Professional Documents

Culture Documents

W10 Work Instructions For Welding

W10 Work Instructions For Welding

Uploaded by

Munazar HussainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

W10 Work Instructions For Welding

W10 Work Instructions For Welding

Uploaded by

Munazar HussainCopyright:

Available Formats

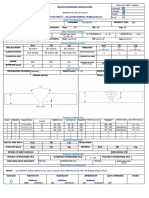

Hamad Abdullah AL Huwais Arabian Industrial Services Est

TITLE : Work Instructions for Welding

1. Purpose : To establish a process for Welding to carryout the activity as instructed

below under controlled conditions.

2. Scope : Components of all types of machines received for repairs are covered under

the scope of this Work Instruction.

3. Responsibility : Engineer / Supervisor is responsible for the implementation of these Work

Instructions

4. I.S.O. Ref. : ISO 9001 – 2008 Clause no 7.5.1

Quality Manual Section 7.5.1

5. Format/W.I : Job card cum in process inspection record

Ref.

6. WORK INSTRUCTION

Sr. No. Activity Responsibility

6.1 Work is allocated by Engineer / supervisor to the operator Engr/Supervisor

Check the type of material to be welded. e.g. Mild steel, Cast iron, Cast steel Carbon Operator

6.2 steel such as EN8, EN 9 etc. to select the welding rod and setting of welding machine

suitably.

6.3 Clean the portion to be welded from oil, grease, dirt etc. using Thinner and allow the Operator

portion to dry.

6.4 Take a light cut on the portion to be welded or make a V groove by grinder to ensure Operator

proper deposition of weld material of adequate thickness.

6.5 For welding for metallising, heat the potion to be welded to 200 deg. Cent. to remove Operator

moisture deposition particularly during rainy season

6.6 Welding rod to be heated to 80 deg. Cent. before use. Operator

6.7 Depending on the geometry of surface to be welded, decide the welded area to be

covered. Welding in staggered manner on the surface will help in restricting welding Operator

stresses and avoid destortion / bending / de-shaping of welded portion. In such a case,

weld the portion at 0 , 180, 270, 360 degrees intermittently with two runs at a time.

Before starting welding of the next run, completely remove the deposition of slag /

6.8 flux of the previous layer using wire brush and tigging and grinder if required. This is Operator

essential to avoid trapping of slag and get smooth finish after machining.

6.9 Half lap welding is recommended for metalising of bearing seats of shaft. Operator

6.10 The Engineer /supervisor monitors the work done by operators. Engineer/

Supervisor

Rev01/30-1-2018/Alhu-WI Prepared by: Engr.Munazar Hussain

You might also like

- Quality Assurance Plan: Pre-Engineered Steel BuildingDocument3 pagesQuality Assurance Plan: Pre-Engineered Steel BuildingsivakumarNo ratings yet

- Weld MapDocument4 pagesWeld MapSatish Keskar33% (3)

- Welding Consumable and Storage ProcedureDocument10 pagesWelding Consumable and Storage Procedurehasan_676489616100% (1)

- Valid SOP: Standard Operating ProceduresDocument10 pagesValid SOP: Standard Operating ProceduresShahid Raza100% (2)

- AWS D1-1 PQR-WPS Yes Pre QualifiedDocument2 pagesAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineer0% (1)

- Sam G. Dukelow The Control of BoilersDocument414 pagesSam G. Dukelow The Control of Boilerskanbouch80% (5)

- Work Instructions For Rolling of PlatesDocument3 pagesWork Instructions For Rolling of PlatesPravin Patil100% (1)

- Welding Machine Calibration ProcedureDocument10 pagesWelding Machine Calibration ProcedureGerman Favela0% (1)

- Material Traceability Record: Report No Rev. Date Shift (Day) (Night) SheetDocument1 pageMaterial Traceability Record: Report No Rev. Date Shift (Day) (Night) SheetAlfian Imaduddin100% (1)

- Welding Consumables Control RegisterDocument5 pagesWelding Consumables Control RegisterAli Mhaskar100% (2)

- Method Statement - Pipe WorksDocument14 pagesMethod Statement - Pipe WorksDarl Anthony Veloso100% (4)

- Tablas C-15, C-16Document38 pagesTablas C-15, C-16Jonathan Francisco Perez Ayala100% (1)

- TM 9-815 FWD Har-1Document414 pagesTM 9-815 FWD Har-1Advocate100% (3)

- SOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesDocument3 pagesSOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesMagesh Waran100% (1)

- Inspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A CommentsDocument1 pageInspection Check List PWHT-Post Weld Heat-Treatment: Inspection Process Yes No N/A Commentsmukeshayoor100% (1)

- Electrode Baking ProcedureDocument3 pagesElectrode Baking ProcedureAkhilesh Kumar90% (10)

- Weld Map (17007 Ab)Document22 pagesWeld Map (17007 Ab)9913489806100% (2)

- Welding SopDocument6 pagesWelding SopRuban George100% (1)

- Weld Inspection ReportDocument5 pagesWeld Inspection ReportFord Katim100% (2)

- M 111 Tank Weld Repair ProcedureDocument8 pagesM 111 Tank Weld Repair ProcedureAAISATNo ratings yet

- Dye Pentrant Test ProcedureDocument6 pagesDye Pentrant Test ProcedurePer DCNo ratings yet

- Method Statement For Rigging System Rev-01Document13 pagesMethod Statement For Rigging System Rev-01Anwar Mohiuddin50% (2)

- Induction Motor Failure AnalysisDocument8 pagesInduction Motor Failure AnalysisMunazar HussainNo ratings yet

- CDR Report Sample For Mechanical EngineersDocument4 pagesCDR Report Sample For Mechanical EngineersstephengatesNo ratings yet

- F 1600 Mud Pump PDFDocument2 pagesF 1600 Mud Pump PDFJohn0% (2)

- SOP - 03C Rev 1 Weld Shop PDFDocument9 pagesSOP - 03C Rev 1 Weld Shop PDFGohilakrishnan Thiagarajan100% (1)

- NIP - Weld Check SheetDocument1 pageNIP - Weld Check SheetAlanka Prasad100% (2)

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Document2 pagesWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- Sop For Fabrication of Fuel TankDocument3 pagesSop For Fabrication of Fuel TankVinod Kumar Verma75% (8)

- CERTIFICATE NO 2 Electric Welding MachineDocument2 pagesCERTIFICATE NO 2 Electric Welding MachineOwais MalikNo ratings yet

- Powder Coating ProcedureDocument1 pagePowder Coating Procedurenastyn-1No ratings yet

- Before, During and After Welding.Document2 pagesBefore, During and After Welding.ashwinNo ratings yet

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- Cir-Seam Fit-Up Inspection Report.Document4 pagesCir-Seam Fit-Up Inspection Report.Akhilesh KumarNo ratings yet

- Material Rejection ReportDocument4 pagesMaterial Rejection ReportMunazar HussainNo ratings yet

- Weld Visual Report Rev.0Document1 pageWeld Visual Report Rev.0John TerryNo ratings yet

- Welder Qualification Test Certificate: Parameters Variables Qualified With Qualified RangeDocument4 pagesWelder Qualification Test Certificate: Parameters Variables Qualified With Qualified RangeSpectex dubaiNo ratings yet

- Welder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationDocument1 pageWelder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationPerminder Singh100% (1)

- 16.work Instruction For VMCDocument1 page16.work Instruction For VMCSAKTHIVEL A50% (4)

- Work Instructions - FabricationDocument3 pagesWork Instructions - Fabricationvivek suresh0% (1)

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- Welding Control ProcedureDocument4 pagesWelding Control Procedurevenkatesh100% (2)

- Work Instructions For Arc Welding Machine: ReferenceDocument1 pageWork Instructions For Arc Welding Machine: Referencevivek sureshNo ratings yet

- Work Instruction For Bending Rev. 01.01.2013Document3 pagesWork Instruction For Bending Rev. 01.01.2013aymanmalah100% (1)

- Back Gouging ProcedureDocument8 pagesBack Gouging Proceduremahi1437100% (1)

- DPT Acceptance Code ReferenceDocument5 pagesDPT Acceptance Code ReferenceMidhun K Chandrabose100% (2)

- TIG Welding SOPDocument2 pagesTIG Welding SOPGnanasekaran M (TECHNICAL TRAINING/TVSTS)100% (1)

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil SorcaruNo ratings yet

- 6-12-0002 Rev 8 Supplementary Specification For Carbon Steel VesselsDocument7 pages6-12-0002 Rev 8 Supplementary Specification For Carbon Steel Vesselsravi2007No ratings yet

- DOs & Donts of WeldingDocument21 pagesDOs & Donts of WeldingkamalNo ratings yet

- Ms For Fabrication - UpdatedDocument4 pagesMs For Fabrication - UpdatedYasar arafat SHNo ratings yet

- AA00046C Partes & Servicios SM930E-4Document9 pagesAA00046C Partes & Servicios SM930E-4Emmanuel Torres HerreraNo ratings yet

- Robotic Welding Machine Procedure: 5.0 Activies Perior To Machine Start UpDocument4 pagesRobotic Welding Machine Procedure: 5.0 Activies Perior To Machine Start UpchandraNo ratings yet

- Work Instruction For Pluging Redundant Holes in Structural MembersDocument5 pagesWork Instruction For Pluging Redundant Holes in Structural MembersRakesh RanjanNo ratings yet

- MEI - Aluminium MIG WeldDocument56 pagesMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- I Hereby Declare That The Project Entitled "DESIGN AND FABRICATION OF WORKINGDocument29 pagesI Hereby Declare That The Project Entitled "DESIGN AND FABRICATION OF WORKINGGadadhar DeyNo ratings yet

- Assignment 1 - EPP201Document5 pagesAssignment 1 - EPP201shahanmhd51No ratings yet

- Standard Operating Procedure: Indus Pharma (PVT.) LTDDocument4 pagesStandard Operating Procedure: Indus Pharma (PVT.) LTDUmair ShekhaniNo ratings yet

- Work Procedure For Steel Fab & ErectionDocument5 pagesWork Procedure For Steel Fab & ErectionHiren Thakkar100% (1)

- ESCL-SOP-015, Procedure For Production of Egba Split-Sleeve ClampsDocument12 pagesESCL-SOP-015, Procedure For Production of Egba Split-Sleeve Clampsadiqualityconsult100% (1)

- WX 100Document17 pagesWX 100anon_967426204100% (1)

- GMW - 4707-2002 Corrosion Protective Coating Zinc Plating OrganicDocument3 pagesGMW - 4707-2002 Corrosion Protective Coating Zinc Plating Organichorse888No ratings yet

- Surface Treatment ProcedureDocument5 pagesSurface Treatment Proceduredeepan85No ratings yet

- Fabrication ProcedurDocument7 pagesFabrication ProcedurHarry PangestuNo ratings yet

- Ams 2449 - 2004Document12 pagesAms 2449 - 2004Ehab HarbNo ratings yet

- SSVX190C04-SW Swing Type PDFDocument2 pagesSSVX190C04-SW Swing Type PDFMunazar HussainNo ratings yet

- Maths Winter TaskDocument1 pageMaths Winter TaskMunazar HussainNo ratings yet

- SSVX18-16500 Data Sheet PDFDocument2 pagesSSVX18-16500 Data Sheet PDFMunazar HussainNo ratings yet

- Comment Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument41 pagesComment Insulation Resistance (IR) Values - Electrical Notes & ArticlesMunazar HussainNo ratings yet

- Rotating Diode Detection Delay RHS-J6-88Document2 pagesRotating Diode Detection Delay RHS-J6-88Munazar HussainNo ratings yet

- Scope Notes: Accreditation Audit Checklist (Version 3.0) With Criteria ExplanationsDocument26 pagesScope Notes: Accreditation Audit Checklist (Version 3.0) With Criteria ExplanationsMunazar HussainNo ratings yet

- Introduction To Rotating MachinesDocument54 pagesIntroduction To Rotating MachinesMunazar HussainNo ratings yet

- Certified Sprinkler ITM Specialist (CSITMS) For Facility Managers Exam Weighted Criteria TableDocument2 pagesCertified Sprinkler ITM Specialist (CSITMS) For Facility Managers Exam Weighted Criteria TableMunazar HussainNo ratings yet

- Bad Actor Defect EliminationDocument28 pagesBad Actor Defect EliminationMunazar HussainNo ratings yet

- Bank Authority FormDocument1 pageBank Authority FormMunazar HussainNo ratings yet

- Material Rejection ReportDocument4 pagesMaterial Rejection ReportMunazar HussainNo ratings yet

- Summary of AC Motor Induction ProceduresDocument1 pageSummary of AC Motor Induction ProceduresMunazar HussainNo ratings yet

- ThermodynamicsDocument2 pagesThermodynamicsVijetha SvNo ratings yet

- Model Stand NorbarDocument3 pagesModel Stand NorbarDexter PoliNo ratings yet

- Mechanical/Automobile Final Year Projects 2018: Sr. No Project Name CostDocument2 pagesMechanical/Automobile Final Year Projects 2018: Sr. No Project Name CostDinesh RathorNo ratings yet

- Lesson 7 - Simple Machines (Kinds and Safety Use)Document22 pagesLesson 7 - Simple Machines (Kinds and Safety Use)Ian Amurao100% (1)

- Joining & Assembly Processes: Fundamentals of WeldingDocument18 pagesJoining & Assembly Processes: Fundamentals of WeldingSajjadNo ratings yet

- Yanmar 6HA2M WHT - Datasheet PDFDocument2 pagesYanmar 6HA2M WHT - Datasheet PDFsumardizeroNo ratings yet

- Statics Module5Document42 pagesStatics Module5Glenn Paul TalhaNo ratings yet

- Designandfabricatonofsoapploddingmachineinresponsetohighdemandofsoapanddetergentduringthecovid 19eraDocument12 pagesDesignandfabricatonofsoapploddingmachineinresponsetohighdemandofsoapanddetergentduringthecovid 19erakhalil alhatabNo ratings yet

- Pipelines and Pipe NetworksDocument6 pagesPipelines and Pipe NetworksMohammad Mustafa MirzadNo ratings yet

- CLPG - GL - Rekapitulasi - Mutasi - Pe - April SD Juni 2021Document15 pagesCLPG - GL - Rekapitulasi - Mutasi - Pe - April SD Juni 2021Imelda RatnaNo ratings yet

- Écrouissage D'alliages D'aluminium: P O U R E N S A V O I R P L U SDocument2 pagesÉcrouissage D'alliages D'aluminium: P O U R E N S A V O I R P L U SdinoNo ratings yet

- Summary of Revised Codes For Concrete in 2018Document4 pagesSummary of Revised Codes For Concrete in 2018Vijayakrishna SingamsettiNo ratings yet

- Arc Welding ProjectDocument11 pagesArc Welding ProjectLeahNo ratings yet

- Adaptador de Tacometro DieselDocument2 pagesAdaptador de Tacometro DieselJj ValdezNo ratings yet

- ABE223 TextBook 2016Document335 pagesABE223 TextBook 2016Bianca ChanNo ratings yet

- HONEYWELL INDUSTRIAL COMBUSTION EMEA - Components Technical Catalogue PDFDocument129 pagesHONEYWELL INDUSTRIAL COMBUSTION EMEA - Components Technical Catalogue PDFPatricioFranciscoVásquezMillaquén100% (1)

- Gas Fuel SpecificationDocument27 pagesGas Fuel SpecificationgdgfdNo ratings yet

- Kanya PVS Catalogue 2008Document170 pagesKanya PVS Catalogue 2008james2271No ratings yet

- Benchmark The Fuel Cost PDFDocument2 pagesBenchmark The Fuel Cost PDFrajib0403050cuetNo ratings yet

- Bost Tools ZooKooDocument39 pagesBost Tools ZooKooTavrisTasosNo ratings yet

- Sans62 1Document21 pagesSans62 1johndupNo ratings yet

- Petrol Engine vs. Diesel EngineDocument12 pagesPetrol Engine vs. Diesel EngineGirish SahareNo ratings yet

- Tutorial 6 CouplingsDocument3 pagesTutorial 6 Couplingsallahm123No ratings yet

- Calculations and Graphs ReportDocument11 pagesCalculations and Graphs ReportKenneth C.LinojNo ratings yet

- Class IX - Physics NLMDocument3 pagesClass IX - Physics NLMNirjhar MazumderNo ratings yet