Professional Documents

Culture Documents

Hydrocracking Processes 1

Hydrocracking Processes 1

Uploaded by

Annu Rawat0 ratings0% found this document useful (0 votes)

15 views1 pageHydrocracking is a refining process that uses hydrogen gas and a catalyst under heat and pressure to convert heavy gas oils and distillates into lighter products like naphtha, kerosene, and diesel. During this process, sulfur and nitrogen are removed from the feedstock through reactions with hydrogen that produce hydrogen sulfide and ammonia, both of which are then separated out, leaving behind desulfurized and denitrified hydrocarbon products.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHydrocracking is a refining process that uses hydrogen gas and a catalyst under heat and pressure to convert heavy gas oils and distillates into lighter products like naphtha, kerosene, and diesel. During this process, sulfur and nitrogen are removed from the feedstock through reactions with hydrogen that produce hydrogen sulfide and ammonia, both of which are then separated out, leaving behind desulfurized and denitrified hydrocarbon products.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

15 views1 pageHydrocracking Processes 1

Hydrocracking Processes 1

Uploaded by

Annu RawatHydrocracking is a refining process that uses hydrogen gas and a catalyst under heat and pressure to convert heavy gas oils and distillates into lighter products like naphtha, kerosene, and diesel. During this process, sulfur and nitrogen are removed from the feedstock through reactions with hydrogen that produce hydrogen sulfide and ammonia, both of which are then separated out, leaving behind desulfurized and denitrified hydrocarbon products.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Hydrocracking Processes

Distillate hydrocracking is a refining process for conversion of heavy

gas oils and heavy diesels or similar boiling-range heavy distillates into

light distillates (naphtha, kerosene, diesel, etc.) or base stocks for lubri-

cating oil manufacture. The process consists of causing feed to react with

hydrogen in the presence of a catalyst under specified operating condi-

tions: temperature, pressure, and space velocity.

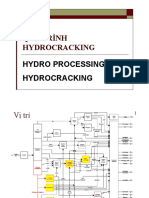

HYDROCRACKING REACTIONS

DESULFURIZATION

The feedstock is desulfurized by the hydrogenation of the sulfur con-

taining compounds to form hydrocarbon and hydrogen sulfide. The H2S is

removed from the reactor effluent leaving only the hydrocarbon product.

The heat of reaction for desulfurization is about 60 Btu/scf of hydrogen

consumed:

CATALYST

Thiophene Paraffin Hydrogen Sulphide

DENITRIFICATION

Nitrogen is removed from feedstock by the hydrogenation of nitrogen-

containing compounds to form ammonia and hydrocarbons. Ammonia is

later removed from the reactor effluent, leaving only the hydrocarbons in

the product. The heat of reaction of the denitrification reactions is about

You might also like

- 02 Naphtha Hydro Treating (Compatibility Mode) - OptDocument52 pages02 Naphtha Hydro Treating (Compatibility Mode) - OptJhon Molina100% (6)

- CHAPTER 5 HydrotreatingDocument41 pagesCHAPTER 5 HydrotreatingNurfarhana JelenNo ratings yet

- Chlorine Dioxide ProcessesDocument4 pagesChlorine Dioxide ProcessesKani Kanii50% (2)

- Purpose: To Separate The Substance in Crude Oil With Lower and Higher Boiling Point. MethodDocument7 pagesPurpose: To Separate The Substance in Crude Oil With Lower and Higher Boiling Point. MethodHafiz ImranNo ratings yet

- 16 - Impurities Removal From Liqued FuelsDocument21 pages16 - Impurities Removal From Liqued FuelsSHREENo ratings yet

- Petroleum Refining GlossaryDocument7 pagesPetroleum Refining GlossaryPradeep MunnaNo ratings yet

- Solvent Extraction and DewaxingDocument21 pagesSolvent Extraction and DewaxingAnwesh SatapathyNo ratings yet

- HD Ro FinishingDocument6 pagesHD Ro FinishingMuhammad sherazNo ratings yet

- Hydro ProcessingDocument56 pagesHydro ProcessinggeorgiadisgNo ratings yet

- Producing Naphtha and KeroseneDocument10 pagesProducing Naphtha and KeroseneSelvia Pratiwi100% (1)

- Petroleum Chemistry and Its Refineries05Document21 pagesPetroleum Chemistry and Its Refineries05Louis ThianNo ratings yet

- Lec 23Document5 pagesLec 23Abder RaheemNo ratings yet

- Naptha Hydrotreating UnitDocument7 pagesNaptha Hydrotreating UnitreetiNo ratings yet

- HydrodesulfurisationDocument3 pagesHydrodesulfurisationSO R ANNo ratings yet

- H2O2 Manufacturing ProcessDocument6 pagesH2O2 Manufacturing ProcessJames YatesNo ratings yet

- Refinery OverviewDocument79 pagesRefinery Overviewchikukotwal100% (1)

- NHTDocument6 pagesNHTPadarthi Venkateswarlu50% (2)

- Modern Chemical ManufacturerDocument8 pagesModern Chemical ManufacturerUltra Gamer (sishant)No ratings yet

- UpdatedChapter3 4Document48 pagesUpdatedChapter3 4mystorewelcome1No ratings yet

- Petrochemical ProcessDocument20 pagesPetrochemical Processsanjeevs01No ratings yet

- Define Steam Reforming Process?: Chemical Reaction Carbon Monoxide Water Vapor Carbon Dioxide HydrogenDocument7 pagesDefine Steam Reforming Process?: Chemical Reaction Carbon Monoxide Water Vapor Carbon Dioxide Hydrogenjeevanantham 5846No ratings yet

- Hydroprocessing Pilot PlantsDocument4 pagesHydroprocessing Pilot PlantsNattapong PongbootNo ratings yet

- Lecture Notes On Refining PDFDocument23 pagesLecture Notes On Refining PDFdivakarNo ratings yet

- Basic Refinery ProcessDocument44 pagesBasic Refinery ProcessJohn Kris San LuisNo ratings yet

- Gas PurificationDocument26 pagesGas PurificationMahmud Rahman BizoyNo ratings yet

- Alkylation and Hydrogen ProductionDocument24 pagesAlkylation and Hydrogen Productiondie lutionNo ratings yet

- Lecture 5Document18 pagesLecture 5Rehman ManiNo ratings yet

- Ammonia Training 1Document32 pagesAmmonia Training 1rohit100% (1)

- DesulphurizationDocument43 pagesDesulphurizationNithinKallayilNo ratings yet

- Hydrocarbon ProcessingDocument20 pagesHydrocarbon Processingsanjeevs01No ratings yet

- Chapter6a Hydrotreating 170106114901 PDFDocument26 pagesChapter6a Hydrotreating 170106114901 PDFMI MNo ratings yet

- HFU and HGUDocument3 pagesHFU and HGUumairz01No ratings yet

- Material ScienceDocument33 pagesMaterial ScienceLyvea PagaduanNo ratings yet

- Hydro Treating CompleteDocument19 pagesHydro Treating CompleteFaiq Ahmad Khan100% (3)

- Refinery Asigment AwatDocument7 pagesRefinery Asigment AwatAwat MuhammadNo ratings yet

- Naphtha Production: Department of Chemical Engineering NIT CalicutDocument9 pagesNaphtha Production: Department of Chemical Engineering NIT CalicutAhmed Khamees ShatlaNo ratings yet

- 8 HydrotreatingDocument31 pages8 HydrotreatingAmroKasht100% (2)

- Hydrogenatin ProcessDocument14 pagesHydrogenatin ProcessNazar AhmedNo ratings yet

- Diesel Hydro Treating UnitDocument4 pagesDiesel Hydro Treating UnittalhawasimNo ratings yet

- Petroleum RefiningDocument5 pagesPetroleum RefiningSusbsisvNo ratings yet

- Chapter 2 Oil Refinery Plant - Conversion and TreatmentDocument52 pagesChapter 2 Oil Refinery Plant - Conversion and Treatmenthafizulhakim02No ratings yet

- Refining ProcessDocument15 pagesRefining Processtechy TalksNo ratings yet

- What Are The Techniques Used in Reforming Unit To Reduce Catalyst Dust While Removing Catalyst Fines From Regenerator Unit?Document3 pagesWhat Are The Techniques Used in Reforming Unit To Reduce Catalyst Dust While Removing Catalyst Fines From Regenerator Unit?Chetan CherryNo ratings yet

- Go 5 Ammonia, Sulphuric Acid, Nitric AcidDocument21 pagesGo 5 Ammonia, Sulphuric Acid, Nitric AcidcikaifaNo ratings yet

- Quiz Mohd Rafiq Mohd ZubirDocument11 pagesQuiz Mohd Rafiq Mohd ZubirMohd RafiqNo ratings yet

- Industrial Inorganic ChemistryDocument39 pagesIndustrial Inorganic ChemistryIct Pfa ClubNo ratings yet

- Merox & HydrotreatmentDocument18 pagesMerox & HydrotreatmentLuis Acid100% (2)

- Lecture 1Document22 pagesLecture 1Amit Narayan RaiNo ratings yet

- HydrocrackingDocument24 pagesHydrocrackingSaj BhaiNo ratings yet

- Chem Unit 2 Module 3Document74 pagesChem Unit 2 Module 3Shanieza AliNo ratings yet

- Unit 3 Chemical Process Technology II Lesson 1 Nitrogen Industries (M)Document22 pagesUnit 3 Chemical Process Technology II Lesson 1 Nitrogen Industries (M)Green JeskNo ratings yet

- Air Polluition ControlDocument37 pagesAir Polluition ControlGendewa Tunas RancakNo ratings yet

- Chương 5 HydroCrackingDocument23 pagesChương 5 HydroCrackingAn Lê TrườngNo ratings yet

- Refining Process Simulation HYSYS V10 (Hydrocracking, Visbreaking, Delayed Coking)Document11 pagesRefining Process Simulation HYSYS V10 (Hydrocracking, Visbreaking, Delayed Coking)Borisvc8100% (2)

- Hydrotreating UnitDocument11 pagesHydrotreating UnitAbhishek GogoiNo ratings yet

- Hassan Jomaa & Zeinab Srour Diesel ProjectDocument19 pagesHassan Jomaa & Zeinab Srour Diesel Projectنور الزهراءNo ratings yet

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- Hydroformylation: Fundamentals, Processes, and Applications in Organic SynthesisFrom EverandHydroformylation: Fundamentals, Processes, and Applications in Organic SynthesisNo ratings yet

- Nanoporous Catalysts for Biomass ConversionFrom EverandNanoporous Catalysts for Biomass ConversionFeng-Shou XiaoNo ratings yet

- Bio-Based SolventsFrom EverandBio-Based SolventsFrançois JérômeNo ratings yet