Professional Documents

Culture Documents

Saep 65

Saep 65

Uploaded by

munnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saep 65

Saep 65

Uploaded by

munnaCopyright:

Available Formats

Engineering Procedure

SAEP-65 2 October 2017

Empty Container Management

Document Responsibility: Environmental Standards Committee

Contents

1 Overview ........................................................... 2

2 Scope ................................................................ 2

3 Applicable Documents ...................................... 2

4 Definitions ......................................................... 4

5 Instructions........................................................ 5

6 Responsibilities ............................................... 10

Revision Summary................................................. 13

Previous Issue: New Next Planned Update: 2 October 2020

Page 1 of 13

Contact: Khasawinah, Salim A. (khasawsa) on phone +966-13-8809429

©Saudi Aramco 2017. All rights reserved.

Document Responsibility: Environmental Standards Committee SAEP-65

Issue Date: 2 October 2017

Next Planned Update: 2 October 2020 Empty Container Management

1 Overview

This empty container management procedure requires proponents who use chemicals or

hydrocarbons contained in less than or equal to 275 gallons containers to comply with

Saudi Aramco Environmental Protection Policy (INT-5) and Implementation of

Hazardous Waste Code (GI-0430.001).

The objectives of this procedure is to:

Fully utilize materials in containers;

Minimize waste generation;

Reduce material purchasing costs;

Ensure proper treatment of wastewater and residuals generated from empty

containers cleaning activities;

Prevent or minimize environmental and health impacts associated with the

inappropriate disposal of containers containing hazardous or acutely hazardous

materials or waste; and

Reduce the Company’s legal liability due to illegal and / or improper disposal of

hazardous waste.

2 Scope

This procedure establishes the environmental instructions and responsibilities for the

management of empty 55-gallon drums (steel or plastic) and 275-gallon Intermediate

Bulk Containers (IBC) containing residues (heel) referred to in this document as

“Empty Container”. The procedure defines the responsibilities of all departments who

use materials contained in these containers. It also outlines the requirements for

efficient utilization of materials, waste minimization, proper management of empty

containers, and treatment of residual wastewater generated from empty containers

cleaning activities. This procedure excludes storage tanks and ISO Containers.

3 Applicable Documents

All referenced specifications, standards, codes, forms, drawings and similar material

shall be of the latest issue (including all revisions, addenda, and supplements) unless

stated otherwise.

3.1 Company Documents

Saudi Aramco Engineering Procedures

SAEP-302 Instructions for Obtaining a Waiver of a Mandatory

Saudi Aramco: Company General Use

Page 2 of 13

Document Responsibility: Environmental Standards Committee SAEP-65

Issue Date: 2 October 2017

Next Planned Update: 2 October 2020 Empty Container Management

Saudi Aramco Engineering Requirement

SAEP-327 Management of Wastewater from Cleaning,

Flushing and Dewatering Pipelines and Vessels

Saudi Aramco Engineering Standards

SAES-A-104 Wastewater Treatment, Reuse, and Disposal

SAES-B-069 Emergency Eyewashes and Showers

SAES-M-006 Saudi Aramco Security and General Purpose Fencing

SAES-S-007 Solid Waste Landfill Requirements

SAES-S-010 Sanitary Sewers

SAES-S-020 Oily Water Drainage Systems

SAES-S-030 Storm Water Drainage Systems

SAES-S-040 Saudi Aramco Water Systems

Saudi Aramco General Instructions

GI-0002.716 Land Use Permit Procedures

GI-0151.006 Implementing the Saudi Aramco Sanitary Code –

SASC-S-02, Sanitary Wastewater and Sewerage

Systems

GI-0430.001 Implementing the Saudi Aramco Hazardous Waste

Code

Saudi Aramco Policies

INT-5 Saudi Aramco Environmental Protection Policy

3.2 Government Regulations

General Environmental Regulations for the Kingdom of Saudi Arabia

Royal Commission Environmental Regulations (RCER 2015)

3.3 Industry Standards

USEPA 40 CFR 261.7 Residues of Hazardous Waste in Empty Containers.

California Code of Regulations, Title 22,

Section 66261.7.

International Maritime Dangerous Goods (IMDG) Code

Saudi Aramco: Company General Use

Page 3 of 13

Document Responsibility: Environmental Standards Committee SAEP-65

Issue Date: 2 October 2017

Next Planned Update: 2 October 2020 Empty Container Management

4 Definitions

Empty Container: The Empty Container definition was adopted from the State of

California Department of Toxic Substances Control standard, which requires the

generator to empty the container as much as reasonably possible. This definition shall

replace Saudi Aramco Hazardous Waste Code definition, which allows up to one inch

or 3% of the total weight of the container’s hazardous content to remain in the

container. It sets three standards to define an empty container, each standard is based

on the type of material held by the container:

Containers That Held Pourable Materials: For containers that held a material

that can be readily poured, all material must be removed by any practicable means

(including draining, pouring, pumping or aspirating) before the container can be

considered empty. In regards to draining, a container is empty when there is no

longer a continuous stream of material coming from the opening when the container

is held in any orientation.

Containers Holding Non-pourable Materials: For containers that previously held

materials that are non-pourable, no hazardous material shall remain in the container

that can feasibly be removed by physical methods, including scraping and chipping,

but not rinsing. This standard applies to materials that pour slowly or do not pour at

all from the container, including, but not limited to, viscous materials, solids which

have “caked up” inside the container, and non-pourable sludge.

Containers Holding Acute or Extremely Hazardous Materials: Containers

which previously held acute or extremely hazardous materials are considered empty

only if the container has been triple-rinsed using a solvent capable of removing the

material, steam cleaning, or cleaning by another method which is proven to achieve

equivalent removal to triple-rinsing.

ISO Containers: ISO or intermodal containers are used for the intermodal transport of

freight. They are manufactured according to specifications from the International

Organization for Standardization (ISO) and are suitable for multiple transportation

methods such as truck, rail, or ship.

Chaining: Within a steel drum cleaning process, the insertion of chains into the drum,

along with caustic, and tumbling the drum to remove remaining materials (i.e., heel)

from the drum interior.

Drum: A metal or plastic cylindrical container with either an open-head or a tight-head

(also known as bung-type top) used to hold liquid, solid, or gaseous commodities or

cargos which are in direct contact with the container interior.

Effluent: Wastewater discharges.

Saudi Aramco: Company General Use

Page 4 of 13

Document Responsibility: Environmental Standards Committee SAEP-65

Issue Date: 2 October 2017

Next Planned Update: 2 October 2020 Empty Container Management

Heel: Any material remaining in a drum or container following unloading, delivery, or

discharge of the transported material. Heel may also be referred to as container residue,

residual materials, or residuals.

Intermediate Bulk Container (IBC or Tote): A completely enclosed storage vessel

used to hold liquid, solid, or gaseous commodities or material which are in direct

contact with the container interior.

Preflush: Within a drum or container cleaning process, a rinse, typically with hot

or cold water, performed at the beginning of the cleaning sequence to remove heel

(i.e., residual material) from the drum or container.

Pre-steam: Within a drum or container cleaning process, use of steam at the beginning

of the cleaning process to remove heel (i.e., residual material) from the drum, or container

interior.

5 Instructions

5.1 Waste Reduction

The first-in, first-out inventory (FIFO) system shall be utilized at materials

storage facilities. Such system shall optimize chemical utilization and

minimize waste generation.

Containers shall be emptied as designed using appropriate techniques.

Other methods, such as puncturing or damaging the containers, which could

cause spillage, shall not be used.

55 gallon drums shall be emptied using pumps equipped with a non-return

valve. Using such pumps shall reduce 1–5 liters of heel (residue), equating

to 0.5–2.5% of the drum’s contents.

The opening of the container shall be sealed or closed after each use.

Containers previously used for Volatile Organic Compounds (VOCs) shall

be sealed immediately after use to avoid volatilization of materials.

Where feasible, any un-pumpable heels remaining at the bottom of the

container shall be recovered. Heel can be recovered by safely inverting the

container in any orientation and draining the content into another container

for further use.

Chemicals shall be purchased in appropriate volumes and container sizes.

Ordering excess material shall always be avoided.

It is recommended to purchase chemicals from suppliers who are willing to

accept return of used containers for refilling.

Saudi Aramco: Company General Use

Page 5 of 13

Document Responsibility: Environmental Standards Committee SAEP-65

Issue Date: 2 October 2017

Next Planned Update: 2 October 2020 Empty Container Management

Whenever possible, substitution of hazardous materials with non-hazardous

materials shall always be investigated.

5.2 Container Handling

Hazardous materials shall be handled as per the company Construction

Safety Manual (CSM).

Containers should be handled as if full, even if marked “empty”.

Containers should be labelled to indicate their contents.

Labels should be preferably stenciled with paint onto containers or labels

shall be used that are resistant to deterioration due to weather, etc., until the

containers are finally disposed of.

Safety Data Sheets (SDS) and/or Chemical Hazard Bulletins (CHBs) shall be

provided for the specifically named products within the containers,

generic/read-across chemicals shall not be used.

Close all bungholes and lids before containers are transported to prevent

spillage of contents.

Basic training and knowledge shall be provided to personnel handling

containers so they are aware of handling hazards.

Operators of forklifts and cranes shall be certified for the equipment they

use, and carry current proof of certification at all times.

5.3 Storage Requirements

The container storage area shall be aboveground with impervious surface to

contain leaks or spills. Storage areas shall be curbed and coated or lined

with liquid-tight, chemical-resistant coatings or liners.

The storage area shall be sloped downward to a collection sump pit.

Containers of volatile chemicals shall be stored in shaded areas to avoid

excessive pressure build-up in the drums.

Containers containing incompatible chemicals (e.g., acids and bases or

flammables and oxidants) shall be segregated. The storage area shall be

designed so that spills or leaks from incompatible materials drain to separate

collection sumps or low points.

Inspect storage areas regularly for any cracks or leaks and repair as soon as

possible.

Saudi Aramco: Company General Use

Page 6 of 13

Document Responsibility: Environmental Standards Committee SAEP-65

Issue Date: 2 October 2017

Next Planned Update: 2 October 2020 Empty Container Management

5.4 Spill Control and Handling

An appropriate spill kit containing absorbent materials shall be located in the

container storage area.

A leak-sealing kit (for temporarily seal leaking drums) shall be available at

delivery and handling areas and at other high-risk locations. Consider

establishing a ‘quarantine area’ where leaking containers can be placed safely.

Any spillage from hazardous materials shall be contained for proper disposal

at an EPD-approved waste management facility.

A detailed spill control plan (SPCC Spill Prevention Containment and

Countermeasure) shall be kept available at storage facilities.

5.5 Transport Requirements

Prepare a waste manifest form for the containers having acutely

hazardous/hazardous materials using SAP-EH&S.

Attached the Chemical Hazard Bulletin (CHB) of each material with the

manifest form.

Containers shall be strapped and palletized.

Containers shall be inspected before transportation to ensure they are not

leaking.

Containers shall be transported by all around secured vehicle.

Drivers shall always be in close proximity of the truck to prevent theft and to

take any action if an emergency occurs.

Transportation of containers shall not take place in private vehicles.

Vehicles transporting containers shall be appropriately placarded.

For road safety, the transport vehicle shall not be overloaded with containers

beyond its intended capacity.

Containers transported to contractors for cleaning shall be manifested using

SAP EH&S system.

5.6 Heel Recovery

The heel remaining in the container shall be safely removed before cleaning

the container. Removal of heel shall significantly minimize water and

chemicals consumption used for cleaning containers.

Saudi Aramco: Company General Use

Page 7 of 13

Document Responsibility: Environmental Standards Committee SAEP-65

Issue Date: 2 October 2017

Next Planned Update: 2 October 2020 Empty Container Management

The heel recovery shall be conducted in a safe manner that reduces human

exposure to hazardous chemicals and prevents soil and groundwater

contamination.

A qualified Hazardous Materials Advisor shall be consulted before

recovering hazardous materials from containers.

Incompatible heel materials shall not be mixed in a single container.

Highly reactive materials, and acutely hazardous materials shall not be

drained at Saudi Aramco facilities. These materials shall remain in their

containers for proper treatment and disposal at EPD approved waste

management facility or returned back to Procurement & Supply Chain

Management (P&SCM).

The recovered heel shall either be used by the proponent, or treated and

disposed of at an EPD-approved waste management facility.

5.7 Cleaning Procedures

Containers Containing Hazardous Materials/Waste

1. Inspection: The containers shall be inspected to identify any remaining heel.

2. Pre-steaming: Containers shall be pre-steamed to enhance heel removal.

3. Caustic Washing: Empty containers shall be washed by spraying the

interior and exterior with hot caustic solution.

4. Rinsing: After caustic washing, containers shall be multiple-rinsed with

clean water.

5. Chaining: When the contents of a steel drum are difficult to remove using

only hot caustic, the facility may use a process called chaining in which

chains are inserted into the drum, along with caustic, and the drum is

tumbled to remove remaining materials. (Chaining is not applicable to

washing plastic drums). Drums may require a second chaining cycle.

Rusty drums are washed with a hydrochloric acid solution in the same

manner as caustic washing described above, followed by one or more

rinses.

Containers Containing Non-hazardous Materials/Waste

1. Inspection: The Containers shall be inspected to identify any remaining heel

2. Rinsing: Containers shall be single rinsed with clean water

Saudi Aramco: Company General Use

Page 8 of 13

Document Responsibility: Environmental Standards Committee SAEP-65

Issue Date: 2 October 2017

Next Planned Update: 2 October 2020 Empty Container Management

5.8 Wastewater Treatment and Disposal

If containers cleaning activities are performed inside Saudi Aramco premises,

treatment and disposal of residual wastewater shall be in accordance with

SAES-A-104 and the Saudi Aramco Hazardous Waste Code. If there is no

adequate treatment facility, effluent wastewater shall be treated and disposed of

by an EPD approved drum cleaning contractor.

5.9 Personal Protective Equipment (PPE)

Body: Coveralls or chemical resistant aprons shall be worn while transferring

chemicals and while cleaning Containers.

Head Protection: A hardhat or helmet shall be worn while operating heavy

equipment (e.g., forklifts or cranes) or when working under anything that

could fall.

Eye and Face Protection: Chemical goggles shall be worn while transferring

chemicals and while cleaning Containers.

Hand Protection: The type of the gloves should be based on the job criteria

as follows:

o Leather gloves: For handling and moving Containers

o Chemical resistant gloves: For cleaning the Containers

o Cut resistant (Kevlar) gloves: While drums are being crushed

Foot Protection: Chemical resistant boots shall be worn while transferring

chemicals and cleaning Containers.

Hearing Protection: Ear protection such as earplugs shall be worn at work

sites where the noise level exceeds 85 dBA.

Respiratory Protection: Respirators with the appropriate cartridges

shall be worn according to the SDS or CHB of the chemicals being handled.

A respirator program shall be in place that includes employee training,

respirator maintenance and cartridge change out schedule.

The emergency eyewash and shower facilities shall comply with

SAES-B-069.

5.10 Training

HAZCOM training shall be provided before any person handles, uses, or

disposes of hazardous materials.

Saudi Aramco: Company General Use

Page 9 of 13

Document Responsibility: Environmental Standards Committee SAEP-65

Issue Date: 2 October 2017

Next Planned Update: 2 October 2020 Empty Container Management

Hazard awareness and familiarization for all employees handling chemicals,

including minimum PPE requirements and how to wear PPE.

Emergency Response Plan training shall be provided to hazardous materials

transporters.

6 Responsibilities

Title or

Action or Task

Organization

Environmental Protection Department (EPD) shall be responsible for

the administration, coordination, and execution of the containers

cleaning contractor program. Duties include planning survey

schedules, setting up Survey Teams, conducting all meetings,

leading the on-site surveys, preparing the Final Reports, and tracking

follow-up actions and approving qualified contractors for container

cleaning services.

Environmental

Protection EPD shall initially assess containers cleaning contractors and

Department approve them.

(EPD)

EPD shall monitor the performance of the approved empty containers

cleaning contractors on an annual basis and suspend them if they

violate Saudi Aramco procedures or they fail to maintain valid

General Authority for Meteorology and Environmental Protection

(GAMEP) or Royal Commission (RC) permits.

EPD shall submit the inspection report to the contracting department

if the contractor was found violating EPD requirements.

Proponents shall exert all possible efforts to completely empty

Containers and IBCs at their facilities.

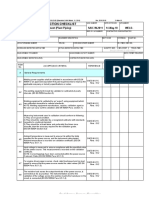

Small quantity generators (less than 2000 drums or IBCs per year)

shall transport their empty containers to DPC-280 for cleaning.

Figure 1 describes the empty container process flow for small

Proponent quantity generators.

Large quantity generators (more than 2000 drums and IBCs per year)

shall secure a contract with EPD approved container cleaning

contractor. The contractor shall coordinate with the proponent and

P&SCM before transporting clean containers to DPC-280. Figure 2

describes the empty container process flow for large quantity

generators.

Contracting The Contracting Department is responsible for the procurement of

Department contracts and for administrative procedures as specified in the Saudi

Aramco Contracting Manual.

Saudi Aramco: Company General Use

Page 10 of 13

Document Responsibility: Environmental Standards Committee SAEP-65

Issue Date: 2 October 2017

Next Planned Update: 2 October 2020 Empty Container Management

Title or

Action or Task

Organization

Materials Logistics Department shall receive 55 gallon Empty

Containers and IBCs from small quantity generators at DPC-280

reclamation yard.

Materials Materials Logistics Department shall transport Containers that require

Logistics cleaning to EPD approved Containers cleaning contractors.

Department

P&SCM shall ensure that empty container cleaning contractors

return clean drums to DPC-280. Each Proponent and P&SCM are

responsible to verify the number of empty drums sent to container

cleaning contractors with the number received at DPC-280.

Loss Prevention Advise on field safety precautions on request.

Department

Shall be approved by the General Authority for Meteorology and

Used Environmental Protection (GAMEP) as hazardous waste transporter

Containers

Transporter Shall submit to EPD a detailed Emergency Response Plan (ERP) for

review and approval.

Shall be approved by GAMEP for hazardous waste management.

Shall submit to EPD the empty containers cleaning process.

The contractor shall clean Containers as described in 5.7 and return

them to Saudi Aramco.

The contractor shall treat the effluent wastewater generated from

cleaning activities to levels that meet GAMEP or RC effluent

discharge regulations.

No hazardous wastewater shall be discharged to evaporation ponds

prior to treatment.

Used

Containers If the Containers are damaged and can no longer be reused, the

Cleaning contractor shall shred the Containers after notifying Materials Logistic

Contractors Department. If the Containers contained Hazardous waste,

Contractor shall shred and dispose them at hazardous waste landfill.

If it is agreed upon in the contract, the facility undergoing an

inspection should furnish a technical liaison that is qualified to work

with the EPD inspection team. The contractor shall provide access

and logistical support to the team and allow them to inspect their

facilities, interview their employees, and review their documents as

requested by the inspection Team Leader.

The Contractor shall address and resolve all of the survey team's

findings and provide status reports, as requested.

The contractor shall maintain a current and valid PME license.

Saudi Aramco: Company General Use

Page 11 of 13

Document Responsibility: Environmental Standards Committee SAEP-65

Issue Date: 2 October 2017

Next Planned Update: 2 October 2020 Empty Container Management

Figure 1 – Small Quantity Generators

Saudi Aramco: Company General Use

Page 12 of 13

Document Responsibility: Environmental Standards Committee SAEP-65

Issue Date: 2 October 2017

Next Planned Update: 2 October 2020 Empty Container Management

Figure 2 – Large Quantity Generators

Revision Summary

2 October 2017 New Saudi Aramco Engineering Procedure developed by a multi-departmental taskforce led by

EPD to assess and streamline empty drum management practices.

Saudi Aramco: Company General Use

Page 13 of 13

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Biological Wastewater Treatment Process Design Calculations: Harlan H. Bengtson, Pe, PHDDocument116 pagesBiological Wastewater Treatment Process Design Calculations: Harlan H. Bengtson, Pe, PHDEnder Gökmen100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pre Welding ChecklistDocument2 pagesPre Welding Checklistmunna100% (3)

- Schedule I Company Attachment IDocument1 pageSchedule I Company Attachment ImunnaNo ratings yet

- Edible Oil GheeDocument25 pagesEdible Oil GheeLTE00233% (3)

- ESWTD 2ndedn Final PDFDocument396 pagesESWTD 2ndedn Final PDFrupak100% (1)

- Satip M 100 09Document10 pagesSatip M 100 09munnaNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Saic RT 2001Document24 pagesSaic RT 2001munnaNo ratings yet

- Satip Q 001 03Document10 pagesSatip Q 001 03munnaNo ratings yet

- Satr P 3206Document6 pagesSatr P 3206munnaNo ratings yet

- Satip X 400 01Document11 pagesSatip X 400 01munnaNo ratings yet

- Saic RT 2007Document9 pagesSaic RT 2007munnaNo ratings yet

- Architectural Painting Works Ins ChecklistDocument2 pagesArchitectural Painting Works Ins Checklistmunna100% (1)

- Satip M 100 07Document10 pagesSatip M 100 07munnaNo ratings yet

- Satip Q 006 03Document10 pagesSatip Q 006 03munnaNo ratings yet

- Satip M 100 10Document10 pagesSatip M 100 10munnaNo ratings yet

- Saic W 2090Document2 pagesSaic W 2090munnaNo ratings yet

- Saep 342Document5 pagesSaep 342munnaNo ratings yet

- Saic P 3105Document2 pagesSaic P 3105munnaNo ratings yet

- 01 Samss 010Document12 pages01 Samss 010Ahmed Shaban KotbNo ratings yet

- Saep 397Document9 pagesSaep 397munnaNo ratings yet

- Schedule B - Attachment IDocument27 pagesSchedule B - Attachment Imunna100% (2)

- Schedule FDocument5 pagesSchedule FmunnaNo ratings yet

- Saep 42Document11 pagesSaep 42munnaNo ratings yet

- Schedule C - Attachment 01Document50 pagesSchedule C - Attachment 01munnaNo ratings yet

- Saep 74Document29 pagesSaep 74munna100% (2)

- Saep 750Document19 pagesSaep 750munnaNo ratings yet

- 01-SAMSS-333-HF Welded Line Pipe PDFDocument35 pages01-SAMSS-333-HF Welded Line Pipe PDFmunnaNo ratings yet

- Dp-07design Principles Transmission Water WW Pipeline SystemsDocument70 pagesDp-07design Principles Transmission Water WW Pipeline SystemsEko PrasetyoNo ratings yet

- Indonesia Country Report..Document18 pagesIndonesia Country Report..Prashanta PanditNo ratings yet

- Chemical Engineering Journal: Yingshi Zhu, Fengxia Deng, Shan Qiu, Fang Ma, Yanshi Zheng, Lei GaoDocument11 pagesChemical Engineering Journal: Yingshi Zhu, Fengxia Deng, Shan Qiu, Fang Ma, Yanshi Zheng, Lei GaoFlori DediuNo ratings yet

- Trickling Filter For HighDocument3 pagesTrickling Filter For HighepebeNo ratings yet

- Blue Plains Plant Brochure PDFDocument7 pagesBlue Plains Plant Brochure PDFAfzal AhmadNo ratings yet

- Waste Water PDFDocument150 pagesWaste Water PDFAnonymous TjdHCu100% (1)

- Passavant E&E Company Profile-4th QTRDocument77 pagesPassavant E&E Company Profile-4th QTRSami Sawalha100% (1)

- WHO On MicroplasticsDocument124 pagesWHO On MicroplasticsEuronews Digital Platforms100% (1)

- Water Treatment Processes and Treatment Units: Process of Treating Water by Plain SedimentationDocument6 pagesWater Treatment Processes and Treatment Units: Process of Treating Water by Plain SedimentationStanley Scott ArroyoNo ratings yet

- Techno-Commercial Proposal of 100 KLD STPDocument9 pagesTechno-Commercial Proposal of 100 KLD STPpccmitsNo ratings yet

- Nurlina DKK 2015 Pengolahan Limbah Cair Dengan TawasDocument11 pagesNurlina DKK 2015 Pengolahan Limbah Cair Dengan Tawasmay andy dwi wantoroNo ratings yet

- 17 Lab SolidsDocument5 pages17 Lab SolidsNoah BenkoNo ratings yet

- Sludge ProductionDocument6 pagesSludge ProductionjnmanivannanmechNo ratings yet

- Ahn 1999 PDFDocument11 pagesAhn 1999 PDFevinNo ratings yet

- Presby Environmental, Inc.: Technical BulletinDocument3 pagesPresby Environmental, Inc.: Technical BulletinSteve DennisNo ratings yet

- Creando Una Universidad VerdeDocument7 pagesCreando Una Universidad VerdeRivera Abraham JoseNo ratings yet

- Trends and Resource Recovery in Biological Wastewater Treatment System PDFDocument16 pagesTrends and Resource Recovery in Biological Wastewater Treatment System PDFCarlos GamarraNo ratings yet

- Wastewater CollectionDocument11 pagesWastewater CollectionkaiNo ratings yet

- Pak Water Expo: EnergyDocument7 pagesPak Water Expo: EnergyasmaNo ratings yet

- Colloidal Silica Removal in Coagulation - PubMed MobileDocument1 pageColloidal Silica Removal in Coagulation - PubMed MobileSandeep MishraNo ratings yet

- FIP Water Treatment Solutions 2017 LRDocument28 pagesFIP Water Treatment Solutions 2017 LRSomaia Al-AkrasNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 Mechkarthi51289No ratings yet

- Potential Use of Eco-Enzyme For The Treatment of Metal Based EffluentDocument7 pagesPotential Use of Eco-Enzyme For The Treatment of Metal Based EffluentAdvennie NuhujananNo ratings yet

- MPCA Water Quality Rule Report April 9, 2021Document35 pagesMPCA Water Quality Rule Report April 9, 2021Duluth News TribuneNo ratings yet

- Zeolites in Water Treatment PDFDocument32 pagesZeolites in Water Treatment PDFsili11No ratings yet

- Palm Oil Thesis StatementDocument9 pagesPalm Oil Thesis StatementCollegePaperGhostWriterAkron100% (2)

- Weftec19 ProspectusDocument60 pagesWeftec19 ProspectusFrank HayesNo ratings yet