Professional Documents

Culture Documents

Seleccion - Bomba Liquiflo - Modelo H

Seleccion - Bomba Liquiflo - Modelo H

Uploaded by

Jonathan VillagraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seleccion - Bomba Liquiflo - Modelo H

Seleccion - Bomba Liquiflo - Modelo H

Uploaded by

Jonathan VillagraCopyright:

Available Formats

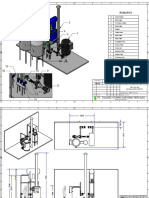

H-SERIES EXTERNAL GEAR PUMP

LIQUIFLO Chemical Processing Pumps

Sealed Pump 1 2 3 Size/Model, Housings & Port Type Bearings

7

Coupling Method Wear Plates

For Close-coupled Pumps; this position indicates the

motor frame size used with the pump. 6

For Long-coupled pumps, simply select Code ”9”. Seal Type Retaining Rings

12

14 8

O-Rings

11

Optional

Shaft

Coating

10

Idler

Shaft

Drive

Shaft

13

Anti-rotation

Pins for Bearings

4 5

Drive Idler 9 Bearing Flush(Option)

Gear Gear (not shown)

Mag-Drive Pump

Magnetic Coupling (inner and outer magnet)

Bore Size

for

Outer 14

Magnet

8 Containment

Can

15

All positions above (in Sealed Pump drawing) not shown

here are the same for the Mag-drive version except for

Positions 8 & 14, which denote type of pump.

15 tel. 908.518.0777 fax. 908.518.1847 w w w. l i q u i f l o . c o m

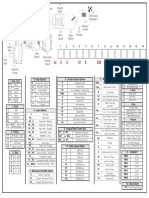

PUMP MODEL CODING Liquiflo H-Series Gear Pumps

Selection & Availability

H-Series Gear Pumps Sample Model No. H5 F S 6 P E E U 0 0 0 0 0 0

Position No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Position 1 Pump Model H1 H3 H5 H7N H7 H9 H12 H14

Example: Model

F = Full Capacity n n n U n n n n

H5FS6PEEU000000, designates a Model Position

Model

2 R = Reduced Capacity U U n U n n n U

H5F Pump with Single Mechanical Seal.

S = 316 SS NPT n n n n n n n U

H5F S 6 P E E U 0 0 0 0 0 0

Position

Basic Material &

3 L

X

=

=

316 SS

316 SS

Flanged 150#

BSPT

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

U

Port Type H = Alloy-C NPT n n n n n n n U

1&2 3 4 5 6 7 8 9 10 11 12 13 14 15 C = Alloy-C Flanged 150# n n n n n n n U

Y = Alloy-C BSPT n n n n n n n U

1 = Alloy-C n n n n n n n U

Pos. Description Selection

Position

Drive Gear

4 3

6

=

=

Teflon

316 SS

CF

n

n

n

n

n

n

n

n

n

n

n

n

n

U

n

K = Kynar n n n n n n U U

1&2 Pump Model H5F H5F Pump P = PEEK n n n n n n n n

3 Basic Mat’l/Ports S 316 SS NPT 1 = Alloy-C n n n n n n n U

4 Drive Gear Mat’l 6 316 SS

Position

Idler Gear

5 2 = Carbon U n n n n n U U

5 Idler Gear Mat’l P PEEK 3 = Teflon CF n n n n n n U

6 Wear Plate Mat’l E Carbon 60 6 = 316 SS n n n n n n n n

8 = Ryton n n n n n n n U

7 Bearing Mat’l E Carbon 60 K = Kynar n n n n n n U U

8 Seal Type U Single-Int, Carbon-SiC P = PEEK n n n n n n n n

9 Bearing Flush 0 None 3 = Teflon n n n n n n n U

10 Shafts 0 316 SS, uncoated

Position

Wear Plates

6 4 = Silicon Carbide n n n n n n n n

11 O-Rings 0 Teflon E = Carbon 60 n n n n n n n n

P = PEEK n n n n n n n U

12 Retaining Ring 0 316 SS

Bearing Pins 0 Teflon Position 3 = Teflon n n n n n n n U

13

14 Coupling Method 0 Close-Coupled (56C motor) Bearings 7 B = Silicon Carbide n n n n n n n n

E = Carbon 60 n n n n n n n n

15 N/A P = PEEK n n n n n n n U

0 = 0.625” (NEMA 56C) n n n n n n U U

Position

Outer Magnet

8 1 = 0.875” (NEMA 143/145TC) n n n n n n U U

Bore 2 = 14 mm (IEC 71 - B5) n n n n n n U U

Liquiflo’s Model Code describes (Mag-Drive) 3 = 19 mm (IEC 80 - B5) n n n n n n U U

both the pump’s size and materials 4 = 24 mm (IEC 90 - B5) n n n n n n U U

selected. This model code is required 5 = 1.125” (NEMA 182/184TC) n n n n n n n n

6 = 1.375” (NEMA 213/215TC) U U U U U U n n

for the future identification of your 7 = 1.625” (NEMA 254/256TC) U U U U U U n n

pump when reordering either a pump 8 = 28 mm (IEC 100/112-B5) U U U n n n n n

or replacement parts. Model code is 9 = 38 mm (IEC 132 - B5) U U U U U U n n

permanently stamped into pump Position U = Single-Int Carbon - SiC n n n n n n n n

housing. Seal Type

8 S = Single-Int Teflon - SiC n n n n n n n U

(Sealed) W = Single-Ext Carbon - SiC n n n n n n U U

X = Single-Ext Teflon - SiC n n n n n n U U

F = Double Carbon - SiC n n n n n n n n

H = Double Teflon - SiC n n n n n n n U

L = Packing Teflon n n n n n n n n

R = Packing Graphoil n n n n n n n n

n Available 0 = Standard Housings n n n n n n U U

U Not Available

Position

Bearing Flush

9 1 = External Bearing Flush n n n n n n n n

Option 2 = Internal Bearing Flush n n n n n n n n

CF Contact Factory

Position 0 = Material same as housing (uncoated) n n n n n n n n

Shafts

10 1 = Chrome Oxide Coated n n n n n n n U

2 = Tungsten Carbide Coated n n n n n n n n

Position 0 = Teflon CF n n n n n n n

O-Rings 11 6 = 316 SS / FEP encapsulated n n n n n n n n

B = Buna-N n n n n n n n n

E = EPDM n n n n n n n n

V = Viton n n n n n n n n

K = Kalrez n n n n n n n n

Flanges available: ANSI, DIN. Position

Retaining Rings 12 0 = Material same as housing n n n n n n n n

Position 0 = Teflon n n n n n n U U

CONNECTION SIZES Bearing Pins 13 1 = Alloy-C n n n n n n n U

6 = 316 SS n n n n n n n n

H1/H3 H5 H7 H9R H9F H12 H14 0 = Close-Coupled (NEMA 56C) n n n n n n U U

Position

NPT/BSPT 1/

4

1/

2

3/

4 1 11/4 11/4 – Coupling Method 14 1

2

=

=

Close-Coupled (NEMA 143/145TC)

Close-Coupled (IEC 71 - B5)

n

n

n

n

n

n

n

n

n

n

n

n

n

U

n

U

(Sealed)

ANSI 150# RF 1/ 1/ 3/ 1 11/ 11/2 21/ 3 = Close-Coupled (IEC 80 - B5) n n n n n n U U

2 2 4 4 2 4 = Close-Coupled (IEC 90 - B5) n n n n n n U U

DIN PN16 10 15 20 25 32 40 65 5 = Close-Coupled (NEMA 182/184TC) n n n n n n n n

6 = Close-Coupled (NEMA 213/215TC) U U U U U U n n

7 = Close-Coupled (NEMA 254/256TC) U U U U U U n n

8 = Close-Coupled (IEC 100/112 – B5) U U U n n n n n

9 = Close-Coupled (IEC 132 – B5) U U U U U U n n

† Position 3: 9 = Long-Coupled n n n n n n U U

Other Flanged styles available: Position U = 75 in-lbs n n n n n n U U

Contact Factory. Magnetic Coupling 14 B = 120 in-lbs n n n n n n U U

(Mag-Drive) V = 200 in-lbs U U n n n n U U

E = 316 SS Flanged DIN PN16 K = 325 in-lbs U U U U U U n n

F = Alloy-C Flanged DIN PN16 J = 650 in-lbs U U U U U U n n

K = 316 SS Flanged ANSI 300# Position S = Single Wall Can n n n n n n n n

M = Alloy-C Flanged ANSI 300# Containment Can

15 D = Dual Kan n n n n n n n n

-8 = Temperature Trim n n n n n n n n

N = 316 SS Flanged Sanitary Suffix -9D = Viscosity Trim (double clearance) n n n n n n n n

Options -9T = Viscosity Trim (triple clearance) n n n n n n n n

-9D-8 = Visc. Trim (2X) & Temp. Trim n n n n n n n n

-9T-8 = Visc. Trim (3X) & Temp. Trim n n n n n n n n

-8(LT) = Low Temperature (-40 to 32 ˚F) n n n n n n n n

n Long-coupled Sealed pumps (1.125” dia. shaft) 16

You might also like

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualFrom EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualRating: 4.5 out of 5 stars4.5/5 (2)

- Hyundai R130W-3 Hydraulic SystemDocument31 pagesHyundai R130W-3 Hydraulic SystemHai Van100% (1)

- Parts Info 211-212-213-241-243 PDFDocument8 pagesParts Info 211-212-213-241-243 PDFmanutecnicoNo ratings yet

- SSP 055 20 110kw 16 85kw Fsi EngineDocument58 pagesSSP 055 20 110kw 16 85kw Fsi EngineutfNo ratings yet

- 1PF2G Stare Zupcaste PumpeDocument10 pages1PF2G Stare Zupcaste PumpeZlatan Đulbić100% (1)

- Assy - Poppin150Document1 pageAssy - Poppin150Ramos DavidNo ratings yet

- Cardan PDFDocument32 pagesCardan PDFDIEGO FRAUSTONo ratings yet

- DR412i Maintenance Kit PlannerDocument2 pagesDR412i Maintenance Kit PlannerEmanuel Nicolas VillarruelNo ratings yet

- Char Lyn HP30 Motor OrbitalDocument36 pagesChar Lyn HP30 Motor OrbitalDarioNo ratings yet

- 8.1.3 Fork LiftDocument2 pages8.1.3 Fork LiftAdi GhrstaNo ratings yet

- 500 Series Eng. BrochureDocument12 pages500 Series Eng. Brochurelimani76No ratings yet

- g3.. Gear Pump..Re10039Document10 pagesg3.. Gear Pump..Re10039vijayramchandra88No ratings yet

- SeriesV EC VC1 PartsMap 20220405Document2 pagesSeriesV EC VC1 PartsMap 20220405activitybookmarketplaceNo ratings yet

- 3-1 гидравлическая схемаDocument1 page3-1 гидравлическая схемаdima65No ratings yet

- POSTER HolsetHX35Document1 pagePOSTER HolsetHX35Juan Carlos Constanzo PincheiraNo ratings yet

- VIS Standard and Wheel Motors 45 Series: Parts and Repair InformationDocument14 pagesVIS Standard and Wheel Motors 45 Series: Parts and Repair Informationeaglego00100% (1)

- Group 4 Disassembly and Assembly Group 4 Disassembly and AssemblyDocument9 pagesGroup 4 Disassembly and Assembly Group 4 Disassembly and AssemblyREMZONANo ratings yet

- ZF As Tronic Schematic - EDocument2 pagesZF As Tronic Schematic - EBienvenu Massouangui50% (2)

- PGP/PGM 505 How To Specify: PGP/PGM505 Ordering Code Single or Multiple Aluminum Pumps & MotorsDocument5 pagesPGP/PGM 505 How To Specify: PGP/PGM505 Ordering Code Single or Multiple Aluminum Pumps & MotorsMOISESNo ratings yet

- S0020034920-ŠkodaSuperb 2 5-Ltr 114 KW TDI V6 Diesel EngineDocument46 pagesS0020034920-ŠkodaSuperb 2 5-Ltr 114 KW TDI V6 Diesel EngineIongornistuNo ratings yet

- Wpa1210a20 1Document1 pageWpa1210a20 1carlos.delatorreNo ratings yet

- Nitro Catalog 2015Document35 pagesNitro Catalog 2015Carlos Machuca pinoNo ratings yet

- Parts Information: Char-LynnDocument9 pagesParts Information: Char-LynnINVESTIGACION Y DESARROLLONo ratings yet

- Orbitrol Repairing1Document13 pagesOrbitrol Repairing1Islam ShoukryNo ratings yet

- Fork LiftDocument1 pageFork Liftherbert situmorangNo ratings yet

- Sierra Silverado Electrical Body Builders Manual Service Manual 2015 en USDocument898 pagesSierra Silverado Electrical Body Builders Manual Service Manual 2015 en USjocker100% (3)

- BPW Drum Brake CatalogueDocument45 pagesBPW Drum Brake Cataloguesharef18No ratings yet

- En LiquidPumpsDocument13 pagesEn LiquidPumpsJesus RodriguezNo ratings yet

- Predicted. Use As First Guide Only. FGD Acceptance Criteria According To Iso 9906 With No Negative ToleranceDocument1 pagePredicted. Use As First Guide Only. FGD Acceptance Criteria According To Iso 9906 With No Negative ToleranceGabriel MarinoNo ratings yet

- Alim Knit (BD) LTD.: Coagulation Tank With AgitatorDocument1 pageAlim Knit (BD) LTD.: Coagulation Tank With AgitatorKamrul HasanNo ratings yet

- Permanent Gauging BlocksDocument2 pagesPermanent Gauging BlocksJaime RichardsonNo ratings yet

- Q SectionDocument5 pagesQ Sectionm606pazNo ratings yet

- Schema Fonctionnel PDFDocument2 pagesSchema Fonctionnel PDFTiago RomeroNo ratings yet

- 3D View Front Side TOP Slideshow: ClickDocument1 page3D View Front Side TOP Slideshow: ClickMitchell DanielsNo ratings yet

- TECO AEEB AEVB-Pump (Dimension)Document6 pagesTECO AEEB AEVB-Pump (Dimension)Naqib FuadNo ratings yet

- Fixed Displacement Radial Piston Pump: Replaces: 03.95Document16 pagesFixed Displacement Radial Piston Pump: Replaces: 03.95kamalNo ratings yet

- Heavy Duty FD 6 Ton - 10 Ton-BrochureDocument5 pagesHeavy Duty FD 6 Ton - 10 Ton-BrochureRidwanNurAhmadNo ratings yet

- H9 NewDocument2 pagesH9 NewEven VanNo ratings yet

- Power UnitDocument24 pagesPower UnitJohnnot PeagunNo ratings yet

- Wilwood Disc Brakes - Front Brake Kit DescriptionDocument1 pageWilwood Disc Brakes - Front Brake Kit DescriptionAnil dNo ratings yet

- Outline 12 - 2 Troubleshooting Guide 12 - 2 Wheels and Tires 1 2 - 3Document6 pagesOutline 12 - 2 Troubleshooting Guide 12 - 2 Wheels and Tires 1 2 - 3Fernando VargasNo ratings yet

- Service Description CB DRIVE HMB4-8 1HC0082505 E01 AADocument2 pagesService Description CB DRIVE HMB4-8 1HC0082505 E01 AAaalbaki1No ratings yet

- Renr 3976Document1 pageRenr 3976jose luis baldiviezo olmosNo ratings yet

- Renr2876 01Document2 pagesRenr2876 01Ebied Yousif AlyNo ratings yet

- SBS Instalment Plans at 0% Markup : Alfalah Credit Cards Application FormDocument2 pagesSBS Instalment Plans at 0% Markup : Alfalah Credit Cards Application FormAdeel ShafqatNo ratings yet

- 15-5 Cylinder Head Assembly PDFDocument2 pages15-5 Cylinder Head Assembly PDFmefisto06cNo ratings yet

- 216 and 226 Hydraulic System Skid Steer LoadersDocument2 pages216 and 226 Hydraulic System Skid Steer LoadersRICHARDNo ratings yet

- DWO-P-05-76 - Intalasi + Layout TOH 200 VDCDocument2 pagesDWO-P-05-76 - Intalasi + Layout TOH 200 VDCMuhamad Shofiyuddin EsteNo ratings yet

- 6D1l 2Document1 page6D1l 2Jasm LiuNo ratings yet

- 50/51 Series: Continental Shaft OnlyDocument1 page50/51 Series: Continental Shaft OnlyJuan Alejandro Cañas ColoradoNo ratings yet

- A New Robot With The Fastest Motion Speed in Its Class Is Born!Document2 pagesA New Robot With The Fastest Motion Speed in Its Class Is Born!Anonymous 0WUktHN0No ratings yet

- PFI Housing Filter Cartridge High FlowDocument3 pagesPFI Housing Filter Cartridge High Flowbennypartono407No ratings yet

- Make Tail Wheel Doors From 1/16"x1/8" Balsa Strip StockDocument8 pagesMake Tail Wheel Doors From 1/16"x1/8" Balsa Strip StockJose Antonio Lobo GerardinoNo ratings yet

- Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2Document1 pageWpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2risa ridmaNo ratings yet

- Char-Lynn: Power SteeringDocument13 pagesChar-Lynn: Power SteeringJohn Cadenillas Rumay100% (1)

- SEW Eurodrive DTDV - Gearmotor - NomenclatureDocument2 pagesSEW Eurodrive DTDV - Gearmotor - NomenclaturesachinumaryeNo ratings yet

- Supply Circuit Front Circuit Rear Circuit Parking Brake Circuit Accessories CircuitDocument1 pageSupply Circuit Front Circuit Rear Circuit Parking Brake Circuit Accessories Circuitalfredo reyesNo ratings yet

- Porsche 356: The Engine Handbook: An Engine Assembly GuideFrom EverandPorsche 356: The Engine Handbook: An Engine Assembly GuideNo ratings yet

- Informacion - Bombas de Trasvase Portatil - Gruen PumpsDocument8 pagesInformacion - Bombas de Trasvase Portatil - Gruen PumpsJonathan VillagraNo ratings yet

- Informacion - Motobomba Wastecorp - Modelo TFCC-6MLDocument3 pagesInformacion - Motobomba Wastecorp - Modelo TFCC-6MLJonathan VillagraNo ratings yet

- Bombas Vogelsang - Industria AzucaceraDocument16 pagesBombas Vogelsang - Industria AzucaceraJonathan VillagraNo ratings yet

- Hoja Tecnica - Sello Mecanico - Marca FlowserveDocument4 pagesHoja Tecnica - Sello Mecanico - Marca FlowserveJonathan Villagra100% (1)

- Catalogo Seko Tekna EvoDocument12 pagesCatalogo Seko Tekna EvoJonathan VillagraNo ratings yet

- Cabezal Scanjet - Modelo Bio10Document2 pagesCabezal Scanjet - Modelo Bio10Jonathan VillagraNo ratings yet

- Bomba SERA - Modelo RF410.2 PDFDocument2 pagesBomba SERA - Modelo RF410.2 PDFJonathan VillagraNo ratings yet

- Hollow Cone Nozzles Tangential-Flow Ramp Bottom Series 373: (Female NPT)Document1 pageHollow Cone Nozzles Tangential-Flow Ramp Bottom Series 373: (Female NPT)Jonathan VillagraNo ratings yet

- Informacion Tecnica - Bomba SERA - Modelo RF409.2 PDFDocument2 pagesInformacion Tecnica - Bomba SERA - Modelo RF409.2 PDFJonathan VillagraNo ratings yet

- InglesDocument6 pagesInglesJonathan VillagraNo ratings yet

- Linksys AdapterDocument1 pageLinksys AdapterJonathan VillagraNo ratings yet

- Duro Drive Installation PDFDocument14 pagesDuro Drive Installation PDFmagantiramuduNo ratings yet

- Combinepdf (3) - MinDocument15 pagesCombinepdf (3) - MinGabriel BwalyaNo ratings yet

- 32 Sensors Rotary-EncodersDocument74 pages32 Sensors Rotary-Encoderssoryn_25No ratings yet

- Scanned Manual: Cooper Nuclear Station Vendor Manual Mfr. Byron Jackson Pump DivisionDocument77 pagesScanned Manual: Cooper Nuclear Station Vendor Manual Mfr. Byron Jackson Pump DivisionEdison Marin MuñozNo ratings yet

- UntitledDocument417 pagesUntitledNam HongNo ratings yet

- ASD Tug Specification - PTBDocument29 pagesASD Tug Specification - PTBNasrulSyahruddinNo ratings yet

- Acoples Bowex - Larrique Rulemanes PDFDocument15 pagesAcoples Bowex - Larrique Rulemanes PDFSergio ManzurNo ratings yet

- 2018 Winter Model Answer PaperDocument23 pages2018 Winter Model Answer Papershantanu waraleNo ratings yet

- A Novel Gear Test Rig With Adjustable PDFDocument10 pagesA Novel Gear Test Rig With Adjustable PDFjgjNo ratings yet

- ABB Motors MaintenanceDocument52 pagesABB Motors MaintenanceArdelean Paul100% (1)

- Dynatech T56 Spares ListDocument109 pagesDynatech T56 Spares ListrizkyNo ratings yet

- Taylor Gauge Catalog 7.14Document40 pagesTaylor Gauge Catalog 7.14Marco CastilloNo ratings yet

- Variable Fill Fluid CouplingsDocument8 pagesVariable Fill Fluid CouplingsAnupam XessNo ratings yet

- 6 Sem SyllabusDocument7 pages6 Sem SyllabusAjinkya NawghareNo ratings yet

- Combined With LCP Locking Compression Plate.: DLS Dynamic Locking ScrewDocument24 pagesCombined With LCP Locking Compression Plate.: DLS Dynamic Locking ScrewGenni Jose Leli HernandezNo ratings yet

- SGEA Series Drive CouplingsDocument5 pagesSGEA Series Drive CouplingsJorge De FezNo ratings yet

- BHEL EncoderDocument248 pagesBHEL EncoderArnab GhoshNo ratings yet

- E2 Product Overview CatalogueDocument76 pagesE2 Product Overview CatalogueKrzysztof OkrajekNo ratings yet

- S-001-M-004 Mechanical Equipment InstallationDocument23 pagesS-001-M-004 Mechanical Equipment InstallationGeoffWilliams1956No ratings yet

- Design of Quick Connect-Disconnect Hydraulic CouplingDocument13 pagesDesign of Quick Connect-Disconnect Hydraulic CouplingSharat ChandraNo ratings yet

- Fundamentals of Machine DesignDocument2 pagesFundamentals of Machine DesignGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- QST30 FIP Replace PDFDocument18 pagesQST30 FIP Replace PDFAli Samhat100% (2)

- Centrifugal PumpsDocument30 pagesCentrifugal PumpsNitish NairNo ratings yet

- Question Bank 2 DME 1Document4 pagesQuestion Bank 2 DME 1Ayush KothariNo ratings yet

- Sdtork: 4000-SERIES Data Sheet Ref. No: SD-5000-001 Electrical Actuator Technical SpecificationsDocument6 pagesSdtork: 4000-SERIES Data Sheet Ref. No: SD-5000-001 Electrical Actuator Technical SpecificationsChaitannya MahatmeNo ratings yet

- JH 7 Types of AbnormalitiesDocument30 pagesJH 7 Types of AbnormalitiesAnil ShelkeNo ratings yet

- Methodology For Sag Mill InstallationDocument5 pagesMethodology For Sag Mill InstallationFranco Angelo RegenciaNo ratings yet

- The DIY Smart Saw - Desktop Version - PlansDocument39 pagesThe DIY Smart Saw - Desktop Version - PlansEduardo Hassin RodriguesNo ratings yet

- Goulds 3910 BulletinDocument12 pagesGoulds 3910 BulletinLuevandresNo ratings yet

- Motor Selection 1Document22 pagesMotor Selection 1abhishek_918No ratings yet