Professional Documents

Culture Documents

Special Procurement Types

Special Procurement Types

Uploaded by

Shrikant Baviskar0 ratings0% found this document useful (0 votes)

352 views5 pagesThe document describes several special procurement types in Materials Management (MM) including consignment, subcontracting, stock transfer using stock transport order, third-party processing, returnable transport packaging (RTP) process, and pipeline handling process. For each type, it provides a brief overview and the key steps to perform the respective process.

Original Description:

Special Procurement Types

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes several special procurement types in Materials Management (MM) including consignment, subcontracting, stock transfer using stock transport order, third-party processing, returnable transport packaging (RTP) process, and pipeline handling process. For each type, it provides a brief overview and the key steps to perform the respective process.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

352 views5 pagesSpecial Procurement Types

Special Procurement Types

Uploaded by

Shrikant BaviskarThe document describes several special procurement types in Materials Management (MM) including consignment, subcontracting, stock transfer using stock transport order, third-party processing, returnable transport packaging (RTP) process, and pipeline handling process. For each type, it provides a brief overview and the key steps to perform the respective process.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 5

Special Stocks and Special Procurement Types

The following special procurement types exist in MM

1. Consignment

2. Subcontracting

3. Stock Transfer Using Stock Transport Order

4. Third-Party Processing

5. Returnable Transport Packaging (RTP) Process

6. Pipeline Handling Process

Consignment

When buying goods on consignment, the ordered goods

still belong to the vendor, even after delivery. The goods

only become the property of the company supplied

when they are consumed. The quantity

consumed/withdrawn is settled with the vendor

periodically, for example on a monthly basis.

Steps to perform Consignment

*****************************************

1. Create a Material Master - MM01

2. Create Consignment Info Record - ME11

3. Create Consignment PO - ME21N

With Item Category - K

4. Create GR - MIGO - 101 K

5. Monitor Stock Overview - MMBE - VENDOR

CONSIGNMENT STOCK

6. Create TP - MB1B/ 411 K

7. Monitor Stock Overview - MMBE

8. Create Consignment Settlement – MRKO

Pipeline Handling Process

In pipeline handling, the company does not need to

order or store the material concerned. It is ready

available as and when required via a pipeline (for

example, oil or water), or some other type of cable (for

example, electricity). Consumption of the material is

settled with the vendor on a regular basis.

Steps to perform Pipeline Handling Process

**********************************************************

1. Create a Material Master - MM01 with Matl.Type - PIPE

2. Create Pipeline Info Record - ME11

3. Create GI - MB1A/201 P

4. Create Pipeline Settlement - MRKO

Returnable Transport Packaging Process – RTP Process

The company orders goods from a vendor. The goods

are delivered with returnable transport packaging

(pallets, containers, cylinders) that belongs to the

vendor and is stored on the customer premises until

they return it to the RTP Vendor.

Steps to perform RTP Process

*****************************************

1. Create two material masters with matl.type LEIH,

FERT - MM01

2. Create PO - ME21N

3. Create GR - MIGO / 501M for RTP material

4. Monitor Stock Overview - MMBE for RTP material

5. Return RTP material back to the vendor - MB1C/ 502 M

6. Monitor Stock Overview – MMBE

Stock Transfer Using Stock Transport Order

In stock transfer processing, goods are procured and

supplied within a company. One plant orders the goods

internally from another plant (receiving plant/issuing

plant).

The goods are procured with a special type of purchase

order - the stock transport order. You can request and

monitor the transfer of goods with a stock transport

order. The delivery can be processed in Inventory

Management or in the Shipping component.

Steps to perform Stock Transport Order Process

*************************************************************

1. Create material master in both supplying and

receiving plants - MM01

2. Maintain the stock in the supplying plant - MB1C/501

3. Create Stock Transport Order with Item Category - U -

ME21N

4. Create Transfer posting with supplying plant and

supplying storage location - MB1B/351

5. Monitor Stock Overview - MMBE

6. Create GR with reference to STO with receiving plant -

MIGO

7. Monitor Stock Overview – MMBE

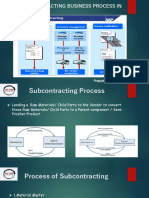

Subcontracting

In subcontracting, the vendor (the subcontractor)

receives components from which it produces a product.

The product is then ordered by your company through a

purchase order. The components required by the vendor

to manufacture the ordered product are listed in the

purchase order and provided to the subcontractor. The

components can be determined by the system via a bill

of material.

Steps to perform Subcontracting Process

******************************************************

1. Create material master for the subcomponents and for

the finished component - MM01 with material type ROH

and FERT

2. Maintain the stock for the subcomponents - MB1C/501

3. Create Subcontracting Info record for the finished

component - ME11

4. Create a Subcontracting PO with Item Category - L -

ME21N

5. Create Transfer Posting - MB1B/541

6. Stocks at Subcontractor - MBLB

7. Monitor Stock Overview - MMBE

8. Create GR - MIGO

9. Monitor Material Doc - MB03

10. Then the system displays movement type 101 for the

finished component and 543 for all the subcomponents.

Third-Party Processing

In third-party processing, a company passes on a sales

order to an external vendor who sends the goods

directly to the customer. The sales order is not

processed by your company, but by the vendor. Third-

party items can be entered in purchase requisitions,

purchase orders, and sales orders.

Third-party processing is integrated with the Sales and

Distribution (SD) component. If the sales order contains

third-party items, the system creates a purchase

requisition from the sales order.

Steps to perform Third Party Processing Process

**************************************************************

1. Create material master with material type FERT -

MM01

2. Maintain the stock for the material - MB1C/501

3. Create Sales Order - VA01

4. Create Third Party PO with A - 1, I - S - ME21N

5. Create Invoice - MIRO

6. Create Sales Invoice - VF01

You might also like

- Audit of Inventories - Roque 2018Document60 pagesAudit of Inventories - Roque 2018Renelyn David69% (13)

- Sap S4 Hana MMDocument12 pagesSap S4 Hana MMJosé RoblesNo ratings yet

- The Up & Away Advisors’ Guide to Implementing and Executing Sap’s Vehicle Management SystemFrom EverandThe Up & Away Advisors’ Guide to Implementing and Executing Sap’s Vehicle Management SystemNo ratings yet

- MD01 MD02 MD03Document10 pagesMD01 MD02 MD03G LINo ratings yet

- INVENTORYDocument10 pagesINVENTORYGiulia Tabara100% (1)

- Resume: Est Engg. Career ObjectiveDocument2 pagesResume: Est Engg. Career ObjectiveShrikant BaviskarNo ratings yet

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyFrom EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyRating: 4 out of 5 stars4/5 (6)

- SAP MM Process Flow Document PDFDocument36 pagesSAP MM Process Flow Document PDFAMIT AMBRENo ratings yet

- Sap MM: Material Requirement PlanningDocument11 pagesSap MM: Material Requirement Planningమనోహర్ రెడ్డిNo ratings yet

- Static GK Trick Complete-Book PDFDocument72 pagesStatic GK Trick Complete-Book PDFShrikant BaviskarNo ratings yet

- El PerplexionDocument6 pagesEl Perplexion123r12f1No ratings yet

- Sap MM: PipelineDocument5 pagesSap MM: PipelineManoj reddy100% (1)

- Stock Transfer Process in Sap Venkat TurlapatiDocument21 pagesStock Transfer Process in Sap Venkat Turlapativenkat100% (1)

- Intra Company Sto: Sap MMDocument5 pagesIntra Company Sto: Sap MMManoj reddyNo ratings yet

- Import Procurement Process in SAP MMDocument1 pageImport Procurement Process in SAP MMJayabalaji GNo ratings yet

- SAP MM Syllabus - Incell Services - I - PVT LTDDocument7 pagesSAP MM Syllabus - Incell Services - I - PVT LTDgiri nayakNo ratings yet

- SAP MM Interview Questions and Answers (2022) - AdafaceDocument18 pagesSAP MM Interview Questions and Answers (2022) - AdafaceprasanthNo ratings yet

- Sap MM Interview QuestionsDocument5 pagesSap MM Interview QuestionsAntony HegdeNo ratings yet

- 01 SAP MM Questions and AnswersDocument15 pages01 SAP MM Questions and AnswersPranav Swaroop100% (1)

- Vendor Return Process in SAP MMDocument15 pagesVendor Return Process in SAP MMmaniNo ratings yet

- Sap MM Interview QuestionaireDocument34 pagesSap MM Interview QuestionaireGadigota Suresh ReddyNo ratings yet

- Standard Import Pricing Procedure (India) in SAP MMDocument11 pagesStandard Import Pricing Procedure (India) in SAP MMMallu LoharNo ratings yet

- SAP MM Material Management Training TutorialsDocument5 pagesSAP MM Material Management Training TutorialssaranpcNo ratings yet

- Interview Questions On SAP MMDocument3 pagesInterview Questions On SAP MMdjsoumyaNo ratings yet

- Contracts and Scheduling AgreementDocument28 pagesContracts and Scheduling Agreementqingpingle100% (2)

- Special Stock & Special Procurement in SAPDocument17 pagesSpecial Stock & Special Procurement in SAProbnunesNo ratings yet

- Material Management by Using SAP in Real Estate Construction SectorDocument6 pagesMaterial Management by Using SAP in Real Estate Construction Sectorcodertutorial comNo ratings yet

- MM Sap I at AnsDocument42 pagesMM Sap I at Ansvenkateswarlu mandalapu100% (1)

- Define Material Groups PDFDocument3 pagesDefine Material Groups PDFHẬU Nguyễn NhưNo ratings yet

- Progress Tracking in Materials ManagementDocument15 pagesProgress Tracking in Materials ManagementbirojivenkatNo ratings yet

- Special Procurement Sap MMDocument7 pagesSpecial Procurement Sap MMAjith KumarNo ratings yet

- Stock Transfer Between Plants in One StepDocument5 pagesStock Transfer Between Plants in One StepRahul JainNo ratings yet

- Stock Transfer Using A Stock Transport Order: Sap MMDocument43 pagesStock Transfer Using A Stock Transport Order: Sap MMVaibhav ChaudhariNo ratings yet

- The Integration Between FI, SD, MM, and SF: Prepared By: Mona IbrahimDocument6 pagesThe Integration Between FI, SD, MM, and SF: Prepared By: Mona IbrahimSUBHOJIT BANERJEENo ratings yet

- Import Purchase CycleDocument14 pagesImport Purchase CycleNeha SinghNo ratings yet

- Output Determination in SAP MMDocument8 pagesOutput Determination in SAP MMsumit jain100% (1)

- Sap MM IqDocument56 pagesSap MM IqLavanya Hari Krishnan100% (1)

- FS - MM - Vendor GET OPEN PO DETAILSDocument13 pagesFS - MM - Vendor GET OPEN PO DETAILSSUBHOJIT BANERJEENo ratings yet

- Account Key Sap MMDocument2 pagesAccount Key Sap MMKumar AjitNo ratings yet

- Top Sap MM Job Interview Questions and Answers File 2Document10 pagesTop Sap MM Job Interview Questions and Answers File 2RP Tech100% (1)

- Delivery Completed Indicator and TolerancesDocument15 pagesDelivery Completed Indicator and TolerancesnandhakumarmeNo ratings yet

- Discrete Vs REMDocument4 pagesDiscrete Vs REMShashank Mani TripathiNo ratings yet

- Sap - Wms Warehouse Management Key User Manual FOR Wipro Unza - VietnamDocument16 pagesSap - Wms Warehouse Management Key User Manual FOR Wipro Unza - VietnamJagadish JaganNo ratings yet

- Questionnaire MMDocument130 pagesQuestionnaire MMMuhammad NassrNo ratings yet

- Material MasterDocument17 pagesMaterial Mastermic29100% (3)

- FINALSAPMMINTERVIEWDocument66 pagesFINALSAPMMINTERVIEWNiranjan BeheraNo ratings yet

- CV For SuccessDocument3 pagesCV For SuccessPropell AntNo ratings yet

- Process Flow Stock Transfer Order + ConfigurationDocument7 pagesProcess Flow Stock Transfer Order + Configurationsumitjain_25100% (1)

- 300+ TOP Sap MM Interview Questions and AnswersDocument16 pages300+ TOP Sap MM Interview Questions and AnswersRaghavendra M R100% (2)

- Jaya Prakash SAP MM ResumeDocument4 pagesJaya Prakash SAP MM Resumesandeepsankar777No ratings yet

- SAP-MM PowerpointDocument11 pagesSAP-MM PowerpointHimanshu GoyalNo ratings yet

- Creation of Plant in SAPDocument31 pagesCreation of Plant in SAPnagibvbNo ratings yet

- Sap MM Material Master DataDocument4 pagesSap MM Material Master DataUlul AzmiNo ratings yet

- SAP MM Tips & TricksDocument57 pagesSAP MM Tips & Tricksamal100% (2)

- Sap MM Interview QuestionsDocument3 pagesSap MM Interview QuestionsSrinu Kakollu100% (1)

- Subcontracting Business Process in SapDocument19 pagesSubcontracting Business Process in SapPrateek Mohapatra100% (1)

- 03 - 08 - PO Release Procedure by Ganesh PadalaDocument11 pages03 - 08 - PO Release Procedure by Ganesh PadalaDeepak WaghNo ratings yet

- SAP MM - Procurement ScenarioDocument6 pagesSAP MM - Procurement Scenariosyamsu866764100% (1)

- Basics of Sap SD ModuleDocument20 pagesBasics of Sap SD ModuleSourav Daruka100% (1)

- Return DeliveryDocument35 pagesReturn DeliverySunil BonalaNo ratings yet

- Sap StoDocument6 pagesSap StoPavanARKNo ratings yet

- Subcontracting Scrap Return ProcessDocument9 pagesSubcontracting Scrap Return ProcessSahil JadhavNo ratings yet

- SAP MM Accounting Entries With Movement TypeDocument6 pagesSAP MM Accounting Entries With Movement TypejagadeeshNo ratings yet

- Interview Questions On SAP MMDocument49 pagesInterview Questions On SAP MMshankari24381No ratings yet

- Performance Evaluation Workshop Hour Training 091913Document36 pagesPerformance Evaluation Workshop Hour Training 091913Shrikant BaviskarNo ratings yet

- Cold Calling: Direct Marketing When A Sales Rep-Whose Primary Job Is To SellDocument4 pagesCold Calling: Direct Marketing When A Sales Rep-Whose Primary Job Is To SellShrikant BaviskarNo ratings yet

- What Is Physical Inventory?Document6 pagesWhat Is Physical Inventory?Shrikant BaviskarNo ratings yet

- Warehouse Management-2Document14 pagesWarehouse Management-2Shrikant BaviskarNo ratings yet

- Sap Fico - Interview Questions: Types of Servers in SapDocument10 pagesSap Fico - Interview Questions: Types of Servers in SapShrikant BaviskarNo ratings yet

- Setting Up Purchase Order Release Strategy - SAP BlogsDocument18 pagesSetting Up Purchase Order Release Strategy - SAP BlogsShrikant BaviskarNo ratings yet

- UGC NET Syllabus 2021 - Download Subject-Wise Paper 1 & 2 Syllabus PDFs HereDocument12 pagesUGC NET Syllabus 2021 - Download Subject-Wise Paper 1 & 2 Syllabus PDFs HereShrikant BaviskarNo ratings yet

- Cold Calling: Direct Marketing When A Sales Rep-Whose Primary Job Is To SellDocument4 pagesCold Calling: Direct Marketing When A Sales Rep-Whose Primary Job Is To SellShrikant BaviskarNo ratings yet

- Communication Process EffectiveDocument14 pagesCommunication Process EffectiveShrikant BaviskarNo ratings yet

- SAP LandscapeDocument3 pagesSAP LandscapeShrikant BaviskarNo ratings yet

- Overview of SAP MM Module PDFDocument3 pagesOverview of SAP MM Module PDFShrikant BaviskarNo ratings yet

- T Codes: Events Source Purchase (MM) Finance (FI) Central Vendor Acc GRP Create Material Create/ MaintainDocument2 pagesT Codes: Events Source Purchase (MM) Finance (FI) Central Vendor Acc GRP Create Material Create/ MaintainShrikant BaviskarNo ratings yet

- Quiz No. 4 - InventoriesDocument8 pagesQuiz No. 4 - Inventoriesremalyn rigorNo ratings yet

- In The Books of Consignor: Accounting Treatment of ConsignmentDocument9 pagesIn The Books of Consignor: Accounting Treatment of ConsignmentZAKA ULLAHNo ratings yet

- Ict Application in Textile IndustryDocument50 pagesIct Application in Textile Industry01mrvikashNo ratings yet

- SAP MM ConsignmentDocument1 pageSAP MM ConsignmentraynojNo ratings yet

- Summary Notes Installment Sales and Consignment SalesDocument11 pagesSummary Notes Installment Sales and Consignment SalesJaycel OngyNo ratings yet

- General 2sem-1Document20 pagesGeneral 2sem-1hussainzohair3No ratings yet

- European Union: Certification by Competent Authorities (G)Document3 pagesEuropean Union: Certification by Competent Authorities (G)Narsa Reddy MaraNo ratings yet

- 20 SOP For Transportation To Deliver Defect Free ProdDocument4 pages20 SOP For Transportation To Deliver Defect Free ProdQAD LotusNo ratings yet

- Farap 4503Document12 pagesFarap 4503Marya Nvlz100% (1)

- Textile IndustryDocument44 pagesTextile Industry01mrvikashNo ratings yet

- Evans, Grimmer, and Grimmer 2022 - Consumer Orientations of Secondhand Fashion Shoppers - The Role of Shopping Frequency and Store TypeDocument11 pagesEvans, Grimmer, and Grimmer 2022 - Consumer Orientations of Secondhand Fashion Shoppers - The Role of Shopping Frequency and Store TypeFadilah KamilahNo ratings yet

- Case Study On FMCDDocument4 pagesCase Study On FMCDdattuffNo ratings yet

- Determinations (1) SD ModuleDocument3 pagesDeterminations (1) SD ModulerajeshNo ratings yet

- Inventories - Practice Set - Questionnaire-1Document5 pagesInventories - Practice Set - Questionnaire-1ashleydelmundo14No ratings yet

- AFAR - Installment, Customer, ConsignmentDocument3 pagesAFAR - Installment, Customer, ConsignmentJoanna Rose DeciarNo ratings yet

- AP 500Q Pages 1 19 Quizzer Audit of Current AssetsDocument19 pagesAP 500Q Pages 1 19 Quizzer Audit of Current AssetsJessa Crystal QuinagonNo ratings yet

- Zozo General Information & Financial Performance: Customer Value PropositionDocument4 pagesZozo General Information & Financial Performance: Customer Value PropositionÁi Thi DươngNo ratings yet

- Dayag CH 10Document10 pagesDayag CH 10Marjorie PagsinuhinNo ratings yet

- What Customs Manual Says About Disposal of Unclaimed and Uncleared CargoDocument3 pagesWhat Customs Manual Says About Disposal of Unclaimed and Uncleared CargoCM AngNo ratings yet

- SAP SD Consignment Sales Process.Document2 pagesSAP SD Consignment Sales Process.praveennbsNo ratings yet

- Special Procurement TypesDocument5 pagesSpecial Procurement TypesShrikant BaviskarNo ratings yet

- 6481 FinalExamDocument48 pages6481 FinalExamJuan Dela cruzNo ratings yet

- Returnable PackingDocument19 pagesReturnable Packingdharmendra.bbsr100% (1)

- Test II - Question PaperDocument3 pagesTest II - Question PaperRahulNo ratings yet

- Marketing AgreementDocument4 pagesMarketing AgreementRoy PersonalNo ratings yet

- Quiz Solution Consignment 2AAC and 2BAC Apr 2023Document10 pagesQuiz Solution Consignment 2AAC and 2BAC Apr 2023Lorifel Antonette Laoreno TejeroNo ratings yet