Professional Documents

Culture Documents

Cirebon #1, Power System Diagram (660 MW X 1 Unit) PDF

Cirebon #1, Power System Diagram (660 MW X 1 Unit) PDF

Uploaded by

Dzikri LatifOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cirebon #1, Power System Diagram (660 MW X 1 Unit) PDF

Cirebon #1, Power System Diagram (660 MW X 1 Unit) PDF

Uploaded by

Dzikri LatifCopyright:

Available Formats

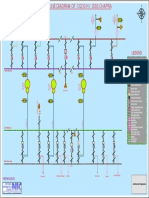

To PLN Substation Brebes 2

To PLN Substation Sunyaragi 2

Cirebon # 1, Power System Diagram (660 MW x 1 Unit) CIREBON

POWER SERVICES

To PLN Substation Brebes 1

To PLN Substation Sunyaragi 1

150 KV Switchyard 50 kg/㎠, 569 ℃ Hot Reheat

Main Bus-2 150 KV 255 kg/㎠ , 569 ℃

C11 C21 C31 HP

Bypass

C12 C22 C32 Valve

C23 C33 Final SH

C13 Separ

Main Bus-1 150 KV Cold Reheat Reheater Waste Water Treatment

ator

System

22kV

Abnormal WWFP

LP SH DIV Panel (2x100%)

To Switchgear: Bypass From Boiler & (21 m³/hr) From Plant

P1 BBA Valve

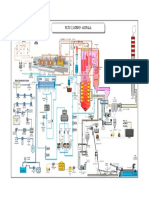

660 MW ESP Ditch

P1 BBB

Generator Normal Waste

Station Generator Water Pond.

Transformer LP B Turbine

Transformer LP A Turbine IP Turbine (440 ㎥)

HP Turbine Water Economizer Abnormal Waste PH

48/60 MVA 512.4/683.2/854 MVA Strorag 질소산화물 Water Pond. Normal WWFP Control Stack

Effluent

150/11.5 KV 165/23 KV e Tank 제거설비 (1500 ㎥) (2x100%) Water

(Height 215 M)

LT SH

(50 m³/hr)

Condensate

Vaccum Pump To BFPT

Chemical

Injection Clarified

Atm LP Shell A Water Pump

LP Shell B (2x100%)

LP No.1 HTR From All Furnace

Condenser Economizer (50 m³/hr)

Boiler Clarifier

Ignition Volume : 20,264 ㎥ (50㎥)

Flash Drain (12 EA)

To Cooling Tower Tank

Sludge Transfer Sludge

Water Desalination System

Boiler Pump Thickener Belt Press

To WWTP (2x100%)

Sump Filter

(0.7㎥/hr) (1x100%)

Demin Water

(0.8 ㎥/hr)

(2x100%) Mixbed Demin Supply Pump

Water (2x100%) Thickened sludge

(26.5㎥/hr) Polisher

Boiler Transfer Pump Cake Hopper

Tank

Circulation (2x100%) (1x100%) To Ash

(2 x 1500 ㎥ COP Pump (0.8 ㎥/hr) (2 ㎥/hr) Pond

Cooling Tower (3x50%) (784.8 T/hr)

Fresh (24 EA) Air Heater

(1x680㎥) 공기예열기

Water (97.400 ㎥/hr) Burner

Tank (24 EA)

From EP

To Continual Gas Volume (wet) : 3,850,716 A㎥/hr

Plant Usage Condenser ID FAN

BWRO Design inlet /outlet gas temperature : 150oC/145oC

Potable (2x50% BMCR)

(2 x14㎥/hr) Water.

Gland Steam Total Collecting Area : 86,400 perboiler

Cond.

Tank Dea

HP No.8 HTR

Backris Submarged scrapper

CPP FW TANK FD FAN

(2x1200㎥) h Water Chain Conveyor

Tank (2x50% BMCR)

CW Pump From WWT

(4x25%) Cond. Booster HP No.7 HTR Ash Silo

From EP Ash

Pump

SWRO Clinker

(3x50%) TT 6

(3x30.3 ㎥/hr) BC-08A/B From Bottom Ash

PA FAN

(2x50% BMCR)

HP No.6 HTR Ash

Dry Ash EP Ash Wet Ash ASH POND

DRN CLR

Container

Dual (10.495 MTPH)

(4x90 ㎥/hr) media+ Coal Silo

Sand To To (6 x 760㎥) To Ash Pond

Filter SW Supply Pump Condenser

Condenser To Ash Pond

(2x100%)

CW Basin From Cold Bottom Ash.

LP No.2 HTR

From Cold

Reheat (5.248 MTPH)

Reheat Coal Handling System

M Coal Feeder BC-07A/B

From Cold (6 x 95.28 T/hr)

LP No.3 HTR

BFPM BFPT Primary Air

(1x40 kg Cl/hr) Chlorination (2x50%)

Plant (1x25%) TT 5

TT 4

LP No.4 HTR

Pulverizer

S.W.Makeup (6 x 86.6 T/hr)

BC-05A/B Ship Unloader

Pump

(2x100%) BC-06A/B Jetty Conveyor (2 x 1300 T/hr)

(2x6,225 ㎥/hr) Jetty Distance : 2 KM

Speed : 3.33 M/s

From Cold stacker/

BC-10A S.W.Makeup BC-01A

Primary Air Raclamer TT 3

Light Oil Tank TT 2 Pump

Unloading BC-03A TT 1

Cap: 800㎥ BC-02A

To CW Basin (2x100%)

Pump BC-04A

Java Sea (1x100%) coal pile-B

Pulverizer Sealing Air Fan coal pile-A BC-09A

Light Oil Truck L.O Pump Coalyard

Light Fuel Oil System (2 x 100%)

(2x100%) (307,000 Ton) Barge

Java Sea

(13000 DWT)

You might also like

- Improving A Classroom-Based Assessment TestDocument27 pagesImproving A Classroom-Based Assessment TestKenneth Kim Villocino100% (9)

- Generator Set: 13. JPS - SOP.04 (21) .ME 03E: Factory Acceptance Test: Electrical StandbyDocument4 pagesGenerator Set: 13. JPS - SOP.04 (21) .ME 03E: Factory Acceptance Test: Electrical StandbyWAN CHANDNo ratings yet

- JIS ChlorideDocument2 pagesJIS ChlorideAndhikaAgraWisesaNo ratings yet

- MSDS MC22Document4 pagesMSDS MC22Fhail MechanicalNo ratings yet

- Daniel: Achieve Ultimate Measurement Confidence in Gas Custody TransferDocument2 pagesDaniel: Achieve Ultimate Measurement Confidence in Gas Custody TransferElizabeth Razo100% (1)

- Self Dehydrating BreatherDocument12 pagesSelf Dehydrating BreatherJOSE DANIEL PEREZNo ratings yet

- SLR Jh13: High Speed Master Trip RelayDocument2 pagesSLR Jh13: High Speed Master Trip Relayvishnusinghal2007No ratings yet

- Shell Thermia BDocument2 pagesShell Thermia Bsegunoyes100% (1)

- Efficiency of A Modified Conical Metallic Cooking Stove Incorporating Clay For Optimal Charcoal Consumption in Kara Region - TogoDocument8 pagesEfficiency of A Modified Conical Metallic Cooking Stove Incorporating Clay For Optimal Charcoal Consumption in Kara Region - TogoIJAR JOURNALNo ratings yet

- Document 1 WatanabeDocument58 pagesDocument 1 WatanabeHendrik BastiwNo ratings yet

- NEP9800 En1-8Document76 pagesNEP9800 En1-8hoang van tuyenNo ratings yet

- Anly Floatless Relay AFR-1Document4 pagesAnly Floatless Relay AFR-1JenniferValle100% (2)

- Spec 2000 KVA R1Document1 pageSpec 2000 KVA R1Ashadi PrimaNo ratings yet

- 3 Phase Decanter CentrifugeDocument14 pages3 Phase Decanter CentrifugeJamesNo ratings yet

- IESR Flexible Thermal Power Plant 2022Document66 pagesIESR Flexible Thermal Power Plant 2022jonny herbartNo ratings yet

- BOILERDocument34 pagesBOILERKurnia PadangNo ratings yet

- List NEPDocument4 pagesList NEPIlham_lahiya25No ratings yet

- M624 MBATech Electrical Subrat Sharma Final ReportDocument64 pagesM624 MBATech Electrical Subrat Sharma Final ReportJosef MorganNo ratings yet

- Chapte R Ultracool: LAUDA - The Big OneDocument10 pagesChapte R Ultracool: LAUDA - The Big Onegilberto floresNo ratings yet

- Functional Change of Sac Into Iac: Standard Field Operating ProcedureDocument7 pagesFunctional Change of Sac Into Iac: Standard Field Operating ProcedureMithun Singh RajputNo ratings yet

- Ionic Exchange HazopDocument64 pagesIonic Exchange Hazopjotas254No ratings yet

- WEEKLY MOTOR VIBRATION ChecklistDocument9 pagesWEEKLY MOTOR VIBRATION ChecklistJoyanta Maity100% (1)

- Meditran SX Plus SAE 15W-40Document2 pagesMeditran SX Plus SAE 15W-40JohnyNo ratings yet

- R S O TestDocument5 pagesR S O TestSchubert D'SouzaNo ratings yet

- Checklist Cooling TowerDocument1 pageChecklist Cooling TowerAfraz ShaikhNo ratings yet

- OS PTW Dwi Bahasa - RevDocument79 pagesOS PTW Dwi Bahasa - RevTatak Bay Ahmed100% (2)

- Tan Delta CDF-6000Document2 pagesTan Delta CDF-6000MarcoGiraldoNo ratings yet

- D5865 GCVDocument14 pagesD5865 GCVArunkumar ChandaranNo ratings yet

- Test Report For Unit-1 Generator Transformer-B Phase Page NoDocument4 pagesTest Report For Unit-1 Generator Transformer-B Phase Page NoAnonymous dH3DIEtzNo ratings yet

- GP1A30R: OPIC Photointerrupter With Encoder FunctionDocument4 pagesGP1A30R: OPIC Photointerrupter With Encoder FunctionnospherathusNo ratings yet

- Mollier Diagram ColoredDocument1 pageMollier Diagram ColoredhalerNo ratings yet

- Viscosity Kekentalan PDFDocument22 pagesViscosity Kekentalan PDFaishsimileyNo ratings yet

- Suspended & Surface Mounted Luminaires: HDK900 RangeDocument2 pagesSuspended & Surface Mounted Luminaires: HDK900 Rangesihabudin kolyubiNo ratings yet

- Transmisi - VOLTAGE DROPDocument9 pagesTransmisi - VOLTAGE DROPOkIlhamMuhammadNo ratings yet

- Galuh Cakra Panigas - Yayuk Deviyanti - 2bd4 - PFD Pt. Samator Gas - Referensi PFDDocument1 pageGaluh Cakra Panigas - Yayuk Deviyanti - 2bd4 - PFD Pt. Samator Gas - Referensi PFDlebay cokNo ratings yet

- Technical Manual For Standard Air Handling Unit - (FAS02-2016,17A)Document40 pagesTechnical Manual For Standard Air Handling Unit - (FAS02-2016,17A)JAY ROD AWIT100% (1)

- MCB UL489 CatalogDocument8 pagesMCB UL489 CatalogNguyễn Văn ThọNo ratings yet

- Federal Cable Catalogue-MinDocument17 pagesFederal Cable Catalogue-MinAhmadBintangNegoroNo ratings yet

- Catalogue - ElysisPUREDocument20 pagesCatalogue - ElysisPURETAREK ALMAHDYNo ratings yet

- NPHRDocument9 pagesNPHRAndreas Sahat P. SinagaNo ratings yet

- Model Hfs-4 Hydride Formation System: Instruction ManualDocument67 pagesModel Hfs-4 Hydride Formation System: Instruction ManualPrianurraufikachmadNo ratings yet

- Animasi PLTUDocument4 pagesAnimasi PLTUAngjuang Adi Panji PratamaNo ratings yet

- DTA62 Quick User Guide EnglishRevB PDFDocument9 pagesDTA62 Quick User Guide EnglishRevB PDF322399mk7086No ratings yet

- Ba Test Com Panel TMDocument7 pagesBa Test Com Panel TMAhmad Gofur100% (1)

- Electrocoagulation Flotation ETPDocument2 pagesElectrocoagulation Flotation ETPPatricia TungpalanNo ratings yet

- PowerPoint Presentation Solar Water HeatersDocument16 pagesPowerPoint Presentation Solar Water HeatersDawid AmutenyaNo ratings yet

- Standard Test Method For Hydrogen Sulfide and Mercaptan Sulfur in Natural Gas (Cadmium Sulfate Lodometric Titration Method) 'Document4 pagesStandard Test Method For Hydrogen Sulfide and Mercaptan Sulfur in Natural Gas (Cadmium Sulfate Lodometric Titration Method) 'Ray Emmanuelle CorsigaNo ratings yet

- CP TD1Document1 pageCP TD1Ahsan IqbalNo ratings yet

- Optimally Economic Design of Flare Systems PDFDocument5 pagesOptimally Economic Design of Flare Systems PDFMedaculoNo ratings yet

- Test Procedure For VTDocument2 pagesTest Procedure For VTSameer SyedNo ratings yet

- ATV12 Communication Parameters BBV51917 1.4IE05bDocument12 pagesATV12 Communication Parameters BBV51917 1.4IE05bRicardo Rodriguez ParedesNo ratings yet

- Mit 185UD5Document2 pagesMit 185UD5Pakito ChocolateroNo ratings yet

- Operasi Trash RakeDocument5 pagesOperasi Trash RakeKea PratamaNo ratings yet

- Gas Turbine Cycle TempoDocument3 pagesGas Turbine Cycle TempoReza TeflissiNo ratings yet

- Functional Test of Feeder Cubicles and IsolatorsDocument1 pageFunctional Test of Feeder Cubicles and Isolatorsaslam shaikhNo ratings yet

- Ultrasonic - Calibration Inspection Checklist PDFDocument2 pagesUltrasonic - Calibration Inspection Checklist PDFbhaskarNo ratings yet

- Jumo Dtrans CR02Document120 pagesJumo Dtrans CR02eliasnasrNo ratings yet

- Electrostatic Precipitator: KC Cottrell Co., LTDDocument51 pagesElectrostatic Precipitator: KC Cottrell Co., LTDvijayrajuNo ratings yet

- CHAPRADocument1 pageCHAPRAAyaz Ahmad KhanNo ratings yet

- SLD 132kv Ss ObulapuramDocument1 pageSLD 132kv Ss Obulapuramveera chaitanyaNo ratings yet

- Adipala Power System Diagram (660 MW)Document1 pageAdipala Power System Diagram (660 MW)Budi WahyonoNo ratings yet

- DaturaDocument18 pagesDaturaSundara Veer Raju MEDNo ratings yet

- 7.1.1 Administrator's Guide AIXDocument1,170 pages7.1.1 Administrator's Guide AIXÁgoston Péter100% (1)

- Module 1 PDFDocument18 pagesModule 1 PDFYashaswiniNo ratings yet

- AV UWorld EOs (Rough Draft) - Data - Repeat LandscapeDocument139 pagesAV UWorld EOs (Rough Draft) - Data - Repeat LandscapeJonathan AiresNo ratings yet

- Ws Restwsdl PDFDocument14 pagesWs Restwsdl PDFvadivel.km1527No ratings yet

- Grade 10 News Clips Unit OutlineDocument6 pagesGrade 10 News Clips Unit Outlineapi-245846103No ratings yet

- Mco 2 3 337 PDF PDFDocument4 pagesMco 2 3 337 PDF PDFhendra ardiantoNo ratings yet

- Eastern Europe ManufacturingDocument14 pagesEastern Europe ManufacturingNB Thushara HarithasNo ratings yet

- Unit-1 Introduction To Management and OrganizationsDocument73 pagesUnit-1 Introduction To Management and OrganizationsGnanesh GNo ratings yet

- Cfas Narrative Report 1Document2 pagesCfas Narrative Report 1Maryden BurgosNo ratings yet

- Gavin Degraw ChariotDocument2 pagesGavin Degraw ChariotLuiz Henrique Ferreira de Sousa100% (1)

- Professor Charles Fraser Beckingham 19141998Document4 pagesProfessor Charles Fraser Beckingham 19141998aymericNo ratings yet

- Fundmentals Energy ProcessDocument11 pagesFundmentals Energy ProcessepjxNo ratings yet

- DejectionDocument6 pagesDejectionMani Kandan100% (1)

- 04-MiCOM C264 HMI - Rev GDocument34 pages04-MiCOM C264 HMI - Rev GSaddam Hossen BiplobNo ratings yet

- Group 3 Financial MarketsDocument17 pagesGroup 3 Financial MarketsLady Lou Ignacio LepasanaNo ratings yet

- Pares 60.11Document633 pagesPares 60.11John SeversonNo ratings yet

- c4pdf PDFDocument32 pagesc4pdf PDFdbr trackdNo ratings yet

- Student Spending BehaviorDocument4 pagesStudent Spending BehaviorIka GhozaliNo ratings yet

- Chapter 28 Bouguer and Isostatic Maps of The Central Andes PDFDocument4 pagesChapter 28 Bouguer and Isostatic Maps of The Central Andes PDFTato Amoros BarrantesNo ratings yet

- The Nature of Human Resource ManagementDocument14 pagesThe Nature of Human Resource ManagementEmerito PerezNo ratings yet

- Ideas and Methods of Turbomachinery Aerodynamics A Historical ViewDocument12 pagesIdeas and Methods of Turbomachinery Aerodynamics A Historical ViewLos MagandosNo ratings yet

- Drought in Bangladesh and Its Adaptive Measures: Part-ADocument4 pagesDrought in Bangladesh and Its Adaptive Measures: Part-ASADIA AFRINNo ratings yet

- Poet, Lover, BirdwatcherDocument13 pagesPoet, Lover, BirdwatcherFhjjhhvNo ratings yet

- Femto SONDocument19 pagesFemto SONIlya KryuchkovNo ratings yet

- Difficult Airway? Difficult Mask Ventilation?Document10 pagesDifficult Airway? Difficult Mask Ventilation?Parvathy R NairNo ratings yet

- Mycoplasma ContaminationDocument4 pagesMycoplasma ContaminationashueinNo ratings yet

- Drainage SystemDocument48 pagesDrainage SystemArt Wadsilang100% (1)

- Childrens Guide Feb 2015Document12 pagesChildrens Guide Feb 2015Aziz RehmanNo ratings yet