Professional Documents

Culture Documents

Jsa 54 Installation of Underground Drinking Water Piping, Irrigation Piping, Utility Water Piping, Testing With Valve Installation

Jsa 54 Installation of Underground Drinking Water Piping, Irrigation Piping, Utility Water Piping, Testing With Valve Installation

Uploaded by

Salah Abd Eldayem0 ratings0% found this document useful (0 votes)

196 views31 pagesJSA for Aramco project

Original Title

JSA 54 INSTALLATION OF UNDERGROUND DRINKING WATER PIPING,IRRIGATION PIPING,UTILITY WATER PIPING,TESTING WITH VALVE INSTALLATION

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJSA for Aramco project

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

196 views31 pagesJsa 54 Installation of Underground Drinking Water Piping, Irrigation Piping, Utility Water Piping, Testing With Valve Installation

Jsa 54 Installation of Underground Drinking Water Piping, Irrigation Piping, Utility Water Piping, Testing With Valve Installation

Uploaded by

Salah Abd EldayemJSA for Aramco project

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 31

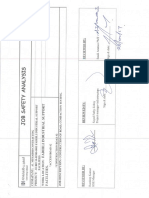

JOB SAFETY ANALYSIS

WORK LOCATION: FADHILI PF-1

JOB DESCRIPTION: INSTALLATION OF UNDERGROUND DRINKING WATER PIPING, IRRIGATION PIPING, UTILITY WATER PIPING &

‘TESTING WITH VALVE INSTALLATION

PREPARED BY: REVIEWED BY: REVIEWED BY:

i

(Name & Sign) Amr Ahmed : Saudi Afamco PMT

Randeep Kumar Construction Manager

HSE manager wr

Sign & date: v? Sign & date:

/ Yn

/

P.P.E REQUIREMENTS PLANT, EQUIPMENT & TOOLS FOR JOB TAGGING & SIGNS: ep

“Check” “Check BY” “Check” “Check”

Safety Harness | BQ scBa CH] eadaer | BQ | Asphatt cutter | J | Men Working Above | Msbs’s Q

suticue |[O CO] maroc | 6) wien [| parrtermen | BQ oO

‘Steel Capped Boots | [R]| Air Purifying Respirator | [] Shovel & oO Flagging @ Procedures @

Hard tat | BR] Confined Space Harness | [| welding tachine | C}| —nacknoe | C1] rersonat Locks | | worktustructons | 62

Dark Safety Glasses |] Gloves-Ppve | 1] Compactor | BY | Power source | £] | Personat Danger Tags | CJ} not workrermit | BQ

Clear Safety Glasses | [RJ] Gloves —Htynex cNitie) | Drill BI] crane | C1] ontorservice tags | 1} tsotation Permit | CJ

Gozgles Ly] ctoves-teather niggers | | ringer | BQ] ewe | | tntormacion tags | 1 | excavation permie | Ba

Face Shield B oOo Scaffold o Fans oOo Fork lift g rea oO

Sunscreen = |] D1] Pireestinguister | | scisoruiee | O oO Oo

isachig Pro Q O| meena || sectenme | 6 oO a

Ww

HAZARD PROMPT - “Checkbq”. Identify the job hazards and assess the RISK personnel may be exposed to before safe guards are implemented:

BINA Ona Bawa INA Ona INA BINA

Radiation

lLow ILow Dow Fhe Dow Low | SMF or Low

rms | Fg | vom |G rome | | me (ee | ts [Ete | noe (Bh | sme | en

bi righ i High High High Daten

vA | Height | BINA Bi GNA Bi wa nN

i ILow yw Low Low | Rotating | Flow JLow at | EILow

Chemical | Pevied ted | °° | Bea | Pr | Tied | Equipment | lvied | Petvarition | Fiyrog | aeument | Far

igh is Ohigh Ohigh Bien figh Ohigh

vA vA Na Fra DNA vA Bina

JLow ow Low wv | Moving ow | not/coa | Siow | |, Low

Tools | ey | Depth fay | Vibration | FOWL ust ct | enim Obj, Lighting

Hi Grigh sigh igh

Eh

vA INIA vA vA Ona

Clow Low tow | sips |Ehtow | citing yw | Overhead

Gawes Timea | Welant fed nieiae) Med | Trip Med | Kquipment ed | hazards

i igh igh Baieh High Dtign

* Likelihood values based on table $4-1 criteria,

‘** Hazard Severity / Consequence values based on Table $4-2 criteria.

‘Table $4-1 Likelihood Categories

Description

Level Frequency

Very Low _| Never heard of in the industry

Low ‘Some incidents have occurred in the industry

‘Medium | Incident has occurred in Saudi Aramco

High Has occurred several times in Saudi Arameo

Very High | Has occurred several items in facility, proponent organization or project.

Level | Frequency Description

People: No injury or damage to health

a| | Veptaw Environment: No or slight effect/damage within a system

Econor ight damage and/or operational impact < $10K

Reputation: No impact and or public concern

People: Minor employee injury or damage to health not affecting work performance nor requiring treatment beyond first aid

i i Environment: Minor contamination within fence; no permanent effect

Economic: Equipment damage and/or operational impact < $100K

it impact and no public concern. Public or media awareness may exist

People: Serious employee injury or health effect that can result in lose time injury, restricted work or irreversible health

effects

C Medium Environment: Localizes effect within the plant fence with limited damage and spontaneous recovery

Economic: Equipment damage and/or operational impact < $1 MM

Reputation: Regional public/media attention, causing considerable reputation impact

People: Single employee fatality or permanent disability, or some impact on third party

7 a Environment: Severe damage to be ext restored with no significant lasting consequences

igh

$10 MM.

: Multiple employee or third party fatalities

EB | VeyHigh Environment: environmentally sensitive area(s) w/ significant consequence and loss

Economic: Equipment damage and/or operational impact > $10 MM

Reputation: Reputation: International public/media attention, with severe impact

Job Step Task Hazard / Risk Risk | Control Methods and Monitoring a i

Describe the job step by | What are the hazards with each | SIS What hazard safe guards will be use? ee i

step? {job step? @_ | How will the effectiveness of the controls be determined? | S°° Li

(Inspection & ongoing monitoring)

‘Mobilization of manpower a) Lack of site awareness i nto new workers prior to

and equipment on the site start any work at field.

ii, Train all employees on traffic management plan and

requirements,

b) Interaction with Light & it 80 km on temporary access road

Heavy vehicles femnal project access road 40 km/hr and AMC site and

yydown 20km/hr.

4D_| ii, Head lights to be turn on when on the move. 3c | AMC

c)Adverse road condition

4) unauthorised entry

Hazard lights to be turn on when vehicle is temporary

ipped along the side of the highway.

iv) No reverse parking allowed all equipment’s and

;chicles to be parked “in” and “out” system.

Not to take any unwanted risk during shifting.

Plan ahead for the route and always be alert for any

consequences,

Get a map and use alternative route for better road

condition,

Presence of mind while behind the wheel & expect the

unexpected, Make eye contact with other commuters.

v. Vehicle/equipment check pre-start, First aid kit,

warning triangle, spare tire, jack & communication

i, Barricade the area with hard barricade.

Place safety warning signs in the area. A

2 | Delivery of materials:

a) Unsecured load

b) Road condition

i, Inspect all binding equipment’s and ensure all are in

good condition.

i, Load shall be secured properly at the starting point.

3c 1c

©) Over speeding i. Driver should follow the required speed limit in the

road as well as on the construction si

ii, Escort to be provided to the trailers.

3. | Welfare 2) Heat stress i. Cool drinking water station shall be available with

regular water supply.

b) Sanitary waste let facilities with proper disposal of sanitary waste.

3C | ii. Hand wash facilities, Dis

©)General waste

No proper prayer area

€) Improper parking

i, General waste to be collected in designated area and

disposed properly.

i,Prayer area shall shall be provided with proper signs. No

prayer allowed in non-designated areas in site.

i.Proper parking area shalll be provided.

AMC.

4 | Remoteness

a)No Proper Transport

+b) Venomous insect or snake

bite,

©) Vehicle stuck

d)Sand storm

©) Heat stress

f) Alone worker

3c

i.No employees are allowed to walk outside the site,

supervisor to arrange transportation as needed,

i, Awareness to the employees to be far from the snakes

and updated emergeney contact numbers which include

AMC medical clinic and ambulance to use in case of

emergency.

ii. Train people & standard for towing & removing

stuck vehicle,

i, Use dust mask and keep vehicle standby.

i, Ample cold water storage should be available, drink

plenty of water.

ii Proper shade or vehicle standby.

i.Buddy system to be followed.

2c

AMC

Surveying A\

a) Venomous insect or snake

bite.

b)Protruding rebar

©) Tools in poor condition

Flying Objects

3B

i, Awareness to the employees to stay away from the

snakes and updated emergency contact numbers

which include AMC medical clinic and ambulance

to use in case of emergency shall be provided to

the employee.

. Use dedicated area for resting

Do not disturb the existing fauna by hand if any

use wood stick.

i, After marking and installing rebar put rebar cap.

spect tools and monthly colour code before use.

‘Wear hand gloves epoxy (cotted)

i, Wear eye protection

3A

AMC

"| Manual handling

a) Improper technique

b)Strain

©)Sharp edges

3B

i

Use proper lifting technique don’t bent your back.

Use enough man power for heavy load.

Work rotation or rest to be provided at regular

intervals as per the heat stress plan,

‘Wear cut resistant gloves.

Use minimum 3 people for long pipes.

Be aware of pinch points do not work on pipes.

Do not throw materials.

2c

AMC

Toading and Unloading of

materials at

Use of forl

truck/trailer

a) Stored Energy

b)No proper access

c)Damage lifting gears

4) Improper position of

equipment (boom truck)

©) Unauthorised entry

f) Wind speed

2)Swinging of suspended load

3c

Inspect load prior to loosening holding straps.

Do not remove the straps if the load has shifted.

Use ladder to access into the trailer bed and

‘maintain three points of contact when climbing the

ladder.

Do not move around on top of load.

. Use certified lifting gear, do not exceed the

. Position the boom truck should be in properly

compacted surface.

. Outrigger to be used properly with outrigger pad.

Determine the safe work load,

Use SA approved rigger.

Barricade the area, proved warning signage and

flagman,

No lifting activities if wind speed is higher than

32kmv/hr.

. Use tag line to control the load.

. Never stand or walk under suspended load.

._No lifting in winds higher than 32knvh.

3A

AMC

© Use of forklift

+h) Unauthorised riding of

forklift

i) Protruding Elevated forks

{j) Overload

1) Blind spots

3D

Only SA certified operators shall operate for

Personnel other than the operator shall be prohibited

from riding.

Do not use forklift if materials is not in wooden

pallets.

iv. Forks shall not be left in the up position while

forklift is unattended,

Forklift shall not be used beyond their rated

capacity,

Avoid over stacking of the load.

Load forklifts only when moving on a level surface

or uphill on an incline,

Do not allow any person to stand or walk under the

elevated forks, whether loaded or unloaded.

Reverse alarm to be checked by the operator prior to

run the forklift

Forklift shall not be left running while unattended,

. Trained Flagman shall be present.

Move reverse if the load obstructing the front view.

gman & operator shall be trained of blind spot of

the vehicle

PWAS system to be installed & make sure it is

functioning properly for earth moving

equipment’

. Trained flagman shall be available while reversing

Do not store materials inside or edge of the

excavati

. Reduce or avoid reversing as much as possible

|. Use dedicated parking areas

Do not use unauthorised area for praying,

._ Provide & use pedestrian walkways.

3A

AMC

dN

8 | Road closing or diverting

Access Road.

a) Incomplete barrication &

signages

b)Blind spots

¢) Vehicle accident

4)Deep excavations

3B

i, Provide proper barrication, signages & identify

detour.

ii, Area to be identified with proper lights during night

(ol

Driver/operator to aware about road closing or

sion during tool box talk.

iv. Follow posted speed limit.

v. Proper coordination & communication with direct

supervisor.

i, Flagman & operator shall be trained of blind spot of

the vehicle

PWAS system to be installed & make sure it is

functioning properly for earth moving

equipment’s,

‘Trained flagman shall be available while reversing

Do not store materials inside or edge of the

excavation,

Reduce of avoid reversing as much as possible

|. Use dedicated parking areas

. Do not use unauthorised area for praying,

Provide & use pedestrian walkways.

. Trained flagman to be assigned for the road

closing/diversion area

ii, Area to be identified with proper signages &

barrications|

ional lights,

barrication, signages, wherever diverting or

closing.

. Excavation shall be done as per the approved jsa.

. Deep excavation near y the road shall be done

according to the approved jsa.

3A

AMC

Provide lights during night

v. Follow posted speed limi

Knows about updated logistic plan

fear seat le driving

Mechanical excavation

a) Underground Services

b)Movement of machinery /

equipments.

©)Man- machine Interfacing

4D

vi.

. Assafe and adeq

AA joint site inspection shall be done by civil

engincer, foreman & HSE representative prior to

start excavation,

Excavation has to be done based on the drawing

done by qualified civil engineer,

iii, Relevant permit to be obtained prior to start of

excavation.

Underground services to be identified and start the

method, no mechanical

excavation within a proximity of 3 meters from the

underground services.

. All heavy equipment shall be equipped with reverse

alarm, revolving warning light and PWAS.

Alll equipment / vehicles shall be inspected by

IC/Aramco and provided with specific sticker,

I be carried out by the operator

tain daily inspection check list.

iv. Trained flagman wearing reflective jacket shall be

assigned with all heavy equipment.

1¢ access to the site shall be

maintained at all time by demarking and

barricading with relevant warning signs and

hazard warning lights.

Heavy equipment shall not be operated within 6 ft

of any excavation.

- Keeping safe distance § meter away from the

vehicle movement or shall not be present in the

radius of 5 meter,

Should provide pedestrian walkway

Designated parking area.

4c

AMC

Q

‘Machine “Machine

Interfacing

€) Incompetent (Not trained

Operator)

1) Blind Spot

4D

Proper two-way access to be provided.

i. Flagman shall control on intersection roads,

in & out system

the excavation soil & reduce reversing,

i. Operator should be Aramco certified and shall have

undergone defensive driving training,

Flagman and the operator shall be trained before

starting the activity & fully aware of the blind spot

of the vehicle.

No heavy trucks are allowed at least Smeter from

the edge of the excavation.

4c

AMC

)Cave in and soil collapse

h)Open excavation

4D

All heavy equipment and vehicles shall maintain a

safe distance (minimum of 1.8 m} from the edge

of excavation,

Site engineer and safety representative is

responsible for proper Sloping, benching and

shoring to be applied as applicable,

Daily excavation checklist shall be maintained to

ensure all precautions are being taken.

Excavated material to be kept away minimum 2 feet

from the edge of excavation, And excavated soil to

be removed/ disposed regularly to avoid bulk

accumulation,

Excavated area must be barricaded adequately by

‘means of hard barricades for excavation more than

1.2-meter-deep warning signs and hazard warming

AMC

i) Loose material on the edge

of

the excavation

{) Improper access

4D

flash Tight shall be provided.

Barriers shall be at least 1.5 meters back from the

edge of excavation and be a minimum of 1.1

No materials are allowed on the edge of the

excavation,

Make sure at least | meter walkway around the lift

station

. Make sure no obstruction or materials on the

walkway.

Material and tools to be stored only in designated

area,

No people are allowed inside the excavation while

equipment is working

Shoring, sloping or benching shall be adapted to

protect cave in based on the approved ja,

iv. No traffic or heavy equipment movement allowed at

least Smeter from the edge of the excave

Supervisor to make sure no loose materi

the edge of the excavation & slop shall be

maintain 1:1.5 m. sloping as per class-c soil.

Proper Access/egress shall be provided at every 25

feet.

Do not obstruct the access with materials & debs

Access steps must be identified & with hand ri

system,

AMC

10 | Installation of pipe, valve,

flanges & fittings.

a) Inadequate working space

b)Strain

©)Sharp edges

4)Protruded objects

e) Improper access

3B

Keep work area free from obstructions & maintain

housekeeping,

Use at least two or three-man power for material

handling,

Work rotation or rest to be provided at regular

intervals.

Wear cut resistant gloves. (epoxy coted gloves)

Use proper hack saw blade with frame.do not use

Without frame.

All protruded objects to be capped or from the

roofwall to be identify.

i. Make sure at least 1 meter clear access for the work

area.

ii. Keep work area free from obstructions & maintain

housekeeping.

. Maintain both side of the duct bank as a proper

working space.

2c

AMC

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Rigger III Certification Study Guide 2019Document45 pagesRigger III Certification Study Guide 2019Salah Abd Eldayem81% (26)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Rigger III Cerification Test Study GuideDocument20 pagesRigger III Cerification Test Study GuideSalah Abd Eldayem89% (18)

- Aramco HSE ExamDocument66 pagesAramco HSE ExamSalah Abd Eldayem89% (9)

- Jsa 13 Rev-003 Steel Fixing, Cutting, Bending WorkDocument13 pagesJsa 13 Rev-003 Steel Fixing, Cutting, Bending WorkSalah Abd EldayemNo ratings yet

- Jsa 53 Installation of Potable Water Piping, Testing With Valve InstallationDocument30 pagesJsa 53 Installation of Potable Water Piping, Testing With Valve InstallationSalah Abd EldayemNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Jsa 32 Rev 03 RTR Pipe Installation, Loading & Unloading of Pre Casted Valve ChambersDocument39 pagesJsa 32 Rev 03 RTR Pipe Installation, Loading & Unloading of Pre Casted Valve ChambersSalah Abd Eldayem100% (1)

- دهان مؤخر انتشار الحريق صناعيDocument2 pagesدهان مؤخر انتشار الحريق صناعيSalah Abd EldayemNo ratings yet

- Environment Awareness PostersDocument3 pagesEnvironment Awareness PostersSalah Abd EldayemNo ratings yet

- MSDS Fire Retardant Solvent BasedDocument4 pagesMSDS Fire Retardant Solvent BasedSalah Abd EldayemNo ratings yet

- Excavation JSADocument4 pagesExcavation JSASalah Abd EldayemNo ratings yet

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- Fabrication Work Shop RADocument4 pagesFabrication Work Shop RASalah Abd Eldayem67% (3)

- Erection of Tanks JSADocument4 pagesErection of Tanks JSASalah Abd EldayemNo ratings yet

- Rescue Plan SRS 1Document4 pagesRescue Plan SRS 1Salah Abd EldayemNo ratings yet

- Civil Works JSADocument3 pagesCivil Works JSASalah Abd EldayemNo ratings yet

- Hawiyah Gas Plant Expansion Project: Don't Forget Your Water IglooDocument1 pageHawiyah Gas Plant Expansion Project: Don't Forget Your Water IglooSalah Abd EldayemNo ratings yet

- Heat Stress Prevention Campaign Poster - 2019Document2 pagesHeat Stress Prevention Campaign Poster - 2019Salah Abd Eldayem100% (1)

- Jsa No 91 Rev-06 Installation of Ohtl Conductor and Optical Ground WireDocument18 pagesJsa No 91 Rev-06 Installation of Ohtl Conductor and Optical Ground WireSalah Abd EldayemNo ratings yet

- JSA 51 Approved - Electrical PVC Conduit Direct in Slab & Underground Direct BurialDocument33 pagesJSA 51 Approved - Electrical PVC Conduit Direct in Slab & Underground Direct BurialSalah Abd EldayemNo ratings yet

- Jsa 86 Rev 02 Sand Blasting PDFDocument21 pagesJsa 86 Rev 02 Sand Blasting PDFSalah Abd EldayemNo ratings yet

- Jsa 57 Rev-003 Erection of Peb BuildingsDocument33 pagesJsa 57 Rev-003 Erection of Peb BuildingsSalah Abd Eldayem100% (1)

- Jsa 43 RTR HydrotestDocument14 pagesJsa 43 RTR HydrotestSalah Abd EldayemNo ratings yet

- Jsa 16 Rev-002 Carpentry WorkDocument13 pagesJsa 16 Rev-002 Carpentry WorkSalah Abd EldayemNo ratings yet

- Jsa 46 Rev 04 Erectioning, Assembling Tower & Gantry StructuresDocument9 pagesJsa 46 Rev 04 Erectioning, Assembling Tower & Gantry StructuresSalah Abd EldayemNo ratings yet

- Jsa 42-Electrical Duct Bank InstallationDocument34 pagesJsa 42-Electrical Duct Bank InstallationSalah Abd Eldayem100% (2)

- Jsa 38-Construction of Road, Compaction TestDocument11 pagesJsa 38-Construction of Road, Compaction TestSalah Abd EldayemNo ratings yet

- Jsa 14 Rev 02 Scaffolding Erection & DismantlingDocument15 pagesJsa 14 Rev 02 Scaffolding Erection & DismantlingSalah Abd EldayemNo ratings yet

- Rigger-Lll Aramco NotesDocument55 pagesRigger-Lll Aramco NotesSalah Abd Eldayem100% (5)

- Jsa No.105 Rev 04 Installation & Commissioning of ElevatorDocument35 pagesJsa No.105 Rev 04 Installation & Commissioning of ElevatorSalah Abd Eldayem0% (1)

- 001 - JSA For Back Filling - TCF AreaDocument5 pages001 - JSA For Back Filling - TCF AreaSalah Abd Eldayem100% (2)