Professional Documents

Culture Documents

Introduction To Hindustan Unilever Limited: Supply Chain Management Solution For Hindustan Unilever: Case Study

Introduction To Hindustan Unilever Limited: Supply Chain Management Solution For Hindustan Unilever: Case Study

Uploaded by

DHIRAJMALIVAL7221Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction To Hindustan Unilever Limited: Supply Chain Management Solution For Hindustan Unilever: Case Study

Introduction To Hindustan Unilever Limited: Supply Chain Management Solution For Hindustan Unilever: Case Study

Uploaded by

DHIRAJMALIVAL7221Copyright:

Available Formats

Supply Chain Management Solution for Hindustan Unilever: Case

Study

INTRODUCTION TO HINDUSTAN UNILEVER LIMITED

In the summer of 1888, visitors to the Kolkata harbour noticed crates

full of Sunlight soap bars, embossed with the words "Made in England

by Lever Brothers". With it, began an era of marketing branded Fast

Moving Consumer Goods (FMCG). Soon after followed Lifebuoy in

1895 and other famous brands like Pears, Lux and Vim. Vanaspati

was launched in 1918 and the famous Dalda brand came to the

market in 1937.

Existing Situation

With nearly 1000 products, HLL distributes them nationally through a

network of four warehouses, more than 40 agents, 7,500 wholesalers and

a number of large institutional customers.

HLL, in its endeavor to move from the existing push-based planning

system to a pull-based system, wanted to build a Supply Chain

Management (SCM) solution that would ensure informed decisions are

made during procurement, manufacturing, replenishment and

distribution. Specifically, the distribution operation was suffering

because of a high margin of errors. There were frequent instances of

excess finished-goods inventory reaching HLL’s distribution centers.

This problem was compounded by increasing instances of out-of-stock

inventory, which led to demand-supply mismatches. Finally, the system

was not able to handle the dynamic nature of the company’s source-

destination network, and adversely affected the demand-fulfillment

rates.

HLL needed a solution that could provide visibility across its supply

chain. Considering the diverse nature of the company’s customer base,

the solution needed to prioritize the demand-fulfillment process based on

individual profiles. The company also required precise vehicle loading

plans for the source-destination lane in tune with its dynamic network.

Tool Selection

In an effort to streamline its distribution network, HLL initiated a

comprehensive project to seamlessly integrate its supply chain and

promote collaboration. The key objectives of the initiative were:

Implementation of a Supply Chain Planning and Optimization Tool.

Development and implementation of a Web-enabled solution to extend

visibility across the company’s network of wholesalers.

Adexa’s collaboration Suite 5.0 (Supply Chain Planner and Strategic

Planner) was selected as the tool for production, distribution and

materials functions. The Supply Chain Planner’s (SCP) powerful

constraint-based planning capability delivers detailed-level plans. On the

other hand, Strategic Planner allows HLL to decide on the product mix

and manufacturing locations, and optimizes the source-destination

network, on a long-term basis.

Our Approach

Mind Tree has a portfolio of process models, management tools, and

operational best practices, which can be customized to address any SCM

engagement. Mind Tree has a specific methodology for Adexa. Adexa-

certified consultants from Mind Tree worked closely with HLL’s IT

application team and consultants from Adexa in designing a detailed

system architecture, system building and model, and system-verification

steps.

Solution

MindTree evaluated the key supply-chain processes for each of HLL’s

lines of business. The solution is geared to fulfill supply and demand. It

gives precise production plans for all the factories and a replenishment-

based distribution plan for all the distribution centers. All entities in the

supply chain were modeled on the Adexa collaboration suite. The key

inputs for building the SCM model were distribution demand for all

stock keeping units (SKUs); factory-wise capacities; and linkages

between the distribution centers, finished goods warehouses, factories

and suppliers.

With inputs from HLL’s team, MindTree contributed towards modeling

the following requirements with respect to key resource and material

constraints:

Shop-floor complexities (SKU-specific levels for bill of material,

resource and capacity constraints) to arrive at a feasible production plan

using discrete and continuous modes of consumption.

Site-specific holidays as capacity patterns.

Collaborative production planning optimizing individual plan

utilization, time fences, customized threshold logic, and post-processing

time for quality clearance at plants.

Equitable demand fulfillment (both planned and extraordinary) for

finished goods based on customer prioritization across the supply chain.

Periods of cover and safety stock at distribution centers for SKU

rationalization, handling consumer promotions, etc.

Handling in-transits on source-destination lane.

Meeting the demands from individual whole sellers by direct dispatches

from factories.

Precise vehicle load plans for shipments from the factories and

warehouses.

Dynamic allocation of source factories to each distribution center.

Data integration between the SCP and ERP systems was addressed with

the implementation of MFG/PRO.

Implemented specific requirements through plug-in business rules in

Supply Chain Planner such as work-order sizing and method

(production/transportation) selection.

For implementing the requirements mentioned above, MindTree

developed an exclusive set of the following algorithms:

Demand prioritization and equalization logic, based on pre-

determined “starvation levels”.

Balancing and scheduling logic.

Transportation logic.

Vehicle loadability logic.

Results

This Adexa implementation has improved HLL’s proactive planning

capability and manufacturing and distribution efficiency, which have

helped ensure a more responsive supply chain. The solution has also

helped the company gain visibility across its supply chain, reduce

distribution lead-time, and minimize the total supply-chain cost.

Stock availability, measured in terms of Stock Service Index, has

significantly increased, moving from 65% to 90%. The company has

also realized a more equitable distribution of stocks with overall mal-

distribution reducing from 19% to 6% of total volume transported.

Manual intervention has come down from 40% to sub-zero levels. Direct

dispatches from the factories to the wholesaler network have increased.

Finally, in terms of volume, indirect dispatches from finished goods

warehouses have come down from a range between 70-80% to between

30-40%.

Tools Used

Sun Solaris (OS), Windows NT, Adexa collaboration 5.0 (Supply Chain

Planner and Strategic Planner) and TCL/UCL.

You might also like

- Ceat 29 01 11Document2 pagesCeat 29 01 11Himanshu Shekhar50% (2)

- HUL LogisticDocument4 pagesHUL Logisticnkhl_mhatreNo ratings yet

- Supply Chain Management Solution For Hindustan UnileverDocument3 pagesSupply Chain Management Solution For Hindustan UnileverSannel SunnyNo ratings yet

- Supply Chain of HULDocument3 pagesSupply Chain of HULNagaraju NaguNo ratings yet

- DS LLamasoft For Chemical USDocument3 pagesDS LLamasoft For Chemical USsappz3545448No ratings yet

- Organising and Planning For LSCM FunctionsDocument13 pagesOrganising and Planning For LSCM FunctionsAnab ZaishaNo ratings yet

- Project Supply Chain Management: Introduction To SC, SCM, in ProjectDocument35 pagesProject Supply Chain Management: Introduction To SC, SCM, in ProjectMuazam AliNo ratings yet

- Supply Chain & Logistics Analytics - Session 8 Distribution NetworkDocument38 pagesSupply Chain & Logistics Analytics - Session 8 Distribution NetworkArya KeoliyaNo ratings yet

- Study of IT Reinforced Supply Chain Management ModelDocument23 pagesStudy of IT Reinforced Supply Chain Management ModelPuneetGuptaNo ratings yet

- Current Status of Supplychain Management Industryin IndiaDocument14 pagesCurrent Status of Supplychain Management Industryin IndiaVishwas JoshiNo ratings yet

- Modelling and SimulationDocument13 pagesModelling and Simulationsuresh_ramanujam007100% (1)

- Operations and Supply Chain StrategiesDocument8 pagesOperations and Supply Chain StrategiesBijesh SiwachNo ratings yet

- Logistics and Supply ChainDocument54 pagesLogistics and Supply Chainshouvik chouduryNo ratings yet

- LogisticsDocument6 pagesLogisticsJosé SalazarNo ratings yet

- Supply Chain Management Research Paper OutlineDocument4 pagesSupply Chain Management Research Paper Outlinegz7vxzyz100% (1)

- Supply Chain Model PDFDocument6 pagesSupply Chain Model PDFNeha KumarNo ratings yet

- Unit 1 - NotesDocument8 pagesUnit 1 - NotesAnas K MakNo ratings yet

- Llamasoft Gartner Issue1 PDFDocument22 pagesLlamasoft Gartner Issue1 PDFDarshan HDNo ratings yet

- Supply Chain Information TechnologyDocument23 pagesSupply Chain Information TechnologyBusiness Expert Press100% (22)

- Ops Gyan CapsuleDocument4 pagesOps Gyan CapsuleMahesh KundrapuNo ratings yet

- Operations and Supply Chain Strategies CA1Document11 pagesOperations and Supply Chain Strategies CA1vibhor shrivastavaNo ratings yet

- Research Paper On Logistics and Supply Chain ManagementDocument4 pagesResearch Paper On Logistics and Supply Chain Managementgz3ezhjcNo ratings yet

- C2X - SCM Weekly - Issue 1 PDFDocument2 pagesC2X - SCM Weekly - Issue 1 PDFdeveshjhNo ratings yet

- Introduction of Store Operations: Chapter - 1Document13 pagesIntroduction of Store Operations: Chapter - 1Prakash BoroNo ratings yet

- Assignment Supply Chain Management BY Virupaksha Reddy.T ROLL NUMBER: 510916226 OM0003 SET-1Document12 pagesAssignment Supply Chain Management BY Virupaksha Reddy.T ROLL NUMBER: 510916226 OM0003 SET-1virupaksha12No ratings yet

- Enterprise Resource Planning: MODULE 11: Supply Chain Management (SCM) SystemsDocument8 pagesEnterprise Resource Planning: MODULE 11: Supply Chain Management (SCM) SystemsPradeeP VNo ratings yet

- Key Concepts of Supply Chain Management: Chapter - 1Document19 pagesKey Concepts of Supply Chain Management: Chapter - 1Dilip NareNo ratings yet

- PPPDocument6 pagesPPPshreyikapNo ratings yet

- Supply Chain ManagementDocument11 pagesSupply Chain ManagementPinkeshNo ratings yet

- SCM in GeneralDocument22 pagesSCM in GeneralMartin JohnNo ratings yet

- 1 Key Concepts of SCMDocument19 pages1 Key Concepts of SCMIsha MittalNo ratings yet

- Supply Chain ManagementDocument6 pagesSupply Chain ManagementSheikh Saad Bin ZareefNo ratings yet

- Sap SCMDocument21 pagesSap SCMAffizul AzuwarNo ratings yet

- SC & OS - FinalDocument20 pagesSC & OS - FinalPrasad ChamaraNo ratings yet

- Report On Supply Chain ManagementDocument31 pagesReport On Supply Chain ManagementAseem Sharda100% (1)

- Recent Trends in OperationsDocument7 pagesRecent Trends in Operationsgag90No ratings yet

- SCM GCPLDocument32 pagesSCM GCPLRuta DaveNo ratings yet

- Supply Chain ManagementDocument124 pagesSupply Chain ManagementLeena SharmaNo ratings yet

- Supply Chain Management Approaches: Plan Driven Approaches or Predictive MethodsDocument16 pagesSupply Chain Management Approaches: Plan Driven Approaches or Predictive MethodstradagNo ratings yet

- A Study On Supply Chain Management in DSM Textile in KarurDocument82 pagesA Study On Supply Chain Management in DSM Textile in Karurk eswariNo ratings yet

- Assessment 3 OmDocument5 pagesAssessment 3 OmHarpreet KaurNo ratings yet

- A I T S C: N Ntroduction O Upply HainDocument33 pagesA I T S C: N Ntroduction O Upply HainSmn BoparaiNo ratings yet

- What Is Supply Chain ManagementDocument6 pagesWhat Is Supply Chain ManagementHusain ShiyajiNo ratings yet

- FacilitiesDocument4 pagesFacilitiesBhaskar SahaNo ratings yet

- Assignment Of: Lovely School of BusinessDocument7 pagesAssignment Of: Lovely School of BusinessDhirendra YadavNo ratings yet

- Rahul Final Project Final PDFDocument72 pagesRahul Final Project Final PDFNandan KesariNo ratings yet

- Lifeline - Supply ChainDocument41 pagesLifeline - Supply Chainvnewaskar_1No ratings yet

- Supply Chain ManagementDocument20 pagesSupply Chain ManagementŞermin ŞahinNo ratings yet

- Case Study Analsys of International Trade Logistics: Prof. K K K ChandDocument6 pagesCase Study Analsys of International Trade Logistics: Prof. K K K Chandsuchanda87No ratings yet

- CHP - 49 - Lean and Agile Supply ChainDocument14 pagesCHP - 49 - Lean and Agile Supply ChainSiddesh SiddappaNo ratings yet

- SC Working Capital: Virtual IntegrationDocument7 pagesSC Working Capital: Virtual Integrationarsenal GunnerNo ratings yet

- Supply Chain Information SystemsDocument57 pagesSupply Chain Information SystemsM AbdulAzizNo ratings yet

- Supplier Customer Raw Materials Value ChainsDocument44 pagesSupplier Customer Raw Materials Value ChainsniyaramakrishnanNo ratings yet

- UNIT-4 Supply Chain Management (SCM) : Key TakeawaysDocument13 pagesUNIT-4 Supply Chain Management (SCM) : Key TakeawaysThakur RudreshwarNo ratings yet

- Operations and Supply Chain Strategies HrsDocument8 pagesOperations and Supply Chain Strategies HrsNehaNo ratings yet

- Supply Chain ManagementDocument22 pagesSupply Chain ManagementPalak Sonam ParyaniNo ratings yet

- Military Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceFrom EverandMilitary Supply Chain Management: From Deployment to Victory, Mastering the Logistics DanceNo ratings yet

- Supply Chain and Procurement Quick Reference: How to navigate and be successful in structured organizationsFrom EverandSupply Chain and Procurement Quick Reference: How to navigate and be successful in structured organizationsNo ratings yet

- Introduction To Econometrics Ii (Econ-3062) : Mohammed Adem (PHD)Document83 pagesIntroduction To Econometrics Ii (Econ-3062) : Mohammed Adem (PHD)ፍቅር እስከ መቃብር100% (2)

- Safety Grating CatalogDocument22 pagesSafety Grating CatalogzhukeeNo ratings yet

- Mod 4 AdministrativeDocument8 pagesMod 4 AdministrativeElla AlogNo ratings yet

- Group 3 - Strategies For Classroom ManagementDocument25 pagesGroup 3 - Strategies For Classroom ManagementSiti AisyahNo ratings yet

- HBS Assessment Feedback Form IndividualDocument1 pageHBS Assessment Feedback Form IndividualsarithaNo ratings yet

- The Outlaw (1871)Document21 pagesThe Outlaw (1871)ViannisoNo ratings yet

- Hardness TestDocument8 pagesHardness TestlvasuthavanNo ratings yet

- RC Depron F 35Document25 pagesRC Depron F 35pccdtkNo ratings yet

- Tổng Hợp Đề Thi Và Bài Mẫu IELTS Writing Năm 2021Document38 pagesTổng Hợp Đề Thi Và Bài Mẫu IELTS Writing Năm 2021Đoan Trang Trần NữNo ratings yet

- Section 2 Digital OutputDocument1 pageSection 2 Digital Outputsamim_khNo ratings yet

- Creativity in Engineering Design ProcessDocument12 pagesCreativity in Engineering Design ProcessNurhuda HayatiNo ratings yet

- Security ManagementDocument35 pagesSecurity ManagementVanessa CarreteNo ratings yet

- What Is Multilayer Fr4 PCB Substrate MaterialDocument10 pagesWhat Is Multilayer Fr4 PCB Substrate MaterialjackNo ratings yet

- Website ErrorDocument5 pagesWebsite ErrorJosé DavidNo ratings yet

- Microsoft - Testinises.az 900.vce - Download.2021 May 25.by - Max.132q.vceDocument10 pagesMicrosoft - Testinises.az 900.vce - Download.2021 May 25.by - Max.132q.vceGowri Prasanth ChaduvulaNo ratings yet

- 8 Parts of A Business LetterDocument41 pages8 Parts of A Business LetterkennysawegNo ratings yet

- Simple Past TenseDocument3 pagesSimple Past TenseClara UbaltonNo ratings yet

- Financial Statement Analysis of Automobile Sector: Tata Motors Mahindra and MahindraDocument25 pagesFinancial Statement Analysis of Automobile Sector: Tata Motors Mahindra and MahindraAshwini MahaleNo ratings yet

- Commercial Paper: Presented by Dharani Dharan.m Vijaya Kumar S.BDocument16 pagesCommercial Paper: Presented by Dharani Dharan.m Vijaya Kumar S.Budaya37No ratings yet

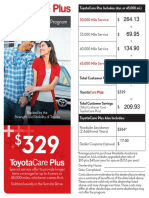

- ToyotaCare Plus CalculationDocument2 pagesToyotaCare Plus CalculationShao MaNo ratings yet

- Bunker & FW Supply ChecklistDocument3 pagesBunker & FW Supply ChecklistSampetua StmrgNo ratings yet

- Food & Beverage Service Operation: Prepared By: Mr. Lance MercadoDocument22 pagesFood & Beverage Service Operation: Prepared By: Mr. Lance MercadoLyzelNo ratings yet

- Nigeria's Agenda 21 Draft Objectives and Strategies ForDocument77 pagesNigeria's Agenda 21 Draft Objectives and Strategies ForbenNo ratings yet

- SKRAMDocument14 pagesSKRAMSebastián BoteroNo ratings yet

- R (Ax) 30 KipsDocument9 pagesR (Ax) 30 KipsRey Kevin OrtuosteNo ratings yet

- Introduction To Time and Frequency MetrologyDocument30 pagesIntroduction To Time and Frequency MetrologyJBSfanNo ratings yet

- Commonly Asked Short QuestionsDocument4 pagesCommonly Asked Short QuestionsShubham JainNo ratings yet

- Ubuntu FeistyDocument242 pagesUbuntu FeistySlamet Budi SantosoNo ratings yet

- CIT-3200 Data CommunicationDocument19 pagesCIT-3200 Data CommunicationOsama ShaqaqiNo ratings yet

- PunctuationsDocument5 pagesPunctuationsPrincess De VegaNo ratings yet