Professional Documents

Culture Documents

Ldpe

Ldpe

Uploaded by

Ardy WiyogoCopyright:

Available Formats

You might also like

- Road Construction Production Output RatesDocument23 pagesRoad Construction Production Output Rateslimbadz100% (14)

- Ale Part 2 Answer KeyDocument27 pagesAle Part 2 Answer KeyTimothy Ryan Wang100% (2)

- Trirex 3020HF: Polycarbonate ResinDocument5 pagesTrirex 3020HF: Polycarbonate ResinAlbert FortunatoNo ratings yet

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneDocument1 pageTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamNo ratings yet

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Document1 pageTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PNo ratings yet

- Polye PDocument2 pagesPolye PFranco Gabriel MercadoNo ratings yet

- PolystyreneDocument1 pagePolystyrenejoshkajasmineNo ratings yet

- Polypropylene PDFDocument2 pagesPolypropylene PDFSabuj SaikiaNo ratings yet

- CastacrylicDocument1 pageCastacrylicuyenNo ratings yet

- Technical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekDocument2 pagesTechnical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekSyed MoinNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- Teflon (PTFE) Data SheetDocument1 pageTeflon (PTFE) Data SheetMarisa Yuni Nur AzizaNo ratings yet

- Technical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Document1 pageTechnical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Dharmendra DubeyNo ratings yet

- Data Sheet PPSUDocument2 pagesData Sheet PPSUluuiissNo ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- Technical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Document1 pageTechnical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Paulo RicardoNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- Acrylic Not Recc For ChlorinatedDocument2 pagesAcrylic Not Recc For ChlorinatedoktavNo ratings yet

- Technical Data Sheet PVC: (Polyvinyl Chloride)Document1 pageTechnical Data Sheet PVC: (Polyvinyl Chloride)Adnan KhanNo ratings yet

- Typical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesDocument2 pagesTypical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesAdnan KhanNo ratings yet

- Properties of High Density Polyethylene (HDPE) : Astm or UL Test Property HdpeDocument1 pageProperties of High Density Polyethylene (HDPE) : Astm or UL Test Property HdpedangdinhthyNo ratings yet

- VERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good SealabilityDocument1 pageVERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good Sealabilityseeralan_1986No ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- Static Dissipative Polyetherimide (Pei) / Static Dissipative UltemDocument1 pageStatic Dissipative Polyetherimide (Pei) / Static Dissipative UltemVC KannanNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- Delrin SpecsDocument1 pageDelrin SpecsabhijitNo ratings yet

- Delrin SpecsDocument1 pageDelrin SpecsGrimmo1979No ratings yet

- Delrin - Mechanical PropertyDocument1 pageDelrin - Mechanical PropertyGovarthanan GovaNo ratings yet

- Teflon PTFE - PSG - Mechanical PropertyDocument1 pageTeflon PTFE - PSG - Mechanical PropertyGovarthanan GovaNo ratings yet

- Anti-Static Ultra-High Molecular Weight Polyethylene/Anti-Static Uhmw PeDocument1 pageAnti-Static Ultra-High Molecular Weight Polyethylene/Anti-Static Uhmw PeVC KannanNo ratings yet

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Document1 pageTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngNo ratings yet

- Acetal: Acetal Grades ACETAL COPOLYMER (Unfilled)Document1 pageAcetal: Acetal Grades ACETAL COPOLYMER (Unfilled)Anonymous UcmNTu6rNo ratings yet

- Delrin PDFDocument2 pagesDelrin PDFA. Kumar RaiNo ratings yet

- Delrin Mat PDFDocument2 pagesDelrin Mat PDFyajneshwaradixitNo ratings yet

- Delrin MaterialDocument2 pagesDelrin MaterialyajneshwaradixitNo ratings yet

- Technical Data Sheet Nylon: (Polyamide)Document3 pagesTechnical Data Sheet Nylon: (Polyamide)Dharmendra DubeyNo ratings yet

- Delrin 150Document1 pageDelrin 150Sardar. Vikramjit Singh RandhawaNo ratings yet

- Teflon® FEP (Fluorinated Ethylene Propylene)Document1 pageTeflon® FEP (Fluorinated Ethylene Propylene)mohammed goudaNo ratings yet

- Ptfe PDFDocument1 pagePtfe PDFXiwen CloudNo ratings yet

- FS DatasheetDocument1 pageFS Datasheetazeem bilalNo ratings yet

- Technical Information: (BR) (WR-2) (Special F)Document1 pageTechnical Information: (BR) (WR-2) (Special F)johnNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- PSG Epoxy Glass PhenolicsDocument1 pagePSG Epoxy Glass PhenolicsmadhunnadigNo ratings yet

- RX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourDocument1 pageRX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourEetu SatosalmiNo ratings yet

- MC 907 Natural NylonDocument2 pagesMC 907 Natural NylonJunior TaHuaNo ratings yet

- Scotch Heavy Duty Mining Tape 31: Data Sheet June 2013Document2 pagesScotch Heavy Duty Mining Tape 31: Data Sheet June 2013Kishan MohtaNo ratings yet

- PP TD20 Lotte JHC-372Document1 pagePP TD20 Lotte JHC-372Herman SujarwantoNo ratings yet

- NorylDocument1 pageNorylAnonymous P8Bt46mk5INo ratings yet

- Ptfe Data SheetDocument1 pagePtfe Data SheetEko PrastyoNo ratings yet

- TECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETDocument2 pagesTECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETFeby Shyntia AfirantiNo ratings yet

- 7-1882 TDS Blue Liquid Epoxy-UrethaneDocument2 pages7-1882 TDS Blue Liquid Epoxy-UrethanePedro Santo Orsini RevengaNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Technical Data Sheet Linen PhenolicDocument1 pageTechnical Data Sheet Linen PhenolicKissa DolautaNo ratings yet

- Technical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Document1 pageTechnical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Nam NguyenNo ratings yet

- Material Data Sheet: HDPE NaturalDocument2 pagesMaterial Data Sheet: HDPE NaturalSyed MoinNo ratings yet

- DP03HDocument1 pageDP03HDiadam SharmaNo ratings yet

- Technical Data Sheet Ultem (Pei) : (Polyetherimide)Document3 pagesTechnical Data Sheet Ultem (Pei) : (Polyetherimide)Dynamic SaravananNo ratings yet

- ST5101-Advance Concrete StructuresDocument16 pagesST5101-Advance Concrete Structurescmurugan50% (2)

- Conex CompressionDocument32 pagesConex Compressionh2odavid100% (1)

- Analysis Methods For Leakage Rates in Pressurized ComponentsDocument20 pagesAnalysis Methods For Leakage Rates in Pressurized ComponentsGeorgiosLupusMogueidaNo ratings yet

- Experimental Study of Water Wetting in Oil Water Two Phase Flow - JCaiDocument11 pagesExperimental Study of Water Wetting in Oil Water Two Phase Flow - JCaiSyafiqah IsmailNo ratings yet

- Commercial Specification Sheet Cordlash 105 & HDB 10 N - 6310000 6310900 7400300Document2 pagesCommercial Specification Sheet Cordlash 105 & HDB 10 N - 6310000 6310900 7400300Juanma SalamancaNo ratings yet

- 135 - Guidelines For Classification of Well Control Incidents and Well Integrity Incidents - Rev. 2Document21 pages135 - Guidelines For Classification of Well Control Incidents and Well Integrity Incidents - Rev. 2Sean CurnowNo ratings yet

- Parametric Study of Cable Stayed Bridge Using Different Pylon ConfigurationDocument7 pagesParametric Study of Cable Stayed Bridge Using Different Pylon ConfigurationTanjil MominNo ratings yet

- Laminar or Viscous Flow 6Document26 pagesLaminar or Viscous Flow 6Sunil BagadeNo ratings yet

- Sanitary EngineeringDocument44 pagesSanitary Engineeringمحمد الددحNo ratings yet

- ACI 341-C Retrofit Presentation - Part 1Document65 pagesACI 341-C Retrofit Presentation - Part 1chithirai10100% (2)

- CIVIL ENGINEERING prEN 1995-2 2004 (Final Draft) - Design of Timber Structures - Bridges PDFDocument29 pagesCIVIL ENGINEERING prEN 1995-2 2004 (Final Draft) - Design of Timber Structures - Bridges PDFcaballerolangNo ratings yet

- Acceptance Checklist: Elevator Machine Room And/or Control SpaceDocument4 pagesAcceptance Checklist: Elevator Machine Room And/or Control SpaceImran KhanNo ratings yet

- Designed With Dlubal Software: Crossrail Station in Canary Wharf LondonDocument1 pageDesigned With Dlubal Software: Crossrail Station in Canary Wharf Londonweb76280No ratings yet

- Flexure Beam Analysis and Design - (Printed)Document18 pagesFlexure Beam Analysis and Design - (Printed)saleh34534rf34No ratings yet

- Structural Systems in A High Rise Building.Document24 pagesStructural Systems in A High Rise Building.Tanya YadavNo ratings yet

- Voulume III - Technical AnnexDocument140 pagesVoulume III - Technical AnnexyeyenNo ratings yet

- Modified UFMDocument306 pagesModified UFMjay4111No ratings yet

- Design of High-Density Polyethylene (HDPE) Manholes For Subsurface ApplicationsDocument12 pagesDesign of High-Density Polyethylene (HDPE) Manholes For Subsurface Applicationsjabh311No ratings yet

- TP8 EN Manual 20180822Document4 pagesTP8 EN Manual 20180822Nico SkyNo ratings yet

- Labour Cost Estimate and Material Estimate For 2bed and 1bedroom Flat 6flat Building Quantity Rates Amount Foundation To DPC MaterialDocument11 pagesLabour Cost Estimate and Material Estimate For 2bed and 1bedroom Flat 6flat Building Quantity Rates Amount Foundation To DPC MaterialAmadi HenryNo ratings yet

- Lateral Pile Capacity Caculation Using Broms's Method (Free Head Type)Document4 pagesLateral Pile Capacity Caculation Using Broms's Method (Free Head Type)Sanjeewani Disna JayamaliNo ratings yet

- Civil Engineering MCQ'S: Ans. (C) Ans. (D)Document4 pagesCivil Engineering MCQ'S: Ans. (C) Ans. (D)NISHIKANTA MONDALNo ratings yet

- Geogrid Reinforced Earth Versus Piles FoDocument225 pagesGeogrid Reinforced Earth Versus Piles FoSaswati DattaNo ratings yet

- Domestic Roof Water Harvesting - Technical Guidance - v4.2Document18 pagesDomestic Roof Water Harvesting - Technical Guidance - v4.2Carlos PratsNo ratings yet

- Offshore Structures Under Earthquake Loads: 22.1 GeneralDocument12 pagesOffshore Structures Under Earthquake Loads: 22.1 GeneralIrfan KhanNo ratings yet

- DRSLPII W10 Bidding Forms - 20-MayDocument124 pagesDRSLPII W10 Bidding Forms - 20-MayEng Abdikarim WalhadNo ratings yet

- Discovery School at Khodiyar 8.0 M 1 BoreholeDocument16 pagesDiscovery School at Khodiyar 8.0 M 1 BoreholeShreeji LabNo ratings yet

- EjerciciosDocument14 pagesEjerciciosmmontesmNo ratings yet

Ldpe

Ldpe

Uploaded by

Ardy WiyogoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ldpe

Ldpe

Uploaded by

Ardy WiyogoCopyright:

Available Formats

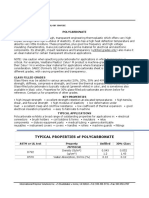

Technical Data Sheet

Low Density Polyethylene

(LDPE)

This extruded material offers good corrosion resistance and low moisture permeability. It can be used in applications where

corrosion resistance is important, but stiffness, high temperature, and structural strength are not. A highly flexible product,

LDPE is used widely in orthopedic products, or where mobility without stress fatigue is desired. LDPE is also frequently used in

consumer packaging, bags, bottles, and liners.

TYPICAL PROPERTIES of POLYETHYLENE

ASTM or UL

Property LDPE HDPE UHMW Benefits

test

PHYSICAL Lightweight

Density (lb/in³) 0.033 0.035 0.034 Formable

D792

(g/cm³) 0.92 0.96 0.93 Impact Resistant

D570 Water Absorption, 24 hrs (%) <0.01 <0.01 <0.01 Good electrical properties

MECHANICAL Easily cleaned

D638 Tensile Strength (psi) at 72°F 1,400 4,600 5,800 Easily Fabricated

D638 Tensile Strength (psi) at 150°F 400 400 400

D638 Tensile Modulus (psi) 57,000 200,000 80,000

D638 Tensile Elongation at Break (%) 100 400 300

D790 Flexural Strength at Yield (psi) 1,500 4,600 3,500

Applications

D790 Flexural Modulus (psi) 29,000 174,000 88,000

D695 Compressive Strength (psi) 1,400 4,600 3,000

Chemical resistant tank

D695 Compressive Modulus (psi) 54,000 100,000 80,000

and containers

D732 Shear Strength (psi) - - 3,000 Food storage containers

D785 Hardness, Shore D D45 D69 D62-D66 Laboratory equipment

D256 IZOD Notched Impact (ft-lb/in) No Break 1.3 No Break Corrosion resistant work

THERMAL surfaces

Coefficient of Linear Thermal Expansion Vacuum formed end caps

D696 -5 - 6 11

(x 10 in./in./°F) and tops

Heat Deflection Temp (°F / °C) Moisture barrier

D648 at 66 psi 120 / 48 170 / 76 203 / 95

at 264 psi 116 / 46 176 / 80 180 / 82

244 / 260 / 275 /

D3418 Approx. Melting Temperature (°F / °C)

118 125 136

- Max Operating Temp (°F / °C) 160 / 71 180 / 82 180 / 82

Thermal Conductivity Shapes Available

C177 (BTU-in/ft²-hr-°F) - - 2.84

-4

(x 10 cal/cm-sec-°C) - - 10.0

UL94 Flammability Rating HB HB< HB

ELECTRICAL

Dielectric Strength (V/mil) short time, 1/8"

D149 460-700 450-500 2300

thick

2.25- 2.30- 2.30-

D150 Dielectric Constant at 1 MHz

2.30 2.35 2.35

D150 Dissipation Factor at 1 kHz 0.0002 0.0002 0.0005

Surface Resistivity (ohm/square) at 50% 15 15 15

D257 > 10 > 10 > 10

RH

D495 Arc Resistance (sec) 135-160 200-250 250-350

NOTE: The information contained herein are typical values intended for reference and comparison purposes only. They should NOT be

used as a basis for design specifications or quality control. Contact us for manufacturers’ complete material property datasheets.

All values at 73°F (23°C) unless otherwise noted.

You might also like

- Road Construction Production Output RatesDocument23 pagesRoad Construction Production Output Rateslimbadz100% (14)

- Ale Part 2 Answer KeyDocument27 pagesAle Part 2 Answer KeyTimothy Ryan Wang100% (2)

- Trirex 3020HF: Polycarbonate ResinDocument5 pagesTrirex 3020HF: Polycarbonate ResinAlbert FortunatoNo ratings yet

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneDocument1 pageTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamNo ratings yet

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Document1 pageTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PNo ratings yet

- Polye PDocument2 pagesPolye PFranco Gabriel MercadoNo ratings yet

- PolystyreneDocument1 pagePolystyrenejoshkajasmineNo ratings yet

- Polypropylene PDFDocument2 pagesPolypropylene PDFSabuj SaikiaNo ratings yet

- CastacrylicDocument1 pageCastacrylicuyenNo ratings yet

- Technical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekDocument2 pagesTechnical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekSyed MoinNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- Teflon (PTFE) Data SheetDocument1 pageTeflon (PTFE) Data SheetMarisa Yuni Nur AzizaNo ratings yet

- Technical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Document1 pageTechnical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Dharmendra DubeyNo ratings yet

- Data Sheet PPSUDocument2 pagesData Sheet PPSUluuiissNo ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- Technical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Document1 pageTechnical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Paulo RicardoNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- Acrylic Not Recc For ChlorinatedDocument2 pagesAcrylic Not Recc For ChlorinatedoktavNo ratings yet

- Technical Data Sheet PVC: (Polyvinyl Chloride)Document1 pageTechnical Data Sheet PVC: (Polyvinyl Chloride)Adnan KhanNo ratings yet

- Typical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesDocument2 pagesTypical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesAdnan KhanNo ratings yet

- Properties of High Density Polyethylene (HDPE) : Astm or UL Test Property HdpeDocument1 pageProperties of High Density Polyethylene (HDPE) : Astm or UL Test Property HdpedangdinhthyNo ratings yet

- VERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good SealabilityDocument1 pageVERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good Sealabilityseeralan_1986No ratings yet

- Technical Data Sheet G-10: General DescriptionDocument1 pageTechnical Data Sheet G-10: General Descriptionbahtiar affandyNo ratings yet

- Static Dissipative Polyetherimide (Pei) / Static Dissipative UltemDocument1 pageStatic Dissipative Polyetherimide (Pei) / Static Dissipative UltemVC KannanNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- Delrin SpecsDocument1 pageDelrin SpecsabhijitNo ratings yet

- Delrin SpecsDocument1 pageDelrin SpecsGrimmo1979No ratings yet

- Delrin - Mechanical PropertyDocument1 pageDelrin - Mechanical PropertyGovarthanan GovaNo ratings yet

- Teflon PTFE - PSG - Mechanical PropertyDocument1 pageTeflon PTFE - PSG - Mechanical PropertyGovarthanan GovaNo ratings yet

- Anti-Static Ultra-High Molecular Weight Polyethylene/Anti-Static Uhmw PeDocument1 pageAnti-Static Ultra-High Molecular Weight Polyethylene/Anti-Static Uhmw PeVC KannanNo ratings yet

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Document1 pageTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngNo ratings yet

- Acetal: Acetal Grades ACETAL COPOLYMER (Unfilled)Document1 pageAcetal: Acetal Grades ACETAL COPOLYMER (Unfilled)Anonymous UcmNTu6rNo ratings yet

- Delrin PDFDocument2 pagesDelrin PDFA. Kumar RaiNo ratings yet

- Delrin Mat PDFDocument2 pagesDelrin Mat PDFyajneshwaradixitNo ratings yet

- Delrin MaterialDocument2 pagesDelrin MaterialyajneshwaradixitNo ratings yet

- Technical Data Sheet Nylon: (Polyamide)Document3 pagesTechnical Data Sheet Nylon: (Polyamide)Dharmendra DubeyNo ratings yet

- Delrin 150Document1 pageDelrin 150Sardar. Vikramjit Singh RandhawaNo ratings yet

- Teflon® FEP (Fluorinated Ethylene Propylene)Document1 pageTeflon® FEP (Fluorinated Ethylene Propylene)mohammed goudaNo ratings yet

- Ptfe PDFDocument1 pagePtfe PDFXiwen CloudNo ratings yet

- FS DatasheetDocument1 pageFS Datasheetazeem bilalNo ratings yet

- Technical Information: (BR) (WR-2) (Special F)Document1 pageTechnical Information: (BR) (WR-2) (Special F)johnNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- PSG Epoxy Glass PhenolicsDocument1 pagePSG Epoxy Glass PhenolicsmadhunnadigNo ratings yet

- RX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourDocument1 pageRX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourEetu SatosalmiNo ratings yet

- MC 907 Natural NylonDocument2 pagesMC 907 Natural NylonJunior TaHuaNo ratings yet

- Scotch Heavy Duty Mining Tape 31: Data Sheet June 2013Document2 pagesScotch Heavy Duty Mining Tape 31: Data Sheet June 2013Kishan MohtaNo ratings yet

- PP TD20 Lotte JHC-372Document1 pagePP TD20 Lotte JHC-372Herman SujarwantoNo ratings yet

- NorylDocument1 pageNorylAnonymous P8Bt46mk5INo ratings yet

- Ptfe Data SheetDocument1 pagePtfe Data SheetEko PrastyoNo ratings yet

- TECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETDocument2 pagesTECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETFeby Shyntia AfirantiNo ratings yet

- 7-1882 TDS Blue Liquid Epoxy-UrethaneDocument2 pages7-1882 TDS Blue Liquid Epoxy-UrethanePedro Santo Orsini RevengaNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Technical Data Sheet Linen PhenolicDocument1 pageTechnical Data Sheet Linen PhenolicKissa DolautaNo ratings yet

- Technical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Document1 pageTechnical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Nam NguyenNo ratings yet

- Material Data Sheet: HDPE NaturalDocument2 pagesMaterial Data Sheet: HDPE NaturalSyed MoinNo ratings yet

- DP03HDocument1 pageDP03HDiadam SharmaNo ratings yet

- Technical Data Sheet Ultem (Pei) : (Polyetherimide)Document3 pagesTechnical Data Sheet Ultem (Pei) : (Polyetherimide)Dynamic SaravananNo ratings yet

- ST5101-Advance Concrete StructuresDocument16 pagesST5101-Advance Concrete Structurescmurugan50% (2)

- Conex CompressionDocument32 pagesConex Compressionh2odavid100% (1)

- Analysis Methods For Leakage Rates in Pressurized ComponentsDocument20 pagesAnalysis Methods For Leakage Rates in Pressurized ComponentsGeorgiosLupusMogueidaNo ratings yet

- Experimental Study of Water Wetting in Oil Water Two Phase Flow - JCaiDocument11 pagesExperimental Study of Water Wetting in Oil Water Two Phase Flow - JCaiSyafiqah IsmailNo ratings yet

- Commercial Specification Sheet Cordlash 105 & HDB 10 N - 6310000 6310900 7400300Document2 pagesCommercial Specification Sheet Cordlash 105 & HDB 10 N - 6310000 6310900 7400300Juanma SalamancaNo ratings yet

- 135 - Guidelines For Classification of Well Control Incidents and Well Integrity Incidents - Rev. 2Document21 pages135 - Guidelines For Classification of Well Control Incidents and Well Integrity Incidents - Rev. 2Sean CurnowNo ratings yet

- Parametric Study of Cable Stayed Bridge Using Different Pylon ConfigurationDocument7 pagesParametric Study of Cable Stayed Bridge Using Different Pylon ConfigurationTanjil MominNo ratings yet

- Laminar or Viscous Flow 6Document26 pagesLaminar or Viscous Flow 6Sunil BagadeNo ratings yet

- Sanitary EngineeringDocument44 pagesSanitary Engineeringمحمد الددحNo ratings yet

- ACI 341-C Retrofit Presentation - Part 1Document65 pagesACI 341-C Retrofit Presentation - Part 1chithirai10100% (2)

- CIVIL ENGINEERING prEN 1995-2 2004 (Final Draft) - Design of Timber Structures - Bridges PDFDocument29 pagesCIVIL ENGINEERING prEN 1995-2 2004 (Final Draft) - Design of Timber Structures - Bridges PDFcaballerolangNo ratings yet

- Acceptance Checklist: Elevator Machine Room And/or Control SpaceDocument4 pagesAcceptance Checklist: Elevator Machine Room And/or Control SpaceImran KhanNo ratings yet

- Designed With Dlubal Software: Crossrail Station in Canary Wharf LondonDocument1 pageDesigned With Dlubal Software: Crossrail Station in Canary Wharf Londonweb76280No ratings yet

- Flexure Beam Analysis and Design - (Printed)Document18 pagesFlexure Beam Analysis and Design - (Printed)saleh34534rf34No ratings yet

- Structural Systems in A High Rise Building.Document24 pagesStructural Systems in A High Rise Building.Tanya YadavNo ratings yet

- Voulume III - Technical AnnexDocument140 pagesVoulume III - Technical AnnexyeyenNo ratings yet

- Modified UFMDocument306 pagesModified UFMjay4111No ratings yet

- Design of High-Density Polyethylene (HDPE) Manholes For Subsurface ApplicationsDocument12 pagesDesign of High-Density Polyethylene (HDPE) Manholes For Subsurface Applicationsjabh311No ratings yet

- TP8 EN Manual 20180822Document4 pagesTP8 EN Manual 20180822Nico SkyNo ratings yet

- Labour Cost Estimate and Material Estimate For 2bed and 1bedroom Flat 6flat Building Quantity Rates Amount Foundation To DPC MaterialDocument11 pagesLabour Cost Estimate and Material Estimate For 2bed and 1bedroom Flat 6flat Building Quantity Rates Amount Foundation To DPC MaterialAmadi HenryNo ratings yet

- Lateral Pile Capacity Caculation Using Broms's Method (Free Head Type)Document4 pagesLateral Pile Capacity Caculation Using Broms's Method (Free Head Type)Sanjeewani Disna JayamaliNo ratings yet

- Civil Engineering MCQ'S: Ans. (C) Ans. (D)Document4 pagesCivil Engineering MCQ'S: Ans. (C) Ans. (D)NISHIKANTA MONDALNo ratings yet

- Geogrid Reinforced Earth Versus Piles FoDocument225 pagesGeogrid Reinforced Earth Versus Piles FoSaswati DattaNo ratings yet

- Domestic Roof Water Harvesting - Technical Guidance - v4.2Document18 pagesDomestic Roof Water Harvesting - Technical Guidance - v4.2Carlos PratsNo ratings yet

- Offshore Structures Under Earthquake Loads: 22.1 GeneralDocument12 pagesOffshore Structures Under Earthquake Loads: 22.1 GeneralIrfan KhanNo ratings yet

- DRSLPII W10 Bidding Forms - 20-MayDocument124 pagesDRSLPII W10 Bidding Forms - 20-MayEng Abdikarim WalhadNo ratings yet

- Discovery School at Khodiyar 8.0 M 1 BoreholeDocument16 pagesDiscovery School at Khodiyar 8.0 M 1 BoreholeShreeji LabNo ratings yet

- EjerciciosDocument14 pagesEjerciciosmmontesmNo ratings yet