Professional Documents

Culture Documents

gc35mh 32mr D Compact PLC

gc35mh 32mr D Compact PLC

Uploaded by

LEKH021Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

gc35mh 32mr D Compact PLC

gc35mh 32mr D Compact PLC

Uploaded by

LEKH021Copyright:

Available Formats

1 2

Fixing of Main Unit

Unit Description

Detach all the terminal blocks (10-pin

GC35MH-32MT-DS 16 Pt. 24 VDC Digital Input, Sink/ Source + 16 Pt. 24 VDC Transistor Output, Sink type, 300mA per output

I/O terminal blocks and 3-pin power

GC35MH-16MT-DS 8 Pt. 24 VDC Digital Input, Sink/ Source + 8 Pt. 24 VDC Transistor Output, Sink type, 300mA per output supply terminal block) from Main unit.

Make sure that gasket on outer

GRAPHIC OPERATION CONTROLLER - MAIN UNIT periphery of front panel backside is in

MODEL 4 GENERAL SPECIFICATIONS place.

GC35MH-32MT-DS Environmental EMC–Immunity: As required by IEC 61131-2, IEC 61000-6-2

1. Normally, Main unit is provided with

default slide-in label inserted. But user

GC35MH-16MT-DS Operating

Temperature

Operating:

0 to 55 °C

Storage:

-20 to 75 °C

Electro Static Discharge

(IEC 61000-4-2)

±8 KV Air discharge,

±4KV contact discharge

can remove it and insert customized

label as shown in Figure 1. Slit is

provided to insert slide-in label. It is

3

INSTALLATION MANUAL Humidity Operating: Storage: Electrical Fast Transient Power line: ±2 KV,

10 to 90 % RH, 10 to 90 % RH, (IEC 61000-4-4) Digital I/O: ±1 KV,

located at left top on the backside of

Thanks for choosing Graphic Operation Controller (GOC), a micro range of controller which consists of PLC function, HMI Main unit.

No condensation No condensation Analog and communication I/O: ±1 KV

function and illuminated keys embedded. User can attach I/O extension units (up to 2) and COM extension units (up to 2) Insert label from side opposite to the

to add I/Os and to enhance functionality. It is designed to cater most of the automation requirements of any small size, Altitude 2000 m or less Radiation Susceptibility 80 MHz ~ 2.7 GHz, fold such that fold line is aligned with 4

standalone machine. Before installation and wiring of Main unit, please read this manual carefully for safety precautions, (IEC 61000-4-3) 10 V/m to 1 V/m, 80% AM at 1 KHz

slit edge. Shape of folded part is

specifications, dimensional details, installation and wiring guidelines. Pollution level 2 max. (only non-conductive pollution)

Conducted by Radio 0.15 MHz~80 MHz,10V/m, designed such that it doesn’t obstruct

Operating Corrosive gas must not be present Frequency 80% AM at 1 KHz mounding clamp.

1 SAFETY RECOMMENDATIONS atmosphere (IEC 61000-4-6)

Over voltage II (IEC 60664-1) Surge Power line: ±0.5 KV,

2. Remove adhesive tapes provided at

Read and understand the manual carefully before controller use, to avoid damages to persons, property and corners of backside of mounting

category The surge voltage withstand level for up to (IEC 61000-4-5) Digital I/O: ±1 KV,

environments. Ensure safe and proper usage of this controller. the rated voltage of 30V is ±500 V template and stick the mounting

Analog and communication I/O: ±1 KV

The qualified personnel should only install and operate the controller. The personnel should be aware of all safety template on front panel where Main unit

Vibration, Shock As required by EN- 61131-2, Power Frequency 30 A/m, 50 /60 Hz

of automated products and completely familiar with all associated documentation for the said controller. is to be mounted. Mark 4 corners of the

IEC 60068 -2-6 (test Fc),

Manual should be located at the easily retrievable location for reference. Also, share this manual with the end user IEC 60068-2-27 test Ea (IEC 61000-4-8) rectangular cut-out and make a cut out.

of this controller. Dimensions of cut out are 166.5 X 107.5

Class of equipment Front panel mount mm as shown on mounting template in

This controller should be considered as Industrial waste. EMC–Emission: As required by IEC 61131-2, IEC 61000-6-4

IP protection IP65 from front, Figure 2.

Protect the controller from conductive dust, corrosive gases, wire debris, flammable gases, rain and fluid from IP20 from rear Radiated Emission 30 MHz ~ 1000 MHz

entering into the controller through ventilation slits. This may cause malfunction, damage, fire, electrical shock and (CISPR 16-2-3)

3. Insert Main unit from outside through cut 5

deterioration to the controller. out on panel. Make sure that folded part

The controller should not be exposed to direct sunlight, high explosive risk, excessive magnetic interference and of slide-in label is passed through the

inflammable substances.

5 INSTALLATION cut out. Hold Main unit by hand from

Do not modify, dismantle, reconstruct and repair the controller. Do not paint the controller. For repair, contact the Install the controller in an environment conforming to the general specifications and mounting recommendations and outer side of the panel so that it will not

nearest authorized sales office/ technical support. precautions. fall during fitment of mounting clamps.

Provide external interlock circuit like emergency stop or protective circuit to keep the control system safe, in case,

Mounting Recommendations 40° or less 40° or less 4. 2 rectangular openings are provided 6

there is problem in the controller. Especially for output, place fail safe protective circuit external to the controller to near each corner on the extended part

ensure that machine operates safely, in case of the controller fault condition. Also, it is recommended to build 1. Mount controller on a firm, plane and conducting surface. on back side. Insert 'L' shaped

external output monitoring circuit to identify the output to which the problem has occurred. Installation in orientation other than recommended one projections of mounting clamp into

During installation and wiring or maintenance activities of the controller, switch off the controller supply as well as (as shown in adjuscent figure), may cause overheating, matching slots and pull it away from

all the phases of power supply for control panel. Failure to do so may cause personnel injury or controller damage and malfunctioning of the controller. Frontal of panel to engage it into the slots as

malfunction. 2. Mount controller on non-vibrating surface and should be Main unit shown in Figure 4.

Do not touch any terminal while the controller power is on. It may cause electric shocks and malfunction due to protected by rubber pads so that the shock is not felt.

static electricity. 3. Mounting plate thickness should not exceed 4 mm 5. Turn mounting clamp screw in clockwise

direction till tip of screw slightly touches 7

Use controller within the range of general and technical specifications.

inner surface of panel as shown in

Figure 5. Rotate screw an additional ¼ -

2 REFERENCES Control panel or other device

½ turn in clockwise direction and ensure

Programming of the controller is possible by attaching controller is firmly mounted in the panel.

Title Document No. Title Document No. COM extension (GC-ENET-COM or GC-RS232-COM) Fix all the 4 mounting clamps by

unit in COM1 slot. This unit is optional and should be 40 tightening screws one by one

GOC User Manual ED-2002-114 GOC Tool Kit Installation Manual ED-2002-116

purchased separately. Installation should take care of progressively.

GOC 1 Port RS232 Serial COM PD-2002-107 GOC 1 Port Ethernet COM PD-2002-115 keeping free space considering depth of controller with

Extension Installation Manual Extension Installation Manual COM extension unit installed on it i.e. 90 mm inclusive 6. Insert 10-pin input terminal blocks/s at

of additional space required for communication cable upper side.

routing.

3 NOMENCLATURE AND DIMENSIONS Insert 10-pin output terminal block/s at

lower side.

Product packaging consists of Main unit, installation manual, mounting template and 4 mounting clamps. Main unit is User can install upto 2 I/O extension units and upto 2

dispatched with all the terminal blocks attached to it and default slide-in label inserted. Slot covers are attached to I/O slots COM extension units on the back side of Main unit. 7. Insert 3-pin power supply terminal block.

and COM slots. The figure below shows model GC35MH-32MT-DS with 2 terminal blocks each for inputs and outputs. Refer installation manuals of respective extension

Model GC35MH-16MT-DS provides 1 terminal blocks each for input and output. units.

40

18.0

164.5 7.65

Removal of Main Unit

4. Ensure the gap of 40 mm between controller and cabinet 90

16 Slide-in label Cut off all the phases of the power supply

6 97.0 walls, other equipments and wiring duct. 8

130 to the control panel.

177.0 5. Leave a minimum space of 40 mm around the Main unit to

facilitate air circulation for heat transfer by natural 8. Remove 3 pin power supply terminal

6 5 1 42.3

54.5 6 8 12 14 convection and easy fixing and removal of unit. block.

40

38.3 Remove all the I/O terminal blocks. For

Graphic Operation Controller GOC35

removal, pull terminal block from one

side first. Once this part is out, pull

K1 K2

24VDC, Digital input, Sink/Source type 24VDC, Digital input, Sink/Source type

40 40

remaining part easily.

K3 K4 123.0 106.5 9. Turn mounting clamp screws in

K5 K6 17 15 anti-clockwise direction to loosen it.

9

abcde05# fghij16% klmno27@ pqrst38_ uvwxyz49.

K7 K8

Push body of clamp towards panel

to disengage it from matching slots

a/A +/- Esc

I/O Sys

40 on the Main unit.

Pull body of clamps off the Main 10

Precautions to be taken

unit. Hold Main unit with one hand while

9 2 3 4 undoing last of the clamps.

7 10 9 11 13 1. Make sure to cut off all the phases of the power supply externally before attempting installation or wiring work.

Failure to do so may cause electric shock or damage to the product.

16 10. After removing all mounting

Note: All dimensions are in mm

2. Maintain proper thermal distances between equipments producing heat (like heaters, transformers, etc) inside clamps, pull out unit from outside,

7

the control panel. Do not install controller above such equipments. to remove it from cut out.

3. Exposure to humid environment for a long time can reduce component life. It may cause corrosion of electrical

1. 128 x 64 pixels LCD with backlit 10. IO1 slot and electronic components, or may lead to shorts or malfunctions. Do not expose controller to humid

2. Function keys [F1 to F5] 11. IO2 slot atmosphere for an extended period.

3. HMI keys for display navigation and settings 12. IO slot cover 4. Avoid controller exposure to excessive or continuous vibrations or shocks. Failure to do so may cause

4. 8 illuminated keys 13. COM1 slot disenguagement of PCB components, sockets, on-board soldered components etc. from their counter

5. LED indications [POWER: RUN] 14. COM2 slot positions.

6. Slide-in label 15. COM slot cover 5. Cover unused slots (IO and COM) to protect them against dust, moisture and ESD (Electric Static Discharge).

7. 24 VDC supply terminal block [+24VDC, 0V, Earth] 16. Slot for mounting clamp 6. Use controller within the range of general and technical specifications

8. 2 nos., 10-pins input terminal block 17. Slot projection

9. 2 nos., 10-pins output terminal block

Precautions to be taken

6 TECHNICAL SPECIFICATIONS Make sure to cut off all phases of the power supply externally before attempting installation or wiring work. Failure to

8 CONFIGURATION AND PROGRAMMING

do so may cause electric shock or damage to the product. Programming software CoDeSys V2.3 is required to program the controller. Integrated tool Hardware Configuration Tool

Power Supply HMI Do not use wire without lug. Do not solder-plate the wire ends.It may cause loose connection. Ensure that only one lug facilitates configuration of special functionality of digital inputs and extension units. Controller HMI functionality can be

Input voltage 24 VDC (18 to 30 VDC including ripple) Display 128 x 64 pixel graphics LCD, is connected to one terminal. programmed by HMI Configuration Tool.

400 mA, 9.6 Watt View size: 70.7 x 38.8 mm Ensure that size of wire and lug used are as per the specifications. Use screw driver with specified size of tip. Tightening Controller can be programmed through Ethernet port or RS232 serial port. For the same, user can fix COM extension unit

torque should be as per the specifications. (GS-ENET-COM or GC-RS232-COM) in COM1 slot. Once programming and commissioning is over, it can be removed if

Inrush current 15 Amps for 6 ms HMI keys

keys for display navigation and settings.

not needed to interface any third party device. In COM1 slot, user can fix and remove COM extension unit as and when

Ensure the gap of 40 mm between controller and cabinet walls, other equipments and wiring duct This will help in

Fuse protection Subminiature fuse T630 mA, 250V, Type required. Refer ED-2002-107 GOC 1 Port RS232 Serial COM Extension Unit Installation Manual, ED-2002-115 GOC 1

natural cooling of controller and also easy mounting or unmounting of hardware.

372, Littelfuse make Illuminated keys 4 x 2 key matrix with dual colored LED Port Ethernet COM Extension Unit Installation Manual. Also refer ED-2002-116 GOC Tool Kit Installation Manual and

(Red, Green) Separate wiring by signal types. Bundle wiring with similar electrical characteristics together. Context sensitive help provided in Hardware Configuration Tool.

Reverse polarity Protected by series diode up to 40 V.

Slide-in label Inserted over illuminated keys Differnetiate wiring with different electrical characteristics by coloured insulations e.g. AC wiring and DC wiring

Dimensions (in mm) Cut-out: 166.5 (W) x 107.5 (H)

Make sure that there is a separate bundle and routing for input and output wires. Fixup the wire bundle with support on

COM extension unit

Front: 177.0 (W) x 123.0 (H) x 4 (D) panel so that there is no stress on wires and subsequently on unit. Ensure that bunch is routed properly and wires are

GC-ENET-COM

not kept hanging.

Rear: 164.5 (W) x 106.5 (H) x 38.3 (D)

Transistor Outputs (Sink type) Do not bundle 24 VDC I/O wires with main control panel wiring. Ethernet

Weight (in grams) GC35MH-32MT-DS 460 Do not bundle cable carrying low level signals like communication and analog signals with input output wiring and

Number of outputs 16 for GC35MH-32MT-DS

GC35MH-16MT-DS 400 8 for GC35MH-16MT-DS control panel wiring.

COM extension unit

Certification CE Type of output Transistor sink type

50 to 100 meter long wiring for input/output will not cause any problems of noise but, generally, the wiring length should GC-RS232-COM

not exceed 30 meters to ensure the safety. For longer distance, route the input and output signal lines separately.

Voltage rating 24 VDC (18 to 30 V including ripple) RS232

Digital Inputs (Sink/ Source type) Ensure that length of wire that connects 24 VDC power supply to I/O unit is less than 3 meters. Locate 24 VDC power

Current rating 300 mA per point supply near to the controller

Number of inputs 16 for GC35MH-32MT-DS 1 common per group of 8 outputs

8 for GC35MH-16MT-DS Power Supply Wiring

On voltage drop 0.6 VDC maximum For programming of GOC, fix RS232 serial / Ethernet COM extension unit in COM1 slot. Use programming cable

Voltage rating 24 VDC (18 to 30 V including ripple) Connect EARTH terminal directly to clean earth in the control panel avoiding ground loops.

Off state leakage 5 µA maximum (ordering code 9910) with RS232 serial COM extension unit

Type Sink or Source in group of 4, with one current

Perform Class D grounding. (Grounding resistance: 100 Ω or less)

common per group Ground the controller independently. If it cannot be grounded independently, ground it jointly as shown.

Response time OFF to ON 82 µs

ON voltage level 18 VDC minimum 9 STATUS AND DIAGNOSTICS ON LCD SCREEN

ON to OFF 92 µs External External External

OFF voltage level 5 VDC maximum Controller Circuits Controller Circuits Controller Circuits After powering on the controller, CPU detects presence of Main unit as well as I/O extension units if attached. The status

Isolation Optical 1.5 KV between output and internal

of Main unit is available in system variables and can be monitored on LCD screen. I/O status can be monitored on LCD

Input Current 6 mA at 24 VDC circuit

screen.

On / OFF current ON current : OFF current : Protection Output short circuit protection

6 mA at 24VDC 3.8 mA maximum

Fast demagnetization for inductive loads

Long Key press

Input impedance 5.2 KΩ Ensure that EARTH cable is thick and short as far as possible to provide low impedance path.

Load supply 24 VDC (18 to 30 VDC including ripple)

Transition delay Reverse polarity protection If EARTH is not connected, it may result in electric shock or erroneous operation. +

- Input status (0/1) Output status (0/1)

Isolation Optical 1.5 KV between input and internal I/O terminal blocks Two 10-pin, screw type removable terminal It is recommended to twist power supply cable to minimize adverse effects of noise. for Main unit for Main unit

circuit. blocks for GC35MH-32MT-DS

1.5 KV between groups.

Nil between individual input points in a group. One 10-pin, screw type removable terminal

block for GC35MH-16MT-DS

I/O terminal blocks Two 10-pin, screw type removable terminal

blocks for GC35MH-32MT-DS

One 10-pin, screw type removable terminal User friendly system menu and HMI keys to navigate through menu screens facilitate user to monitor status of the I/O

block for GC35MH-16MT-DS points (Main unit and I/O extension units) in one screen only. For more details, refer ED-2002-114 GOC User Manual.

User can monitor ordering code of Main unit using CoDeSys project, in Global variables list. →

Digital Input Wiring Click on CoDeSys tab, Resources→Global_variables→_SYSVARCPU →

AMODULEOREDERINGCODE.AMODULEOREDERINGCODE[0]

Digital Inputs Special Functions (User Configurable) Unit provides 1 common each for a group of 4 inputs. Any group can be wired for sink or source operation independently.

Single phase counters (up to 2 nos.) Counter Input The wiring diagram below shows how to connect field input devices like potential free push buttons and limit switches for LED Indications

sink and source operation. The diagram also shows connection of typical proximity switch. PNP type of switch is connected

Counter0 Input I00 Main unit provides 2 LED indications on front panel. The table below explains the significance of CPU diagnostics related

for sink type of operation and NPN type of switch is connected for source type of operation.

Counter1 Input I03

LEDs

Here, input group I00 to I03 connected for source type of operation and input group I08 to I11 connected for sink type of

Input frequency: 20 KHz maximum operation

Status Power ( ) Run ( )

Pulse ON/ OFF time: 20 µsec minimum

Some of the input devices like proximity switches may malfunction due to inherent off state leakage current. Red Green

Quadra-ture encoder (Up to 2 nos.) Encoder A phase B phase Z marker Ensure that proper bleeder resistor is connected as a load considering maximum OFF current specified.

OFF No power User stop,

Encoder0 Input I00 Input I01 Input I02 Firmware update

Encoder1 Input I03 Input I04 Input I05 SOURCE type input SINK type input System error

Input frequency: 10 KHz maximum (for each phase) ON Power ON Run mode

- + + - Blinking 1x Not IO Error

Pulse ON / OFF time for A and B phase: 20 µsec minimum.

24VDC 24VDC applicable

Pulse ON / OFF time for Z marker pulse: 50 µsec minimum. Blinking 1X

Blinking 2x Forcing is active

Interrupt events

Blinking 3x Scan error

Periodic: 1, 0.5/1 ms resolution, settable from 0.5/1 ms to 1250/ 2500 ms Blinking 2X

Flashing Memory Error

Application Download in progress

iKey Error

Pulse ON time: 100 µsec minimum - If any Ikey is observed as pressed, at power ON

Blinking 3X

- Ikey (Hardware) fault occurs

Pulse OFF time: 2 msec minimum HMI Key Error

Pulse catch 24VDC, Digital input, Sink/Source type 24VDC, Digital input, Sink/Source type - If any HMI key is observed as pressed, at power ON

- HMI key (Hardware) fault occurs

Minimum pulse duration: 500 μs

GOC Main unit models GC35MH-32MT-DS and GC35MH-32MR-D provide 2 input terminal blocks. Models

GC35MH-16MT-DS and GC35MH-16MR-D provide 1 input terminal block. CPU permanently goes in Stop mode, when input supply falls below 18 VDC but above 10 VDC approx. It

continues in Stop mode even though input supply is recovered above 18 VDC for safety purpose.

7 WIRING This condition is indicated by blinking ^ (Green coloured) LED associated with Home key. To recover the system,

Digital Output (Sink type Transistor Output) Wiring

it is necessary to power cycle the Main unit.

The ON voltage drop specified for the transistor output is 0.6V. When driving a semiconductor element, carefully check

Wiring recommendations the input voltage characteristics of the applied element.

Terminal block pitch size is 5.08 mm. The adjacent figure shows Insulation 24VDC, Transistor Output, Sink type, 300mA 24VDC, Transistor Output, Sink type, 300mA

Use stranded (flexible) or solid wire of recommended size of lug.

Crimp

size 0.5 to 1 mm² (AWG 22 to 18). Strip

Terminal has M3 size of screw. For part

insulation of stranded wire and twist the

strands to prevent it from spreading and tightening terminal screw, use flat 6mm Copyright © Mitsubishi Electric India Pvt. Ltd. 2014. All rights reserved. MITSUBISHI ELECTRIC INDIA PVT. LTD.

crimp the lug. blade screw driver. The figure shows Specifications are subject to change without prior notice EL 2, J Block, MIDC, Bhosari, Pune – 411026 (INDIA)

desired size of screwdriver blade. L L L L L L L L L L L L L L L L Document No. PD-2002-121, Version: V1.2 Published Aug, 2015 Factory Automation and Industrial Division

3mm wide Email – mei-faid-enquiry@asia.meap.com

Insulation 24VDC Load

The tightening torque should not

supply PRINTED IN INDIA Web – www.MitsubishiElectric.in

exceed 0.50 Nm + - + -

Copper wire

0.4mm thick

7mm

GOC Main unit model GC35MH-32MT-DS provide 2 output terminal blocks. Model GC35MH-16MT-DS provide 1

output terminal block.

You might also like

- E38 ECM Connector PinoutsDocument4 pagesE38 ECM Connector Pinoutsjemaliz100% (8)

- Linde 393 Service Manual PDFDocument126 pagesLinde 393 Service Manual PDFnenad100% (9)

- 988H Hydraulic System PDFDocument2 pages988H Hydraulic System PDFtom souza100% (1)

- Classics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoFrom EverandClassics meet Jazz: 10 jazz fantasies on classical themes for flute and pianoRating: 3.5 out of 5 stars3.5/5 (14)

- MC Case PDFDocument20 pagesMC Case PDFShivani KarkeraNo ratings yet

- Kleiberit PUR 501 - FISPQDocument8 pagesKleiberit PUR 501 - FISPQYuri SouzaNo ratings yet

- Noblex nxc939bt js-15002b Mmotion-Electronics rcd3227bt Car Audio SMDocument17 pagesNoblex nxc939bt js-15002b Mmotion-Electronics rcd3227bt Car Audio SMCiclo TucumanNo ratings yet

- PLCDocument2 pagesPLCnidhushan RNo ratings yet

- 12AX7 Phono Tube Preamplifier User ManualDocument7 pages12AX7 Phono Tube Preamplifier User ManualmikelikespieNo ratings yet

- Noblex: PLL Synthesizer Stereo Radio With Compact Disc Player DigitalDocument14 pagesNoblex: PLL Synthesizer Stereo Radio With Compact Disc Player DigitalHernánSchusterNo ratings yet

- ANT Block Diagram CurrentDocument1 pageANT Block Diagram CurrentGurinderjeet SinghNo ratings yet

- Level 3 Repair: 8-1. Block DiagramDocument79 pagesLevel 3 Repair: 8-1. Block DiagramAli UnlockNo ratings yet

- COPIER (B264/B265) Point To Point Diagram: Bicu PCB 1Document14 pagesCOPIER (B264/B265) Point To Point Diagram: Bicu PCB 1josdavisNo ratings yet

- Vestax Vss PMC 280Document33 pagesVestax Vss PMC 280Diogo SilvaNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar TransistorDocument2 pagesDarlington: Silicon NPN Triple Diffused Planar TransistorGilberto DiazNo ratings yet

- Ems AlimentacionDocument1 pageEms AlimentacionmiltonNo ratings yet

- 143H and 163H Motor Grader Hydraulic System Ripper AttachmentDocument2 pages143H and 163H Motor Grader Hydraulic System Ripper AttachmentMohamed Harb100% (1)

- 323D Excavator Hydraulic System: Machine Component LocationsDocument2 pages323D Excavator Hydraulic System: Machine Component LocationsKJDNKJZEF100% (1)

- User'S Guide: JY992D50401EDocument6 pagesUser'S Guide: JY992D50401Evuitinhnhd9817No ratings yet

- 2P162816-1 Dcs302ca61Document1 page2P162816-1 Dcs302ca61Ruan FernandesNo ratings yet

- Plano Huidráulico Itm 324DDocument2 pagesPlano Huidráulico Itm 324DTONINo ratings yet

- SYS-1019D-16C-RAN13TP+ Quick Reference GuideDocument1 pageSYS-1019D-16C-RAN13TP+ Quick Reference GuideSribller DribbleNo ratings yet

- 1 Overview: STC8A8K64S4A12 Series ManualDocument18 pages1 Overview: STC8A8K64S4A12 Series Manualhossein gholamiNo ratings yet

- GE Renewal Parts: Contactor Model 17Cm53E10ADocument3 pagesGE Renewal Parts: Contactor Model 17Cm53E10ARafael Dutil LucianaNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar TransistorDocument1 pageDarlington: Silicon NPN Triple Diffused Planar TransistorLucas JúniorNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar TransistorDocument2 pagesDarlington: Silicon NPN Triple Diffused Planar Transistorroberto carlos martinez narvaezNo ratings yet

- Toyota-Corolla 1998 en US Diagrama Electrico Tablero B55a406dbcDocument2 pagesToyota-Corolla 1998 en US Diagrama Electrico Tablero B55a406dbcJulio huanriNo ratings yet

- 797F - Kenr8379-02Document6 pages797F - Kenr8379-02Marco Antonio Pampa CondoriNo ratings yet

- PV21DSC 504Document8 pagesPV21DSC 504matanNo ratings yet

- Patented PAT No.: TW 099352: HT1621/1621G RAM Mapping 324 LCD Controller For I/O MCUDocument19 pagesPatented PAT No.: TW 099352: HT1621/1621G RAM Mapping 324 LCD Controller For I/O MCUSanyel Saito Freire da SilvaNo ratings yet

- RENR8305-02 Esquematico Hidraulico 777FDocument4 pagesRENR8305-02 Esquematico Hidraulico 777FEIDER LEYESNo ratings yet

- Features General Description: Ht78Xx Series 500ma Tinypower LdoDocument9 pagesFeatures General Description: Ht78Xx Series 500ma Tinypower LdomessyaxNo ratings yet

- Q64AD GH UserManual Hardware IB 0800223 BDocument1 pageQ64AD GH UserManual Hardware IB 0800223 BSebastián LozadaNo ratings yet

- 3408E Industrial Engine Electrical System: Top ViewDocument2 pages3408E Industrial Engine Electrical System: Top ViewxuanNo ratings yet

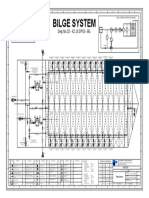

- Bilge System of Oil CarrierDocument1 pageBilge System of Oil CarrierArrijal PratamaNo ratings yet

- Preventive Maintenance PM-Freq (Q/H/Y) : - Check Points Checked Remarks Action Taken Status YES NODocument1 pagePreventive Maintenance PM-Freq (Q/H/Y) : - Check Points Checked Remarks Action Taken Status YES NOGnanavel GNo ratings yet

- An7348s-E1 Q1017 B1aarc000003Document1 pageAn7348s-E1 Q1017 B1aarc000003wilfreddelgadoNo ratings yet

- Bolt-L Uma (17938-1 FW8G6) 18790-1 RefDocument67 pagesBolt-L Uma (17938-1 FW8G6) 18790-1 RefElizabeth AbarcaNo ratings yet

- Diagrama Electrico PM200 PerfiladoraDocument2 pagesDiagrama Electrico PM200 PerfiladoraPlstina Rams100% (2)

- ME-1831 Service ManualDocument13 pagesME-1831 Service ManualmeahdiNo ratings yet

- 44 LAND CRUISER Station Wagon (Cont. Next Page) : Air ConditionerDocument8 pages44 LAND CRUISER Station Wagon (Cont. Next Page) : Air ConditionerSherman KillerNo ratings yet

- R3000H Load Haul Dump Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pagesR3000H Load Haul Dump Electrical System: Harness and Wire Electrical Schematic Symbolsمهدي شقرونNo ratings yet

- Wiring Diagrams: 1-1. Outdoor UnitDocument1 pageWiring Diagrams: 1-1. Outdoor UnitPhonemyat MoeNo ratings yet

- Uenr2628uenr2628-02 SisDocument12 pagesUenr2628uenr2628-02 SisNicole SmithNo ratings yet

- CONTROLLINO MEGA PinoutDocument1 pageCONTROLLINO MEGA PinoutAlf RojasNo ratings yet

- Parts Catalogue DCD 250Document23 pagesParts Catalogue DCD 250Quốc Viêtj HuỳnhNo ratings yet

- (Kas001043 - Inq - 2021 - 10 - 0016256) - Ewd Kick Sensor 716BDocument1 page(Kas001043 - Inq - 2021 - 10 - 0016256) - Ewd Kick Sensor 716BBYU OTOVLOGNo ratings yet

- Hazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoDocument4 pagesHazop Action Sheet: Project Title Yanbu Phase 3 Power & Desalination Plant Interfaces P&ID Drawing NoVijaya Seharan NairNo ratings yet

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis ControllerAhmedNo ratings yet

- File USRP N310 N300 MB SchematicDocument24 pagesFile USRP N310 N300 MB SchematicAhsan ShabbirNo ratings yet

- Diagrama Eletrico-Secador CD550+Document12 pagesDiagrama Eletrico-Secador CD550+Ricardo Limaymanta Ticse100% (1)

- A C D E F B: Level 01 Fire Alarm System Layout 1Document1 pageA C D E F B: Level 01 Fire Alarm System Layout 1Mhmd GhanimNo ratings yet

- 777F PDFDocument4 pages777F PDFIgnacio Lazo JhsúsNo ratings yet

- Hydraulic 992G - Azx PDFDocument2 pagesHydraulic 992G - Azx PDFGuztiNo ratings yet

- 11 Corolla / Auris (Cont. Next Page) : Engine Control (1ND-TV)Document3 pages11 Corolla / Auris (Cont. Next Page) : Engine Control (1ND-TV)varenziaNo ratings yet

- BMW N55 Diagnostic Fault Codes DTCDocument19 pagesBMW N55 Diagnostic Fault Codes DTCgimmethatassNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar TransistorDocument1 pageDarlington: Silicon PNP Epitaxial Planar Transistorroberto carlos martinez narvaezNo ratings yet

- IndraDocument2 pagesIndravsv mnaNo ratings yet

- Pe 324DDocument4 pagesPe 324DNss Nery100% (1)

- MPC6000 - MPC7500 PP - v00 PDFDocument30 pagesMPC6000 - MPC7500 PP - v00 PDFStart Good HouNo ratings yet

- Regional Economic Prospects: A Cold Winter Ahead?Document34 pagesRegional Economic Prospects: A Cold Winter Ahead?LEKH021No ratings yet

- Global Economics Intelligence: Global Summary Report February 2023Document30 pagesGlobal Economics Intelligence: Global Summary Report February 2023LEKH021No ratings yet

- CR UiDocument20 pagesCR UiLEKH021No ratings yet

- InfltiDocument13 pagesInfltiLEKH021No ratings yet

- ComoDocument12 pagesComoLEKH021No ratings yet

- Product CatalogDocument60 pagesProduct CatalogLEKH021No ratings yet

- Aro-Flo Series: Filters, Regulators and LubricatorsDocument90 pagesAro-Flo Series: Filters, Regulators and LubricatorsLEKH021No ratings yet

- Brighter Prospects Amid Ongoing ChallengesDocument12 pagesBrighter Prospects Amid Ongoing ChallengesLEKH021No ratings yet

- R SeriaDocument3 pagesR SeriaLEKH021No ratings yet

- EU Declaration of Conformity: Adjustable Frequency AC Drives and AccessoriesDocument3 pagesEU Declaration of Conformity: Adjustable Frequency AC Drives and AccessoriesLEKH021No ratings yet

- Brochure - Fuels of Future 2023Document4 pagesBrochure - Fuels of Future 2023LEKH021No ratings yet

- 660 Series: Features Base ModelsDocument3 pages660 Series: Features Base ModelsLEKH021No ratings yet

- IndexDocument1 pageIndexLEKH021No ratings yet

- Ng16dl Compact PLCDocument2 pagesNg16dl Compact PLCLEKH02150% (2)

- Filter StandardDocument81 pagesFilter StandardLEKH021100% (1)

- Cts35Un: 35 SQ - MM Feed Through Terminal Blocks With Slotted ScrewsDocument3 pagesCts35Un: 35 SQ - MM Feed Through Terminal Blocks With Slotted ScrewsLEKH021No ratings yet

- HPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIDocument13 pagesHPB21-0457 FINAL Submittal 09-07-2021 - Ritz Sagamore LOIthe next miamiNo ratings yet

- James Coleman (October Files) by George BakerDocument226 pagesJames Coleman (October Files) by George Bakersaknjdasdjlk100% (1)

- TapingDocument3 pagesTapingEdeza MatarumNo ratings yet

- Kerr EffectDocument5 pagesKerr EffectJose GalvanNo ratings yet

- 1 Kawasaki FSDocument16 pages1 Kawasaki FSmatgoffNo ratings yet

- 10 Science TP 11 1Document5 pages10 Science TP 11 1Ananaya BansalNo ratings yet

- Hybrid Vehicle A Study On Technology IJERTV3IS120917 PDFDocument8 pagesHybrid Vehicle A Study On Technology IJERTV3IS120917 PDFAshish MathurNo ratings yet

- Open-Circuit Time Constant Analysis: Asas As Hs K Bsbs BsDocument24 pagesOpen-Circuit Time Constant Analysis: Asas As Hs K Bsbs BsSHAIK MUSTHAFANo ratings yet

- 9 Exercise Physiology Handout 2011Document20 pages9 Exercise Physiology Handout 2011maraj687No ratings yet

- Quatre Agro Enterprise Private LimitedDocument25 pagesQuatre Agro Enterprise Private Limitedp23pallavNo ratings yet

- Cefixime and Palpitations - From FDA ReportsDocument3 pagesCefixime and Palpitations - From FDA ReportsMuhammad UbaidNo ratings yet

- Hilton Chapter 5 Adobe Connect Activity-Based Costing and ManagementDocument11 pagesHilton Chapter 5 Adobe Connect Activity-Based Costing and ManagementyosepjoltNo ratings yet

- Exit Poll CedatosDocument1 pageExit Poll CedatosEcuadorenvivoNo ratings yet

- Mouser TestsectionDocument33 pagesMouser TestsectionalltheloveintheworldNo ratings yet

- ProductSheet Iq200 Rackmount SatelliteModemDocument2 pagesProductSheet Iq200 Rackmount SatelliteModemAsim Penkar PenkarNo ratings yet

- MATH 4 PPT Q3 W4 - Lesson 52 - Quadrilateral 1Document17 pagesMATH 4 PPT Q3 W4 - Lesson 52 - Quadrilateral 1Erika Mae TupagNo ratings yet

- Oil & Chemical Tanker Summer 7 - Prepurchase Survey Report - S&a 230098 PpsDocument62 pagesOil & Chemical Tanker Summer 7 - Prepurchase Survey Report - S&a 230098 Ppsp_k_sahuNo ratings yet

- UntitledDocument4 pagesUntitleddwky KrnwnNo ratings yet

- Unit I-Cloud ComputingDocument29 pagesUnit I-Cloud ComputingAR OFFICIALNo ratings yet

- South Africa Hard Copy Lit 2Document20 pagesSouth Africa Hard Copy Lit 2Jennifer Española BernalNo ratings yet

- Battles Fought On The Great Wall of China Qin DynastyDocument2 pagesBattles Fought On The Great Wall of China Qin DynastySachin NagmotiNo ratings yet

- Tax System SriLankaDocument44 pagesTax System SriLankamandarak7146No ratings yet

- Anjana Seminar SlideshareDocument38 pagesAnjana Seminar SlideshareAnjana kpNo ratings yet

- MGje 6 Fix GX PK Yp RBJ LBRDocument9 pagesMGje 6 Fix GX PK Yp RBJ LBRBANOTH KUMARNo ratings yet

- Ciclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateDocument1 pageCiclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateMaffone NumerounoNo ratings yet

- OHara PDFDocument17 pagesOHara PDFTomás HidalgoNo ratings yet

- TSB-1139 8SC Wiring DiagramDocument2 pagesTSB-1139 8SC Wiring Diagramxavier marsNo ratings yet

- Problem: Determine The Total Volume of Earth To Be Excavated Up To Elevation 0Document17 pagesProblem: Determine The Total Volume of Earth To Be Excavated Up To Elevation 0gtech00100% (1)