Professional Documents

Culture Documents

90 79135 006 PDF

90 79135 006 PDF

Uploaded by

Wanda MarthaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

90 79135 006 PDF

90 79135 006 PDF

Uploaded by

Wanda MarthaCopyright:

Available Formats

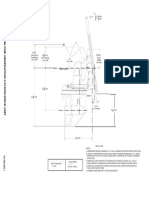

8 7 6 5 4 3 2 1

LET REVISIONS ZONE BY DATE CA

A DRAWING RELEASE - KCG 04-AUG-2005 -

B REDRAWN IN PRO-E & UPDATED TO CURRENT STANDARDS - VN 22-JAN-2008 30279-07

H H

G G

NOTE:

IF TRANSOM ASSY HAS STUD AT THIS

LOCATION - DRILL TWO 15 mm (9/16 in.)

HOLES THRU AT POSITION MARKED (B)-

HOLES TO BE SQUARE WITH TRANSOM.

IF NOT - DO NOT DRILL THESE TWO

HOLES.

OUTSIDE 60° 60°

TRANSOM

44 mm(1.75 in.) DIA HOLE SAW SURFACE

6 mm(1/4 IN.) DIA.

DRILL IN 2 PLACES

FOR HOLE SAW GUIDE

(B) (B)

F TRANSOM PARALLELISM SPECIFICATIONS

Inner Surface - Flat within 3 mm (1/8 in.)

F

Outer Surface - Flat within 2 mm (1/16 in.)

b

a a

a. Transom plate coverage - 203 mm (8 in.) from center

b. 533 mm (21 in.) from top

"X" DIMENSION FOR LOCATING TEMPLATE

E E

IMPORTANT: The following instructions will provide a sterndrive unit mounting

location that is suitable for most boats. Best mounting location for a particular boat,

however, can be determined only by testing.

THE AREA WITHIN THIS

PERIMETER TO BE FLAT 1) BELOW 25 M.P.H. (40.24 Km/h): Subtract 13 mm (1/2 in.) from "X" Dimension Shown.

WITHIN 2 mm (1/16 IN.) ON

(A)

OUTSIDE OF TRANSOM. 2) HEAVY DUTY APPLICATIONS: Subtract 25 mm (1 in.) from "X" Dimension Shown.

(A) 3) ABOVE 25 M.P.H. (40.24 Km/h): Use "X" Dimension as shown in table below.

4) ABOVE 50 M.P.H. (80.47 Km/h): "X" Dimension can be increased to improve

performance in some applications, but pulling power (for skiing) will decrease.

During testing, "X" Dimension should be increased 13 mm (1/2 in.) at a time

until desired performance is achieved but in no case should it ever be

increased by more than:

ALPHA ONE: 64 mm (2-1/2 in.) maximum.

SAW CUT OPENING

SQUARE (90°) WITH

BRAVO ONE/THREE: 76 mm (3 in.) maximum.

TRANSOM FACE.

BRAVO TWO: 25 mm (1 in.) maximum.

In ALL sterndrive applicatiohns, extreme care should be taken when raising drive unit

to ensure that water supply does not become aerated. Use clean water inlet hose to

monitor incoming water and monitor engine temperature gauge to ensure engine does

D not overheat.

D

IMPORTANT: DAMAGE TO MERCRUISER PRODUCTS CAUSED BY TOO HIGH

OF AN INSTALLED HEIGHT WILL NOT BE COVERED BY MERCRUISER WARRANTY.

TRANSOM ALPHA & BRAVO: THIS LOCATION PLACES DRIVE UNIT

ANGLE ANTI-VENTILATION PLATE EVEN WITH BOTTOM OF BOAT.

10° 354 mm (13.94 in.)

11° 356 mm (14.00 in.)

12° 357 mm (14.06 in.)

13° 359 mm (14.13 in.)

BRAVO AND ALPHA MODELS 14° 360 mm (14.19 in.)

15mm (9/16 in.) DIA DRILL THRU 6 HOLES

15° 362 mm (14.25 in.)

MARKED (A)- HOLES TO BE

SQUARE (90°) WITH TRANSOM FACE 16° 364 mm (14.31 in.)

MERCRUISER ALPHA & BRAVO

(A) (A) DUAL INSTALLATION ON DEEP VEE BOATS

REFER TO THE INSTALLATION MANUALS FOR RECOMMENDED

MINIMUM CENTER DISTANCE.

MINIMUM CENTER

DISTANCE

C B C

VERTICAL

CENTERLINE

"X"

"X"

(A) (A)

B

MEASURE "X" ALONG

SECTION B-B

SLANT OF TRANSOM

0 KPC'S PER MERC SPEC M-251-G AS NOTED BY OR .

B

90-79135-006 MATERIAL

BOND PAPER

PER MERC SPEC: B

TEMPLATE - TRANSOM

ALPHA, BRAVO FINISH

N/A

REV. B, 22-JAN-2008 PER MERC SPEC:

REF SPECS

M-251-G

THE INFORMATION CONTAINED IN THIS DOCUMENT IS TO BE TREATED

AS TRADE SECRET AND CONFIDENTIAL TO MERCURY

UNLESS OTHERWISE SPECIFIED

TOLERANCE DIMENSIONS ARE AFTER PLATING

BREAK ALL SHARP EDGES

THIRD ANGLE PROJ 2 PL DEC ±

CHAM. TAPPED HOLES 90° X THD DIA

SCALE: 1:1 3 PL DEC ± MACHINED SURFACES

125

DO NOT SCALE ANGLES ± THREAD LENGTH = FULL THREADS

MANUF CAST MATL ENG

MANUF MACH / ASSY PURCH

A A

QC PRODUCT LINE TITLE

ALPHA, BRAVO

APPROVED DATE

TEMPLATE - TRANSOM

KCG 04-AUG-2005 PART NUMBER SHEETS

CHECKED DESIGNED

KCG KCG 90-79135-006 1 OF1

0 1 2 3 4

7 6 5 4 3 2 1 FORMAT ESIZE

You might also like

- Risk Assessment For Testing & Commissioning of Electrical InstallationDocument14 pagesRisk Assessment For Testing & Commissioning of Electrical InstallationAnandu Ashokan100% (18)

- Polaris Ranger 500 2017Document574 pagesPolaris Ranger 500 2017trutechazNo ratings yet

- Preliminary: Engine and Control SystemsDocument24 pagesPreliminary: Engine and Control SystemsAnderson VulczakNo ratings yet

- 31 GM SBC 2001Document1,096 pages31 GM SBC 2001The Boat DocturNo ratings yet

- MFS 75 115 Tohatsu ManualDocument89 pagesMFS 75 115 Tohatsu Manualabdulateefnsr100% (1)

- Alpha One Generation Ii Stern Drive: IndexDocument37 pagesAlpha One Generation Ii Stern Drive: IndexNicholas Ribic100% (1)

- Cylinder Head MERCRUISERDocument2 pagesCylinder Head MERCRUISERMartinez Valladares OscarNo ratings yet

- 2003 200 Bow RiderDocument36 pages2003 200 Bow Riderbbenz62No ratings yet

- Mercruiser Sterndrive Drive Shaft Housing Components Exploded View Diagram and PartsDocument8 pagesMercruiser Sterndrive Drive Shaft Housing Components Exploded View Diagram and PartsGerardo Espinola Cardozo100% (1)

- 10-Pin Blue Data Cable RiggingDocument6 pages10-Pin Blue Data Cable RiggingajcapetillogNo ratings yet

- Mercury VeradoDocument107 pagesMercury VeradoStefanos Grammenos67% (3)

- Owner'S Manual: Ilmor EnginesDocument60 pagesOwner'S Manual: Ilmor EnginesBill MontgomeryNo ratings yet

- Instruction: Se RviceDocument3 pagesInstruction: Se RvicecarlNo ratings yet

- Technical Specification For High Mast Lighting System PDFDocument6 pagesTechnical Specification For High Mast Lighting System PDFTTaan100% (1)

- FILE 20201102 103605 Bravo PDFDocument597 pagesFILE 20201102 103605 Bravo PDFho van hatNo ratings yet

- 49 Toc PDFDocument8 pages49 Toc PDFAnonymous 31OOGD9Kg0% (1)

- v6 v8 Model InformationDocument25 pagesv6 v8 Model InformationjisuuuNo ratings yet

- Mercruiser Gimble BearingsDocument3 pagesMercruiser Gimble BearingsJSMarine Parts ChinaNo ratings yet

- Motor 2030 Workshop ManualDocument81 pagesMotor 2030 Workshop ManualRD100% (1)

- Mercury 454 MagnumDocument146 pagesMercury 454 MagnumPeter KayNo ratings yet

- Alpha One Gen IIDocument1 pageAlpha One Gen IIWanda MarthaNo ratings yet

- Volvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.7Document33 pagesVolvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.7Luciano LiuzziNo ratings yet

- Mercruiser Installation and AdjustmentDocument66 pagesMercruiser Installation and Adjustmentsalvatore dalessandro100% (1)

- DF150 175 SetupDocument16 pagesDF150 175 SetupElvin HernándezNo ratings yet

- Smartcraft Fuel/Paddle/Oil Boat Harness: Components Contained in KitDocument3 pagesSmartcraft Fuel/Paddle/Oil Boat Harness: Components Contained in KitajcapetillogNo ratings yet

- Workshop Manual Engine 43Document262 pagesWorkshop Manual Engine 43Michael Tomberger100% (1)

- 02 Zeus Section 2 1 2011Document50 pages02 Zeus Section 2 1 2011engmohsen.ramadanhotmail.comNo ratings yet

- Mercruiser QSD 28 42Document182 pagesMercruiser QSD 28 42Per Østbø100% (1)

- Motor PeninsularDocument60 pagesMotor PeninsularfernandollorentegNo ratings yet

- 8.2L Mag/H.O./Seacore Sterndrive Models Non Ect: Operation and Maintenance ManualDocument119 pages8.2L Mag/H.O./Seacore Sterndrive Models Non Ect: Operation and Maintenance ManualcharlesNo ratings yet

- DF70A DF80A DF90A: Owner'S ManualDocument59 pagesDF70A DF80A DF90A: Owner'S ManualURIEL CABALLERONo ratings yet

- © 2019 Yamaha Motor Corporation, U.S.A.: F200 LF200 F225 F250 LF250Document112 pages© 2019 Yamaha Motor Corporation, U.S.A.: F200 LF200 F225 F250 LF250Tormod LarsenNo ratings yet

- Mercury Mariner Wiring Diagram 75 225 HP 2001 03Document7 pagesMercury Mariner Wiring Diagram 75 225 HP 2001 03erik gerkeNo ratings yet

- Reverse Gear HS80AE-B, Components Ratio 2 Volvo Penta ZFDocument2 pagesReverse Gear HS80AE-B, Components Ratio 2 Volvo Penta ZFErnesto Alonso100% (1)

- 8m0133411 PDFDocument115 pages8m0133411 PDFcharlesNo ratings yet

- 2.1 Zeus Pod Drive Technical PackageDocument20 pages2.1 Zeus Pod Drive Technical Packageengmohsen.ramadanhotmail.comNo ratings yet

- Typical Mercury Ignition SystemsDocument11 pagesTypical Mercury Ignition SystemswguenonNo ratings yet

- 200 Aet 2015 PDFDocument73 pages200 Aet 2015 PDFArdian FitradhiNo ratings yet

- 135-175 VeradoDocument3 pages135-175 Verado이영석50% (2)

- Installation Procedure: EVC-E Volvo Penta IPS Triple: Typical Installation / Main StationDocument2 pagesInstallation Procedure: EVC-E Volvo Penta IPS Triple: Typical Installation / Main StationMehdi Ben AbdelkaderNo ratings yet

- Honda BF35Document133 pagesHonda BF35beaver14100% (1)

- Shift Actuator Kit PN 5010335Document10 pagesShift Actuator Kit PN 5010335URIEL CABALLERONo ratings yet

- Mercury Service Bulletin 1881046Document13 pagesMercury Service Bulletin 1881046thesaneroneNo ratings yet

- Mercruiser D219 Service ManualDocument546 pagesMercruiser D219 Service ManualEerik (stnz)No ratings yet

- DTS Wiring DiagramDocument2 pagesDTS Wiring DiagramTrevor Richardson PeraconNo ratings yet

- Volvo Penta 240 V6Document2 pagesVolvo Penta 240 V6Guido100% (1)

- SUZUKI DF200 225 250 Servis Remont 4Document54 pagesSUZUKI DF200 225 250 Servis Remont 4Вячеслав ИоновNo ratings yet

- Mercruiser Power Trim PumpsDocument1 pageMercruiser Power Trim PumpsJSMarine Parts ChinaNo ratings yet

- Manuel D'installation MFG 2018Document54 pagesManuel D'installation MFG 2018bersalNo ratings yet

- Bravo3 MaintenanceDocument42 pagesBravo3 Maintenancerbarlow320No ratings yet

- Merc Gas EnginesDocument181 pagesMerc Gas EnginesyamyrulesNo ratings yet

- Zeus - Owners ManualDocument126 pagesZeus - Owners Manualengmohsen.ramadanhotmail.comNo ratings yet

- 135-150-175-200 With Serial Numbers United States - 0G960500 and AboveDocument638 pages135-150-175-200 With Serial Numbers United States - 0G960500 and AbovePAVLOSNo ratings yet

- General Information: HandsetDocument17 pagesGeneral Information: HandsetChristian BedoyaNo ratings yet

- Hpdi Main ScheduleDocument2 pagesHpdi Main Schedulefabbromauricioyahoo.com.arNo ratings yet

- Nanni 6.420 TDi Marine Diesel 6cylDocument16 pagesNanni 6.420 TDi Marine Diesel 6cylAlbertoJim90No ratings yet

- Kohler Marine GensetDocument4 pagesKohler Marine GensetENG PTBBSNo ratings yet

- Mercruiser AnodesDocument41 pagesMercruiser AnodesJSMarine Parts ChinaNo ratings yet

- Gti Gti Rfi XP Di GTX 4 Tec SC LTD SC We RXP 4 Tec SC Tehnicheskie DannyeDocument22 pagesGti Gti Rfi XP Di GTX 4 Tec SC LTD SC We RXP 4 Tec SC Tehnicheskie DannyeAlexandru DiaconuNo ratings yet

- Lifting Specification RexDocument1 pageLifting Specification Rexsamir.ahmed7577No ratings yet

- GS RS 500 002Document1 pageGS RS 500 002Xavier LeeNo ratings yet

- A D Section A-A: Lower Housing, R/A II, PB5X0Document7 pagesA D Section A-A: Lower Housing, R/A II, PB5X0zizouhicheNo ratings yet

- Clarkson Kga+ Dn1200 Nps48 HC RDC 08.ADocument1 pageClarkson Kga+ Dn1200 Nps48 HC RDC 08.AAlejandro Pupunovich RodriguezNo ratings yet

- OpenPCR Build InstructionsDocument76 pagesOpenPCR Build InstructionstitojankowskiNo ratings yet

- Omega PR-10Document1 pageOmega PR-10leo walidNo ratings yet

- Surface Mounted Single Jumbo-Roll Toilet Tissue DispenserDocument1 pageSurface Mounted Single Jumbo-Roll Toilet Tissue DispenserOVIEL TORRESNo ratings yet

- 9812/7600 F5-1-2 Transmission, 4WD 4WD, Permanent, PS750Document2 pages9812/7600 F5-1-2 Transmission, 4WD 4WD, Permanent, PS750heroskNo ratings yet

- Uh-60 Capabilities 2Document6 pagesUh-60 Capabilities 2German PinerosNo ratings yet

- WheelHorse Electric Lift Accessory For 800 Series Tractors 8-4231Document4 pagesWheelHorse Electric Lift Accessory For 800 Series Tractors 8-4231Kevins Small Engine and Tractor ServiceNo ratings yet

- Liebherr Wheel Loader l514 1265 Service ManualDocument20 pagesLiebherr Wheel Loader l514 1265 Service Manualida100% (61)

- My I T ReportDocument40 pagesMy I T Reportchikajamesy699No ratings yet

- Karthi CVDocument4 pagesKarthi CVKarthi MarxNo ratings yet

- PPPDocument4 pagesPPPsandeepNo ratings yet

- 12oh Motoniveladora Version Standar 5fm Plano ElectricoDocument2 pages12oh Motoniveladora Version Standar 5fm Plano Electricomiguelcastillo100% (1)

- 12-24 KV Umc Series Metal Clad Switchgear: User ManualDocument8 pages12-24 KV Umc Series Metal Clad Switchgear: User ManualAngeloNo ratings yet

- Leapton 580 600Document2 pagesLeapton 580 600Joel RODRIGUES DA SILVANo ratings yet

- Hydraulic Motors: What Is A Hydraulic Motor and Why Do You Need It?Document7 pagesHydraulic Motors: What Is A Hydraulic Motor and Why Do You Need It?Anil NairNo ratings yet

- QBR101 Battery Wiring DiagramDocument1 pageQBR101 Battery Wiring DiagramNguyễn Văn Trung100% (1)

- 6WG1 ECU PinoutDocument3 pages6WG1 ECU Pinouttruong.fb.04No ratings yet

- eRRU Installation Modes ADocument21 pageseRRU Installation Modes AYalmazNo ratings yet

- Inverter 450Document38 pagesInverter 450Daniel Alejandro G�mez S�nchezNo ratings yet

- Quick Select Product Guide Process Interfaces Tdoct5999 - EngDocument100 pagesQuick Select Product Guide Process Interfaces Tdoct5999 - EngventjeNo ratings yet

- Material Schematic Hydraulic System Track Type Tractors d8r Dozer Caterpillar PDFDocument4 pagesMaterial Schematic Hydraulic System Track Type Tractors d8r Dozer Caterpillar PDFvasanth kumar100% (1)

- Ic 7404Document4 pagesIc 7404Putri Rose Amanda PuriNo ratings yet

- Cambium PTP 700 Series Installation GuideDocument28 pagesCambium PTP 700 Series Installation Guidechangiz2220No ratings yet

- Int MoellerDocument32 pagesInt MoellerRichard GonzalesNo ratings yet

- Electric Car Drive Motor TrainerDocument2 pagesElectric Car Drive Motor Trainermanual imbNo ratings yet

- Edc DiodeDocument11 pagesEdc DiodeAnonymous JnvCyu85No ratings yet

- 03 Instructions Hyundai Man B&W Diesel Engines Components No.1 S42MC (Code Book)Document194 pages03 Instructions Hyundai Man B&W Diesel Engines Components No.1 S42MC (Code Book)roberto luckyNo ratings yet

- Visonic Smarthome Secure Link Installation GuideDocument32 pagesVisonic Smarthome Secure Link Installation Guidekpcakes1No ratings yet