record of such tests shall be maintained and made available to the inspector on

demand.

[12] SAMPLING CRITERIA:

The sampling criteria for acceptance test shall be 10% of the number of reels or drum

of the lot size in accordance with clause No. 12.1 of IS-398 (Part-IV)/1994.

[13] ACCEPTANCE TESTS:

Following acceptance tests as per IS-398 (Part-IV)/1994 with latest amendment if

any shall be carried out on all samples.

(i) Measurement of lay ratio.

(ii) Measurement of diameters of individual wire.

(iii) Measurement of resistance of individual wire.

(iv) Breaking load test of individual wire.

(v) Elongation test of individual wire.

[14] MEASUREMENT OF LENGTH:

(A)The supplier shall provide at his works the necessary facilities for measurement of

conductor length of the drum. The conductor length of minimum one drum shall be

measured in presence of the inspector. The length measurement results shall be

recorded in the test report.

In case the actual conductor length is found short than the declared length, then

length of further 2 (Two) drums are to be verified. The results shall be recorded in

the test report.

(B)The Purchaser will have the option of measuring conductor lengths at on receipt of

material at destination. If, so desired the supplier representative will be allowed to

remain present at the time of the consignee taking the measurement, otherwise the

findings of the consignee will be final and binding on the supplier.

In case of any shortage in length from declared value , the cost of short length shall

be deducted from the relevant invoices / bills raised by the vendor, to take care of

the shortage and penalty to the extent of 30% of the value of such short length

shall also be levied.

DGVCL/SP/CPP/ 16-17/10075/34-55-100 mm2 AAAC/Tech. Spec. >P 3/7

[15] EXPERIENCE:

Bidders should have supplied seven strand AAAC Conductors such as Weasel, Rabbit &

Dog or higher (like ACSR Conductors) in the last two years.

[16] BIS LICENCE:

The tenderers should submit a notarized copy of BIS Licence of IS-398 (Part-

IV)/1994 valid at least up to the date of opening of the tender. If applied for

renewal of the licence, copy of receipt of fees and/or acknowledgement of

application from ISI/BIS shall be furnished along with zerox copy of expired

BIS Licence with the bid.

Bids received without above document shall be rejected.

[17] ISI MARK:

Conductor drums bearing ISI Mark will only be acceptable.

[18] PACKING AND MARKING:

The conductor shall be packed in wooden drums confirming to IS-1778/1980 with latest

amendments if any and detailed specifications as under:

(a)The conductor shall be supplied in non-returnable strong wooden drums provided

with lagging of adequate strength, constructed to protect the conductor against all

damages and displacement during transit, loading, unloading during transport and

subsequent handling and stringing operation in the field.

The Wooden drums shall be generally confirming to IS-1778/1980 with amendment

No.1 of June-1989.

(b)All wooden components shall be manufactured out of seasoned soft wood which

shall be sound and free from defects that may materially weaken the components

parts of the drums. Preservative treatment shall be applied to the entire drum with

preservatives of good quality which is not harmful to the conductor.

(c)The drum sizes and dimensions shall be in accordance with the IS-1778/1980

with amendment No. 1 June-1989.

(d)Before reeling of conductor, the barrel of the drum as well as inside and outside

surface of flanges of drum shall be painted with Aluminum/bitumen based paint.

One layer of water proof and abrasion resistant paper shall be used over barrel.

After reeling the conductor the exposed surface of the outer layer of all conductors

shall be wrapped with water proof and abrasion resistant paper.

(e) Minimum spacing between outer layer of conductor and inner surface of lagging

shall be 75 mm. The external lagging shall be closely fitted and shall be thickness of

not less than 38 mm. There shall be minimum 2 Nos. binders consisting of hoop

iron/galvanized steel wire outside of the protective lagging.

DGVCL/SP/CPP/ 16-17/10075/34-55-100 mm2 AAAC/Tech. Spec. >P 4/7

(f) Arrangement for sealing (seal wire with lead seal) the outer end of conductor may

be provided by supplier. The inspector may provide his seal after inspection.

(g) Each drum shall have the following information stenciled on it in

Indelible ink along with other essential details.

(I). Size and nomenclature of conductor.

(II). Purchaser’s order No. and date.

(III). Name of manufacturer and address.

(IV). Number & length of conductor in meters.

(V). Drum number.

(VI). Net weight of empty drum with lagging.

(VII). Gross weight of drum with conductor and lagging.

(VIII). Property of (write name of relevant DISCOM).

(IX). Name of consignee.

(X). Reference IS Number & ISI Certification mark, if any.

(h) The following details shall also be etched on Aluminium /steel plate of minimum size

of 10 cm x 6 cm on one face of each drum in addition to the above marking by ink.

(i) Name of manufacturer. (ii) Size and nomenclature of conductor.

(iii)Purchase Order No. & Date. (iv) Drum Number & length in meters.

(i) If, the Conductor drum carries more than one length, measurement of each length

of conductor and total of all of them shall be marked on drum. The outermost

length on drum shall be numbered as first and the inner most shall be numbered as

last.

[19]Bidders are required to submit the following documents with the offer without

which the bid shall be liable for rejection.

1. Notarized copy valid BIS Licence.

2. Guaranteed Technical Particulars (GTP) given in App-A.

3. List of testing equipment.

4. List of Plant and Machinery and Production capacity.

5. List of orders executed with GUVNL/DISCOM/Other SEB/Utility.

[20]GUARANTEED TECHNICAL PARTICULARS (GTP):

The Guaranteed Technical Particulars (GTP) given in the Appendix-A are generally in

conformity with IS-398 (Part-IV) of 1994.

The manufacturer offering ISI certificate mark, shall be deemed to be manufacturing

conductor meeting the guaranteed technical particulars given in Appendix-A.

##############

DGVCL/SP/CPP/ 16-17/10075/34-55-100 mm2 AAAC/Tech. Spec. >P 5/7

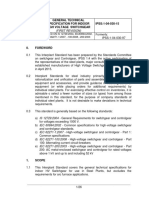

APPENDIX –A

GUARANTEED TECHNICAL PARTICULARS (GTP)

Size of Conductor:

Size of Conductor: Size of Conductor:

55 mm2 AAAC Rabbit 100mm2 AAAC Dog.

34 mm2 AAAC Weasel

Bidder has to confirm following important requirements.

Sr.

PARTICULARS CONFIRMATION

No.

Conductor shall be manufactured as per

A1

IS-398 Part-IV/1994 or latest amendment of it.

Wooden drums shall be as per IS-1778/1980 with

A2 latest amendment, if any and shall be painted as per

specification

Spacing between outer layer of conductor and inner

A3

surface of lagging shall be 75mm min.

Standard length shall be (a) 2000 meters for 34 mm2

&

A4 55 mm2 and (b) 1100 meters for 100 mm2 sizes

with 5% (five percent) tolerance.

Short length shall not be less than 50% of the

standard length. Also such random / short length

A5

shall not exceed 5% (five percent) of the ordered

quantity.

Maximum three numbers of random length shall

A6

be wound on any one drum.

Conductor shall have 7 Nos. of wires. And outer lay

A7

shall be right handed.

Drum Size shall be as per IS-1778/80 with

A8

Amendment No. I of 1989

Properties of individual wires shall be as under:

Dia of wire Weasel Rabbit Dog

Nominal 2.5 3.15 4.26

Minimum 2.47 3.12 4.30

Maximum 2.53 3.18 4.22

Mass in kg/km 13.25 21.04 38.48

Min.BL after stranding 1.44 2.29 4.18

Res.at 20ºC (max) 6.845 4.290 2.345

A9

App. overall diam. of

complete stranded 7.50 9.45 12.78

conductor in mm

App. mass in kg /km 94.00 149.20 272.86

Approx. calculated

breaking load 10.11 16.03 29.26

in KN

Calculated max. res. at

0.990 0.621 0.339

20ºC in ohms/km

DGVCL/SP/CPP/ 16-17/10075/34-55-100 mm2 AAAC/Tech. Spec. >P 6/7

Minimum lay ratio 10 10 10

Maximum lay ratio 14 14 14

B1 BIS License number(Copy Enclosed)

B2 Validity Up to

B3 List of Plant & Machinery.

List of NABL approved test house calibrated Testing

B4

equipments.

PLACE: Signature & Seal of Tenderer

DATE:

DGVCL/SP/CPP/ 16-17/10075/34-55-100 mm2 AAAC/Tech. Spec. >P 7/7

You might also like

- Acsr ConductorsDocument10 pagesAcsr ConductorsPhani KumarNo ratings yet

- Earthing CalculationsDocument2 pagesEarthing Calculationsmazumdar_satyajit75% (4)

- Material Receiving Inspection ReportDocument4 pagesMaterial Receiving Inspection ReportAndiWSutomo100% (1)

- B473Document7 pagesB473djlucho123456No ratings yet

- Technical Specification For All Aluminium Stranded Alloy Conductors (Aaac)Document6 pagesTechnical Specification For All Aluminium Stranded Alloy Conductors (Aaac)kumarpraharaj4571No ratings yet

- Technical Specification of AAACDocument8 pagesTechnical Specification of AAACALOK BEHERANo ratings yet

- AAAC Conductor SpecificationsDocument9 pagesAAAC Conductor SpecificationsShrikant KajaleNo ratings yet

- Telangana SPecificationDocument7 pagesTelangana SPecificationabhi_26tNo ratings yet

- Technical Specification: 2Cx16+25 SQ - MM LT Xlpe Ab CableDocument9 pagesTechnical Specification: 2Cx16+25 SQ - MM LT Xlpe Ab CableRamesh Arjun TNo ratings yet

- Technical Specification For Acsr Conductors: WbsedclDocument9 pagesTechnical Specification For Acsr Conductors: Wbsedclraja kumarNo ratings yet

- Technical Specification AL-59 Conductor 893Document18 pagesTechnical Specification AL-59 Conductor 893pramjitNo ratings yet

- Technical Specification of Dog ConductorDocument6 pagesTechnical Specification of Dog ConductorSupriyo Podder75% (4)

- Technical Specification of 55Sqmm 100Sqmm AAACDocument14 pagesTechnical Specification of 55Sqmm 100Sqmm AAACMurtuzaNo ratings yet

- AcsrDocument9 pagesAcsraeu3csd bdvtNo ratings yet

- 8019 - (3) - 1C LT ABC - Tech. SpecDocument9 pages8019 - (3) - 1C LT ABC - Tech. Specdeepthik27No ratings yet

- Technical Specification For 3C XPLE CableDocument9 pagesTechnical Specification For 3C XPLE Cableramana3339No ratings yet

- 3C-ABC-Technical Spec 948Document9 pages3C-ABC-Technical Spec 948Kanwalnain madaanNo ratings yet

- Technical Specification For 33 KV Aerial Bunched Cable - 2Document7 pagesTechnical Specification For 33 KV Aerial Bunched Cable - 2BijuNo ratings yet

- 33kv Techni8cal Specification Edited FormatDocument16 pages33kv Techni8cal Specification Edited Formatvikas kumarNo ratings yet

- 8044 3 Technical Specification of HT AB Cable 11KVDocument9 pages8044 3 Technical Specification of HT AB Cable 11KVdkshtdkNo ratings yet

- 2 0.2 Acsr Panther Conductor 1 14Document14 pages2 0.2 Acsr Panther Conductor 1 14Anurag SanodiaNo ratings yet

- Acsr Panther Conductor 10 PDFDocument14 pagesAcsr Panther Conductor 10 PDFSenthil ThanappanNo ratings yet

- Acsr Zebra ConductorDocument17 pagesAcsr Zebra ConductorRam Dhani YadavNo ratings yet

- AAC BULL & BERSIMIS Conductor - SpecificationDocument18 pagesAAC BULL & BERSIMIS Conductor - Specificationbalaeee123100% (2)

- 6 +acsr+zebra+conductorDocument17 pages6 +acsr+zebra+conductorBagusIrawanSaputraNo ratings yet

- 2 B 02 Al59 Cond Equiv Zebra MooseDocument28 pages2 B 02 Al59 Cond Equiv Zebra MoosevgovaNo ratings yet

- TS PHIIR Part4Document104 pagesTS PHIIR Part4purechemcabledeptNo ratings yet

- Ab Cable GTPDocument17 pagesAb Cable GTPNaresh Ch MahapatraNo ratings yet

- Technical Specification Rabbit ACSR ConductorDocument5 pagesTechnical Specification Rabbit ACSR ConductorRiyasKadappayilNo ratings yet

- Aluminum Conductors Carbon Fiber Core Reinforced-LAPWINGDocument6 pagesAluminum Conductors Carbon Fiber Core Reinforced-LAPWINGgabriel yair sanchez henandezNo ratings yet

- 11kv CablesDocument46 pages11kv CablesS.k. RathNo ratings yet

- Technical Specification (Medium Voltage) Aaa Covered Conductor & AccesoriesDocument36 pagesTechnical Specification (Medium Voltage) Aaa Covered Conductor & AccesoriesCabcon India100% (1)

- AAAC ConductorsDocument14 pagesAAAC ConductorsDipanku GoswamiNo ratings yet

- Aluminium Pipe Bus PDFDocument6 pagesAluminium Pipe Bus PDFaviral mishraNo ratings yet

- Technical Specification For Aac / Acsr ConductorsDocument8 pagesTechnical Specification For Aac / Acsr ConductorsDeepeshMaliNo ratings yet

- 2B P6 MVCC - RDSS - PGVCL - Infra SBD - Part 2 - TS - Version-2 - 28062022Document202 pages2B P6 MVCC - RDSS - PGVCL - Infra SBD - Part 2 - TS - Version-2 - 28062022Mrugesh Samsung.m31sNo ratings yet

- 1 ACSR380/50mm2 (NA)Document3 pages1 ACSR380/50mm2 (NA)bassamwael6689No ratings yet

- Acsr Panther ConductorDocument17 pagesAcsr Panther ConductorRam Dhani Yadav100% (1)

- L T A B Cable Spec 08.08.2019Document17 pagesL T A B Cable Spec 08.08.2019Ashish bhattNo ratings yet

- A12 Appendix 12 Technical ScheduleDocument79 pagesA12 Appendix 12 Technical Scheduleanon_31581079No ratings yet

- Acsr ConductorDocument8 pagesAcsr ConductorKoushik BhaumikNo ratings yet

- RDSO Quad Cables 0.9 MMDocument45 pagesRDSO Quad Cables 0.9 MMAbhimanyu Singh ChauhanNo ratings yet

- Technical Specification For ACSR Conductor, 24F OPGWDocument3 pagesTechnical Specification For ACSR Conductor, 24F OPGWMd MohsinNo ratings yet

- Acsr Moose ConductorDocument17 pagesAcsr Moose ConductorRam Dhani Yadav100% (1)

- Aluminium Conductor For Overhead Transmission Purposes - SpecificationDocument11 pagesAluminium Conductor For Overhead Transmission Purposes - Specificationmanir_b4u2002No ratings yet

- MVCC-Tech SpecDocument3 pagesMVCC-Tech Specvishnu ojhaNo ratings yet

- Irs 30-2005Document62 pagesIrs 30-2005Pratyaksh AgarwalNo ratings yet

- HT Cable RFQ Specifications PDFDocument7 pagesHT Cable RFQ Specifications PDFAshil ThomasNo ratings yet

- 18.1-1996 Aerial Bundled ConductorsDocument11 pages18.1-1996 Aerial Bundled ConductorsnilushkaaNo ratings yet

- 9061 - Conductors - Primary Distribution Aluminum BareDocument7 pages9061 - Conductors - Primary Distribution Aluminum BareDionisio Gallardo RodríguezNo ratings yet

- Aluminiumconductorforoverhead Transmissionpurposes-SpecificationDocument12 pagesAluminiumconductorforoverhead Transmissionpurposes-SpecificationSINU0607IITEEENo ratings yet

- 24 - 1 Core LT XLPE CableDocument9 pages24 - 1 Core LT XLPE CabledrravijainNo ratings yet

- Lumino Conductor SpecificationDocument5 pagesLumino Conductor SpecificationSatish MishraNo ratings yet

- Vol-Ii (PART-II) : Guaranteed Technical ParticularsDocument70 pagesVol-Ii (PART-II) : Guaranteed Technical ParticularsNarendra ChhatriaNo ratings yet

- TS US Gabion, GalMac Jan19Document8 pagesTS US Gabion, GalMac Jan19johnnee98No ratings yet

- CSC-XII 1 C Is 7098 Part 2Document8 pagesCSC-XII 1 C Is 7098 Part 2Ashish bhattNo ratings yet

- ACSR Some Equal Standards-Indian StandardDocument20 pagesACSR Some Equal Standards-Indian StandardHabib EmamiNo ratings yet

- Radio Frequency Identification and Sensors: From RFID to Chipless RFIDFrom EverandRadio Frequency Identification and Sensors: From RFID to Chipless RFIDNo ratings yet

- Millimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextFrom EverandMillimetre Wave Antennas for Gigabit Wireless Communications: A Practical Guide to Design and Analysis in a System ContextNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Guide To The Installation of Photovoltaic SystemsDocument124 pagesGuide To The Installation of Photovoltaic SystemsWorcester Renewables100% (21)

- Switchgear Specification For High Voltage Switchgears CT PT BreakerDocument26 pagesSwitchgear Specification For High Voltage Switchgears CT PT BreakerSumit TyagiNo ratings yet

- Acdb 17 in 1 Out - Groung PDFDocument7 pagesAcdb 17 in 1 Out - Groung PDFSumit TyagiNo ratings yet

- Transformer Tender DocumentDocument2 pagesTransformer Tender DocumentSumit TyagiNo ratings yet

- Guidelines 11 KV 33KV OUTDOOR TRANSFORMERS PDFDocument89 pagesGuidelines 11 KV 33KV OUTDOOR TRANSFORMERS PDFSwaroop Biswas100% (1)

- El DWG 016 Grounding LayoutDocument1 pageEl DWG 016 Grounding LayoutSumit TyagiNo ratings yet

- HT Cable BhelDocument49 pagesHT Cable BhelSumit TyagiNo ratings yet

- El DWG 001 Cover PageDocument1 pageEl DWG 001 Cover PageSumit Tyagi100% (1)

- Rays Sunkit Product Spec SheetDocument3 pagesRays Sunkit Product Spec SheetSumit TyagiNo ratings yet

- Galvanized Earthing PipeDocument32 pagesGalvanized Earthing PipeSumit TyagiNo ratings yet

- Cargil Animal Nutition Bhatinda PunjabDocument3 pagesCargil Animal Nutition Bhatinda PunjabSumit TyagiNo ratings yet

- Water Tank Shadow: 1. Modules On Super Structure - 36 Nos 2. Modules On Tin Sheet - 48 Total Capacity - 27 KWPDocument1 pageWater Tank Shadow: 1. Modules On Super Structure - 36 Nos 2. Modules On Tin Sheet - 48 Total Capacity - 27 KWPSumit TyagiNo ratings yet

- Helio Taj Mahal AgraDocument2 pagesHelio Taj Mahal AgraSumit TyagiNo ratings yet

- 50 MW SECI Rooftop Tender For CPWD Under RESCO ModelDocument98 pages50 MW SECI Rooftop Tender For CPWD Under RESCO ModelSumit TyagiNo ratings yet

- Jindal Hospital - EARTHING - 100 KWDocument1 pageJindal Hospital - EARTHING - 100 KWSumit TyagiNo ratings yet

- In-Plant Training Report PresentationDocument60 pagesIn-Plant Training Report Presentationrajhossie9335100% (3)

- Construction Project Closeout Checklist: Project Name Cutomer Name Project Manager Name Expected Closing DateDocument4 pagesConstruction Project Closeout Checklist: Project Name Cutomer Name Project Manager Name Expected Closing Dategogo2021No ratings yet

- Coating PaintingDocument8 pagesCoating Paintingdeva0170% (2)

- Materials System SpecificationDocument14 pagesMaterials System SpecificationSyed Zain Ali100% (1)

- 0-Wd910-Ej460-00002 Vendor Print For PLC & Sol PNL & HmiDocument317 pages0-Wd910-Ej460-00002 Vendor Print For PLC & Sol PNL & HmiNils Ericsson Sánchez HuayanaNo ratings yet

- Digital Image Processing - Pages-122-126Document5 pagesDigital Image Processing - Pages-122-126Faheem KhanNo ratings yet

- Imran Saeed CVDocument4 pagesImran Saeed CVImran SaeedNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistMohamad Shafey100% (1)

- Visual Inspection WorkshopDocument56 pagesVisual Inspection WorkshopIlyes kNo ratings yet

- Tender - 47 - Metering Cubicles (Final) PDFDocument46 pagesTender - 47 - Metering Cubicles (Final) PDFNitesh GawlliNo ratings yet

- A9jm Ep 0000 255 SPC 59030 ADocument25 pagesA9jm Ep 0000 255 SPC 59030 AEsteban PeraltaNo ratings yet

- Annex To Ed Decision 2020-021-r Amc GM For Ams - Issue 1 Amdt 4Document65 pagesAnnex To Ed Decision 2020-021-r Amc GM For Ams - Issue 1 Amdt 4Stathis BelosNo ratings yet

- Original Version Well Maintained Highways 85645Document316 pagesOriginal Version Well Maintained Highways 85645Diyoke HenryNo ratings yet

- STD-InSP-0006 (Flange Inspection Procedure)Document3 pagesSTD-InSP-0006 (Flange Inspection Procedure)airbroom100% (1)

- Wire Cloth and Sieves For Testing PurposesDocument5 pagesWire Cloth and Sieves For Testing PurposesROHITNo ratings yet

- Curriculum Vitae: Bhavin G. PatelDocument4 pagesCurriculum Vitae: Bhavin G. PatelBhavin PatelNo ratings yet

- ABC Group Checking and Gauge Standard 80-STD-D-01Document53 pagesABC Group Checking and Gauge Standard 80-STD-D-01Quy HoangNo ratings yet

- Saudi Aramco Typical Inspection Plan: Powered In-Plant Communication Systems SATIP-T-481-01 30-Oct-17 TelecommunicationsDocument12 pagesSaudi Aramco Typical Inspection Plan: Powered In-Plant Communication Systems SATIP-T-481-01 30-Oct-17 TelecommunicationsAsif ShareefNo ratings yet

- BTM User Guide Tog L LocDocument20 pagesBTM User Guide Tog L LocXavier CarbajalNo ratings yet

- No Requirements Applicable Status: Section 1 - AdministrationDocument4 pagesNo Requirements Applicable Status: Section 1 - AdministrationJoachim100% (2)

- Jposta. Barbara LPG Plant Safety AuditDocument16 pagesJposta. Barbara LPG Plant Safety AuditМарк Артём Лимот Апалла83% (6)

- Apcs-113a Method StatmentDocument7 pagesApcs-113a Method StatmentNoman AhmedNo ratings yet

- ITP TemplateDocument1 pageITP TemplateEzuan AdamNo ratings yet

- Integrated Farm Assurance All Farm Base - Crops Base - Fruit and VegetablesDocument118 pagesIntegrated Farm Assurance All Farm Base - Crops Base - Fruit and VegetablesBảo ChâuNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (19) Installation of Conductor JumperDocument14 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (19) Installation of Conductor Jumpermohammed tofiqNo ratings yet

- Quality PlanDocument23 pagesQuality PlanArun Kumar88% (8)

- Idoc - Pub - gc3 Candidate Report TemplateDocument2 pagesIdoc - Pub - gc3 Candidate Report Templatefarhanhussain852No ratings yet

- Oil Palm Bunch: National Bureau of Agricultural Commodity and Food Standards Ministry of Agriculture and CooperativesDocument10 pagesOil Palm Bunch: National Bureau of Agricultural Commodity and Food Standards Ministry of Agriculture and CooperativesProjectsNo ratings yet