Professional Documents

Culture Documents

RPS MECH 2304 Manufacturing

RPS MECH 2304 Manufacturing

Uploaded by

Jemica DamarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RPS MECH 2304 Manufacturing

RPS MECH 2304 Manufacturing

Uploaded by

Jemica DamarCopyright:

Available Formats

MECHANICAL ENGINEERING

RPS

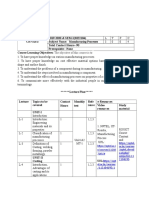

Semester Learning Plan - Rencana Pembelajaran Semester

MANUFACTURING PROCESSES

MECH 2304

Credit hours : 3 credits

Semester : 4, Spring

Pre-requisite(s) : 1. ENGR 1303 Comp. Prog. For Engr. Apps.

Instructor/Coordinator : Dr. Farid Triawan; Budi Hadisujoto, Ph.D

Teaching Team member : Mr. Aditiya Harjon, Mr. Hindra Salim,

Mr. Muhammad Idris, Mr. Reza Hadyansyah

Head of Study Program/

Course Instructor Course Coordinator

Dean*

Hindra Salim Budi Hadisujoto, Ph.D. Dr. Farid Triawan

*Faculty’ courses and/or GenEd should be approved by Dean

1. Course Description

Introduction to theory of manufacturing techniques and processes with an emphasis on metal

working processes for industrial applications. The course discusses various manufacturing processes

and forms basic skills in the operation of standard machine tools and manufacturing processes. The

instructional parts include introduction to manufacturing, metal processing, casting, metal and sheet

metal forming, conventional and non-conventional machining. The students have the chance to

operate various machines: lathe, milling, grinding, and welding.

2. Related Program/Graduate Learning Outcomes –PLOs (CPL)

Upon successful completion of this course, students will meet the following PLOs:

a) An ability to apply knowledge of mathematics, science, and engineering to solve tasks that require

mathematical analysis (PLO-01).

b) An ability to communicate effectively, both orally and in writing, in Indonesian and English (PLO-

05).

c) An ability to utilize information technology, software, computer programming, and modern

engineering equipment, which are required for mechanical engineering tasks (PLO-07).

d) An ability to identify, formulate, and solve engineering problems (PLO-08).

3. Course/Student Learning Outcomes –SLOs (CPMK)

Upon successful completion of this course, students will meet the following SLOs:

Course Learning Outcome (SLO/CPMK) related PLO

Gain the exposures to the scopes in engineering

SLO-1 PLO-1, PLO-5, PLO-8

manufacturing field

SLO-2 Ability to determine the relationship between materials

PLO-1, PLO-5, PLO-8

and the manufacturing processes

SLO-3 Comprehend the basics of manufacturing processes,

PLO-1, PLO-5, PLO-8

including cutting, forming, welding, casting, and polymer

SLO-4 Able to comprehend the non-traditional manufacturing PLO-1, PLO-5, PLO-7,

processes PLO-8

SLO-5 Able to apply basic terminologies in engineering PLO-1, PLO-5, PLO-7,

manufacturing PLO-8

4. Related Key Topics (Bahan Kajian)

a) Mechanical Behavior Testing

b) Heat Treatments of Metal Alloys

c) Metal rolling, forging

d) Metal extrusion and drawing

e) Sheet-metal forming

f) Cutting tools and fluids

g) Turning, lathe, boring, drilling, reaming

h) Milling, planning

i) broaching sawing, filing, gear manufacturing

j) Machine tool structure, vibration

k) Abrasive machining and finishing

MECH 2304 – Manufacturing Processes MECHANICAL ENGINEERING

l) Welding

m) Metrology

5. Learning Resources

a. Textbook

Manufacturing Engineering and Technology, S. Kalpakjian, S. Schmid, 6th edition, Pearson.

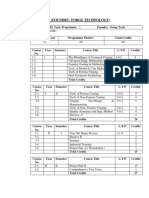

6. Course Outline

Estimated Students’ Related

Instructional

Week Topics time Learning References SLO/

strategy*

needed Experience** CPMK

1 The Structure of Metals, 150 Lecture Chapter 1, SLO-1,

Mechanical Behavior Testing: 2 SLO-2,

Tension, Compression SLO-5

2 Torsion, bending, hardness, 150 Lecture Chapter 2 SLO-1,

creep, impact, residual stresses SLO-2,

SLO-5

3 Metal alloys: their structure and 150 Lecture Chapter 4 SLO-1,

strengthening by heat treatment SLO-2,

SLO-5

4 Metal rolling, metal forging 150 Lecture Chapter SLO-1,

13, 14 SLO-2,

SLO-5

5 Metal extrusion and drawing 150 Lecture Chapter 15 SLO-1,

processes, hot and cold extrusion SLO-2,

SLO-5

6 Fundamentals of Machining, 75 + 90 Lecture + Examination Chapter SLO-1 –

Cutting tools materials and (Exam) exam 21, 22 SLO-3,

cutting fluids; Midterm Exam I SLO-5

7 Machining Process: Turning and 150 Lecture Chapter 23 SLO-1 –

hole making; lathe, boring SLO-3,

SLO-5

8 Machining Process: Turning and 150 Lecture Chapter 23 SLO-1 –

hole making; drilling, reaming SLO-3,

SLO-5

9 Machining Process: milling, 150 Lecture Chapter 24 SLO-1 –

planning, shaping; SLO-3,

SLO-5

10 Machining Process: broaching 150 Lecture Chapter 24 SLO-1 –

sawing, filing, gear SLO-3,

manufacturing; SLO-5

11 Machining center, machine tool 150 Lecture Chapter 25 SLO-1 –

structure, vibration, high speed SLO-5

machining

12 Abrasive machining and finishing 75 + 90 Lecture + Examination Chapter 26 SLO-1 –

operations, grinding, deburring; (Exam) exam SLO-5

Midterm Exam II

13 Fusion-Welding Processes: 150 Lecture Chapter 30 SLO-1 –

Oxyfuel-gas welding, arc-welding, SLO-5

Laser-beam welding, cutting

14 Fusion-Welding Processes: the 150 Lecture Chapter 30 SLO-1 –

weld joint, quality, testing, joint SLO-5

design and process selections

MECH 2304 – Manufacturing Processes MECHANICAL ENGINEERING

15 Engineering Metrology: 150 Lecture Chapter 35 SLO-1 –

Traditional measuring methods, SLO-5

Modern measuring instrument

and machines, Inspection,

Geometric Dimensioning and

Tolerancing

16 Review, Final Exam 75 + 180 Lecture + Examination SLO-1 –

(Exam) exam SLO-5

* please fill with: lecturing, group discussion, simulation, case study, project based, individual assignment, or other strategies

**Activities done by students to achieve the specified SLO, could be in the form of writing paper, FGD, survey, benchmark, practicum, case

study, taking internship, community service, etc

7. Assessment and grading system

7.1. Assessment Type

The assessment of the defined SLOs will be conducted throughout the course, and consist of:

No. Assessment type Weight (%) SLO/ CPMK measured Remark*

1. Midterm Exam I 20 SLO-1 – SLO-3, SLO-5

2. Midterm Exam II 20 SLO-1 – SLO-5

3. Final Exam 35 SLO-1 – SLO-5

4. Homeworks 15 SLO-1 – SLO-5

Class discussion and

5. 10 SLO-1 – SLO-5

participation

Total 100%

*use this column to explain any point(s) that needs to be emphasized

7.2. Grading System

Points/ Grade Description (as stated in the Academic

Grade

weight Policy)

A Excellent/ Memuaskan 4 All SLOs have been fulfilled in an excellent way

B Very Good/ Sangat Baik 3 All SLOs have been fulfilled in a very good way

C Satisfactory/ Baik 2 All SLOs have been fulfilled in a satisfactory way

D Sufficient/ Cukup 1 All SLOs have been fulfilled in a sufficient way

Have not been fulfilled/

F 0 All SLOs have not been fulfilled

Tidak lulus

To successfully pass this course, students must achieve a minimum final grade of C

8. Regulation

Refer to the SU Student Handbook, minimum attendance rate is 75% of the sessions, failure to

fulfill this requirement will prohibit the student to sit in the final exam. Lecturer has the right to

make a discretion for any special circumstances;

Any kind of cheating act during exam and/or plagiarism will not be accepted. Student will get ‘F’

for the respective course and must retake the course in the following semester;

Students are required to read the textbook on the prescribed topics prior to the scheduled

lecturing session;

Late submission of an assignment will not be accepted regardless of the reasons provided;

MECH 2304 – Manufacturing Processes MECHANICAL ENGINEERING

Writing style; to ensure all assignment, quizzes and exams are graded, students are responsible to

write readable writing;

All examination solutions are to be either written on spaces provided on the original examination

paper or on A4 paper.

MECH 2304 – Manufacturing Processes MECHANICAL ENGINEERING

You might also like

- Introduction To Welding Chapter 1 Welding FundamentalsDocument14 pagesIntroduction To Welding Chapter 1 Welding FundamentalsBlakeNo ratings yet

- CBLM Core Smaw nc1Document57 pagesCBLM Core Smaw nc1MANPOWER ORMOC100% (5)

- Stress Young Modulus and Thermal Expansion Coefficients of SteelsDocument51 pagesStress Young Modulus and Thermal Expansion Coefficients of Steelswili_ab8040No ratings yet

- Abs - Approved Welding Consumables Shielded Metal Arc WeldingDocument59 pagesAbs - Approved Welding Consumables Shielded Metal Arc Weldinggeorgekc77No ratings yet

- Engineering Mechanics I: Statics & Strengths of Materials CEE 223 Engineering Fluid MechanicsDocument8 pagesEngineering Mechanics I: Statics & Strengths of Materials CEE 223 Engineering Fluid MechanicsClarence De LeonNo ratings yet

- Production TechniquesDocument2 pagesProduction TechniquesVELUGUBANTLA AALAPNo ratings yet

- MMEE 313 - Elements of Pyrometallurgy Study GuideDocument6 pagesMMEE 313 - Elements of Pyrometallurgy Study GuideResego PhiriNo ratings yet

- ME2201 Manufacturing Technology-IDocument9 pagesME2201 Manufacturing Technology-IHiru Purushothaman HirudayanathanNo ratings yet

- The Objective of This Course Is To: Manufacturing ProcessesDocument5 pagesThe Objective of This Course Is To: Manufacturing ProcessesKARAMTOTHU GANESH NAIK (N160423)No ratings yet

- Jouf University Department of Civil Engineering: Mfelmongy@ju - Edu.saDocument7 pagesJouf University Department of Civil Engineering: Mfelmongy@ju - Edu.saAhmed MohammedNo ratings yet

- ME F219 - Manufacturing Processes-Handout (4)Document3 pagesME F219 - Manufacturing Processes-Handout (4)akumarvarshney104No ratings yet

- Metal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyDocument4 pagesMetal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyFikadu EshetuNo ratings yet

- ME F219 - Course Handout - 2022-23Document3 pagesME F219 - Course Handout - 2022-23YERRAMILLI SRIVATSAVNo ratings yet

- Metal Forming Process 2 2 0 3 Prerequisite: - Course ObjectiveDocument3 pagesMetal Forming Process 2 2 0 3 Prerequisite: - Course ObjectiveB. selvababuNo ratings yet

- ME 503-N Manufacturing TechnologyDocument4 pagesME 503-N Manufacturing Technologyhrana287No ratings yet

- B Tech 4th SemDocument21 pagesB Tech 4th SemKamurti Ajay KumarNo ratings yet

- 4TH Sem Civil Final SyllabusDocument24 pages4TH Sem Civil Final SyllabusAMIT KUMARNo ratings yet

- Production Engineering: Teaching ScheduleDocument2 pagesProduction Engineering: Teaching ScheduleSantosh SangleNo ratings yet

- Manufacturing Technology 2Document2 pagesManufacturing Technology 2Jeremaiah HaylingNo ratings yet

- Manufacturing TechnologyDocument7 pagesManufacturing Technologytrinkle saindaneNo ratings yet

- Me0021 Modern Manufacturing TechniquesDocument6 pagesMe0021 Modern Manufacturing Techniquesgopi sanNo ratings yet

- RMK Group A4 PPT MT-I (UNIT-I)Document82 pagesRMK Group A4 PPT MT-I (UNIT-I)Rajmchz100% (1)

- Production and Industrial EngimeeringDocument47 pagesProduction and Industrial Engimeeringrathish14uNo ratings yet

- MET 204 Manufacturing ProcessDocument8 pagesMET 204 Manufacturing Processrejeesh_rajendranNo ratings yet

- Materials Joining TechnologyDocument4 pagesMaterials Joining Technologykanna nrNo ratings yet

- St. Michael College of Engineering & Technology: Course Plan (Theory)Document5 pagesSt. Michael College of Engineering & Technology: Course Plan (Theory)MECHANICAL SMCET100% (1)

- Manufacturing Tech SyllDocument4 pagesManufacturing Tech SyllJagjit SinghNo ratings yet

- Course plan-21-22-O-SMM - NO BTOBDocument9 pagesCourse plan-21-22-O-SMM - NO BTOBkousikkumaarNo ratings yet

- 3rd Sem Mechanical EnggDocument22 pages3rd Sem Mechanical EnggTabish SamarNo ratings yet

- Computer Integrated ManufacturingDocument51 pagesComputer Integrated ManufacturingAnonymous VDnLHNG7QQNo ratings yet

- Course File FormatDocument18 pagesCourse File FormatUzair BukhariNo ratings yet

- Lesson Plan: Institute of Space TechnologyDocument4 pagesLesson Plan: Institute of Space TechnologyGhayas UdinNo ratings yet

- MEC207Document4 pagesMEC207Senthil Muthu Kumar TNo ratings yet

- University of Engineering & Technology, Taxila Department of Industrial EngineeringDocument2 pagesUniversity of Engineering & Technology, Taxila Department of Industrial EngineeringHassanZameerNo ratings yet

- B.tech, MME, Metallurgical, 6th Sem, 2018-19 Batch 6th SemDocument20 pagesB.tech, MME, Metallurgical, 6th Sem, 2018-19 Batch 6th SemAnand Arya0% (1)

- M.Tech (Foundry-Forge Technology)Document8 pagesM.Tech (Foundry-Forge Technology)JagdishNo ratings yet

- fnlSESSION PLAN 2-GDocument3 pagesfnlSESSION PLAN 2-GButz GhanulNo ratings yet

- 15UME302 Manufacturing Technology - I L T P C 3 0 0 3Document4 pages15UME302 Manufacturing Technology - I L T P C 3 0 0 3Kumareshg GctkumareshNo ratings yet

- ME-220 Manufacturing Processes I Lab Workbook October 2022Document64 pagesME-220 Manufacturing Processes I Lab Workbook October 2022Aayan Ahmed KhanNo ratings yet

- EE 528 (PHY 537) - Semiconductor Device Fundamentals - Nauman ButtDocument4 pagesEE 528 (PHY 537) - Semiconductor Device Fundamentals - Nauman ButtZeeshan RazaNo ratings yet

- Justification 3Document129 pagesJustification 3Naveen SSNo ratings yet

- Sulaiman Afridi 379-2019 Thermo Final - CompressedDocument25 pagesSulaiman Afridi 379-2019 Thermo Final - CompressedSulaiman AfridiNo ratings yet

- Production Syllabus 2017-18-1Document71 pagesProduction Syllabus 2017-18-1Akankshya MishraNo ratings yet

- Manufacturing Engineering Guide BookDocument2 pagesManufacturing Engineering Guide BookGiridharan SharmaNo ratings yet

- Proposal Ready 4 (Dr. Aneela Wakeel) RevisedDocument15 pagesProposal Ready 4 (Dr. Aneela Wakeel) RevisedIrfanButtNo ratings yet

- Birla Institute of Technology & Science, Pilani Work Integrated Learning Programmes Digital Learning Part A: Content DesignDocument5 pagesBirla Institute of Technology & Science, Pilani Work Integrated Learning Programmes Digital Learning Part A: Content Designkansal611No ratings yet

- Hindusthan College of Engineering and Technology: AircraftDocument12 pagesHindusthan College of Engineering and Technology: AircraftKathirvel KNo ratings yet

- Met&mat - Me (Welding TechnologyDocument34 pagesMet&mat - Me (Welding TechnologyDivas AgarwalNo ratings yet

- Production Engineeing PDFDocument64 pagesProduction Engineeing PDFBhat AamirNo ratings yet

- Ae 214 Module 2Document33 pagesAe 214 Module 2kira arashiNo ratings yet

- Course Outline MPIDocument2 pagesCourse Outline MPIgirma workuNo ratings yet

- B.SC. Mechanical Engineering Course Skeleton Manufacturing Processes Muhammad Amjad 2010 3 Sept. 2011-Jan. 2012 3 1 Books and ReferencesDocument1 pageB.SC. Mechanical Engineering Course Skeleton Manufacturing Processes Muhammad Amjad 2010 3 Sept. 2011-Jan. 2012 3 1 Books and ReferencesAmin FarukiNo ratings yet

- Weld Carbon Steel Plate Performing Groove Welding On Carbon Steel PlatesDocument3 pagesWeld Carbon Steel Plate Performing Groove Welding On Carbon Steel Platesveronica_celestial100% (1)

- Syllabus Copy For StudentsDocument2 pagesSyllabus Copy For StudentsAcomplishing DreamsNo ratings yet

- Parts of A Competency-Based Learning Material PackageDocument19 pagesParts of A Competency-Based Learning Material PackageRoedfrey OrtizNo ratings yet

- GNEG 393: Approved byDocument11 pagesGNEG 393: Approved byMohit NarayanNo ratings yet

- GNEG 393: Approved byDocument11 pagesGNEG 393: Approved byMohit NarayanNo ratings yet

- GNEG 393: Approved byDocument11 pagesGNEG 393: Approved byMohit NarayanNo ratings yet

- ME8491-EMM - by WWW - LearnEngineering.inDocument92 pagesME8491-EMM - by WWW - LearnEngineering.inMANOJKUMAR RAJENDRANNo ratings yet

- Thixoforming: Semi-solid Metal ProcessingFrom EverandThixoforming: Semi-solid Metal ProcessingGerhard HirtNo ratings yet

- Electrochemical Surface Modification: Thin Films, Functionalization and CharacterizationFrom EverandElectrochemical Surface Modification: Thin Films, Functionalization and CharacterizationNo ratings yet

- ALS CopperDocument2 pagesALS Copperfachrul.mucharam.ukNo ratings yet

- JP002 Tin Whiskers TheoryDocument30 pagesJP002 Tin Whiskers Theorydemolinux100% (3)

- Panasonic SwitchesDocument16 pagesPanasonic SwitchesMohamed MostafaNo ratings yet

- Explanatory Notes For BC1-2008Document14 pagesExplanatory Notes For BC1-2008geoanburajaNo ratings yet

- Ductile Iron SpecificationsDocument12 pagesDuctile Iron SpecificationsDouglas BooyensNo ratings yet

- ECS-012 Condensate Drain Pipe (G.I Pipe) - SeAHDocument55 pagesECS-012 Condensate Drain Pipe (G.I Pipe) - SeAHRay WanNo ratings yet

- Carbide GradesDocument51 pagesCarbide GradesRicardo BravoNo ratings yet

- Aluminium's Corrosion Resistance - Aluminium DesignDocument7 pagesAluminium's Corrosion Resistance - Aluminium DesignCarlos LuNo ratings yet

- Different Types of Sand Used in 3d PrintingDocument4 pagesDifferent Types of Sand Used in 3d PrintingAni AniNo ratings yet

- DIN-EN-ASTM Material - Comparsion PDFDocument1 pageDIN-EN-ASTM Material - Comparsion PDFDaniel MilosevskiNo ratings yet

- R.Ramakrishnan.: Ex-Scientist - Merado. Asnt Level IiiDocument21 pagesR.Ramakrishnan.: Ex-Scientist - Merado. Asnt Level IiiMadjid OUCHENE100% (1)

- DL-T 5358-2006 Technical Code For Anticorrosion of Metal Structures in Hydroelectric and Hydraulic EngineeringDocument43 pagesDL-T 5358-2006 Technical Code For Anticorrosion of Metal Structures in Hydroelectric and Hydraulic Engineeringsaliyarumesh2292No ratings yet

- B849 Galvanizado ENVIAR PDFDocument3 pagesB849 Galvanizado ENVIAR PDFBraulio Carvajal100% (1)

- A 983 - A 983M - 01 - Qtk4my9botgzts1sruqDocument7 pagesA 983 - A 983M - 01 - Qtk4my9botgzts1sruqhoangNo ratings yet

- Epp Chapter 5.3.1 Grade 6Document24 pagesEpp Chapter 5.3.1 Grade 6John Brad Angelo LacuataNo ratings yet

- Stem B RocksDocument3 pagesStem B RocksarlesjohngabrielmirasolNo ratings yet

- Materials Technical Specification.: Stainless SteelDocument6 pagesMaterials Technical Specification.: Stainless SteelMario TirabassiNo ratings yet

- MCQ 2Document36 pagesMCQ 2bavly waidyNo ratings yet

- Tack Welding ProcedureDocument3 pagesTack Welding Procedureiftekhar ahmed50% (2)

- CODO UNIVERSAL HartrolDocument15 pagesCODO UNIVERSAL HartrolJohana DelgadoNo ratings yet

- TIAC Guide English 2013-Section-02Document3 pagesTIAC Guide English 2013-Section-02tekcellentNo ratings yet

- Weld SolidificationDocument10 pagesWeld SolidificationRodrigo PrinceNo ratings yet

- A Review of Friction Stir Welding Pin ProfileDocument19 pagesA Review of Friction Stir Welding Pin Profilefaris yusofNo ratings yet

- Wps For Ss 304Document3 pagesWps For Ss 304Sajit PillaiNo ratings yet

- Titanium and Titanium AlloysDocument24 pagesTitanium and Titanium AlloysGuilherme FranzoiNo ratings yet

- Automation & ControlDocument107 pagesAutomation & ControlAlpesh Shah100% (1)

- 750 HSS enDocument20 pages750 HSS enPascu Tiberiu CiprianNo ratings yet