Professional Documents

Culture Documents

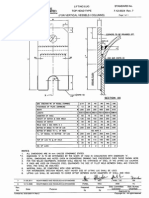

IBR - 1950 - Reg. 366

IBR - 1950 - Reg. 366

Uploaded by

Vijay ParmarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IBR - 1950 - Reg. 366

IBR - 1950 - Reg. 366

Uploaded by

Vijay ParmarCopyright:

Available Formats

Message from Reg. 366

Chairman of Central

Boilers Board Determination of Working Pressure

•

About Central Boilers a) Shells:– The maximum working pressure of shells shall be determined by the

Board following formula:-

•

History of Indian Boiler 2 f E (T -.03)

Regulations W. P. =

• D + T - .03

Foreword

where,

•

Contents Chapter

T is thickness in inches.

Wise

D is maximum internal diameter in inches.

• W. P. is Working pressure in lbs./sq. inch.

Contents Regulation F is maximum permissible working stress as prescribed in regulations 271 or 350,

Wise whichever is applicable.

• E is Efficiency of longitudinal riveted seam as given in Regulation 177.

List of Amendments is Efficiency factor for fusion welded shells as given in table below.

• is 1.00 for seamless shells or shells made from seamless tubes.

Indian Boilers is Efficiency of ligaments between holes or opening in shell expressed as a fraction

Act 1923

• Class Efficiency factor E

Ibr Forms I. 0.90

• 0.75 if welded from both side

Home II.

0.50 if welded from one side only.

• III. 0.45

Search

• Minimum thickness of shells shall be as given in table below:-

Help

• Minimum

Contact Us

Internal diameter

Classification thickness

inches.

inch

Fusion welded Class I 1/4

Upto and including 24 1/4

Fusion welded Class II and Class

Over 24 and upto & including

III, and shells other than fusion 5/16

36

welded shells.

Over 36 3/8

Where steels are intended for service at temperatures in excess of 700°F this shall be

so stated and silicon contents shall be not less than 0.10 per cent or alternatively, the

material must pass the ‘Proof test for creep quality of carbon steel plate of boiler

quality as in Appendix D.

Compensation for openings in shells:- Where the major axis or diameter of any hole cut

in cylindrical part of the shell is greater than 2 ½ times the thickness of the shell plate

plus 2 ¾ inches, compensation shall be provided.

The sectional area to be compensated measured in the plane parallel to the

longitudinal axis of the shell, which makes this area a maximum, shall be the product

of the length of the opening (including any rivet holes in the plane) and the thickness

of a seamless shell of similar material calculated in accordance with Equation 72

(Regulation 270) for the same conditions of pressure and temperature.

When frames, pads or branches are secured by rivets, the compensating area shall be

calculated by the method given in Regulation 170.

Where frames, pads or branches are secured by welding, the compensating area shall

be calculated by the method given in Regulation 279.

Message from Chairman of Central Boilers Board • About Central Boiler Board • History of Indian Boiler

Regulations • Foreword • Contents Chapter Wise • Contents Regulation Wise • List of Amendments

• Indian Boilers Act 1923 • Ibr Forms • Home • Search • Help • Contact Us

You might also like

- CVC Reading PassagesDocument8 pagesCVC Reading PassagesChase Smythe100% (1)

- IBR CalculationDocument1 pageIBR CalculationKarthic Keyan100% (1)

- IBR Design Calculations - FinalDocument6 pagesIBR Design Calculations - Finalshazan100% (1)

- UG-39 - Flat Head ReinforcementDocument3 pagesUG-39 - Flat Head ReinforcementAshish DhokNo ratings yet

- Tube Sheet CalculationDocument3 pagesTube Sheet CalculationAbhay UpadhyayNo ratings yet

- Tank Thickness Calculation: Is 2825 S.No Description Unit Value InputDocument10 pagesTank Thickness Calculation: Is 2825 S.No Description Unit Value InputdineshNo ratings yet

- Crossover Area Calc For Floating HeadDocument2 pagesCrossover Area Calc For Floating HeadRitesh VishambhariNo ratings yet

- Finned Tube Heat ExchangerDocument2 pagesFinned Tube Heat ExchangerjnmanivannanNo ratings yet

- API-653 Now Permits Lap-Welded Patch Plates For Shell Repairs - Carmagen EngineeringDocument2 pagesAPI-653 Now Permits Lap-Welded Patch Plates For Shell Repairs - Carmagen Engineeringmohsen_267100% (1)

- Credit Card EMI 3501 PDFDocument3 pagesCredit Card EMI 3501 PDFVijay ParmarNo ratings yet

- IBR - 1950 - Reg. 626Document2 pagesIBR - 1950 - Reg. 626Vijay ParmarNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- IBR CalculationsDocument20 pagesIBR CalculationsSivi NallamothuNo ratings yet

- Progen: Pipe Thickness Calculation As Per IBR 350 Eqn.Document4 pagesProgen: Pipe Thickness Calculation As Per IBR 350 Eqn.P s JagatheesanNo ratings yet

- IB-PRO Welding FiguresDocument12 pagesIB-PRO Welding FiguresSUNNY GUPTANo ratings yet

- TEMA Shell Bundle Entrance and Exit AreasDocument3 pagesTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaNo ratings yet

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongNo ratings yet

- Highlight of IBRDocument15 pagesHighlight of IBRAnonymous XBq5J84No ratings yet

- Index: L&T, E & C Engineering DECDocument22 pagesIndex: L&T, E & C Engineering DECinderNo ratings yet

- TubesheetDocument14 pagesTubesheethassnain iqbalNo ratings yet

- Section VIII CalDocument22 pagesSection VIII Calthodathers100% (1)

- Studding FlangeDocument6 pagesStudding FlangeDarshan PanchalNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Ibr Calc GSRDocument4 pagesIbr Calc GSRAniket GaikwadNo ratings yet

- IBR Thickness CalculationDocument21 pagesIBR Thickness CalculationAmit BansalNo ratings yet

- Ibr CalculationsDocument12 pagesIbr CalculationsGopal RamalingamNo ratings yet

- Stresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFDocument8 pagesStresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFanishNo ratings yet

- Ferrofab Fze: Collar Bolt Sizing CalculationDocument2 pagesFerrofab Fze: Collar Bolt Sizing CalculationMohammad Zahid50% (2)

- Project 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataDocument13 pagesProject 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataP s Jagatheesan100% (2)

- Sample Design Calculation - Vessel Supported On LugsDocument11 pagesSample Design Calculation - Vessel Supported On LugsSiva baalan100% (2)

- Ligament Efficiency and Thickness of The Support PlateDocument10 pagesLigament Efficiency and Thickness of The Support PlatePankajDhobleNo ratings yet

- Curb AngleDocument1 pageCurb Angle940623015859No ratings yet

- UHX - Osweiller - WhitePaper PDFDocument20 pagesUHX - Osweiller - WhitePaper PDFMichael BasaNo ratings yet

- IBR Calculation SheetDocument9 pagesIBR Calculation Sheetinder0% (1)

- Ibr CalcDocument4 pagesIbr CalcUmesh Kondkar100% (7)

- Design of Partition PlateDocument5 pagesDesign of Partition Platepippo2378793No ratings yet

- STHE Design (Training Material)Document37 pagesSTHE Design (Training Material)Herman_ms2000100% (2)

- UHX STudyDocument12 pagesUHX STudyAKSHAY BHATKARNo ratings yet

- E.4 Leg Support CalculationDocument2 pagesE.4 Leg Support Calculationnaim100% (2)

- Guide Support Issues For A Deflection ColumnDocument17 pagesGuide Support Issues For A Deflection ColumnSachinNo ratings yet

- PTB E4.18.5 Fixed TubesheetDocument83 pagesPTB E4.18.5 Fixed TubesheetNicolaSaviliNo ratings yet

- 1 TPH For 10.54P Boiler IBR Design Calculations - R2-6-2-13Document21 pages1 TPH For 10.54P Boiler IBR Design Calculations - R2-6-2-13Vishal KandNo ratings yet

- Exchanger Tube Min ThicknessDocument2 pagesExchanger Tube Min ThicknessMohamed ElshehnyNo ratings yet

- Ibr RegulationsDocument9 pagesIbr RegulationsAJITSPATILNo ratings yet

- 7-12-0024 Rev 7Document1 page7-12-0024 Rev 7cynideNo ratings yet

- Part UhxDocument51 pagesPart UhxSaif Eddine MJNo ratings yet

- Min Gasket Width CalculationDocument1 pageMin Gasket Width CalculationHunnymijie NorNo ratings yet

- IBR 343-350 Steam PipesDocument7 pagesIBR 343-350 Steam PipesRajivharolikar100% (2)

- Pillow-Plate Heat Exchangers: Fundamental CharacteristicsDocument13 pagesPillow-Plate Heat Exchangers: Fundamental CharacteristicsnityaNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Mo ZeroNo ratings yet

- Ibr Thickness Calculation: DefinitionDocument5 pagesIbr Thickness Calculation: DefinitionVipul SharmaNo ratings yet

- Development of Cone ExcelDocument5 pagesDevelopment of Cone ExcelPratik KarekarNo ratings yet

- Technical Part 1 2 PDFDocument301 pagesTechnical Part 1 2 PDFKumar Kousik Mondal50% (2)

- 400 KPH Boiler IBR Design Calculations - R1-6-2-13Document8 pages400 KPH Boiler IBR Design Calculations - R1-6-2-13Vishal KandNo ratings yet

- Boiler I.B.R. CalculationDocument10 pagesBoiler I.B.R. CalculationGurinder Jit Singh100% (1)

- Body Flange Thkickness CalculationDocument2 pagesBody Flange Thkickness CalculationsachmayaNo ratings yet

- 7-12-0006 Rev6 (Angle Leg Support)Document2 pages7-12-0006 Rev6 (Angle Leg Support)sumit kumarNo ratings yet

- Lug Support DesignDocument3 pagesLug Support DesignSajal KulshresthaNo ratings yet

- Hot Rolled Steel Plates, Sheets and CoilsDocument5 pagesHot Rolled Steel Plates, Sheets and CoilsAnamaria SuzanaNo ratings yet

- Atos CHDocument4 pagesAtos CHStéphane ArnaudNo ratings yet

- Expansion Joint SeminarDocument118 pagesExpansion Joint Seminarsubhadip sadhukhan100% (3)

- Pressure Vessels: Prepared by Batch B of ME-1Document40 pagesPressure Vessels: Prepared by Batch B of ME-1Adhanom G.No ratings yet

- Asep Steel Handbook PDFDocument261 pagesAsep Steel Handbook PDFSAMUEL CRUZALDENo ratings yet

- Surya Led Pricelist 11.09.2018Document5 pagesSurya Led Pricelist 11.09.2018Vijay ParmarNo ratings yet

- IBR - 1950 - Reg. 343 PDFDocument2 pagesIBR - 1950 - Reg. 343 PDFVijay ParmarNo ratings yet

- IBR Amendment 2017,1 PDFDocument6 pagesIBR Amendment 2017,1 PDFVijay ParmarNo ratings yet

- What Types of Seals Are Used in Hydraulic CylindersDocument3 pagesWhat Types of Seals Are Used in Hydraulic CylindersVijay ParmarNo ratings yet

- DM Plant - Demineralization Plant - Industrial Demineralizer Plant - DM Water Plant Manufacturer IndiaDocument4 pagesDM Plant - Demineralization Plant - Industrial Demineralizer Plant - DM Water Plant Manufacturer IndiaVijay ParmarNo ratings yet

- Mechanical Seal HistoryDocument3 pagesMechanical Seal HistoryVijay ParmarNo ratings yet

- V-Belt Sizing and Selection Guide: Standard V Belt Sizes FHP (Fractional Horsepower) V-Belts 3L, 4L, 5LDocument1 pageV-Belt Sizing and Selection Guide: Standard V Belt Sizes FHP (Fractional Horsepower) V-Belts 3L, 4L, 5LVijay ParmarNo ratings yet

- NAFA Guide To Air Filtration 8Document17 pagesNAFA Guide To Air Filtration 8Mohammad IsmailNo ratings yet

- Air Pollution Cocntrol Technology Fact Sheet: Name of Technology: Paper/Nonwoven FilterDocument7 pagesAir Pollution Cocntrol Technology Fact Sheet: Name of Technology: Paper/Nonwoven FilterVijay ParmarNo ratings yet

- HepaDocument2 pagesHepaVijay ParmarNo ratings yet

- GMP & ISO 14644: Clean Room - HVAC Validation ServicesDocument2 pagesGMP & ISO 14644: Clean Room - HVAC Validation ServicesVijay ParmarNo ratings yet

- HEPA Filters - DanforthDocument2 pagesHEPA Filters - DanforthVijay ParmarNo ratings yet

- Fusheng Vertical Air Receivers Instruction Manual 2020 11 18 1Document32 pagesFusheng Vertical Air Receivers Instruction Manual 2020 11 18 1aris wibowoNo ratings yet

- 0 Theme 2 Stalin SOWDocument14 pages0 Theme 2 Stalin SOWEl DeNo ratings yet

- Flood Precast - Super Wideslab Load Span TablesDocument1 pageFlood Precast - Super Wideslab Load Span TablesRaymond KinnairdNo ratings yet

- Contoh Skrip Rakaman AudioDocument2 pagesContoh Skrip Rakaman AudioconankoayNo ratings yet

- LISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsDocument6 pagesLISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsLeandro González De CeccoNo ratings yet

- Toyota Corolla A-131L OVERHAULDocument61 pagesToyota Corolla A-131L OVERHAULgerber damian100% (2)

- F2103033842Document5 pagesF2103033842Matin AhmedNo ratings yet

- 2SUPMaT2019 - Bacani - Number TheoryDocument109 pages2SUPMaT2019 - Bacani - Number TheoryRomelaBalasotoParamiNo ratings yet

- The Dino GameDocument1 pageThe Dino Game296 004 Aditya ChaudhariNo ratings yet

- 電容器絕緣油BDV 黏度 - SAS 40EDocument10 pages電容器絕緣油BDV 黏度 - SAS 40EShihlinElectricNo ratings yet

- What I Need To KnowDocument16 pagesWhat I Need To Knowgirlie paraisoNo ratings yet

- Ball Mill Capacity Dimensions PAUL O ABBEDocument2 pagesBall Mill Capacity Dimensions PAUL O ABBEaghilifNo ratings yet

- GattaniDocument18 pagesGattaniKhushbu NovhalNo ratings yet

- Catálogo Bombas K3V y K5VDocument15 pagesCatálogo Bombas K3V y K5VRamón Rivera100% (2)

- Delayed Hospital Discharges of Older Patients A Systematic Review On Prevalence and CostsDocument12 pagesDelayed Hospital Discharges of Older Patients A Systematic Review On Prevalence and CostsGabriela ObonNo ratings yet

- Shortest Route ProblemDocument7 pagesShortest Route ProblemkaushalmightyNo ratings yet

- 21st Century Skills PaperDocument8 pages21st Century Skills PaperemilyraleyNo ratings yet

- Lab ReportpdfDocument7 pagesLab ReportpdfStefano FochesattoNo ratings yet

- Let's Celebrate Diversity! : English: Level A2+Document10 pagesLet's Celebrate Diversity! : English: Level A2+JAIR DIEGO VIDAURRE QUISPENo ratings yet

- MBB and DR PG Data2kDocument143 pagesMBB and DR PG Data2kYogesh PalNo ratings yet

- Solve The Problems: (1 Marks)Document7 pagesSolve The Problems: (1 Marks)Govin RocketzNo ratings yet

- Earth SpecificationDocument20 pagesEarth SpecificationMohammad Hafiz MahadzirNo ratings yet

- Resistances, Voltages and Current in CircuitsDocument21 pagesResistances, Voltages and Current in CircuitsHisyamAl-MuhammadiNo ratings yet

- Verizon Wiretapping - Comments in Support of MR Cowie's ComplaintDocument8 pagesVerizon Wiretapping - Comments in Support of MR Cowie's ComplaintireportNo ratings yet

- 1001076002-HT8911 Datasheet - V1.1Document13 pages1001076002-HT8911 Datasheet - V1.1Zhang EthanNo ratings yet

- Statistical Methods For Spatial Data AnalysisDocument3 pagesStatistical Methods For Spatial Data Analysissakali ali0% (1)

- CBRDocument3 pagesCBRJunita PasaribuNo ratings yet

- Is Codes ListDocument37 pagesIs Codes Listmoondonoo7No ratings yet

- MATH4971 Response 5965Document16 pagesMATH4971 Response 5965Rindy SimNo ratings yet