Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

12 viewsBlanco Dalmau1983

Blanco Dalmau1983

Uploaded by

Faisal hayatPreventing green discoloration of porcelain

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AWS D1.5 Code Changes - 2020 Edition: Nesmea Mr. Allen W. Sindel - TRC Presented By: Mr. Robert Horwhat - TRCDocument26 pagesAWS D1.5 Code Changes - 2020 Edition: Nesmea Mr. Allen W. Sindel - TRC Presented By: Mr. Robert Horwhat - TRCVuong Tran VanNo ratings yet

- Dielectrics in Electric Fields BookDocument582 pagesDielectrics in Electric Fields Bookk rajendra100% (4)

- Leibinger 77001-00030 Solvent MEK SDS 08 06 2018Document6 pagesLeibinger 77001-00030 Solvent MEK SDS 08 06 2018Codyse Ponce100% (1)

- 02 Samss 011Document31 pages02 Samss 011Nicu Man100% (1)

- Collision TheoryDocument5 pagesCollision TheoryAngel PobleteNo ratings yet

- Solid State-Theory & ExerciseDocument34 pagesSolid State-Theory & ExerciseRaju SinghNo ratings yet

- ! 19 Organic Rankine CycleDocument14 pages! 19 Organic Rankine Cyclesapcuta16smenNo ratings yet

- Phani Gudipati Talks Extrusion in Advanced Materials Processes Magazine 4 - 2021Document4 pagesPhani Gudipati Talks Extrusion in Advanced Materials Processes Magazine 4 - 202118P202 - AJAY SIVARAMAN ANo ratings yet

- Tài Methyl-Acetate-Plant-DesignDocument18 pagesTài Methyl-Acetate-Plant-DesignLe Anh QuânNo ratings yet

- Flashcards - 2e Nutrition - Edexcel Biology IGCSEDocument105 pagesFlashcards - 2e Nutrition - Edexcel Biology IGCSEsohaila ibrahimNo ratings yet

- Feasibility Study On The Seaweed Kappaphycus Alvarezii Cultivation Site in Indari Waters ofDocument9 pagesFeasibility Study On The Seaweed Kappaphycus Alvarezii Cultivation Site in Indari Waters ofUsman MadubunNo ratings yet

- Desalter Operation OptimizationDocument4 pagesDesalter Operation OptimizationVangapanduSrinivasaraoNo ratings yet

- Form SIKA BaruDocument14 pagesForm SIKA BaruLevi Leonardo Maru SinagaNo ratings yet

- Summary Fcaw-2Document4 pagesSummary Fcaw-2Boonnak AmornvuthivornNo ratings yet

- Sterrad 50 Users GuiseDocument78 pagesSterrad 50 Users GuiseJose MorenoNo ratings yet

- CHE 3800 - Mass Transfer and Separation Process (Winter 2017)Document3 pagesCHE 3800 - Mass Transfer and Separation Process (Winter 2017)ssavage03No ratings yet

- Gemma Lesson Plan Lesser Font Size 7Document7 pagesGemma Lesson Plan Lesser Font Size 7Ailyn Saba AquinoNo ratings yet

- Ittr - Sample Training Session PlanDocument4 pagesIttr - Sample Training Session PlanOwenevan EvanowenNo ratings yet

- DL Biotech 2024Document3 pagesDL Biotech 2024sriNo ratings yet

- ADC12 Composition Check SheetDocument4 pagesADC12 Composition Check SheetevanNo ratings yet

- Bioprocesos Exámenes Actualizado Abril 2018 TareaDocument26 pagesBioprocesos Exámenes Actualizado Abril 2018 TareaRuben MarquezNo ratings yet

- Standard 1.3.3 Australia Processing AidsDocument5 pagesStandard 1.3.3 Australia Processing Aidssusantika murtiniNo ratings yet

- Why Is Foam CreatedDocument5 pagesWhy Is Foam CreatedSumeet JainNo ratings yet

- Floor Tech FB Primer DataDocument2 pagesFloor Tech FB Primer DatadogankkuNo ratings yet

- DNA SequencingDocument23 pagesDNA SequencingAleena MustafaNo ratings yet

- Densida ASTM 4052Document9 pagesDensida ASTM 4052Erick LópezNo ratings yet

- Brochure - UnitoxDocument4 pagesBrochure - UnitoxjayashreeNo ratings yet

- TTM Post TensioningDocument103 pagesTTM Post Tensioninghorea67100% (2)

- Innovative and Sustainable Flame Retardants in Building and Construction - Pinfa 2013Document56 pagesInnovative and Sustainable Flame Retardants in Building and Construction - Pinfa 2013Victor CastrejonNo ratings yet

- Expert Review Poly (Ethylene Glycol) - Modified Nanocarriers For Tumor-Targeted and Intracellular DeliveryDocument10 pagesExpert Review Poly (Ethylene Glycol) - Modified Nanocarriers For Tumor-Targeted and Intracellular Deliverym_ssNo ratings yet

Blanco Dalmau1983

Blanco Dalmau1983

Uploaded by

Faisal hayat0 ratings0% found this document useful (0 votes)

12 views1 pagePreventing green discoloration of porcelain

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPreventing green discoloration of porcelain

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

12 views1 pageBlanco Dalmau1983

Blanco Dalmau1983

Uploaded by

Faisal hayatPreventing green discoloration of porcelain

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Preventing green discoloration of porcelain baked

over silver-palladium alloys

Luis Blanco-Dalmau, D.D.S.*

University of Puerto Rico, School of Dentistry, San Juan, Puerto Rico

M any ceramometal crowns are constructed with

nonprecious alloys, which creates problems to the

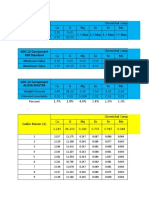

PROCEDURE

1. Sandblast the restoration with aluminum oxide.

technician in laboratory procedures and to the patient 2. Wash with water in an ultrasonic cleaner.

who is allergic to nickel if nickel-containing alloys are 3. Apply ceramic conditioner according to the man-

involved. The laboratory procedures are not modified ufacturer’s instructions.

with silver-palladium alloys, but there is a possibility 4. Apply opaque porcelain at 1,200’ to 1,700“ F

of a green discoloration. Silver melts at 1,761’ F (961’ with Vat and 1,700” to 1,760’ F without Vat. Leave

C) and will varporize above this temperature. The at 1,760” F for 2 to 4 minutes until egg shell

muffle will be impregnated with silver particles that appearance.

will form compounds with the porcelain and form the 5. Apply gingival and incisal porcelain at 1,200” to

green discoloration. 1,700” F with Vat and 1,700” to 1,760” F without

The old principle of time and temperature used in Vat. Leave at 1,760” F up to 30 seconds.

ceramics is applied, with the restoration kept in the 6. Apply a natural glaze at 1,200” to 1,760” F air

oven longer to get the same results obtainable at higher fired. Leave at 1,760“ F for 30 seconds or until

temperatures. The temperature is kept lower than acceptable glaze is obtained. For an artificial glaze,

1,760” F when 1,800” F-type porcelain is used. The follow the manufacturer’s instructions.

oven should be purged periodically; a piece of a carbon

rod may be used during the baking cycle, but this is not CONCLUSION

necessary. The metal framework must be cleansed with A simple technique that will prevent green discolor-

a sandblaster, preferably a nonrecycling one, with 50 ation of porcelain when silver-palladium alloys and

pm aluminum oxide. The restoration is then washed 1,800” F porcelains are used has been described. These

with distilled water in an ultrasonic cleaner for alloys have similar characteristics to gold-containing

approximately IO minutes. A ceramic conditioner rec- alloys, and conventional procedures need not be

ommended by many manufacturers is applied to form a changed. The problem of allergies that could be

coat on the metal and prevent future vaporization of the encountered with nonprecious metals is avoided.

silver in the area to be covered by the porcelain. A

greenish gray color will appear on the metal after the Refmnt requests to:

cycle when the temperature used is approximately DR. Lurs BLANCO-DALMAU

UNIVERSITY OF PUERTO RICO

1,925” F (1,052” C). From there on, the temperature SCHOOL OF DENTISTRY

of the oven is never carried higher than 1,761’ F (961’ G.P.O. Box 5067

C) at any time. SAN JUAN, PR 00936

*Professor, Restorative Sciences Department.

THE JOURNAL OF P’ROSTHETIC DENTISTRY 865

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AWS D1.5 Code Changes - 2020 Edition: Nesmea Mr. Allen W. Sindel - TRC Presented By: Mr. Robert Horwhat - TRCDocument26 pagesAWS D1.5 Code Changes - 2020 Edition: Nesmea Mr. Allen W. Sindel - TRC Presented By: Mr. Robert Horwhat - TRCVuong Tran VanNo ratings yet

- Dielectrics in Electric Fields BookDocument582 pagesDielectrics in Electric Fields Bookk rajendra100% (4)

- Leibinger 77001-00030 Solvent MEK SDS 08 06 2018Document6 pagesLeibinger 77001-00030 Solvent MEK SDS 08 06 2018Codyse Ponce100% (1)

- 02 Samss 011Document31 pages02 Samss 011Nicu Man100% (1)

- Collision TheoryDocument5 pagesCollision TheoryAngel PobleteNo ratings yet

- Solid State-Theory & ExerciseDocument34 pagesSolid State-Theory & ExerciseRaju SinghNo ratings yet

- ! 19 Organic Rankine CycleDocument14 pages! 19 Organic Rankine Cyclesapcuta16smenNo ratings yet

- Phani Gudipati Talks Extrusion in Advanced Materials Processes Magazine 4 - 2021Document4 pagesPhani Gudipati Talks Extrusion in Advanced Materials Processes Magazine 4 - 202118P202 - AJAY SIVARAMAN ANo ratings yet

- Tài Methyl-Acetate-Plant-DesignDocument18 pagesTài Methyl-Acetate-Plant-DesignLe Anh QuânNo ratings yet

- Flashcards - 2e Nutrition - Edexcel Biology IGCSEDocument105 pagesFlashcards - 2e Nutrition - Edexcel Biology IGCSEsohaila ibrahimNo ratings yet

- Feasibility Study On The Seaweed Kappaphycus Alvarezii Cultivation Site in Indari Waters ofDocument9 pagesFeasibility Study On The Seaweed Kappaphycus Alvarezii Cultivation Site in Indari Waters ofUsman MadubunNo ratings yet

- Desalter Operation OptimizationDocument4 pagesDesalter Operation OptimizationVangapanduSrinivasaraoNo ratings yet

- Form SIKA BaruDocument14 pagesForm SIKA BaruLevi Leonardo Maru SinagaNo ratings yet

- Summary Fcaw-2Document4 pagesSummary Fcaw-2Boonnak AmornvuthivornNo ratings yet

- Sterrad 50 Users GuiseDocument78 pagesSterrad 50 Users GuiseJose MorenoNo ratings yet

- CHE 3800 - Mass Transfer and Separation Process (Winter 2017)Document3 pagesCHE 3800 - Mass Transfer and Separation Process (Winter 2017)ssavage03No ratings yet

- Gemma Lesson Plan Lesser Font Size 7Document7 pagesGemma Lesson Plan Lesser Font Size 7Ailyn Saba AquinoNo ratings yet

- Ittr - Sample Training Session PlanDocument4 pagesIttr - Sample Training Session PlanOwenevan EvanowenNo ratings yet

- DL Biotech 2024Document3 pagesDL Biotech 2024sriNo ratings yet

- ADC12 Composition Check SheetDocument4 pagesADC12 Composition Check SheetevanNo ratings yet

- Bioprocesos Exámenes Actualizado Abril 2018 TareaDocument26 pagesBioprocesos Exámenes Actualizado Abril 2018 TareaRuben MarquezNo ratings yet

- Standard 1.3.3 Australia Processing AidsDocument5 pagesStandard 1.3.3 Australia Processing Aidssusantika murtiniNo ratings yet

- Why Is Foam CreatedDocument5 pagesWhy Is Foam CreatedSumeet JainNo ratings yet

- Floor Tech FB Primer DataDocument2 pagesFloor Tech FB Primer DatadogankkuNo ratings yet

- DNA SequencingDocument23 pagesDNA SequencingAleena MustafaNo ratings yet

- Densida ASTM 4052Document9 pagesDensida ASTM 4052Erick LópezNo ratings yet

- Brochure - UnitoxDocument4 pagesBrochure - UnitoxjayashreeNo ratings yet

- TTM Post TensioningDocument103 pagesTTM Post Tensioninghorea67100% (2)

- Innovative and Sustainable Flame Retardants in Building and Construction - Pinfa 2013Document56 pagesInnovative and Sustainable Flame Retardants in Building and Construction - Pinfa 2013Victor CastrejonNo ratings yet

- Expert Review Poly (Ethylene Glycol) - Modified Nanocarriers For Tumor-Targeted and Intracellular DeliveryDocument10 pagesExpert Review Poly (Ethylene Glycol) - Modified Nanocarriers For Tumor-Targeted and Intracellular Deliverym_ssNo ratings yet