Professional Documents

Culture Documents

9 40 5 Ijas PDF

9 40 5 Ijas PDF

Uploaded by

John Albert BioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9 40 5 Ijas PDF

9 40 5 Ijas PDF

Uploaded by

John Albert BioCopyright:

Available Formats

International Journal of Agriculture Sciences

ISSN: 0975-3710&E-ISSN: 0975-9107, Volume 9, Issue 40, 2017, pp.-4638-4641.

Available online at http://www.bioinfopublication.org/jouarchive.php?opt=&jouid=BPJ0000217

Research Article

DESIGN MODIFICATION AND PERFORMANCE COMPARISON OF LAWN MOWER MACHINE BY MULCH AND

FLAT TYPE CUTTING BLADE

BHUTADA SHYAM H.1* AND SHINDE GOPAL U.2

1Department of Farm Power and Machinery Engineering, Aditya College of Agricultural Engineering, Beed, 431 122, M.S., India

2Department of Farm Power and Machinery Engineering, College of Agricultural Engineering, Vasantrao Naik Marathwada Agricultural University, Parbhani, M.S. India

*Corresponding Author: Email-shyamlalbhutada@gmail.com

Received: August 12, 2015; Revised: August 27, 2017; Accepted: August 28, 2017; Published: August 30, 2017

Abstract- The grass cutting machine is available in various types like Reel (cylinder) mower, Rotary and mulching mower, Riding mower, Robotic mower, and

Professional mower. The grass cutting machine is of two types’ electric motor and mechanical power. In the modification of lawn mower we used two types of blade,

mulching type blade and flat type blade. The mulching type blade having field efficiency is 93.7% with average speed 1.822 km/hr and the flat type blade having field

efficiency is 83.17% with average speed 1.89 km/hr. Results shown that the mulching type blade is most suitable.

Keywords- Lawn Mower, Mulching Blade, Flat Cutting Blade, Grass Cutting, Field Efficiency.

Citation: Bhutada Shyam H. and Shinde Gopal U., (2017) Design Modification and Performance Comparison of Lawn Mower Machine by Mulch and Flat Type Cutting

Blade. International Journal of Agriculture Sciences, ISSN: 0975-3710 & E-ISSN: 0975-9107, Volume 9, Issue 40, pp.-4638-4641.

Copyright: Copyright©2017 Bhutada Shyam H. and Shinde Gopal U., This is an open-access article distributed under the terms of the Creative Commons Attribution

License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Academic Editor / Reviewer: Mehulkumar Laljibhai Savalia, Raj Kiran Bakka, Dr Farzin Minoo Parabia, Dr Subhendu Bandyopadhyay, Dr Mrityunjai Kumar Singh

Introduction stand with the load stand will occur against machine elements, its lower cost, easy

The first lawn mower was introduced in 1830 by Edwin Beard Budding. In 1832, availability, machinability it is mostly used in order to reduce the cost of agricultural

Ransoms of Ipswich (under license) stared the making of Budding’s mower. Lawn machine. For fabrication of the machine mild steel was used [9-12].

mowers are useful part and applicable at different places throughout the world. In

small scale industry, like lawn mowing, has new development and designing which Design Consideration

becomes a prestigious art to some. Lawn mowers are complex as a street legal The principle and working of lawn mower is to cut the grass by slicing action of the

vehicle, and even more expensive than others. However, in a quite some years, blades above the ground surface without damaging the blades when it strikes on

many believe lawn mowing will be much more automated, if not completely immovable objects such as rock, stone. The cutting of grass takes place due to

automated in many areas. Agriculture is the most important sector of Indian impact and shearing action.

economic growth. In India, lawn mower machine has great scope. In our country, Now a day work has been done on solar power operated grass cutter. Following

as well as other countries, it is used in various fields like golf ground, football are the various parts of grass cutter or lawn mower designed carefully [13-16].

ground, cricket ground also in garden for grass cutting purpose [1].

A vertical motor mounted electrical lawn mower is an alternative option to common Cutting Unit

rotary mower. That grass cutter does the better job of cutting grass or lawn grass The sickle shaped cutting edge has been sharpened for easy cutting fixed at an

[2]. The vertical rotor shaft has many pairs of swinging knives that cuts the grass angle of curve of 180˚ to its horizontal axis. The cutting blade has been used as a

at equal height. If the blade cannot cut the grass by the first blade then it cuts by curve plane to perform cutting the grass efficiently. Design aspects of cutting unit

the other three remaining blades. The periodical cleaning is the measure problem consist of following consideration [17-22].

faced by the people in India. The commercially available units for mowing or grass

cutting are casting heavily. Hence considering the needs for development of Design of Blades

effective and economic grass cutting management practices, research work is In order to cut the grass the peripheral speed of the blade was calculated by the

under taken entitled “Modification and performance evaluation of lawn mower” formula,

with following objectives [3]- V=πdN

a) To fabricate mulch type and flat type blade 60

b) Performance evaluate of fabricated blade in field. Where,

c) Comparative evaluation of type I and II blades. V= blade speed, m/s; d = diameter of cutting area.

N = shaft speed, rpm.

Materials and Methods:

The available material was used as per the requirement concerning the function of Power Requirement for Cutting

machine and the life of the components [4-8]. The horse power required to cut the grass can found out with the help of formula,

Mild steel is known as soft metal, having less than 0.25 % of carbon, able to with

International Journal of Agriculture Sciences

ISSN: 0975-3710&E-ISSN: 0975-9107, Volume 9, Issue 40, 2017

|| Bioinfo Publications || 4638

Design Modification and Performance Comparison of Lawn Mower Machine by Mulch and Flat Type Cutting Blade

P = 2πNT following unit.

4500

Where, Specification of Grass Cutter

P = Power requirement, hp; T = Torque, Kg-m Specifications of the grass cutter are shown in [Table-1]

3.1.1.3 Power Transmission

To achieve desired transmission of power, the blades are directly mounted on Cutting Height of Grass

motor shaft. So, power transmission is directly from motor to horizontal rotating At the height of 20 mm from the ground surface, the blades were fixed, so that the

blades. cutting of grass was done.

Fabrication Process: Measurement of Output Power

Due attention was provided on the following design aspects while designing and Output power at the rotor was calculated by the idle speed and high speed of the

fabrication of the grass cutter. There are different sections such as cutting unit; rotor shaft and torque as per the formula, Po =T× N974

supporting frame; Power unit; Handle Where,

Transporting unit Po = output power, kW; T = shaft torque, kg-m

N = shaft speed, rpm

Cutter Blades Assume

Cutter blades used, were curved with externally sharpened edges. The cutter W = Width (mm); L = Length of blade (mm);

blades are made of mild steel flats. The cutter blades were hardened and T = Thickness; BT = Total no of blades;

tempered to suitable hardness for longer service life of the cutting edge. The WT= Total weight of blades (gm);

blades were rotated by the motor shaft which was operated electrically and directly NB = Blade Speed (m/s); HAvg=Average cutting height (mm)

fixed on motor shaft. DTr= Diameter of transmission (motor) shaft (mm)

Two types of blades: - 1. Mulch type 2. Flat type LTr=Length of transmission shaft (mm)

The grass was cut by the slicing action of blades revolving at 1420 revolutions per NM= Rated rpm of Motor; PM=Power of Motor (Hp)

min.

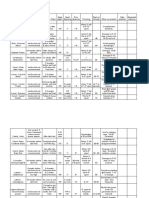

Table-1 Specifications of Lawn Mower with Mulch and Flat type blades

Supporting Frame A] Cutter blades specifications :

Supporting frame comprises of rectangular frame made of (470 x 320, 40 mm) Parameters Mulch Flat

W 20 50

was discussed below. L 140 280

Supporting base: From the economic point of view, to reduce cost of machine, a T 3 5

rectangular wooden plank 460 x 300, 25 mm size which was support the motor BT 4 2

weight. WT 280 280

NB 23.04 20.81

HAvg 20

Power Unit

B] Motor shaft Specifications:

Motor: DTr 18

Power to the machine was provided with the help of single phase electrical motor LTr 2000

of 1 hp to rotate the blades for cutting of grass. NM 1420

PM 1 Hp

On-off lever: It is used to cut and start the electric supply. It was fixed at the front C] Field Plot and Grass Specification

Plot Size 20 x 10

side of handle for easy operation. A 200

Grass HAvg 50

Handle HReq 20

The handle is made of mild steel hallow pipe with outside diameter 25 mm and

inner diameter 23 mm. The adjustable height of handle 950 mm. The handle was There are two type of blade are used:

provided for ease of driving the lawn mower by walking behind the machine. i. Mulch type blade

ii. Flat type blade

Transporting Unit The summery of the performance of field test of the grass cutter for given plot is

Transporting unit consist of ground wheel and axle. Two fronts and two rear presented in Table. Following observations regarding the different performance

wheels of 140 mm diameter made of 40 mm rubber wheel to support and carry the parameters of grass cutter are discussed below

machine. The four wheels were axle by 24 mm; M.S. diameter bar.

Height of Grass

Modification of Lawn Mower From the [Table-2], it was found that the average height of grass was found to be

To avoid human hazard, shaft or blade damage provide supporting small size 50 mm before cut.

metal rod to the frame of lawn mower having 50 mm length and 5 mm dia. 12

Performance Evaluation of Lawn Mower

The grass was tested for lab and field test.

Laboratory Test

Laboratory test was carried out at the Workshop of Farm Machinery and Power of

Aditya College of Agriculture Engineering and Technology, Beed. During Multch (B1)

laboratory test, the different parameters were observed carefully and described as

below. The observations and measurements of machine were categorized into

International Journal of Agriculture Sciences

ISSN: 0975-3710&E-ISSN: 0975-9107, Volume 9, Issue 40, 2017

Flat (B2)

|| Bioinfo Publications || 4639

Bhutada Shyam H. and Shinde Gopal U.

Conclusion

▪ For Mulch Type Blade

▪ 1) The grass cutter is able to cut grass of height 20 mm above ground level.

▪ 2) The effective field capacity of machine is 0.0506 ha/hr.

▪ 3) Field efficiency of grass cutter is 93.7%.

▪ 4) Grass cutter is operated at an average speed 1.822 km/hr without

disturbance in operation.

▪ 5) 1 Hp single phase electric motor is sufficient to operate for the width of

310 mm.

▪ For Flat Type Blade

▪ 1) The grass cutter is able to cut grass of height 20 mm above ground level.

▪ 2) The effective field capacity of machine is 0.0440 ha/hr.

Fig- 1 ▪ 3) Field efficiency of grass cutter is 83.17%.

▪ 4) Grass cutter is operated at an average speed 1.89 km/hr without

Height of Grass after Cut disturbance in operation.

The height of cutting grass was not varies with height of grass before cut because ▪ 5) 1 Hp single phase electric motor is sufficient to operate for the width of

the grass cutter was not adjustable. The height of cut grass was same for the 350 mm.

ground level throughout the testing which was 20 mm after cut [Table-2].

Acknowledgement / Funding: Author are thankful to Vasantrao Naik

Table-2 Performance and Evaluation of Lawn Mower for Mulch and Flat Type Marathwada Agricultural University, Parbhani, M.S., India

Blade with an operating width of 500mm

Performance Parameters P MULCH FLAT Author Contributions: All author equally contributed

Total no of strips (0.3X20m) to S 36 43

cover area

Abbreviations:

Time taken to cover total strips of Ts 1054.8 (17.58 798.34

test plot, sec min) (13.30 min)

Ethical approval: This article does not contain any studies with human

Total no of turns NT 35 42

participants or animals performed by any of the authors.

Time lost to owing to turning, sec TL 367.2 418.83

(6.32 min) (6.98 min)

Speed of operation, km/hr NO 1.82 1.89 Conflict of Interest: None declared

Total time required to cover the TT 1422 1217.17

plot including time losses, sec (23.7 min) (20.28 min) References

[1] Akinola L. A. F. (2008) Grass cutter farming: A new initiative in protein

Theoretical field capacity,ha/hr FCt 0.054 0.0529 supply. An invited paper presented at Agricultural Product Development

h

Strategy Workshop organised by Rivers State Sustainable Development

Effective field capacity FC 0.0506 0.0440

E

Agency (RSSDA), Held on 9 – 10th September, 2008 at the Elkan Terrace,

Field efficiency, % F 93.7% 83.17 % 12B Abacha Road G.R.A Phase 3, Port Harcourt, Rivers State.

[2] Ambujam A.K., Arasu P., Berty Edwin and S. Chandra Mouli (1984) Design

and development of power driven rotary grass cutter. Unpublished B.E.

(Ag.) project work, Tamil Nadu Agriculture University, Coimbatore.

[3] Ashby M.F. and Jones D.R.A. (1993) Engineering Materials 1: An

Introduction to their Properties and Applications. Pergamono Press,

England.

[4] A.S.A.E. (2004) A.S.A.E. Standard S472. Terminology for forage harvesters

and forage harvesting. In A.S.A.E. Standards 2004, 337-340.

[5] Baptist R. and Mensah G. A. (1986) World Animal Review, 60, 2 - 6.

[6] Bhutada S.H., Bhor V. K., Bodkhe R. B., Borey D.S., Deshmukh S.D., Gore

B. K., Jadhav G.S., Kaijkar U.M., Khandare S.M. and Pokale P.T. (2012)

The modification and performance evaluation of lawn mower, Unpublished

B-Tech Thesis at ACAET, Beed.

[7] Celik A. (2001) Present situation of Agriculture Mechanization in Turkey.

Course on Farm Machinery Design. Japan International Co-operation

Agency, TBIC, JR, 01-203, TSUKUBA, Japan.

[8] Chattopadhyay P.S. and Pandey K.P. (2001) Journal of Agriculture

Engineering Research, 78(3), pp. 245-252.

Fig-2 Multch Vs. Flat Blade Graphical Performance

International Journal of Agriculture Sciences

ISSN: 0975-3710&E-ISSN: 0975-9107, Volume 9, Issue 40, 2017

|| Bioinfo Publications || 4640

Design Modification and Performance Comparison of Lawn Mower Machine by Mulch and Flat Type Cutting Blade

[9] Dutta A.C., Chakravarty A.K. and Gupta C.P. (1969) The harvester, I.I.T.

kharagpur, 111(2), pp.99-103.

[10] Erokhin M.N., Belov M.I. and Sundnik Y.A. (2003) Tractor Machinery, 12,

pp. 31-34.

[11] Khurmi R.S. and Gopta J.K. (1997) Machine Design, 11th Edition. Eurasia

Publishing House Ltd. New Delhi.

[12] Khurmi R.S. and Gopta J.K. (2003) Machine Design. Eurasa Publishing

House, Ltd. New Delhi, India.

[13] Magar A.P., Gaikwad N.R., Sawalakhe S.S., Sawant P.V. and Yawatkar

P.G. (2009) Development and performance evaluation of grass cutter.

Unpublished B-Tech Thesis at ACAET, Beed.

[14] Marks I.S. and Banmeister T. (2004) Standard Hand Book for Mechanical

Engineers; 7th Edition. Mc Graw- Hill Book Company, Singapore.

[15] Opara M. N. (2010) Research Journal of Forestry, 4 (3), 119 – 135.

[16] Shigley J.E. and Mischke C.R. (2001) Mechanical Engineering Design. Mc-

Graw Hill Co. Inc. New York.

[17] Siteki G. (1986) Science publishers, Amsterdam, pp.30-31.

[18] Steward E.A. (1928) Agriculture Engineering A.S.A.E., 9(6), pp.175-179.

[19] Tajuddin A. (1996) Madras Agriculture Journal, 83(8), pp.519-522.

[20] Vassalini G. and Fedrizzi M. (2003) Monodo – Macchina, 12(2), pp. 50-54.

[21] Victor V.M., and Verma A.J. (2003) Agricultural Mechanization in Asia,

Africa and Latin America. 34(4), pp. 27-29.

[22] Yong and Chow S.H. (1991) Design and Construction of an Improved

Domestic Lawn Mower. Project Report; Beijing Institute of Technology,

China

International Journal of Agriculture Sciences

ISSN: 0975-3710&E-ISSN: 0975-9107, Volume 9, Issue 40, 2017

|| Bioinfo Publications || 4641

You might also like

- Minimatura 3 PDF Kozak Sprawdzain Unit 7Document3 pagesMinimatura 3 PDF Kozak Sprawdzain Unit 7Krzysztof Włodarz100% (1)

- Data Object Tables in Employee Central: Developer Guide - PUBLIC Document Version: 1H 2021 - 2021-07-21Document152 pagesData Object Tables in Employee Central: Developer Guide - PUBLIC Document Version: 1H 2021 - 2021-07-21nada0% (1)

- Laws Regs Study GuideDocument143 pagesLaws Regs Study Guideopengate2No ratings yet

- Turfgrass Fertilization BasicsDocument3 pagesTurfgrass Fertilization BasicsKirk's Lawn CareNo ratings yet

- Irrigation Course TrainingDocument63 pagesIrrigation Course TrainingDavid DollNo ratings yet

- FINAL Amended Chapter 65 Tree Ordinance Adopted 3.16.21Document12 pagesFINAL Amended Chapter 65 Tree Ordinance Adopted 3.16.21John SharpNo ratings yet

- Arduino Sip PuffDocument7 pagesArduino Sip PuffmarcusNo ratings yet

- Fertilizers - ComponentsDocument33 pagesFertilizers - Componentsbhupendra_10059iariNo ratings yet

- Plant Protestion EquipmentsDocument9 pagesPlant Protestion EquipmentsSreo Sree Roy ʘ‿ʘNo ratings yet

- Mowing TurfgrassesDocument4 pagesMowing TurfgrassesKirk's Lawn CareNo ratings yet

- Voles (Meadow Mice)Document4 pagesVoles (Meadow Mice)Kirk's Lawn CareNo ratings yet

- Agroforestry Production For Energy Production in RwandaDocument11 pagesAgroforestry Production For Energy Production in RwandaRaymond KatabaziNo ratings yet

- Tress and TurfDocument2 pagesTress and Turflahsivlahsiv684No ratings yet

- Plant Protection Equipments and Precautions Vimal PandeyDocument7 pagesPlant Protection Equipments and Precautions Vimal PandeyVimal PratapNo ratings yet

- Horticulture Fact Sheets PDFDocument15 pagesHorticulture Fact Sheets PDFmasumbuko mussaNo ratings yet

- Job CostingDocument16 pagesJob CostingipeeterNo ratings yet

- MACRO AND PRECISION IRRIGATION 2 Drip Design PDFDocument59 pagesMACRO AND PRECISION IRRIGATION 2 Drip Design PDFfawazNo ratings yet

- Guidelines Tree TransplantationDocument4 pagesGuidelines Tree TransplantationRui Basilio100% (1)

- Assn6 PDFDocument2 pagesAssn6 PDFElzNo ratings yet

- Water Wise Landscape Handbook PDFDocument20 pagesWater Wise Landscape Handbook PDFmendes62No ratings yet

- Lawn MaintenanceDocument8 pagesLawn MaintenancemissliniusNo ratings yet

- Garden City DevelopmentDocument135 pagesGarden City DevelopmentMarcus Busby100% (2)

- Managing Thatch in LawnsDocument5 pagesManaging Thatch in LawnsKirk's Lawn CareNo ratings yet

- California Pesticide Registration GuidanceDocument99 pagesCalifornia Pesticide Registration GuidancePepe Jara GinsbergNo ratings yet

- Understanding Your Soil Test ReportDocument24 pagesUnderstanding Your Soil Test ReportdanielNo ratings yet

- LostFile PDF 347990736Document5 pagesLostFile PDF 347990736jhsee72No ratings yet

- Soils-The Good, The Bad, and The BeautifulDocument52 pagesSoils-The Good, The Bad, and The Beautifulkett8233No ratings yet

- Hard N Soft LandscapeDocument5 pagesHard N Soft Landscapeprazol11223350% (2)

- Green Dream ProfileDocument119 pagesGreen Dream Profilelou_villaluzNo ratings yet

- Home Gardeners Guide To Soils and Fertilizers - WSUpdfDocument26 pagesHome Gardeners Guide To Soils and Fertilizers - WSUpdfDNo ratings yet

- TILLAGE SlideDocument18 pagesTILLAGE SlideArnab PaulNo ratings yet

- Primary Tillage ImplementsDocument3 pagesPrimary Tillage ImplementsAvinash Rai100% (2)

- GROUNDMAN'S HandbookDocument11 pagesGROUNDMAN'S Handbookaka_mayhemNo ratings yet

- Eggplant Growing Agfact H8.1.29Document4 pagesEggplant Growing Agfact H8.1.29ronalit malintadNo ratings yet

- Compost Machine 24 100Document1 pageCompost Machine 24 100atul256No ratings yet

- AGR524 CalibrationDocument7 pagesAGR524 CalibrationMuhammad Aliuddin BakarNo ratings yet

- New Text DocumentDocument28 pagesNew Text DocumentAbhijit PolNo ratings yet

- Landscaping GuideDocument8 pagesLandscaping Guidekokosmart007No ratings yet

- KATALOG Fertigation 2010 PDFDocument44 pagesKATALOG Fertigation 2010 PDFsanitermNo ratings yet

- Celery PDFDocument3 pagesCelery PDFRajNo ratings yet

- Model Scheme On Setting Up of High Tech Nursery Under Plantation and HorticultureDocument15 pagesModel Scheme On Setting Up of High Tech Nursery Under Plantation and HorticultureSuresh Kumar Vengali100% (1)

- 7-Direct Seeding and TransplantingDocument43 pages7-Direct Seeding and TransplantingSeverino Jr. SaleraNo ratings yet

- Macadamia Grower's Handbook: Reprint - Information Current in 2004Document9 pagesMacadamia Grower's Handbook: Reprint - Information Current in 2004Dang NguyenNo ratings yet

- Drip Irrigation For The Yard and GardenDocument6 pagesDrip Irrigation For The Yard and GardenladydonnaduqueNo ratings yet

- Deep Pipe IrrigationDocument8 pagesDeep Pipe IrrigationXuxuxelNo ratings yet

- SSA Landscape Architects, Inc.-Landscape Architecture & Arboricultural ServicesDocument22 pagesSSA Landscape Architects, Inc.-Landscape Architecture & Arboricultural ServicesL. A. PatersonNo ratings yet

- Dayananda Sagar School of Architecture: 09 Arc 7.7 Landscape Architecture NotesDocument4 pagesDayananda Sagar School of Architecture: 09 Arc 7.7 Landscape Architecture NotesPrajwal PrakashNo ratings yet

- Integrated Pest Management in GreenhousesDocument13 pagesIntegrated Pest Management in GreenhousesDrSHAILENDRA MANENo ratings yet

- 1Document6 pages1Rajdeep RajdipNo ratings yet

- Aht Forest TractorDocument19 pagesAht Forest Tractorapi-287842695No ratings yet

- Planting and Care - Saffron CrocusDocument1 pagePlanting and Care - Saffron CrocusBrandia Ta'amuNo ratings yet

- Landscaping Estimate: Plants LaborDocument1 pageLandscaping Estimate: Plants LaborMathiTwadCNo ratings yet

- Trees in Hard Landscapes Consultation Draft 28 May 2014Document130 pagesTrees in Hard Landscapes Consultation Draft 28 May 2014martinadam82No ratings yet

- CityGreens CommFarms 202203Document16 pagesCityGreens CommFarms 202203Shri Meenakshi Naturals100% (1)

- Package of Practices For RoseDocument5 pagesPackage of Practices For RoseAnubhav PandaNo ratings yet

- (3-2) Super Handy Lawn Mower - Group A15Document160 pages(3-2) Super Handy Lawn Mower - Group A15Md Sabbir HossainNo ratings yet

- Field Tomato Production Guide 2016 PDFDocument6 pagesField Tomato Production Guide 2016 PDFJonathan de JongNo ratings yet

- Standard: Philippine NationalDocument27 pagesStandard: Philippine NationalCHRISTIAN JOEFEL BESSATNo ratings yet

- Efficient Irrigation A Reference Manual For Turf ADocument34 pagesEfficient Irrigation A Reference Manual For Turf Aflorlis suazoNo ratings yet

- Vegetable GardenDocument5 pagesVegetable GardencshaddowNo ratings yet

- Growing Mushrooms Six Steps To Mushroom FarmingDocument3 pagesGrowing Mushrooms Six Steps To Mushroom Farmingmarco_nicolau6289No ratings yet

- Performance Evaluation of Grass Cutter: Research PaperDocument1 pagePerformance Evaluation of Grass Cutter: Research PaperPrajay BhavsarNo ratings yet

- Irjet V5i1098Document5 pagesIrjet V5i1098Trieu Nguyen KhoaNo ratings yet

- Theories of International TradeDocument35 pagesTheories of International TradeRishika ParmarNo ratings yet

- BAIL 16008 Catalogue Update DE5 PROOF Issuu v2Document38 pagesBAIL 16008 Catalogue Update DE5 PROOF Issuu v2Chris LuiNo ratings yet

- Celstran PP-GF40-04 Natural: Celanese Corporation - PolypropyleneDocument2 pagesCelstran PP-GF40-04 Natural: Celanese Corporation - PolypropyleneZubair AamirNo ratings yet

- Mosses Diversity From Lombok IDocument9 pagesMosses Diversity From Lombok IariNo ratings yet

- Grade 5 - Math - Module 5Document314 pagesGrade 5 - Math - Module 5Folker sNo ratings yet

- PicoStocks Business PlanDocument17 pagesPicoStocks Business PlanJignesh ChaudharyNo ratings yet

- Leonard S Woody - Essential Mathematics For Quantum Computing (2022)Document252 pagesLeonard S Woody - Essential Mathematics For Quantum Computing (2022)kaldrogo2201No ratings yet

- Daily Lesson Log: English For Academic and Professional PurposesDocument5 pagesDaily Lesson Log: English For Academic and Professional PurposesJenelle de VeraNo ratings yet

- 1509846749lecture 11. 2k14eee Signal Flow GraphDocument62 pages1509846749lecture 11. 2k14eee Signal Flow GraphAmin KhanNo ratings yet

- Lecture 08 - Induction MachinesDocument18 pagesLecture 08 - Induction MachinesKarthik VNo ratings yet

- Gall's ProjectionDocument3 pagesGall's ProjectionBiki KunduNo ratings yet

- Webinar Reflection PaperDocument4 pagesWebinar Reflection PaperMitz Lorraine ZambranoNo ratings yet

- Catálogo - Caixa TransmissãoDocument20 pagesCatálogo - Caixa TransmissãoELTON LEMOSNo ratings yet

- Chicago Metro History FairDocument2 pagesChicago Metro History Fairapi-308852006No ratings yet

- 00 Perhitungan Alat Besar 1-DeSKTOP-NJGKKH8Document359 pages00 Perhitungan Alat Besar 1-DeSKTOP-NJGKKH8Muhammad FakhrizalNo ratings yet

- DLL - Tle-Ia 6 - Q3 - W4Document3 pagesDLL - Tle-Ia 6 - Q3 - W4RUTCHE TABANAONo ratings yet

- Insignia Ns l37q 10a Ns l42q 10a LCD TVDocument151 pagesInsignia Ns l37q 10a Ns l42q 10a LCD TVronald stew100% (1)

- Strategic Management Journal PDFDocument21 pagesStrategic Management Journal PDFselvyNo ratings yet

- Process Safety Engineer ResponsibilitiesDocument23 pagesProcess Safety Engineer ResponsibilitiesTFattahNo ratings yet

- 04 - RF Power AmplifiersDocument377 pages04 - RF Power Amplifiersthanhvu_ut100% (12)

- BOTIL Product Catalogue PDFDocument160 pagesBOTIL Product Catalogue PDFPetroMan CMNo ratings yet

- ADGTE Policy Compendium 2012Document135 pagesADGTE Policy Compendium 2012venugopalNo ratings yet

- Meeting PeopleDocument2 pagesMeeting PeopleJose AssisNo ratings yet

- SVP - Tool - FAQ Reset t500 IBM PDFDocument3 pagesSVP - Tool - FAQ Reset t500 IBM PDFJaroslav BiresNo ratings yet

- Tarea Unidad IV AEF 1052 Unidad IvaDocument1 pageTarea Unidad IV AEF 1052 Unidad IvaMaelenBecsaNo ratings yet

- Research Paper On Chatbot 4-HBRP PublicationDocument9 pagesResearch Paper On Chatbot 4-HBRP PublicationPriyanshu MangalNo ratings yet