Professional Documents

Culture Documents

FTR

FTR

Uploaded by

anon_127491670Copyright:

Available Formats

You might also like

- Method of Statement For Hydrostatic TestingDocument6 pagesMethod of Statement For Hydrostatic TestingHalil Güney100% (2)

- Louvers CSI SpecificationDocument6 pagesLouvers CSI SpecificationRowdyRaheelNo ratings yet

- 4.0 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page4.0 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- 1.5 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page1.5 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- 2.5 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page2.5 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- 10 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page10 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- 1.0 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page1.0 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- Data Sheet-Cable-24.12.21Document22 pagesData Sheet-Cable-24.12.21YASHASHWYNo ratings yet

- 12.02.2020 TTC - Kohinoor SalesDocument1 page12.02.2020 TTC - Kohinoor SalesAlok PandeyNo ratings yet

- PUCARO Elboard ZFDocument2 pagesPUCARO Elboard ZFmzagliNo ratings yet

- Guaranteed Technical Particulars Guaranteed: ACCC Casablanca ACCC CasablancaDocument5 pagesGuaranteed Technical Particulars Guaranteed: ACCC Casablanca ACCC CasablancabinodeNo ratings yet

- Voids Ratio Vs Pressure: General InformationDocument6 pagesVoids Ratio Vs Pressure: General InformationMaruda8382No ratings yet

- Presto Geocell - GeogridDocument2 pagesPresto Geocell - GeogridLIMITLESSNo ratings yet

- Effective Stress Triaxial Compression: Consolidated UndrainedDocument2 pagesEffective Stress Triaxial Compression: Consolidated UndrainedgomesNo ratings yet

- Product Brochure - PPCDocument3 pagesProduct Brochure - PPCdigital lifeNo ratings yet

- Certificate of Analysis Conveyor Belt PT. Mutiara Tanjung Lestari Order Tahun 2022Document29 pagesCertificate of Analysis Conveyor Belt PT. Mutiara Tanjung Lestari Order Tahun 2022RestuNo ratings yet

- GTP Acsr Panther ConductorDocument3 pagesGTP Acsr Panther ConductorSECI 2020No ratings yet

- 458 Standar 2 PPMDocument1 page458 Standar 2 PPMShendi SuryanaNo ratings yet

- 120 MM Sq. 3-Core AL-XLPE-SWA-PVC-15KVDocument2 pages120 MM Sq. 3-Core AL-XLPE-SWA-PVC-15KVMuhammad Shabbir AwanNo ratings yet

- Shintech PVC - Se950Document1 pageShintech PVC - Se950David Martinez100% (1)

- GTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding CableDocument1 pageGTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding Cableshivam dwivedi100% (1)

- Sintered Product - Triaxial CU Test ReportDocument5 pagesSintered Product - Triaxial CU Test ReportwaimyintgeonamicsNo ratings yet

- Ecc SF 80Document1 pageEcc SF 80longyiequipmentNo ratings yet

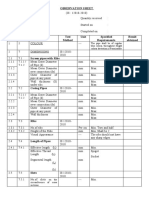

- Observation Sheet: The Pipe Shall Be of Regular Blue Colour, Throughout. Slight Colour Deviation Is PermissibleDocument6 pagesObservation Sheet: The Pipe Shall Be of Regular Blue Colour, Throughout. Slight Colour Deviation Is Permissiblebishnu pandaNo ratings yet

- SFB 2Document1 pageSFB 2Gelbert SilotNo ratings yet

- IS: 10262:2019 Guidelines Keeping in View The Recommended Mix Standard Deviations and Targeted Mean StrengthDocument4 pagesIS: 10262:2019 Guidelines Keeping in View The Recommended Mix Standard Deviations and Targeted Mean StrengthROHIT KUMARNo ratings yet

- API 650 Storage Tank Load Computations With Ring Wall Foundation Design 8 7 M Diameter X 9 0 M HeightDocument15 pagesAPI 650 Storage Tank Load Computations With Ring Wall Foundation Design 8 7 M Diameter X 9 0 M Heighthabibur Rahman KhanNo ratings yet

- GTP For Panther ConductorDocument2 pagesGTP For Panther ConductorPritam SinghNo ratings yet

- Radionuclide Data Sheet: IodineDocument1 pageRadionuclide Data Sheet: IodineCrizzz001No ratings yet

- Stainless Steel Products: Bolt Anchor AN BZ Plus A4Document3 pagesStainless Steel Products: Bolt Anchor AN BZ Plus A4أبومحمدالزياتNo ratings yet

- Load CalculationDocument31 pagesLoad CalculationrahulNo ratings yet

- Technical Data - Epoxy Dotted PaperDocument1 pageTechnical Data - Epoxy Dotted PaperMly Saad BoudiafNo ratings yet

- Precision Plastic Industries PVT - LTDDocument1 pagePrecision Plastic Industries PVT - LTDsonu007adakNo ratings yet

- 15.07 2020 - TTC 2Document1 page15.07 2020 - TTC 2Alok PandeyNo ratings yet

- M25 Mix Design 100 Recycled AggregateDocument9 pagesM25 Mix Design 100 Recycled AggregateRakesh ReddyNo ratings yet

- 300X300 MM Sparta Matt-RDocument2 pages300X300 MM Sparta Matt-Rlalith kumarNo ratings yet

- Ultratech OpcDocument1 pageUltratech Opcce16debojitpoddar1234No ratings yet

- Precision Plastic Industries PVT - LTDDocument1 pagePrecision Plastic Industries PVT - LTDsonu007adakNo ratings yet

- 25mm-Semi-Dense - Bituminous - Concrete (SDBC) - 19-01-2024Document3 pages25mm-Semi-Dense - Bituminous - Concrete (SDBC) - 19-01-2024Mithun RaulNo ratings yet

- Quality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.ŞDocument3 pagesQuality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.Şomar100% (1)

- Concrete Mix DesignDocument12 pagesConcrete Mix DesignAnand.5No ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofAslam khanNo ratings yet

- For Better Building: Diamond Cements (Prop. Heidelbergcement India LTD) Damoh UnitDocument1 pageFor Better Building: Diamond Cements (Prop. Heidelbergcement India LTD) Damoh UnitAjay SinghNo ratings yet

- Polycab Multicore CablesDocument2 pagesPolycab Multicore CablesAkhil SasidharanNo ratings yet

- Rev 02 GTP 1565 LV Cables - FormatDocument8 pagesRev 02 GTP 1565 LV Cables - FormatYuvan PrakashNo ratings yet

- 459 Standar 4 PPMDocument1 page459 Standar 4 PPMShendi SuryanaNo ratings yet

- Noise RequirementDocument8 pagesNoise RequirementSatyajit MNo ratings yet

- Bahik Bianco 38Document1 pageBahik Bianco 38Bharat KoraleNo ratings yet

- SMDJSW Sta 1003 v5 Tr60Document3 pagesSMDJSW Sta 1003 v5 Tr60syedaliabl2023No ratings yet

- TM-126 MIX DESIGN M - 45 - 440 ULTRATECH-Nornet 27-01-2020Document9 pagesTM-126 MIX DESIGN M - 45 - 440 ULTRATECH-Nornet 27-01-2020Gopinath kNo ratings yet

- COHR QBH FiberOpticCable DL DS 1020Document7 pagesCOHR QBH FiberOpticCable DL DS 1020Yomba BorisNo ratings yet

- 460 Standar 6 PPMDocument1 page460 Standar 6 PPMShendi SuryanaNo ratings yet

- M2XCH Flex (FI) 5G25 (Black) - 60Document1 pageM2XCH Flex (FI) 5G25 (Black) - 60omarNo ratings yet

- Product Brochure - MasterDocument3 pagesProduct Brochure - Masterdigital lifeNo ratings yet

- M 30 Concrete Mix Design FinalDocument10 pagesM 30 Concrete Mix Design FinalRakesh ReddyNo ratings yet

- 467 MIP Ruah 6 PPMDocument1 page467 MIP Ruah 6 PPMShendi SuryanaNo ratings yet

- Internal Calibration Procedure: Approved By: H. Woodyat Date: 2004Document2 pagesInternal Calibration Procedure: Approved By: H. Woodyat Date: 2004GEO MSc Group-2016No ratings yet

- Asp-Ea - 21 MLDDocument12 pagesAsp-Ea - 21 MLDDev Kumar Dwivedi100% (1)

- en-lf-drivers-10nw64-8Document3 pagesen-lf-drivers-10nw64-8Paulo VianaNo ratings yet

- Experiment # 5 Quality Assessment of Canned ProductsDocument7 pagesExperiment # 5 Quality Assessment of Canned ProductsFranz MarasiganNo ratings yet

- DIECI3 TechSheet DCX-460 3Document1 pageDIECI3 TechSheet DCX-460 3Kornelijus KornasNo ratings yet

- Noise and Signal Interference in Optical Fiber Transmission Systems: An Optimum Design ApproachFrom EverandNoise and Signal Interference in Optical Fiber Transmission Systems: An Optimum Design ApproachNo ratings yet

- Final National Register of Dams Sep. 2018Document17 pagesFinal National Register of Dams Sep. 2018Anjum AliNo ratings yet

- Building Services Presentation ON Sanitary Fittings: BY:-Sadan Malik Mohd - Akbar Anas Ahmad Chesham Altaf Shah Ashad AlamDocument12 pagesBuilding Services Presentation ON Sanitary Fittings: BY:-Sadan Malik Mohd - Akbar Anas Ahmad Chesham Altaf Shah Ashad AlamKashif KhanNo ratings yet

- Expansive PDFDocument6 pagesExpansive PDFAlê Fabiano CavalcanteNo ratings yet

- Methods of Soil Strength DeterminationDocument13 pagesMethods of Soil Strength DeterminationAdedeji AwodeleNo ratings yet

- Astm B88Document7 pagesAstm B88caop217No ratings yet

- Pipe Repair & Pipe WrappingDocument20 pagesPipe Repair & Pipe WrappingFahmi HusainNo ratings yet

- ASCE - SEI - 7 - 05 شرح PDFDocument26 pagesASCE - SEI - 7 - 05 شرح PDFcomandos882010No ratings yet

- 087 Choosing Plywood For The Shop PDFDocument2 pages087 Choosing Plywood For The Shop PDFHomerSimsonnakisNo ratings yet

- Ks SairamDocument428 pagesKs SairamIshan DograNo ratings yet

- PAC12H Manual 2014Document11 pagesPAC12H Manual 2014ThameeNo ratings yet

- OPSS 1541 Nov05Document5 pagesOPSS 1541 Nov05indra purnamaNo ratings yet

- 102806398Document2 pages102806398Syed HumzaNo ratings yet

- ACI - 201.2R-08 - Guide To Durable ConcreteDocument2 pagesACI - 201.2R-08 - Guide To Durable ConcreteJuanNo ratings yet

- Joinery Detail ElvDocument1 pageJoinery Detail ElvDiksha GargNo ratings yet

- 1 Piping CostingDocument33 pages1 Piping Costingamoldhole97% (36)

- Chapter No 1: 1.1 Introduction To Training Establishment 1.1.1 Introductions To Sanken Construction (PVT) LTDDocument13 pagesChapter No 1: 1.1 Introduction To Training Establishment 1.1.1 Introductions To Sanken Construction (PVT) LTDChameera JulanpitiyaNo ratings yet

- EJN-00625 Installation of Manual Pull Valves in Deluge Systems For SOLPEDocument4 pagesEJN-00625 Installation of Manual Pull Valves in Deluge Systems For SOLPESARAVANAN ARUMUGAMNo ratings yet

- Mirzaei FractureMechanicsLecture PDFDocument61 pagesMirzaei FractureMechanicsLecture PDFkoohestani_afshinNo ratings yet

- Test - R.A 9514 Fire Code - Quizlet PDFDocument3 pagesTest - R.A 9514 Fire Code - Quizlet PDFPenuel G. Bantog100% (1)

- Cable Gland Selection ChartDocument4 pagesCable Gland Selection Chartajeez86100% (2)

- Sutter Health: Developing A Contracting Model To Support Lean Project DeliveryDocument8 pagesSutter Health: Developing A Contracting Model To Support Lean Project DeliveryMarcos Camilo SaldiasNo ratings yet

- Flow Chart: Guidelines To Project SupervisorsDocument1 pageFlow Chart: Guidelines To Project SupervisorsAarah KhalidNo ratings yet

- Astm D3035 - 06Document7 pagesAstm D3035 - 06Raul Humberto Mora VillamizarNo ratings yet

- SEJA CHAPEL 3 - Sheet - A-200 - ELEVATIONSDocument1 pageSEJA CHAPEL 3 - Sheet - A-200 - ELEVATIONSSharah QuilarioNo ratings yet

- Thrust BlocksDocument16 pagesThrust Blockshemantkle2uNo ratings yet

- Confessions of A Construction Defect Litigation Expert: by Don Waller, CPEDocument2 pagesConfessions of A Construction Defect Litigation Expert: by Don Waller, CPESantosh NayakNo ratings yet

- 7B AnswerDocument6 pages7B AnswertarasasankaNo ratings yet

- SATIP H 002 08 Pipe Internal CoatingDocument3 pagesSATIP H 002 08 Pipe Internal CoatinghossamalsherbinyNo ratings yet

FTR

FTR

Uploaded by

anon_127491670Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FTR

FTR

Uploaded by

anon_127491670Copyright:

Available Formats

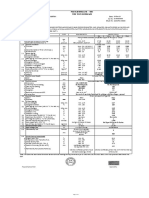

FACTORY TEST REPORT

Size: 90mm Class: 2 (4.0Kg/cm2)

Date of Testing: 16thJun 2016

S.No. Clause Name of the Test Unit Specified Value Test Value

1. 7.0 Dimension

7.1.1.1 (a) Mean OD

i) Minimum mm 90.0 90.18

ii) Maximum mm 90.3 90.26

7.1.1.2 (b) Outside dia at any point

i) Minimum mm 88.9 89.2

ii) Maximum mm 91.1 90.2

7.1.2 (c) Wall thickness

i) Minimum mm 2.1 2.4

ii) Maximum mm 2.6 2.5

iii) Average (Max) mm 2.6 2.5

2. 7.1.4.1 Effective Length of Pipe Mtr 6 6

3. 7.2 Socket Dimension - -

1. Socket Length, Min mm 51.0 60

2. Mean Internal Diameter - -

at midpoint of socket length

a. Minimum mm 90.1 90.16

b. Maximum mm 90.3 90.24

4. 10.1 Colour Of Pipes Visual - Light Grey Grey

Appearance Internal & External surface of pipe

shall be smooth, clean and free

from grooving and other defects Satisfactory

5. 10.2 Opacity (% Visible Light % 0.2% (Max) 0.02

Transmission)

6. 10.4 Reversion Test % Alteration in length ± 5.0 (max) -2

0

7. 10.5 Vicat Softening Temp. C 800C (Min) 84

8. 10.6 Density g/cm3 1.40 -1.46 1.42

9. 10.7 Sulphated Ash Content % 11% (Max) 7.2

10. 11.0 Hydrostatic - Pipe shall not burst in prescribed Pass

11.1 Characteristics for Pipe test duration.

Table-6 Acceptance Test at 4.19 x

PN for 1 hrs at 270C

11. 11.2 Resistance To External % Max. T.I.R 10% 0%

Blows At 00C (Passed)

Q.C.I

You might also like

- Method of Statement For Hydrostatic TestingDocument6 pagesMethod of Statement For Hydrostatic TestingHalil Güney100% (2)

- Louvers CSI SpecificationDocument6 pagesLouvers CSI SpecificationRowdyRaheelNo ratings yet

- 4.0 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page4.0 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- 1.5 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page1.5 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- 2.5 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page2.5 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- 10 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page10 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- 1.0 SQ.MM-FR-LSH-100 MTR-JAN-2021Document1 page1.0 SQ.MM-FR-LSH-100 MTR-JAN-2021Gopikrishnan ThangarajNo ratings yet

- Data Sheet-Cable-24.12.21Document22 pagesData Sheet-Cable-24.12.21YASHASHWYNo ratings yet

- 12.02.2020 TTC - Kohinoor SalesDocument1 page12.02.2020 TTC - Kohinoor SalesAlok PandeyNo ratings yet

- PUCARO Elboard ZFDocument2 pagesPUCARO Elboard ZFmzagliNo ratings yet

- Guaranteed Technical Particulars Guaranteed: ACCC Casablanca ACCC CasablancaDocument5 pagesGuaranteed Technical Particulars Guaranteed: ACCC Casablanca ACCC CasablancabinodeNo ratings yet

- Voids Ratio Vs Pressure: General InformationDocument6 pagesVoids Ratio Vs Pressure: General InformationMaruda8382No ratings yet

- Presto Geocell - GeogridDocument2 pagesPresto Geocell - GeogridLIMITLESSNo ratings yet

- Effective Stress Triaxial Compression: Consolidated UndrainedDocument2 pagesEffective Stress Triaxial Compression: Consolidated UndrainedgomesNo ratings yet

- Product Brochure - PPCDocument3 pagesProduct Brochure - PPCdigital lifeNo ratings yet

- Certificate of Analysis Conveyor Belt PT. Mutiara Tanjung Lestari Order Tahun 2022Document29 pagesCertificate of Analysis Conveyor Belt PT. Mutiara Tanjung Lestari Order Tahun 2022RestuNo ratings yet

- GTP Acsr Panther ConductorDocument3 pagesGTP Acsr Panther ConductorSECI 2020No ratings yet

- 458 Standar 2 PPMDocument1 page458 Standar 2 PPMShendi SuryanaNo ratings yet

- 120 MM Sq. 3-Core AL-XLPE-SWA-PVC-15KVDocument2 pages120 MM Sq. 3-Core AL-XLPE-SWA-PVC-15KVMuhammad Shabbir AwanNo ratings yet

- Shintech PVC - Se950Document1 pageShintech PVC - Se950David Martinez100% (1)

- GTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding CableDocument1 pageGTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding Cableshivam dwivedi100% (1)

- Sintered Product - Triaxial CU Test ReportDocument5 pagesSintered Product - Triaxial CU Test ReportwaimyintgeonamicsNo ratings yet

- Ecc SF 80Document1 pageEcc SF 80longyiequipmentNo ratings yet

- Observation Sheet: The Pipe Shall Be of Regular Blue Colour, Throughout. Slight Colour Deviation Is PermissibleDocument6 pagesObservation Sheet: The Pipe Shall Be of Regular Blue Colour, Throughout. Slight Colour Deviation Is Permissiblebishnu pandaNo ratings yet

- SFB 2Document1 pageSFB 2Gelbert SilotNo ratings yet

- IS: 10262:2019 Guidelines Keeping in View The Recommended Mix Standard Deviations and Targeted Mean StrengthDocument4 pagesIS: 10262:2019 Guidelines Keeping in View The Recommended Mix Standard Deviations and Targeted Mean StrengthROHIT KUMARNo ratings yet

- API 650 Storage Tank Load Computations With Ring Wall Foundation Design 8 7 M Diameter X 9 0 M HeightDocument15 pagesAPI 650 Storage Tank Load Computations With Ring Wall Foundation Design 8 7 M Diameter X 9 0 M Heighthabibur Rahman KhanNo ratings yet

- GTP For Panther ConductorDocument2 pagesGTP For Panther ConductorPritam SinghNo ratings yet

- Radionuclide Data Sheet: IodineDocument1 pageRadionuclide Data Sheet: IodineCrizzz001No ratings yet

- Stainless Steel Products: Bolt Anchor AN BZ Plus A4Document3 pagesStainless Steel Products: Bolt Anchor AN BZ Plus A4أبومحمدالزياتNo ratings yet

- Load CalculationDocument31 pagesLoad CalculationrahulNo ratings yet

- Technical Data - Epoxy Dotted PaperDocument1 pageTechnical Data - Epoxy Dotted PaperMly Saad BoudiafNo ratings yet

- Precision Plastic Industries PVT - LTDDocument1 pagePrecision Plastic Industries PVT - LTDsonu007adakNo ratings yet

- 15.07 2020 - TTC 2Document1 page15.07 2020 - TTC 2Alok PandeyNo ratings yet

- M25 Mix Design 100 Recycled AggregateDocument9 pagesM25 Mix Design 100 Recycled AggregateRakesh ReddyNo ratings yet

- 300X300 MM Sparta Matt-RDocument2 pages300X300 MM Sparta Matt-Rlalith kumarNo ratings yet

- Ultratech OpcDocument1 pageUltratech Opcce16debojitpoddar1234No ratings yet

- Precision Plastic Industries PVT - LTDDocument1 pagePrecision Plastic Industries PVT - LTDsonu007adakNo ratings yet

- 25mm-Semi-Dense - Bituminous - Concrete (SDBC) - 19-01-2024Document3 pages25mm-Semi-Dense - Bituminous - Concrete (SDBC) - 19-01-2024Mithun RaulNo ratings yet

- Quality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.ŞDocument3 pagesQuality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.Şomar100% (1)

- Concrete Mix DesignDocument12 pagesConcrete Mix DesignAnand.5No ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofAslam khanNo ratings yet

- For Better Building: Diamond Cements (Prop. Heidelbergcement India LTD) Damoh UnitDocument1 pageFor Better Building: Diamond Cements (Prop. Heidelbergcement India LTD) Damoh UnitAjay SinghNo ratings yet

- Polycab Multicore CablesDocument2 pagesPolycab Multicore CablesAkhil SasidharanNo ratings yet

- Rev 02 GTP 1565 LV Cables - FormatDocument8 pagesRev 02 GTP 1565 LV Cables - FormatYuvan PrakashNo ratings yet

- 459 Standar 4 PPMDocument1 page459 Standar 4 PPMShendi SuryanaNo ratings yet

- Noise RequirementDocument8 pagesNoise RequirementSatyajit MNo ratings yet

- Bahik Bianco 38Document1 pageBahik Bianco 38Bharat KoraleNo ratings yet

- SMDJSW Sta 1003 v5 Tr60Document3 pagesSMDJSW Sta 1003 v5 Tr60syedaliabl2023No ratings yet

- TM-126 MIX DESIGN M - 45 - 440 ULTRATECH-Nornet 27-01-2020Document9 pagesTM-126 MIX DESIGN M - 45 - 440 ULTRATECH-Nornet 27-01-2020Gopinath kNo ratings yet

- COHR QBH FiberOpticCable DL DS 1020Document7 pagesCOHR QBH FiberOpticCable DL DS 1020Yomba BorisNo ratings yet

- 460 Standar 6 PPMDocument1 page460 Standar 6 PPMShendi SuryanaNo ratings yet

- M2XCH Flex (FI) 5G25 (Black) - 60Document1 pageM2XCH Flex (FI) 5G25 (Black) - 60omarNo ratings yet

- Product Brochure - MasterDocument3 pagesProduct Brochure - Masterdigital lifeNo ratings yet

- M 30 Concrete Mix Design FinalDocument10 pagesM 30 Concrete Mix Design FinalRakesh ReddyNo ratings yet

- 467 MIP Ruah 6 PPMDocument1 page467 MIP Ruah 6 PPMShendi SuryanaNo ratings yet

- Internal Calibration Procedure: Approved By: H. Woodyat Date: 2004Document2 pagesInternal Calibration Procedure: Approved By: H. Woodyat Date: 2004GEO MSc Group-2016No ratings yet

- Asp-Ea - 21 MLDDocument12 pagesAsp-Ea - 21 MLDDev Kumar Dwivedi100% (1)

- en-lf-drivers-10nw64-8Document3 pagesen-lf-drivers-10nw64-8Paulo VianaNo ratings yet

- Experiment # 5 Quality Assessment of Canned ProductsDocument7 pagesExperiment # 5 Quality Assessment of Canned ProductsFranz MarasiganNo ratings yet

- DIECI3 TechSheet DCX-460 3Document1 pageDIECI3 TechSheet DCX-460 3Kornelijus KornasNo ratings yet

- Noise and Signal Interference in Optical Fiber Transmission Systems: An Optimum Design ApproachFrom EverandNoise and Signal Interference in Optical Fiber Transmission Systems: An Optimum Design ApproachNo ratings yet

- Final National Register of Dams Sep. 2018Document17 pagesFinal National Register of Dams Sep. 2018Anjum AliNo ratings yet

- Building Services Presentation ON Sanitary Fittings: BY:-Sadan Malik Mohd - Akbar Anas Ahmad Chesham Altaf Shah Ashad AlamDocument12 pagesBuilding Services Presentation ON Sanitary Fittings: BY:-Sadan Malik Mohd - Akbar Anas Ahmad Chesham Altaf Shah Ashad AlamKashif KhanNo ratings yet

- Expansive PDFDocument6 pagesExpansive PDFAlê Fabiano CavalcanteNo ratings yet

- Methods of Soil Strength DeterminationDocument13 pagesMethods of Soil Strength DeterminationAdedeji AwodeleNo ratings yet

- Astm B88Document7 pagesAstm B88caop217No ratings yet

- Pipe Repair & Pipe WrappingDocument20 pagesPipe Repair & Pipe WrappingFahmi HusainNo ratings yet

- ASCE - SEI - 7 - 05 شرح PDFDocument26 pagesASCE - SEI - 7 - 05 شرح PDFcomandos882010No ratings yet

- 087 Choosing Plywood For The Shop PDFDocument2 pages087 Choosing Plywood For The Shop PDFHomerSimsonnakisNo ratings yet

- Ks SairamDocument428 pagesKs SairamIshan DograNo ratings yet

- PAC12H Manual 2014Document11 pagesPAC12H Manual 2014ThameeNo ratings yet

- OPSS 1541 Nov05Document5 pagesOPSS 1541 Nov05indra purnamaNo ratings yet

- 102806398Document2 pages102806398Syed HumzaNo ratings yet

- ACI - 201.2R-08 - Guide To Durable ConcreteDocument2 pagesACI - 201.2R-08 - Guide To Durable ConcreteJuanNo ratings yet

- Joinery Detail ElvDocument1 pageJoinery Detail ElvDiksha GargNo ratings yet

- 1 Piping CostingDocument33 pages1 Piping Costingamoldhole97% (36)

- Chapter No 1: 1.1 Introduction To Training Establishment 1.1.1 Introductions To Sanken Construction (PVT) LTDDocument13 pagesChapter No 1: 1.1 Introduction To Training Establishment 1.1.1 Introductions To Sanken Construction (PVT) LTDChameera JulanpitiyaNo ratings yet

- EJN-00625 Installation of Manual Pull Valves in Deluge Systems For SOLPEDocument4 pagesEJN-00625 Installation of Manual Pull Valves in Deluge Systems For SOLPESARAVANAN ARUMUGAMNo ratings yet

- Mirzaei FractureMechanicsLecture PDFDocument61 pagesMirzaei FractureMechanicsLecture PDFkoohestani_afshinNo ratings yet

- Test - R.A 9514 Fire Code - Quizlet PDFDocument3 pagesTest - R.A 9514 Fire Code - Quizlet PDFPenuel G. Bantog100% (1)

- Cable Gland Selection ChartDocument4 pagesCable Gland Selection Chartajeez86100% (2)

- Sutter Health: Developing A Contracting Model To Support Lean Project DeliveryDocument8 pagesSutter Health: Developing A Contracting Model To Support Lean Project DeliveryMarcos Camilo SaldiasNo ratings yet

- Flow Chart: Guidelines To Project SupervisorsDocument1 pageFlow Chart: Guidelines To Project SupervisorsAarah KhalidNo ratings yet

- Astm D3035 - 06Document7 pagesAstm D3035 - 06Raul Humberto Mora VillamizarNo ratings yet

- SEJA CHAPEL 3 - Sheet - A-200 - ELEVATIONSDocument1 pageSEJA CHAPEL 3 - Sheet - A-200 - ELEVATIONSSharah QuilarioNo ratings yet

- Thrust BlocksDocument16 pagesThrust Blockshemantkle2uNo ratings yet

- Confessions of A Construction Defect Litigation Expert: by Don Waller, CPEDocument2 pagesConfessions of A Construction Defect Litigation Expert: by Don Waller, CPESantosh NayakNo ratings yet

- 7B AnswerDocument6 pages7B AnswertarasasankaNo ratings yet

- SATIP H 002 08 Pipe Internal CoatingDocument3 pagesSATIP H 002 08 Pipe Internal CoatinghossamalsherbinyNo ratings yet