Professional Documents

Culture Documents

General Inspection Plan PDF

General Inspection Plan PDF

Uploaded by

Cahyadi CahyadiCopyright:

Available Formats

You might also like

- GFC500 Bonanza 190-02291-08 03Document16 pagesGFC500 Bonanza 190-02291-08 03Gustavo Hofstatter100% (1)

- Centrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si UnitsDocument15 pagesCentrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si Unitsf09aiNo ratings yet

- CRANKSHAFT INSPECTION FORM (1st Inspection / After Disassemble)Document2 pagesCRANKSHAFT INSPECTION FORM (1st Inspection / After Disassemble)Yeremia100% (1)

- 1 - Guidelines For The Injection Molding of SarlinkDocument15 pages1 - Guidelines For The Injection Molding of SarlinkMirka LukicNo ratings yet

- Injection MoldingDocument15 pagesInjection Moldingvalvan1988No ratings yet

- Date: September 5, 2016: 8 Rig Operation Cost 3,453 3,453 3,453Document3 pagesDate: September 5, 2016: 8 Rig Operation Cost 3,453 3,453 3,453Shofwan HilalNo ratings yet

- SWC Mec DTS P001abDocument9 pagesSWC Mec DTS P001abAlonso1593No ratings yet

- Process Data Sheet Dpcu Feed Gas Ko Drum 231-D9003: Material SpecificationDocument13 pagesProcess Data Sheet Dpcu Feed Gas Ko Drum 231-D9003: Material Specificationanon_215655183No ratings yet

- Layout DATALOGIC and SEEING MACHINEDocument2 pagesLayout DATALOGIC and SEEING MACHINEkogoro mouriNo ratings yet

- Modelos Folhas de Especificação, Coulson Richardsons ChemicalDocument12 pagesModelos Folhas de Especificação, Coulson Richardsons ChemicalEmmyli SantosNo ratings yet

- 8.1.4 Crawler CraneDocument3 pages8.1.4 Crawler CraneUD. Gunung JatiNo ratings yet

- BCBF FD StatusDocument1 pageBCBF FD StatuschikannosNo ratings yet

- Mukondo Atipaishe-Reduction Plant Section Report FinalDocument20 pagesMukondo Atipaishe-Reduction Plant Section Report FinalMukondoNo ratings yet

- Data SheetDocument1 pageData SheetStephen BeasleyNo ratings yet

- QAQC Daily Inspection Report Sir JabarDocument4 pagesQAQC Daily Inspection Report Sir JabarEngr Saeed AnwarNo ratings yet

- MZ0001-001-PH-00345 Rev1 - Method of Statement Piping STS 1-2 MLV 109-110-111Document16 pagesMZ0001-001-PH-00345 Rev1 - Method of Statement Piping STS 1-2 MLV 109-110-111Saule Larry GrigioniNo ratings yet

- For Dim CRP 059 15 48 HR CheckDocument8 pagesFor Dim CRP 059 15 48 HR CheckJhony GomezNo ratings yet

- 10/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectDocument4 pages10/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectdaemsalNo ratings yet

- Obl MBMC Engels Manual PDFDocument24 pagesObl MBMC Engels Manual PDFJose Eduardo MoralesNo ratings yet

- Material Safety Data Sheet FOR Co2 Recovery UnitDocument6 pagesMaterial Safety Data Sheet FOR Co2 Recovery Unitgudapati9No ratings yet

- Book 2Document8 pagesBook 2Rajamuhamadzamri RajasallehNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- 5 Rule Sheet (Problem Solving Sheet) : 715-0030 GSR P-90Document4 pages5 Rule Sheet (Problem Solving Sheet) : 715-0030 GSR P-90Anonymous rqVd3slYDNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- CAPA Thread OutDocument80 pagesCAPA Thread OutRohtash fastnerNo ratings yet

- 5051 - Copilot ClockDocument4 pages5051 - Copilot ClockMarty SmallwoodNo ratings yet

- TDP Creo Tetra4D 6 2017 PDFDocument7 pagesTDP Creo Tetra4D 6 2017 PDFgarto_voladNo ratings yet

- Instructions: Negative-Sequence Time Overcurrent RelaysDocument42 pagesInstructions: Negative-Sequence Time Overcurrent RelaysSergio Mauricio Jofre InzunzaNo ratings yet

- 82452.csg 2Document55 pages82452.csg 2Saravana GowthamNo ratings yet

- Goldmass Pipe DatasheetsDocument1 pageGoldmass Pipe DatasheetsAnas AR ARqledsNo ratings yet

- Rotary Pump (Api 676-3Rd) Data Sheet: U.S. CustomaryDocument3 pagesRotary Pump (Api 676-3Rd) Data Sheet: U.S. CustomaryEduin MorenoNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- University Technology of Malaysia Faculty of Mechanical EngineeringDocument39 pagesUniversity Technology of Malaysia Faculty of Mechanical EngineeringAHMEDALNHDINo ratings yet

- Production Report Shift WiseDocument5 pagesProduction Report Shift WiseOBSC PerfectionNo ratings yet

- GIP2 IPFSIL-EXE-RTSB (TASB) - 000-INC-TDS-0002 - RevB (Datasheet) (1) - 4Document1 pageGIP2 IPFSIL-EXE-RTSB (TASB) - 000-INC-TDS-0002 - RevB (Datasheet) (1) - 4Kacip BolaNo ratings yet

- Equipment Inspection Checklist: Asset DataDocument4 pagesEquipment Inspection Checklist: Asset DataShamsul AffendiNo ratings yet

- Basic Production Training: Based On Api - 14 CDocument137 pagesBasic Production Training: Based On Api - 14 CAbdul MuqtadirNo ratings yet

- Liquefied Gas SolutionDocument12 pagesLiquefied Gas SolutioncerberusdodoNo ratings yet

- Plantilla Apqp LlenoDocument4 pagesPlantilla Apqp LlenoANDRES GARCIA TLAPANo ratings yet

- Flow Pattern A320 Rev 01Document15 pagesFlow Pattern A320 Rev 01samuelstu01No ratings yet

- Axle General Specs WE0042114 .0: Tolerances To EST0015 AND Est0016 Unless Otherwise StatedDocument1 pageAxle General Specs WE0042114 .0: Tolerances To EST0015 AND Est0016 Unless Otherwise StatedDivineMoyo De[Mo]No ratings yet

- Job Pack Standardized Format Rev2 - SF Duct Burner View Port Repair InsulationDocument14 pagesJob Pack Standardized Format Rev2 - SF Duct Burner View Port Repair InsulationMohd Effiezool YaserNo ratings yet

- Technical Specs PDFDocument12 pagesTechnical Specs PDFcsolanki6586100% (1)

- Pile DriverDocument1 pagePile Driverherbert situmorangNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- ONE Day Look Ahead Activities - 4 JULY 23Document1 pageONE Day Look Ahead Activities - 4 JULY 23sNo ratings yet

- Indian Oil Corporation Limited: Document Transmittal Form (DTF)Document2 pagesIndian Oil Corporation Limited: Document Transmittal Form (DTF)T Anees AHNo ratings yet

- TECU Bond - KMEDocument26 pagesTECU Bond - KMEDániel KlenóczkyNo ratings yet

- Drum RollerDocument1 pageDrum Rollerherbert situmorangNo ratings yet

- Any - Angle - Tool - Vise PDFDocument8 pagesAny - Angle - Tool - Vise PDFmiftah nashrullahNo ratings yet

- TSR KuDocument16 pagesTSR KuAngsaNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- Nasa - Fully-Coupled Fluid-Structure Vibration Analysis Using NastranDocument84 pagesNasa - Fully-Coupled Fluid-Structure Vibration Analysis Using NastranMinseong KimNo ratings yet

- 05 EsightDocument12 pages05 EsightAbrar AhmadNo ratings yet

- Quality Control Equipment For BeveragesDocument8 pagesQuality Control Equipment For Beveragesvio.cirstoc6117No ratings yet

- Ujian Semester 5 Bing Kelas XiiDocument9 pagesUjian Semester 5 Bing Kelas XiiJunNo ratings yet

- Adaptive ControlDocument382 pagesAdaptive ControlAnonymous QakmLc3kTINo ratings yet

- The History of The AtomDocument5 pagesThe History of The AtomEmilyAranas100% (2)

- Title of ExperimentDocument19 pagesTitle of ExperimentLi Xian YongNo ratings yet

- Electrical MCDocument41 pagesElectrical MCphilip00165No ratings yet

- Blower - TrundeanDocument5 pagesBlower - Trundeanwaterlink.faysalNo ratings yet

- Hewitt Hose Identify IDDocument2 pagesHewitt Hose Identify IDEdisonCorderoNo ratings yet

- HP SFP Support MatrixDocument9 pagesHP SFP Support MatrixtdashnikNo ratings yet

- Breaker AH 201: Item Quan-Tity Name Material NoDocument2 pagesBreaker AH 201: Item Quan-Tity Name Material NoPappa Anton FlorinNo ratings yet

- Bedroom 2 Bedroom 1: Ground Floor Mechanical LayoutDocument4 pagesBedroom 2 Bedroom 1: Ground Floor Mechanical LayoutO. QuiritNo ratings yet

- PG PC Oct NovDocument21 pagesPG PC Oct NovTan Kien HockNo ratings yet

- 06 Clicker Questions PhysicsDocument20 pages06 Clicker Questions PhysicsVerenice Fuentes100% (1)

- CMT Electronic Heated ViscometerDocument1 pageCMT Electronic Heated ViscometerIBRAHIM ALMANLANo ratings yet

- MRS StatusDocument80 pagesMRS Statusvicente tanNo ratings yet

- Ahmed Muhammad Abd El-Azim MuhammadDocument3 pagesAhmed Muhammad Abd El-Azim MuhammadEng MessiNo ratings yet

- Global Local Analysis WhitepaperDocument3 pagesGlobal Local Analysis WhitepaperagniflameNo ratings yet

- Squid Proxy3.1Document16 pagesSquid Proxy3.1Norbac OrtizNo ratings yet

- KathreinDocument2 pagesKathreinFlorin CosariuNo ratings yet

- Work Accounts: Section 7 Measurement Books (MBS)Document11 pagesWork Accounts: Section 7 Measurement Books (MBS)Amanulla KhanNo ratings yet

- Chiyoda's High-Pressure Gas Control System and EquipmentDocument40 pagesChiyoda's High-Pressure Gas Control System and EquipmentNIZAM NIZAMNo ratings yet

- Check Swing Cast Steel A216 WCB Class 150: Pressure Temperature RatingsDocument2 pagesCheck Swing Cast Steel A216 WCB Class 150: Pressure Temperature Ratingsbreyca4 bcrNo ratings yet

- RadDocument35 pagesRadabdellaNo ratings yet

- Flight Manual: Preface 0.1Document90 pagesFlight Manual: Preface 0.1mehmeterkanNo ratings yet

- 3RH - Contactor RelaysDocument13 pages3RH - Contactor Relaysreza_powerNo ratings yet

- Checking Bolts in Camshaft Coupling MAN SL02-405Document6 pagesChecking Bolts in Camshaft Coupling MAN SL02-405harikrishnanpd3327No ratings yet

- Audi TB 37-06-13Document5 pagesAudi TB 37-06-13Victor GabrielNo ratings yet

- DNV-CG-0182Document46 pagesDNV-CG-0182Aleksandra MasarNo ratings yet

General Inspection Plan PDF

General Inspection Plan PDF

Uploaded by

Cahyadi CahyadiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Inspection Plan PDF

General Inspection Plan PDF

Uploaded by

Cahyadi CahyadiCopyright:

Available Formats

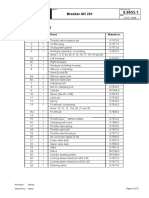

GENERAL INSPECTION PLAN

GIP(E)

END REVISI :- C ISSUED DATE :- 01/ 06 / 2002

START

KALTENBACH (NC) WAGNER & FICEP

CUTTING MACHINE 3 WELDING

MATERIAL RECEIVE MATERIAL REJECT DRILLING&STAMPING 4

FOR ALL PROFILE MATERIAL

MACHINE (CNC)

1

6

ESSAB (TRACER)

GAS BERGONZI DRILLING

MATERIAL 3 4 FITTING 5 WELDING

CUTTING MACHINE MACHINE (MANUAL)

STORAGE AS 2

FOR THICK PLATES

PER PROJECT

13

WORK PREPARAT ION 14 7 7

DARLEY (NC) SHEAR MUBEA & FICEP

GALVANIZING CUTTING FOR THIN 3 PUNCHING MACHINE 4

PLATES (CNC) THIRD PARTY

NDT IF

10 BENDING REQUESTED

9

SCOTCHMAN 14

PACKING & HIW PROCESS ING 3 4

PROCESSING

STORAGE FINISHING &

MARKING

TRIAL

11 ERECTION

10 MUBEA & FICEP (CNC)

9

ANGLE PROFILE MACHINE FOR

3/4

LOADING & PUNCHING, SHEARING & STAMPING

DELIVERY ANGLES 8

PAINTING BLASTING

12

DONE

DESCRIPTIONS DESCRIPTIONS

1. CHECKING OF MATERIAL AS PER DELIVERY ORDER AND AGAINST DAMAGES 8. DIMENSIONS AND FITTING OF PARTS DURING TRIAL ERECTION

REVIEW MILL CERTIFICATES & CROSS CHECK AGAINST PR / PO 9. APPROPRIATE FINISHING OF EDGES, HOLES & WELDING SLAG & ENSURING

2. SELECTION OF CORRECT MATERIAL BEFORE STARTING OF FABRICATION CORRECT MARKING AND COMPLETION OF ALL FABRICATION ACTIVITIES

3. CHECK THE DIMENSIONS AFTER CUTTING OR SHEARING 10. INSPECTION DURING & AFTER PRESERVATION PROCESS

4. CHECK THE POSITIONS AND SIZE OF HOLES AFTER PUNCHING OR DRILLING 11. CHECKING QUANTITY AND CONTROLLING PACKING PROCEDURES

5. CHECK THE SPOT FITTED ITEMS FOR DIMENSIONAL ACCURACY 12. MAINTAINING SAFE LOADING AND REPAIR OF DAMAGES DURING LOADING

6. CORRECT SELECTION OF WELDING ELECTRODES 13. CHECKING CNC PROGRAMES, TEMPLATES & PATTERNS

7. VISUAL INSPECTION OF SIZE AND QUALITY OF WELDING 14. CHECKING QUALITY AND DEGREE OF BEND

You might also like

- GFC500 Bonanza 190-02291-08 03Document16 pagesGFC500 Bonanza 190-02291-08 03Gustavo Hofstatter100% (1)

- Centrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si UnitsDocument15 pagesCentrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si Unitsf09aiNo ratings yet

- CRANKSHAFT INSPECTION FORM (1st Inspection / After Disassemble)Document2 pagesCRANKSHAFT INSPECTION FORM (1st Inspection / After Disassemble)Yeremia100% (1)

- 1 - Guidelines For The Injection Molding of SarlinkDocument15 pages1 - Guidelines For The Injection Molding of SarlinkMirka LukicNo ratings yet

- Injection MoldingDocument15 pagesInjection Moldingvalvan1988No ratings yet

- Date: September 5, 2016: 8 Rig Operation Cost 3,453 3,453 3,453Document3 pagesDate: September 5, 2016: 8 Rig Operation Cost 3,453 3,453 3,453Shofwan HilalNo ratings yet

- SWC Mec DTS P001abDocument9 pagesSWC Mec DTS P001abAlonso1593No ratings yet

- Process Data Sheet Dpcu Feed Gas Ko Drum 231-D9003: Material SpecificationDocument13 pagesProcess Data Sheet Dpcu Feed Gas Ko Drum 231-D9003: Material Specificationanon_215655183No ratings yet

- Layout DATALOGIC and SEEING MACHINEDocument2 pagesLayout DATALOGIC and SEEING MACHINEkogoro mouriNo ratings yet

- Modelos Folhas de Especificação, Coulson Richardsons ChemicalDocument12 pagesModelos Folhas de Especificação, Coulson Richardsons ChemicalEmmyli SantosNo ratings yet

- 8.1.4 Crawler CraneDocument3 pages8.1.4 Crawler CraneUD. Gunung JatiNo ratings yet

- BCBF FD StatusDocument1 pageBCBF FD StatuschikannosNo ratings yet

- Mukondo Atipaishe-Reduction Plant Section Report FinalDocument20 pagesMukondo Atipaishe-Reduction Plant Section Report FinalMukondoNo ratings yet

- Data SheetDocument1 pageData SheetStephen BeasleyNo ratings yet

- QAQC Daily Inspection Report Sir JabarDocument4 pagesQAQC Daily Inspection Report Sir JabarEngr Saeed AnwarNo ratings yet

- MZ0001-001-PH-00345 Rev1 - Method of Statement Piping STS 1-2 MLV 109-110-111Document16 pagesMZ0001-001-PH-00345 Rev1 - Method of Statement Piping STS 1-2 MLV 109-110-111Saule Larry GrigioniNo ratings yet

- For Dim CRP 059 15 48 HR CheckDocument8 pagesFor Dim CRP 059 15 48 HR CheckJhony GomezNo ratings yet

- 10/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectDocument4 pages10/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectdaemsalNo ratings yet

- Obl MBMC Engels Manual PDFDocument24 pagesObl MBMC Engels Manual PDFJose Eduardo MoralesNo ratings yet

- Material Safety Data Sheet FOR Co2 Recovery UnitDocument6 pagesMaterial Safety Data Sheet FOR Co2 Recovery Unitgudapati9No ratings yet

- Book 2Document8 pagesBook 2Rajamuhamadzamri RajasallehNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- 5 Rule Sheet (Problem Solving Sheet) : 715-0030 GSR P-90Document4 pages5 Rule Sheet (Problem Solving Sheet) : 715-0030 GSR P-90Anonymous rqVd3slYDNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- CAPA Thread OutDocument80 pagesCAPA Thread OutRohtash fastnerNo ratings yet

- 5051 - Copilot ClockDocument4 pages5051 - Copilot ClockMarty SmallwoodNo ratings yet

- TDP Creo Tetra4D 6 2017 PDFDocument7 pagesTDP Creo Tetra4D 6 2017 PDFgarto_voladNo ratings yet

- Instructions: Negative-Sequence Time Overcurrent RelaysDocument42 pagesInstructions: Negative-Sequence Time Overcurrent RelaysSergio Mauricio Jofre InzunzaNo ratings yet

- 82452.csg 2Document55 pages82452.csg 2Saravana GowthamNo ratings yet

- Goldmass Pipe DatasheetsDocument1 pageGoldmass Pipe DatasheetsAnas AR ARqledsNo ratings yet

- Rotary Pump (Api 676-3Rd) Data Sheet: U.S. CustomaryDocument3 pagesRotary Pump (Api 676-3Rd) Data Sheet: U.S. CustomaryEduin MorenoNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- University Technology of Malaysia Faculty of Mechanical EngineeringDocument39 pagesUniversity Technology of Malaysia Faculty of Mechanical EngineeringAHMEDALNHDINo ratings yet

- Production Report Shift WiseDocument5 pagesProduction Report Shift WiseOBSC PerfectionNo ratings yet

- GIP2 IPFSIL-EXE-RTSB (TASB) - 000-INC-TDS-0002 - RevB (Datasheet) (1) - 4Document1 pageGIP2 IPFSIL-EXE-RTSB (TASB) - 000-INC-TDS-0002 - RevB (Datasheet) (1) - 4Kacip BolaNo ratings yet

- Equipment Inspection Checklist: Asset DataDocument4 pagesEquipment Inspection Checklist: Asset DataShamsul AffendiNo ratings yet

- Basic Production Training: Based On Api - 14 CDocument137 pagesBasic Production Training: Based On Api - 14 CAbdul MuqtadirNo ratings yet

- Liquefied Gas SolutionDocument12 pagesLiquefied Gas SolutioncerberusdodoNo ratings yet

- Plantilla Apqp LlenoDocument4 pagesPlantilla Apqp LlenoANDRES GARCIA TLAPANo ratings yet

- Flow Pattern A320 Rev 01Document15 pagesFlow Pattern A320 Rev 01samuelstu01No ratings yet

- Axle General Specs WE0042114 .0: Tolerances To EST0015 AND Est0016 Unless Otherwise StatedDocument1 pageAxle General Specs WE0042114 .0: Tolerances To EST0015 AND Est0016 Unless Otherwise StatedDivineMoyo De[Mo]No ratings yet

- Job Pack Standardized Format Rev2 - SF Duct Burner View Port Repair InsulationDocument14 pagesJob Pack Standardized Format Rev2 - SF Duct Burner View Port Repair InsulationMohd Effiezool YaserNo ratings yet

- Technical Specs PDFDocument12 pagesTechnical Specs PDFcsolanki6586100% (1)

- Pile DriverDocument1 pagePile Driverherbert situmorangNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- ONE Day Look Ahead Activities - 4 JULY 23Document1 pageONE Day Look Ahead Activities - 4 JULY 23sNo ratings yet

- Indian Oil Corporation Limited: Document Transmittal Form (DTF)Document2 pagesIndian Oil Corporation Limited: Document Transmittal Form (DTF)T Anees AHNo ratings yet

- TECU Bond - KMEDocument26 pagesTECU Bond - KMEDániel KlenóczkyNo ratings yet

- Drum RollerDocument1 pageDrum Rollerherbert situmorangNo ratings yet

- Any - Angle - Tool - Vise PDFDocument8 pagesAny - Angle - Tool - Vise PDFmiftah nashrullahNo ratings yet

- TSR KuDocument16 pagesTSR KuAngsaNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- Nasa - Fully-Coupled Fluid-Structure Vibration Analysis Using NastranDocument84 pagesNasa - Fully-Coupled Fluid-Structure Vibration Analysis Using NastranMinseong KimNo ratings yet

- 05 EsightDocument12 pages05 EsightAbrar AhmadNo ratings yet

- Quality Control Equipment For BeveragesDocument8 pagesQuality Control Equipment For Beveragesvio.cirstoc6117No ratings yet

- Ujian Semester 5 Bing Kelas XiiDocument9 pagesUjian Semester 5 Bing Kelas XiiJunNo ratings yet

- Adaptive ControlDocument382 pagesAdaptive ControlAnonymous QakmLc3kTINo ratings yet

- The History of The AtomDocument5 pagesThe History of The AtomEmilyAranas100% (2)

- Title of ExperimentDocument19 pagesTitle of ExperimentLi Xian YongNo ratings yet

- Electrical MCDocument41 pagesElectrical MCphilip00165No ratings yet

- Blower - TrundeanDocument5 pagesBlower - Trundeanwaterlink.faysalNo ratings yet

- Hewitt Hose Identify IDDocument2 pagesHewitt Hose Identify IDEdisonCorderoNo ratings yet

- HP SFP Support MatrixDocument9 pagesHP SFP Support MatrixtdashnikNo ratings yet

- Breaker AH 201: Item Quan-Tity Name Material NoDocument2 pagesBreaker AH 201: Item Quan-Tity Name Material NoPappa Anton FlorinNo ratings yet

- Bedroom 2 Bedroom 1: Ground Floor Mechanical LayoutDocument4 pagesBedroom 2 Bedroom 1: Ground Floor Mechanical LayoutO. QuiritNo ratings yet

- PG PC Oct NovDocument21 pagesPG PC Oct NovTan Kien HockNo ratings yet

- 06 Clicker Questions PhysicsDocument20 pages06 Clicker Questions PhysicsVerenice Fuentes100% (1)

- CMT Electronic Heated ViscometerDocument1 pageCMT Electronic Heated ViscometerIBRAHIM ALMANLANo ratings yet

- MRS StatusDocument80 pagesMRS Statusvicente tanNo ratings yet

- Ahmed Muhammad Abd El-Azim MuhammadDocument3 pagesAhmed Muhammad Abd El-Azim MuhammadEng MessiNo ratings yet

- Global Local Analysis WhitepaperDocument3 pagesGlobal Local Analysis WhitepaperagniflameNo ratings yet

- Squid Proxy3.1Document16 pagesSquid Proxy3.1Norbac OrtizNo ratings yet

- KathreinDocument2 pagesKathreinFlorin CosariuNo ratings yet

- Work Accounts: Section 7 Measurement Books (MBS)Document11 pagesWork Accounts: Section 7 Measurement Books (MBS)Amanulla KhanNo ratings yet

- Chiyoda's High-Pressure Gas Control System and EquipmentDocument40 pagesChiyoda's High-Pressure Gas Control System and EquipmentNIZAM NIZAMNo ratings yet

- Check Swing Cast Steel A216 WCB Class 150: Pressure Temperature RatingsDocument2 pagesCheck Swing Cast Steel A216 WCB Class 150: Pressure Temperature Ratingsbreyca4 bcrNo ratings yet

- RadDocument35 pagesRadabdellaNo ratings yet

- Flight Manual: Preface 0.1Document90 pagesFlight Manual: Preface 0.1mehmeterkanNo ratings yet

- 3RH - Contactor RelaysDocument13 pages3RH - Contactor Relaysreza_powerNo ratings yet

- Checking Bolts in Camshaft Coupling MAN SL02-405Document6 pagesChecking Bolts in Camshaft Coupling MAN SL02-405harikrishnanpd3327No ratings yet

- Audi TB 37-06-13Document5 pagesAudi TB 37-06-13Victor GabrielNo ratings yet

- DNV-CG-0182Document46 pagesDNV-CG-0182Aleksandra MasarNo ratings yet