Professional Documents

Culture Documents

MCE 538 en

MCE 538 en

Uploaded by

احمدالاغبري0 ratings0% found this document useful (0 votes)

55 views1 pageThis 3-sentence summary provides the essential information about the MCE 538 Metal Cutting Theory course:

The course is an 8-ECTS elective on metal cutting theory taught in English that introduces topics like cutting mechanics, forces, friction, tool materials, life, and wear through lectures, recitation, and assignments, with students assessed through a midterm, final exam, and expected to understand cutting phenomena theoretically and experimentally.

Original Description:

metal cutting operations

Original Title

MCE 538 En

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis 3-sentence summary provides the essential information about the MCE 538 Metal Cutting Theory course:

The course is an 8-ECTS elective on metal cutting theory taught in English that introduces topics like cutting mechanics, forces, friction, tool materials, life, and wear through lectures, recitation, and assignments, with students assessed through a midterm, final exam, and expected to understand cutting phenomena theoretically and experimentally.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

55 views1 pageMCE 538 en

MCE 538 en

Uploaded by

احمدالاغبريThis 3-sentence summary provides the essential information about the MCE 538 Metal Cutting Theory course:

The course is an 8-ECTS elective on metal cutting theory taught in English that introduces topics like cutting mechanics, forces, friction, tool materials, life, and wear through lectures, recitation, and assignments, with students assessed through a midterm, final exam, and expected to understand cutting phenomena theoretically and experimentally.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

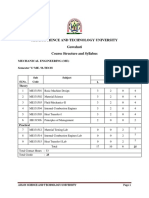

Course Code and Name: MCE 538 Department: Mechanical Engineering Semester

Metal Cutting Theory Dep. Fall/Spring

Credit

Methods of Education

(ECTS)

Recitation Project/Field

Lecture Laboratory Homework Other Total

(Etude) Study 8

42 88 60 50 240

Language English

Compulsory/Elective Elective

Prerequisites None

Introduction to metal cutting, machine tools and machining operations – turning, drilling, milling

and abrasive machining, cutting mechanics, cutting forces, friction and temperature distribution in

Course contents

metal cutting, cutting tool materials, tool life and tool wear, machinability, economics of metal

cutting operations, chip control, machine tool vibrations, surface integrity, cutting fluids.

The main objectives of this course are to present advanced information about metal cutting theory

Course objectives

to students and to enlarge the students’ knowledge in metal cutting theory.

At the end of the course,

Learning outcomes - Students shall know the cutting phenomenon theoretically and experimentally,

and competences - Students shall learn the factors affecting the cutting process,

- Students shall know the components of cutting process and their properties.

Textbook:

1. Grzesik W, Advanced Machining Processes of Metallic Materials, Theory, Modelling and

Applications, 2008, Elsevier.

2. Shaw MC, Metal Cutting Principles, 4th Edition, Oxford University Press, Walton Street,

Textbook and/or Oxford, New York, 1991.

references References:

1. Boothroyd G, Knight WA, Fundamentals of Machining and Machine Tools, CRC Press, Boca

Raton, 2006.

2. Stephenson DA, Agapiou JS, Metal Cutting Theory and Practice, Marcel Dekker, New York,

1997.

If any, mark as (x) Percentage (%)

Midterm exams x 40

Quizzes

Homework

Assessment criteria Projects

Term paper

Laboratory work

Other

Final exam x 60

Week Subject

Introduction to metal cutting, machine tools and machining operations-turning, drilling

1

and milling, abrasive machining

2 Cutting mechanics

3 Cutting forces and their measurement

4 Friction in metal cutting

5 Temperature distribution in metal cutting

6 Cutting tool materials

Course plan

7 Tool life

8 Tool wear

9 Machinability

10 Economics of metal cutting operations

11 Chip control

12 Machine tool vibrations

13 Surface integrity

14 Cutting fluids

Instructor Prof. Dr. Adem ÇİÇEK

You might also like

- The Glass Roses Guided AnalysisDocument7 pagesThe Glass Roses Guided Analysisapi-2631384290% (1)

- VICE - Editorial & Photo GuidelinesDocument5 pagesVICE - Editorial & Photo GuidelinesNadgob NasesemNo ratings yet

- Metal Cutting and Tool DesignDocument3 pagesMetal Cutting and Tool DesignHemanth YadaNo ratings yet

- IAGC OGP HSE Geophysical Ops Schedules PlansDocument84 pagesIAGC OGP HSE Geophysical Ops Schedules PlanselectroscribdNo ratings yet

- Course Outine (Production Engineering I)Document2 pagesCourse Outine (Production Engineering I)GetahunNo ratings yet

- Gujarat Technological University: Metal Cutting & Advanced Manufacturing ProcessesDocument3 pagesGujarat Technological University: Metal Cutting & Advanced Manufacturing ProcessesAoneNo ratings yet

- RTM Nagpur University Mechanical Engineering Machining Processes Syllabus (Theory) Course code-BEME401TDocument27 pagesRTM Nagpur University Mechanical Engineering Machining Processes Syllabus (Theory) Course code-BEME401TxaloliNo ratings yet

- 01 C18 - ME2302 Introduction To Materials Science and Manufacturing EngineeringDocument2 pages01 C18 - ME2302 Introduction To Materials Science and Manufacturing EngineeringVidura PrasadNo ratings yet

- Manufacturing Processes UTA026Document9 pagesManufacturing Processes UTA026Tania CENo ratings yet

- University of Mauritius: Faculty of Engineering Module Specification Sheet (MSS)Document7 pagesUniversity of Mauritius: Faculty of Engineering Module Specification Sheet (MSS)Cheekhoory PraveshNo ratings yet

- r05010302 Engineering MechanicsDocument39 pagesr05010302 Engineering Mechanicsdassault megecNo ratings yet

- RTM Nagpur University Syllabus (Theory)Document5 pagesRTM Nagpur University Syllabus (Theory)Milind KshirsagarNo ratings yet

- متطلبات تخصص الصيانة الكهروميكانيكة العامةDocument68 pagesمتطلبات تخصص الصيانة الكهروميكانيكة العامةibraheemNo ratings yet

- Me785 - Machining and Forming - Lab ManualDocument28 pagesMe785 - Machining and Forming - Lab Manualemily clarkeNo ratings yet

- MEng3181-Manufacturing Engineering I-Course Outline - 103309Document2 pagesMEng3181-Manufacturing Engineering I-Course Outline - 103309Yonael MezmureNo ratings yet

- Metal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyDocument4 pagesMetal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyFikadu EshetuNo ratings yet

- PMC ModuleDocument91 pagesPMC ModuleAbdi ZerihunNo ratings yet

- Applied MaterialsDocument3 pagesApplied Materialsshashank raj kumarNo ratings yet

- Vishwakarma Institute of Technology: Issue 05: Rev No. 0: Dt. 13/03/15 Course Plan FormatDocument3 pagesVishwakarma Institute of Technology: Issue 05: Rev No. 0: Dt. 13/03/15 Course Plan FormatKunalNo ratings yet

- Course Outline MFG IIDocument2 pagesCourse Outline MFG IIAbrham ChanieNo ratings yet

- Manufacturing ProcessDocument3 pagesManufacturing ProcessSatyam PatelNo ratings yet

- Manufacturing ProcessDocument3 pagesManufacturing ProcessReham EltuhamyNo ratings yet

- Tool EngineeringDocument3 pagesTool EngineeringAmirDeshmukhNo ratings yet

- Cc107-N-Engineering PhysicsDocument5 pagesCc107-N-Engineering PhysicsAnkur RanpariyaNo ratings yet

- Manufacturing Tech SyllDocument4 pagesManufacturing Tech SyllJagjit SinghNo ratings yet

- Term Paper 1 Fundamental of Material & Failure: Course ObjectiveDocument2 pagesTerm Paper 1 Fundamental of Material & Failure: Course ObjectivemilanmottaNo ratings yet

- Course File FormatDocument18 pagesCourse File FormatUzair BukhariNo ratings yet

- MME310: Manufacturing Technology-II: Department of Mechanical Mechatronics Engineering The LNM IIT, JaipurDocument2 pagesMME310: Manufacturing Technology-II: Department of Mechanical Mechatronics Engineering The LNM IIT, Jaipurraghav dhamaniNo ratings yet

- We 7102Document3 pagesWe 7102linsonNo ratings yet

- PH.D Programme: Teaching Schedule & Study SchemeDocument3 pagesPH.D Programme: Teaching Schedule & Study SchemeGursharanSinghGandhiNo ratings yet

- First Lecturer PTDocument8 pagesFirst Lecturer PTnashk18No ratings yet

- 08 - Chapter 3Document6 pages08 - Chapter 3AashishNo ratings yet

- ME 503-N Manufacturing TechnologyDocument4 pagesME 503-N Manufacturing Technologyhrana287No ratings yet

- MA2004 Engineering Materials and Manufacturing Processes 23082021Document7 pagesMA2004 Engineering Materials and Manufacturing Processes 23082021Aloysius TobiasNo ratings yet

- Thermal Engg. R.K RajputDocument14 pagesThermal Engg. R.K RajputManash SharmaNo ratings yet

- RMD2508Document5 pagesRMD2508ismail douidiNo ratings yet

- MPR-1 2Document7 pagesMPR-1 2pradipd4271No ratings yet

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909Document3 pagesGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909ShahinNo ratings yet

- Manufacturing Process 4 PDFDocument2 pagesManufacturing Process 4 PDFVijayalaxmi MudhigondaNo ratings yet

- Met&mat - Me (Welding TechnologyDocument34 pagesMet&mat - Me (Welding TechnologyDivas AgarwalNo ratings yet

- Lesson Plan CPE601Document5 pagesLesson Plan CPE601MOHD IZWAN FARHAN MUHAMED NIZAMNo ratings yet

- Un Conventional Machining Process NotesDocument174 pagesUn Conventional Machining Process Notesban murthy0% (1)

- Bmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lDocument3 pagesBmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lKrijayNo ratings yet

- Subject Production Techology SyllabusDocument3 pagesSubject Production Techology SyllabusbmdbmdbmdNo ratings yet

- Academic Plan For Vth-Semester Mae (2011-12) : Subject: Microprocessor and Applications Subject Code: ETME-301Document5 pagesAcademic Plan For Vth-Semester Mae (2011-12) : Subject: Microprocessor and Applications Subject Code: ETME-301Jayesh KatariaNo ratings yet

- Gujarat Technological University Mechanical (Cad/Cam) (08) : SUBJECT CODE: 2710807Document2 pagesGujarat Technological University Mechanical (Cad/Cam) (08) : SUBJECT CODE: 2710807ganeshNo ratings yet

- Syllabus NON-TRADITIONAL MACHININGDocument1 pageSyllabus NON-TRADITIONAL MACHININGranjithkrajNo ratings yet

- MCMT SyllabusDocument3 pagesMCMT SyllabusshahazadNo ratings yet

- Course Outline For Metal Forming, Welding and Casting Laboratory PracticeDocument1 pageCourse Outline For Metal Forming, Welding and Casting Laboratory Practicebirhanubic23No ratings yet

- Mn7203 Material Testing and Characterization L T P CDocument5 pagesMn7203 Material Testing and Characterization L T P CAnonymous p8bHAAxNo ratings yet

- 3140204Document3 pages3140204vikas raiNo ratings yet

- Structure Final MechanicalDocument26 pagesStructure Final MechanicalSalokhaRaj RedevelopmentNo ratings yet

- B Tech Mechanical Engineering 6thDocument17 pagesB Tech Mechanical Engineering 6thprakashkumarsenNo ratings yet

- Mecsyll 49 51Document3 pagesMecsyll 49 51Prakhyath MNo ratings yet

- Machine Shop - SyllabusDocument4 pagesMachine Shop - SyllabusvirupakshaNo ratings yet

- Gujarat Technological University Mechanical (Machine Design)Document3 pagesGujarat Technological University Mechanical (Machine Design)DharmeshPatelNo ratings yet

- Basics of Metal Cutting 1Document70 pagesBasics of Metal Cutting 1Saideep GhimireNo ratings yet

- Tool Life Estimation Model Based On Simulated Ank Wear During High Speed Hard TurningDocument15 pagesTool Life Estimation Model Based On Simulated Ank Wear During High Speed Hard TurningHassen KHLIFINo ratings yet

- 3131904Document4 pages3131904janakNo ratings yet

- Me366 Advanced Metal Joining TechnologyDocument3 pagesMe366 Advanced Metal Joining TechnologyJoby JosephNo ratings yet

- IntroductionDocument38 pagesIntroductionMohamedNo ratings yet

- First Periodical Test in Mathematics 2 Table of SpecificationDocument4 pagesFirst Periodical Test in Mathematics 2 Table of SpecificationAnna Mae GogoNo ratings yet

- Audit Program For Data CentreDocument7 pagesAudit Program For Data CentreTest KingNo ratings yet

- IndividuationDocument8 pagesIndividuationJennifer AnastasiNo ratings yet

- Oracle DB - OLTP New Sizing Questionnaire 11.1Document20 pagesOracle DB - OLTP New Sizing Questionnaire 11.1Pranoti DeshmukhNo ratings yet

- Adaptive: Control For Machine ToolsDocument27 pagesAdaptive: Control For Machine ToolssolteanNo ratings yet

- LPIC 3 ProgramDocument8 pagesLPIC 3 ProgramLeon HomarNo ratings yet

- Lucía Velasco Lebredo & Mercurio Verde Hopson 4ºB: Ultimo Trabajo Tic 1º TrimestreDocument21 pagesLucía Velasco Lebredo & Mercurio Verde Hopson 4ºB: Ultimo Trabajo Tic 1º TrimestreMercu 2002No ratings yet

- How-To Build A Little Autonomous Robot With PIC 18F4520 PDFDocument22 pagesHow-To Build A Little Autonomous Robot With PIC 18F4520 PDFanselmoNo ratings yet

- Wide Eye SpanDocument2 pagesWide Eye SpanKirk George ShepherdNo ratings yet

- 028 Ece 3rdsemDocument217 pages028 Ece 3rdsemKailash BishtNo ratings yet

- Mokveld PositionerDocument2 pagesMokveld PositionerMohd HasbullahNo ratings yet

- Daftar PustakaDocument3 pagesDaftar PustakaIsna DewiyantiNo ratings yet

- BasicDataStructures StudyGuideDocument51 pagesBasicDataStructures StudyGuideRichard McdanielNo ratings yet

- Configuring Workflow Mailer Using Postfix and Dovecot in EBS R12Document13 pagesConfiguring Workflow Mailer Using Postfix and Dovecot in EBS R12Mohamed IbrahimNo ratings yet

- The Socio-Economic Impact of The Airport Upon The CommunityDocument166 pagesThe Socio-Economic Impact of The Airport Upon The CommunitySujin krishnaNo ratings yet

- Time of Setting of Hydraulic Cement by Vicat NeedlDocument3 pagesTime of Setting of Hydraulic Cement by Vicat NeedlGLYCE JOIE PLAZANo ratings yet

- Sat Manual 04jun04Document429 pagesSat Manual 04jun04anon-504116100% (5)

- Physics Notes PDF For Class 9Document3 pagesPhysics Notes PDF For Class 9Mithilesh Kr Prem100% (1)

- Baron CV F2016Document14 pagesBaron CV F2016ImranNo ratings yet

- Barree2002 PDFDocument12 pagesBarree2002 PDFTeam FornaxNo ratings yet

- Track Drainage - NSW - Very GoodDocument83 pagesTrack Drainage - NSW - Very GoodFebrian QodriNo ratings yet

- ParcelFabricMigration HCAD2016Document36 pagesParcelFabricMigration HCAD2016O'Connor AssociateNo ratings yet

- Kartotrak v1.0 Features: 1. Gis-B Ased Interf AceDocument4 pagesKartotrak v1.0 Features: 1. Gis-B Ased Interf AceOurs2fNo ratings yet

- Post-Disturbance Transient Stability Status Prediction Using Synchrophasor MeasurementsDocument9 pagesPost-Disturbance Transient Stability Status Prediction Using Synchrophasor MeasurementsRenzoChavezJuradoNo ratings yet

- Final Inglés Técnico Nivel I - UTN: PreguntasDocument3 pagesFinal Inglés Técnico Nivel I - UTN: PreguntasNahuel De BrasiNo ratings yet

- The ARL Black Box Flight RecorderDocument37 pagesThe ARL Black Box Flight RecorderramchanderNo ratings yet

- SIMULIA Abaqus 6.12-1 - Product Enhancement Overview - Key FeaturesDocument4 pagesSIMULIA Abaqus 6.12-1 - Product Enhancement Overview - Key FeaturesHamed AzarNo ratings yet