Professional Documents

Culture Documents

Machining Line Quote-New

Machining Line Quote-New

Uploaded by

JimmyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machining Line Quote-New

Machining Line Quote-New

Uploaded by

JimmyCopyright:

Available Formats

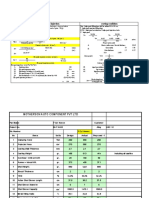

List of Machine at Engine Plant

Quote to Customer

Dimension Coolant

Electric Power Weight Machine Type NC / CNC

Products No Machine Name Machine No Model Control NC , PLC LxWxH Coolant Capacity ( Mfg Year

(KVA) (Ton) Maker

Meter Liter ) Standard Special Use Not

Cylinder Block

1 Vertical Milling CH 10 4 MP-V Relay / Freqrol A200 13 6.3 2.2 X 4 X 2.5 Not Use - 1977 Sanritsu / Hamai V

2 Horizontal Milling CH 15 MS 101 Relay 6 2 1.8 x 2 x 1.8 Not Use - 1977 Sanritsu /Hitachi Seiki V

3 Horizontal Spindle Machining Center CH 45 PN 40 Fanuc 16MB 35 8 3.6 X 2.5 X 2.5 Water soluble 200 1996 Niigata V V

4 Horizontal Spindle Machining Center CH 55 PN 40 Fanuc 16MB 35 8 3.6 X 2.5 X 2.5 Water soluble 200 1996 Niigata V V

Cylinder Head 5 Press Machine for valve guide CH 70 Special Purpose Relay 4 1.5 1.7 x 2 x 2.6 Not Use - 1990 MHI / Mikasaya V V

6 Boring Machine for Valve Seat CH 90 GR.20H-3 Freqrol FR-SFJ 30 11 2.5 X 3.8 X 2.3 Water soluble 1,000 1989 Shibaura / Toshiba V V

7 Press machine for Plug Install CH 110 Special Purpose Melsec A0 5 1 1.6 X 0.6 X 2.5 - - 1989 MHI / Mikasaya V V

8 Leak Tester for water jacket CH 120 KA-1155 Melsec A0 5 1 1.5 x 2.5 x 2.2 Water 100 1977 MHI / Sanyu V V

9 Leak Tester for Oil Room CH 130 SF.028 KAI Relay 5 2 1.3 x 2.5 x 2.2 Water 100 1976 Kiki Kaihatsu V V

10 Boring Machine for Cam Bore CH 140 Special Melsec A0 14 5 3.7 x 2.5 x 2.8 Water soluble 1,100 1989 MHI Kyoto V V

1 Centering Machine CS 05 FC MK - 2S Fanuc 0iTD 28 5 1.7 X 2.9 X 1.9 Water Soluble 120 1977 Fuji Machine V V

2 Turning Machine Front shaft CS 25 LB 15 ll OSP 7000 - L 14 5 2.1 X 2 X 1.7 Water Soluble 120 1994 Okuma Japan V V

3 Journal and Pin Miller CS37 GPM170F2-5 Fanuc 31iB 100 17.5 4.3 x 5.2 x 2.5 - - 2016 Komatsu Japan V V

4 Turning Machine for Journal diameter CS 32 LU 3000EX OSP-P300L 35 6.7 3 X 2.2 X 1.8 Water Soluble 120 2013 Okuma Japan V V

5 Pin Miller CS 50 GPM-200l - 1 Fanuc 9 model A 45 8 2.5 x 3.7 x 2.4 - - 1983 Komatsu Japan V V

6 Drilling machine oil hole CS 60 CS-70 DM-099 Melsec A2N 10 5 3 x 2.5 x 1.8 1974 Utsunomiya / Sanwa V V

Water Soluble 200

7 Drilling machine oil hole CS 70 CS-70 DM-099 Melsec A2N 10 5 3 x 2.5 x 1.8 1974 Utsunomiya / Sanwa V V

8 Horizontal Spindle Machining Center CS 127 GE460H Fanuc 31i - b 60 10 4.5 x 2.5 x 2.7 Water Soluble 540 2012 Enshu Japan V V

9 Horizontal Spindle Machining Center CS 95 JE 50 S Fanuc 31i - b 60 6.6 3.5 x 1.4 x 2.7 Water Soluble 540 2013 Enshu Japan V V

10 Turning Machine for Balance weight cutting. CS 145 LB 15 ll OSP 7000 - L 25 5 2.9 x 1.9 x 2.3 Water Soluble 120 1996 Okuma Japan V V

11 Turning machine oil groove pin CS 160 HS - 2H Fanuc 0TC 23 8 2.5 X 4.3 X 2.2 Water Soluble 300 1989 Horibe V V

12 Turning machine oil groove pin CS 165 HSN -2H -2N Fanuc 31i-model B 58 12 2.1 X 4.6 X 2.1 Water Soluble 300 2012 Horibe V V

13 Fillet Rolling Machine CS 170 7891 - 3NC Fanuc Power mate H 22 6 3.6 x 5.4 x 2.5 Oil 300 1989 Hegenscheidt Germany V V

14 Fillet Rolling Machine CS 175 7893R Siemen 22 10 4.3 x 2.1 x 2.4 Oil 100 2013 Hegenscheidt Germany V V

Crank Shaft

15 Turning and roller burnish machine CS 185 LB 300 OSP - P200LA 25 6.7 1.8 x 4.2 x 1.7 Water Soluble 120 2011 Okuma Japan V V

16 Milling machine Tag Slot CS 130 MH - 2 Melsec 5 2.3 0.7 x 1.2 x 1.6 - - 1970 Enshu / Sanritsu V V

17 Milling machine Key Way CS 140 SM - 6A Melsec 3 2.3 1.4 x 1.8 x 1.5 Water Soluble 100 1985 Howa / Sanritsu V V

18 Angular Grinding machine Rear oil seal Dia. CS 195 GL5A - 63 III Toyopc PC 2 40 8 2.7 x 3.8 x 2.3 Water Soluble 150 2004 JTEKT V V

19 Angular Grinding machine Front oil seal Dia. CS 200 GN - 087 PMM CS -902 -2 38 7 1.6 x 2.6 x 1.5 Water Soluble 300 1985 MHI / Sugiyama V V

20 Grinding Machine diameter Journal 1,2,3 CS 215 GL 32M - 63 Toyopuc PC 3JG 49 10.5 4.7 x 4.6 x 2.6 Water Soluble 800 2011 JTEKT V V

21 Grinding Machine All Pin diameter CS 245 GV 70 C Toyopc PC 2 85.5 10 4.6 x 4.7 x 3 Water Soluble 500 1996 JTEKT V V

22 Grinding Machine All Pin diameter CS 247 GV 70C II Toyopuc PC 3 85.5 10 4.6 x 4.7 x 3 Water Soluble 500 2006 JTEKT V V

23 Balancing Machine CS 257 H-20-N/S Freqrol A200 0.8 1.5 2.1 x 1.2 x 2.5 - - 2015 Nagahama V V

24 Balancing Machine CS 270 H-20-N Freqrol Z200 0.8 1.5 2.1 x 1.2 x 2.5 - - 1989 Nagahama V V

25 Vertical spindle Machining center CS 280 CV - 4 Fanuc 10MA 35 4 2.3 x 2 x 2.7 Water Soluble 130 1989 Niigata V V

26 Lapping Machine All Journal and Pin Diameter CS 300 A M-0783B Melsec A2 6.4 5 2 x 3 x 3.2 1990 Yasunaga V V

Kerosine 300

27 Lapping Machine front and Rear Oil seal Dia. CS 300 B 1024610100 Melsec A2 6.4 5 2 x 3 x 3.2 1990 Yasunaga V V

28 Measuring and sizing all Journal and Pin dia. CS 310 - - 2015 Tokyo Seimitsu V V

1 Centering Machine CM 10 Special Melsec A1 SHCPU 12 5 2.3 x 0.9 x 1.7 Water Soluble 200 1977 Daisho seiki japan V V

2 Turning Machine All Journal diameter CM 25 LCS 15 E OSP 700L 11 3.5 1.5 x 2.2 x 1.9 Water Soluble 200 1996 Okuma Japan V V

3 Drilling and Tapping Machine CM 28 Special A2NCPU 1.3 1.7 2.3 x 1.6 x 1.1 Water Soluble 200 1997 Ooshima LTD V V

4 Angular Grinding for front oil seal diameter CM 30 RB 32 -850A Fanuc 0G Model B 20 4.5 2.5 x 3.6 x 2.5 Water Soluble 200 1989 MHI Japan V V

5 Finish grinding all journal diameter CM 40 RB 32 -850P Fanuc 0G Model B 35 4.5 2.5 x 3.6 x 2.5 Water Soluble 200 1989 MHI Japan V V

6 Finish grinding all journal diameter CM 45 GL4P-50SIII GL4S 17 4 2.5 x 3.6 x 2.5 Water Soluble 230 2011 JTEKT V V

Cam Shaft

7 Horizontal Spindle Machining Center CM 52 JE 50 S Fanuc 31ib 30 6.6 3.5 x 1.4 x 2.7 Water Soluble 540 2014 Enshu Japan V V

8 Cam profile grinding machine CM 60 GCH 32 x 63B GC 300C /Toyopuc PC 1 20 8 2 x 3.3 x 1.7 Water Soluble 1,000 1989 JTEKT V V

9 Cam profile grinding machine CM 65 GCH 32 x 63B GC 300 C / Toyopuc PC 2 20 8 2 x 3.3 x 1.7 Water Soluble 1,000 1991 JTEKT V V

10 Cam profile grinding machine CM 68 GC 20M - 63/RF5842 GC 20 M 75 10.5 2 x 3.7 x 1.7 Water Soluble 600 2013 JTEKT V V

11 Lapping Machine CM 85 SFC 050TNd Melsec A1 S 2 1.5 1.5 x 2 x 1.8 Kerosine 20 2004 Matsuda Seiki V V

12 Hobbing Machine CM 55 SP 1241 Melsec A2NCPU-S1 1.3 4 2.1 x 3.6 x 2 - - 1976 MHI Kyoto V V

1 Rough Surface Grinding Machine CR 10 24A2 Relay 43 12 2.5 x 2.4 2.7 Water Soluble 500 1970 Matison/ Yumoto V V

2 Drilling Machine for Small Bore for Rod CR 20 SD 012 Melsec A2N 9 9 2 x 2.8 x 2.2 Water Soluble 300 1973 MHI / Nishinbo V V

3 Milling Joint Face Cap and Rod CR 40 4MP - H Melsec A0J2 12 4.5 2.8 x 2 x 2.2 Water Soluble 200 1969 Hitachi / Yumoto V V

4 Boring Machine for Big Bore Bore Rod and Cap CR 50 M - BF - 38 Melsec A2N 10 4.5 1 x 2 x 2.8 Water Soluble 300 1970 MMC / Nishinbo V V

5 Drilling Machine for Oil jet Hole CR 65 D - 0030 Melsec K2 6 2 1.8 x 2.9 x 2.2 Water Soluble 100 1996 Sugino V V

6 Surface grinding machine vertical spindle CR 110 LA 12 Relay 18 8 2.1 x 2.6 x 2.6 Water Soluble 600 1974 Sansei / Yumoto V V

Con Rod 7 Press bolt , assy cap and rod , Tightening nut CR 125 N225 Melsec A0J2H 3.5 1.7 0.9 x 1.4 x 2 Water Soluble - 1996 Mikasaya/Yumoto V V

8 Finish Grinding Both end face CR 130 24A Melsec K2 30 10 2.6 x 2.5 x 2.7 Water Soluble 600 1978 Koyo / Yumoto V V

9 Boring Machine for Small and big bore CR 140 M -1769 Melsec A2N 5 3 1.3 x 2.3 x 1.4 Water Soluble 600 1989 Hokoku / Yasunaga V V

10 Finish Boring small and big bore CR 150 M - 1770 Melsec A2N 5 3 1.3 x 2.3 x 1.4 Water Soluble 600 1989 Yasunaga V V

11 Deburring Metal notch CR 160 Special Melsec A0J2 5 1 1 x 1.6 x 1.9 Water Soluble 100 1989 Yamato V V

12 Honing Machine for small Bore CR 170 223 Relay 13 5.5 2.1 x 0.3 x 3.2 Kerosin 200 1973 Fujii / Sugiyama V V

13 Measuring Big, Small Bore and weight machine CR 190 E4N 5 0.5 1.5 x 1 x 1.5 - Marposs V V

You might also like

- Fixture Note PT MSA-PT Anugerah Perdana MV VICTORIA IDocument5 pagesFixture Note PT MSA-PT Anugerah Perdana MV VICTORIA IJimmyNo ratings yet

- Layout Tips For 12-Bit AD Converter Application PDFDocument7 pagesLayout Tips For 12-Bit AD Converter Application PDFGeoFurriel100% (1)

- Form 1 - Residential Listing Input SheetDocument4 pagesForm 1 - Residential Listing Input SheetGabe GrossNo ratings yet

- E-Coat Inputs: A) Part InformationDocument5 pagesE-Coat Inputs: A) Part InformationAnjan MalusareNo ratings yet

- 14.72 KL PP FRP TankDocument24 pages14.72 KL PP FRP TankmaheshdgavaliNo ratings yet

- CSS' CYLINDER HEAD Machining Part Print PQC& DR Verification ListDocument1 pageCSS' CYLINDER HEAD Machining Part Print PQC& DR Verification ListJosemar PorfirioNo ratings yet

- 2) in STN-2 Cycle Time Is OUT As Loading Time Is More in Both Fixture Than Welding TimeDocument1 page2) in STN-2 Cycle Time Is OUT As Loading Time Is More in Both Fixture Than Welding TimeKARTICK PRASADNo ratings yet

- GeneralDocument39 pagesGeneralDeerendra KaranthNo ratings yet

- Uk / India ISO en Ac-France Germany Italy Uni USA USA Japan Aa / Astm SAE LM0 LM2Document13 pagesUk / India ISO en Ac-France Germany Italy Uni USA USA Japan Aa / Astm SAE LM0 LM2Emba MadrasNo ratings yet

- Summary-Costing Sheet For Shell & Tube Heat ExchangerDocument19 pagesSummary-Costing Sheet For Shell & Tube Heat ExchangerAnonymous LKi1w1uNo ratings yet

- 2019 Afab Press Brake ToolsDocument30 pages2019 Afab Press Brake ToolsAFAB Machinery and Tools LtdNo ratings yet

- Far LZ400895Document10 pagesFar LZ400895Soubhagya BeheraNo ratings yet

- Tonase Dan Kebutuhan Material CV04A Dan RF45Document2 pagesTonase Dan Kebutuhan Material CV04A Dan RF45Bagas Lesta CoratiesNo ratings yet

- Incremental Forming in Tailor Welded BlanksDocument24 pagesIncremental Forming in Tailor Welded BlanksSitanshu S0% (1)

- Costing Calculations:: Date: 12/5/2016 Revision: R0 Costing 336Document9 pagesCosting Calculations:: Date: 12/5/2016 Revision: R0 Costing 336Rakesh SharmaNo ratings yet

- F A X TSS: Cutting ForceDocument3 pagesF A X TSS: Cutting ForcesachinNo ratings yet

- Tip Speed Calculation: RPM CalculationDocument13 pagesTip Speed Calculation: RPM CalculationNishant InamdarNo ratings yet

- Die Specification Cold Chamber: AluminiumDocument1 pageDie Specification Cold Chamber: AluminiumARUN KUMAR KoterimadathilNo ratings yet

- Rolling & Extrusion Case StudyDocument20 pagesRolling & Extrusion Case StudyMahmoud KassabNo ratings yet

- TML Norms For Existing Supplier: SL No Part Name Process M/C T Cost No of Strokes Rate/ StrokeDocument7 pagesTML Norms For Existing Supplier: SL No Part Name Process M/C T Cost No of Strokes Rate/ StrokeChandrajeet ShelkeNo ratings yet

- Zuhaltekraftberechnung: Teilbezeichnung Auslegung 1 - FachDocument2 pagesZuhaltekraftberechnung: Teilbezeichnung Auslegung 1 - FachARUN KUMAR KoterimadathilNo ratings yet

- Cost-Benefit AnalysisDocument2 pagesCost-Benefit AnalysisNISREEN WAYANo ratings yet

- Blended Cost BOMs - Rev 1Document30 pagesBlended Cost BOMs - Rev 1RJLockNo ratings yet

- Fixtures Cost Break UpDocument23 pagesFixtures Cost Break UpAshok AroraNo ratings yet

- Material: NRE Pricing Sheet Quantity CostDocument1 pageMaterial: NRE Pricing Sheet Quantity CostAnonymous VRspXsmNo ratings yet

- IPD Costing PDFDocument10 pagesIPD Costing PDFSaddy DipoNo ratings yet

- Costing Sheet 500632403736Document6 pagesCosting Sheet 500632403736Sourabh PradhanNo ratings yet

- Shear Force CalculationDocument2 pagesShear Force Calculationdrwhite48No ratings yet

- Body ModelDocument145 pagesBody ModelDipika PandaNo ratings yet

- Ijme - Optimization of Process Parameters by Warm Deep Drawing of Cylindrical Cup of Nickel 201Document10 pagesIjme - Optimization of Process Parameters by Warm Deep Drawing of Cylindrical Cup of Nickel 201Impact JournalsNo ratings yet

- Internal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00Document2 pagesInternal Costing Sheet: C45 - 36 Dia QT+ IH 1,400.00 400.00ramabhplNo ratings yet

- Position of Hi Speed Injection Casting ConditionDocument4 pagesPosition of Hi Speed Injection Casting ConditionVishal RajputNo ratings yet

- CostTable Fasteners 2022Document17 pagesCostTable Fasteners 2022shaffin jeba shinuNo ratings yet

- 20me702 - Process Planning and Cost Estimation Unit 5 2023-24Document65 pages20me702 - Process Planning and Cost Estimation Unit 5 2023-24CAD With RaoNo ratings yet

- IV ReportDocument22 pagesIV ReportMuhammad Zulhilmi0% (1)

- Form Tooling List Approval Tooling (002) Rev 4Document3 pagesForm Tooling List Approval Tooling (002) Rev 4Kalista BettiNo ratings yet

- Project Cost For Injection Moulding Plant: SL No Description Capacity Short Weight Condition Basic PriceDocument2 pagesProject Cost For Injection Moulding Plant: SL No Description Capacity Short Weight Condition Basic PriceNihar RanjanNo ratings yet

- Tailor Welded BlanksDocument52 pagesTailor Welded BlanksYuvaraj YuvarajNo ratings yet

- Basic Heat TreatmentDocument8 pagesBasic Heat TreatmentAnonymous VRspXsmNo ratings yet

- 110 KG CastingsDocument4 pages110 KG CastingsGurudutta MishraNo ratings yet

- Design and Analysis of Progressive Tool For An Automobile ComponentDocument9 pagesDesign and Analysis of Progressive Tool For An Automobile ComponentAnna100% (1)

- Cost Estimate For Tricked Out 14 X 14 CabinDocument3 pagesCost Estimate For Tricked Out 14 X 14 CabinAlex Tango FuegoNo ratings yet

- How To Compute Tonnage RequirementsDocument5 pagesHow To Compute Tonnage RequirementsPrabhat SharmaNo ratings yet

- Npi Cdo - Cost MatrixDocument21 pagesNpi Cdo - Cost MatrixGreen AvatarNo ratings yet

- Part Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailDocument2 pagesPart Cost Analysis Report: A. Raw Material Detail B. Purchased Part DetailramabhplNo ratings yet

- Template For Quoting Sheet Metal PartsDocument100 pagesTemplate For Quoting Sheet Metal PartsCarlos RetamozaNo ratings yet

- Production of Automotive Components: Jerome GDocument24 pagesProduction of Automotive Components: Jerome GMr. Jerome Nithin Gladson100% (1)

- Caparo Price ListDocument20 pagesCaparo Price ListkutbiahtNo ratings yet

- Costing Sheet - 1835 - ExtrusionDocument3 pagesCosting Sheet - 1835 - ExtrusionER RAKESHNo ratings yet

- Tonnage CalculatorDocument2 pagesTonnage CalculatorLoveofyouth ReddyNo ratings yet

- Injection Timing Calculator 2020Document43 pagesInjection Timing Calculator 2020Tim JuddNo ratings yet

- How To Calculate The Tonnage of Die Casting MachineDocument2 pagesHow To Calculate The Tonnage of Die Casting MachineRafał LesiczkaNo ratings yet

- 04 421 40033 Clutch CoverDocument1 page04 421 40033 Clutch CoverPress TechNo ratings yet

- Enter Data:: MM M Weld Size (Leg) Unit Weld LengthDocument8 pagesEnter Data:: MM M Weld Size (Leg) Unit Weld LengthBassamOmarFarghlNo ratings yet

- Project: TML (Emc) : Part No 1A014117 Customer TMLDocument2 pagesProject: TML (Emc) : Part No 1A014117 Customer TMLShrikant YashNo ratings yet

- Welding Cost Formula For Different Welding ProcessesDocument2 pagesWelding Cost Formula For Different Welding ProcessesmekoxxxNo ratings yet

- ForgingDocument17 pagesForgingNAGARAJUNo ratings yet

- Final ReportDocument25 pagesFinal ReportAdil SaleemNo ratings yet

- Tipos de Tratamientos PDFDocument1 pageTipos de Tratamientos PDFJose PerezNo ratings yet

- Asa - Injection Mould Component Cost EstimationDocument7 pagesAsa - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Product or Service Technical Design Specifications, Including Unit of Measure (UOM)Document1 pageProduct or Service Technical Design Specifications, Including Unit of Measure (UOM)Priyaprasad PandaNo ratings yet

- GPI - Cost Sheet For Cap Prodcution-2Document54 pagesGPI - Cost Sheet For Cap Prodcution-2Narayana MugalurNo ratings yet

- Mills - Machineries Lubrication DataDocument7 pagesMills - Machineries Lubrication DataSulaksono Cahyo PrabowoNo ratings yet

- Ricky ExpressDocument1 pageRicky ExpressJimmyNo ratings yet

- Hotel BaliDocument2 pagesHotel BaliJimmyNo ratings yet

- CourseDocument13 pagesCourseJimmyNo ratings yet

- PriceDocument1 pagePriceJimmyNo ratings yet

- Daftar Hadir Entry Meeting Monitoring BUDocument4 pagesDaftar Hadir Entry Meeting Monitoring BUJimmyNo ratings yet

- Bee SumoDocument26 pagesBee SumoJimmyNo ratings yet

- Major Noel HouseDocument27 pagesMajor Noel Houseeduard bulanonNo ratings yet

- Admin CVDocument5 pagesAdmin CVFurqan SohailNo ratings yet

- Jig JigDocument3 pagesJig JignsbNo ratings yet

- Chemical Safety Board Investigates Chevron Refinery Fire - Chemical & Engineering NewsDocument4 pagesChemical Safety Board Investigates Chevron Refinery Fire - Chemical & Engineering NewsFatemeh MehrbakhshNo ratings yet

- Developers GuideDocument45 pagesDevelopers GuideCraciun Paul100% (1)

- Thyssenkrupp Steels For Enameling Product Information Steel enDocument6 pagesThyssenkrupp Steels For Enameling Product Information Steel enle hoangNo ratings yet

- EDS+06 0012+Earthing+Design+CriteriaDocument20 pagesEDS+06 0012+Earthing+Design+Criteriasandeep_chauhan3770No ratings yet

- Caterpillar - Product StrategyDocument2 pagesCaterpillar - Product StrategyKaran ShahNo ratings yet

- Design Fabrication & Testing of Screw Conveyor: BY V. Durga Karthik A. Manoj Kumar G.I Manoj RamachandranDocument24 pagesDesign Fabrication & Testing of Screw Conveyor: BY V. Durga Karthik A. Manoj Kumar G.I Manoj RamachandranKing Maker100% (1)

- Environmentally-Friendly Surface TreatmentsDocument13 pagesEnvironmentally-Friendly Surface TreatmentsSeema NadigNo ratings yet

- Appendix MDocument15 pagesAppendix MPiNo ratings yet

- Round BalerDocument2 pagesRound Balervinitdhy1No ratings yet

- Lead Acid BatteryDocument11 pagesLead Acid BatterymapalptsNo ratings yet

- Padslogic UserDocument1,012 pagesPadslogic Userruinam_engineeringNo ratings yet

- PP ADC TransponderDocument12 pagesPP ADC TransponderEduardo Almeida SilvaNo ratings yet

- Sagar DhumalDocument2 pagesSagar Dhumalranaware ajinkyaNo ratings yet

- Member Information: Dues and FeesDocument3 pagesMember Information: Dues and FeesWilliam Condori RafaelNo ratings yet

- SPAviation 2008-03Document36 pagesSPAviation 2008-03Luiz AlvesNo ratings yet

- Techno Sales Price ListDocument431 pagesTechno Sales Price ListYossiAprianiNo ratings yet

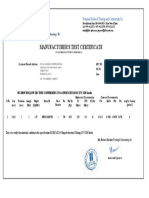

- Manufacturer'S Test Certificate: National Builtech Trading and Contracting CoDocument1 pageManufacturer'S Test Certificate: National Builtech Trading and Contracting CoQc QatarNo ratings yet

- Unit 2 (Esbm)Document46 pagesUnit 2 (Esbm)prachi158No ratings yet

- SK 830-MF (NiBSi) Thermal Spraying PDFDocument2 pagesSK 830-MF (NiBSi) Thermal Spraying PDFborovniskiNo ratings yet

- Unisphere VMAX Configuration GuideDocument17 pagesUnisphere VMAX Configuration Guidesamcool1717No ratings yet

- Composites Market Report 2017: Market Developments, Trends, Outlook and ChallengesDocument54 pagesComposites Market Report 2017: Market Developments, Trends, Outlook and ChallengesJuan S. León BecerraNo ratings yet

- Soutis - Fibre Reinforced Composites in Aircraft Construction (2005)Document9 pagesSoutis - Fibre Reinforced Composites in Aircraft Construction (2005)joereisNo ratings yet

- SAP ISU - SAP Expertise ConsultingDocument11 pagesSAP ISU - SAP Expertise Consultingabhimittal007No ratings yet

- Michelle Sheridan: A Closer Look Inside Laboratory Products & Services With Sartorius Team MembersDocument2 pagesMichelle Sheridan: A Closer Look Inside Laboratory Products & Services With Sartorius Team MembersJai MurugeshNo ratings yet

- Matri4Web-9 04Document9 pagesMatri4Web-9 04AjayNo ratings yet