Professional Documents

Culture Documents

Fettling

Fettling

Uploaded by

Aakash KumarCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Iso 9001 2015 Standard PDFDocument34 pagesIso 9001 2015 Standard PDFAakash KumarNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

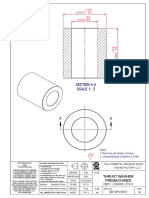

- DB10R13003 - Thrust Washer Premachined - DBFV - DN 300 - PN 16 - Series 14 Rev 00Document1 pageDB10R13003 - Thrust Washer Premachined - DBFV - DN 300 - PN 16 - Series 14 Rev 00Aakash KumarNo ratings yet

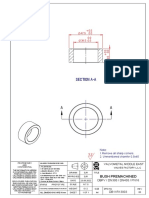

- DB11R13003 - Bush Premachined - DBFV - DN 300 - PN 16 - Series 14 Rev 00Document1 pageDB11R13003 - Bush Premachined - DBFV - DN 300 - PN 16 - Series 14 Rev 00Aakash KumarNo ratings yet

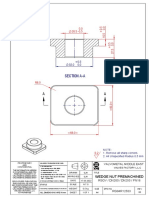

- RG04R12503 - Wedge Nut Premachined - RSGV - DN 250 - PN 16 Rev 00Document1 pageRG04R12503 - Wedge Nut Premachined - RSGV - DN 250 - PN 16 Rev 00Aakash KumarNo ratings yet

- DB10R18003 - Thrust Washer Premachined - DBFV - DN 800 - PN 16 - Series 14 Rev 00Document1 pageDB10R18003 - Thrust Washer Premachined - DBFV - DN 800 - PN 16 - Series 14 Rev 00Aakash KumarNo ratings yet

- TSTPL Presentation PDFDocument15 pagesTSTPL Presentation PDFAakash KumarNo ratings yet

- Neer Drains SolutionDocument25 pagesNeer Drains SolutionAakash KumarNo ratings yet

- Kunal JRFDocument3 pagesKunal JRFAakash KumarNo ratings yet

- Tarasree Technocast Private Limited: Nickel Aluminum Bronze, Leaded Tin Bronze, Mangnese Bronze, Phosphor Bronze, Cu-NiDocument4 pagesTarasree Technocast Private Limited: Nickel Aluminum Bronze, Leaded Tin Bronze, Mangnese Bronze, Phosphor Bronze, Cu-NiAakash KumarNo ratings yet

- Brochures - Bronze Roof Drains PDFDocument2 pagesBrochures - Bronze Roof Drains PDFAakash KumarNo ratings yet

- Globe Valve Specification Manuf'S OfferDocument1 pageGlobe Valve Specification Manuf'S OfferAakash KumarNo ratings yet

- Gate Valve Specification Manuf'S OfferDocument1 pageGate Valve Specification Manuf'S OfferAakash KumarNo ratings yet

Fettling

Fettling

Uploaded by

Aakash KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fettling

Fettling

Uploaded by

Aakash KumarCopyright:

Available Formats

DOC. NO.

: WI-PRD-11

EFF. DATE : 00

FOR FETTLING AND GRINDING REV. NO. : 00

REV. DATE :00

FETTLING & GRINDING :

1) Check the castings to be fettled for foundry defects sand drop, blow holes, pin hole, neck

shrinkage, etc.

2) Understand the area / portions to be fettled / ground. Incase of doubt, study the reference sample

casting / sketches provided or consult supervisor / In charge.

3) Understand the amount of fettling / grinding to be done and the required finish.

4) In general the following areas / portions are to be fettled.

a. Riser neck connection.

b. Ingate connection.

c. Parting line, fins and flashes.

d. If any other fins/flashes/Extra Material, is require to be fettled and ground without damaging

the castings.

5) In general carryout the fettling / grinding.

a. Provide a small riser remainder (0.3mm to 0.5mm) on the riser connection area and on the

line unless plain surface is specially asked for

b. Other projections and extra material, if any found in castings are to be fettled & smoothly me

Finished level with main surface.

c. The fettling / grinding should be smooth without cut marking.

d. Despatch the fettled castings for further processing.

APPROVED BY:- REVIEWED BY:- ISSUED BY:-

GM QMT MR

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Iso 9001 2015 Standard PDFDocument34 pagesIso 9001 2015 Standard PDFAakash KumarNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DB10R13003 - Thrust Washer Premachined - DBFV - DN 300 - PN 16 - Series 14 Rev 00Document1 pageDB10R13003 - Thrust Washer Premachined - DBFV - DN 300 - PN 16 - Series 14 Rev 00Aakash KumarNo ratings yet

- DB11R13003 - Bush Premachined - DBFV - DN 300 - PN 16 - Series 14 Rev 00Document1 pageDB11R13003 - Bush Premachined - DBFV - DN 300 - PN 16 - Series 14 Rev 00Aakash KumarNo ratings yet

- RG04R12503 - Wedge Nut Premachined - RSGV - DN 250 - PN 16 Rev 00Document1 pageRG04R12503 - Wedge Nut Premachined - RSGV - DN 250 - PN 16 Rev 00Aakash KumarNo ratings yet

- DB10R18003 - Thrust Washer Premachined - DBFV - DN 800 - PN 16 - Series 14 Rev 00Document1 pageDB10R18003 - Thrust Washer Premachined - DBFV - DN 800 - PN 16 - Series 14 Rev 00Aakash KumarNo ratings yet

- TSTPL Presentation PDFDocument15 pagesTSTPL Presentation PDFAakash KumarNo ratings yet

- Neer Drains SolutionDocument25 pagesNeer Drains SolutionAakash KumarNo ratings yet

- Kunal JRFDocument3 pagesKunal JRFAakash KumarNo ratings yet

- Tarasree Technocast Private Limited: Nickel Aluminum Bronze, Leaded Tin Bronze, Mangnese Bronze, Phosphor Bronze, Cu-NiDocument4 pagesTarasree Technocast Private Limited: Nickel Aluminum Bronze, Leaded Tin Bronze, Mangnese Bronze, Phosphor Bronze, Cu-NiAakash KumarNo ratings yet

- Brochures - Bronze Roof Drains PDFDocument2 pagesBrochures - Bronze Roof Drains PDFAakash KumarNo ratings yet

- Globe Valve Specification Manuf'S OfferDocument1 pageGlobe Valve Specification Manuf'S OfferAakash KumarNo ratings yet

- Gate Valve Specification Manuf'S OfferDocument1 pageGate Valve Specification Manuf'S OfferAakash KumarNo ratings yet