Professional Documents

Culture Documents

Blasting Basics - Empire Abrasive

Blasting Basics - Empire Abrasive

Uploaded by

Youtube For EducationCopyright:

Available Formats

You might also like

- Rosemarie Garland Thomson Extraordinary BodiesDocument224 pagesRosemarie Garland Thomson Extraordinary Bodiescourursula89% (9)

- PSC 1000 Parts Washer SDS PDFDocument9 pagesPSC 1000 Parts Washer SDS PDFYoutube For EducationNo ratings yet

- Springride Air Bellows PDFDocument123 pagesSpringride Air Bellows PDFMichael AkhramovichNo ratings yet

- IQ3 Haltech LD Manual v2 PDFDocument92 pagesIQ3 Haltech LD Manual v2 PDFEdwinNo ratings yet

- CarQuest Wearever Brake Parts Cleaner WES W5089 PDFDocument1 pageCarQuest Wearever Brake Parts Cleaner WES W5089 PDFYoutube For EducationNo ratings yet

- Azuregreen Catalog 2013Document298 pagesAzuregreen Catalog 2013zadkiel20037309100% (3)

- Autel Scanner MaxiCOM MK808BT Diagnostic Tool, Upgraded Version of MK808, With MaxiVCI Supports Full System Scan & IMMOEPBSASDocument1 pageAutel Scanner MaxiCOM MK808BT Diagnostic Tool, Upgraded Version of MK808, With MaxiVCI Supports Full System Scan & IMMOEPBSASRashid RazaNo ratings yet

- Truck Type AppendixDocument25 pagesTruck Type AppendixHoang Minh HungNo ratings yet

- Ammco 800OTV Operation ManualDocument27 pagesAmmco 800OTV Operation Manualabul hussainNo ratings yet

- Aerator Type ABS Venturi Jet: ApplicationsDocument4 pagesAerator Type ABS Venturi Jet: ApplicationsRafael ZimmermannNo ratings yet

- CNC Milling: Adam YouensDocument21 pagesCNC Milling: Adam YouensGundhi AsmoroNo ratings yet

- Zedfull BrochureDocument4 pagesZedfull BrochureAdil SejadNo ratings yet

- Guyson Formula Blast ManualDocument33 pagesGuyson Formula Blast ManualYoutube For EducationNo ratings yet

- Design and Development of The Valve Train of A Motorcycle EngineDocument15 pagesDesign and Development of The Valve Train of A Motorcycle EngineDimitris MakrisNo ratings yet

- 1 PDFsam Book Adams-Tutorial-3rdEditionDocument96 pages1 PDFsam Book Adams-Tutorial-3rdEditionShevon FernandoNo ratings yet

- DME Power Screw Dr. F. TauheedDocument13 pagesDME Power Screw Dr. F. TauheedDr Praveen KumarNo ratings yet

- GMAcronymsDocument320 pagesGMAcronymsRadamez RangelNo ratings yet

- 285-700 Glasurit® Primer FillerDocument2 pages285-700 Glasurit® Primer FillerJordanNo ratings yet

- (Metalworking) Welding and MachiningDocument1,767 pages(Metalworking) Welding and MachiningEugeneNo ratings yet

- Discontinued: Liebert® PSI XR™Document38 pagesDiscontinued: Liebert® PSI XR™josmelNo ratings yet

- A Survey On Low Speed Low Power Axial Flux Generator Design andDocument18 pagesA Survey On Low Speed Low Power Axial Flux Generator Design andZiqing L100% (1)

- Wiper and Washer SystemsDocument14 pagesWiper and Washer SystemsArt DoeNo ratings yet

- Wire Arc Additive ManufacturingDocument8 pagesWire Arc Additive ManufacturingSerdar MermerNo ratings yet

- International Business Environment and Market Entry Strategy AnalysisDocument14 pagesInternational Business Environment and Market Entry Strategy AnalysisAshuNo ratings yet

- John Deere 46 Backhoe BrochureDocument2 pagesJohn Deere 46 Backhoe Brochurevovoboss0% (1)

- High Flow Hydraulics (S - N A5GK20356 & Below, A5GL20029 & Below) - S220Document3 pagesHigh Flow Hydraulics (S - N A5GK20356 & Below, A5GL20029 & Below) - S220Joan CzNo ratings yet

- Sheet Bending PlansDocument47 pagesSheet Bending Plansleonardo fabio pasichana ricaurte100% (1)

- 121E Gear Cutting by Hobbing (20070930)Document51 pages121E Gear Cutting by Hobbing (20070930)Jaskaran SinghNo ratings yet

- 2020 Ford F 150 Owners Manual Version3 - Om - EN US - 04 - 2020 PDFDocument625 pages2020 Ford F 150 Owners Manual Version3 - Om - EN US - 04 - 2020 PDFHuawei ITMOVP7P8No ratings yet

- Manufacturer Directory: AmeriquipDocument16 pagesManufacturer Directory: AmeriquipAbdou AbdouNo ratings yet

- RAS-3015T 1000W: Technical ProposalDocument15 pagesRAS-3015T 1000W: Technical ProposalAhmed ShafeekNo ratings yet

- EV Go KartDocument19 pagesEV Go KartShrimant H. Nikam100% (1)

- DrillbitDocument4 pagesDrillbitColeen SiazonNo ratings yet

- Wiring Harness DesignDocument5 pagesWiring Harness Designerfan_nugroho9063No ratings yet

- FP 3400 DatasheetDocument4 pagesFP 3400 DatasheetVictor Bermejo0% (1)

- Gs 3 MDocument316 pagesGs 3 MNazielNo ratings yet

- EscortsDocument2 pagesEscortspratikNo ratings yet

- Complete PDFDocument82 pagesComplete PDFleonardoNo ratings yet

- KliteDocument47 pagesKliteDwiyan FitraNo ratings yet

- Automotive Paint MarketDocument5 pagesAutomotive Paint Marketsurendra choudharyNo ratings yet

- Additive Manufacturing 2Document12 pagesAdditive Manufacturing 2Gourav SamaNo ratings yet

- Catalogo Grimme WR 200Document6 pagesCatalogo Grimme WR 200Soledad Navarro LazoNo ratings yet

- Tekla Structures: Task Manager User GuideDocument61 pagesTekla Structures: Task Manager User GuideMG Xie100% (1)

- ViktorDocument140 pagesViktorDani Sherlock100% (1)

- Manual - AR2 Wiring HarnessDocument77 pagesManual - AR2 Wiring HarnessMickNo ratings yet

- Pressure Balancing of Duct For Duct ExtrDocument15 pagesPressure Balancing of Duct For Duct ExtrCarlos BarrazaNo ratings yet

- CATALOGUE FORD 2020 - Portrait - Anglais - LIGHTDocument64 pagesCATALOGUE FORD 2020 - Portrait - Anglais - LIGHTAnxo Ferreira ParadaNo ratings yet

- Caliber SOP Guidelines - 3M & Akzo - Final PDFDocument43 pagesCaliber SOP Guidelines - 3M & Akzo - Final PDFAnonymous ZNIVWABX1No ratings yet

- Cit Sio Bsit At112 FLPDocument68 pagesCit Sio Bsit At112 FLPEric JacobsNo ratings yet

- Flow of Fluids Through Valves, Fittings and PipeDocument129 pagesFlow of Fluids Through Valves, Fittings and PipeAugusta FacvestNo ratings yet

- Electrical Harness Repair KitDocument5 pagesElectrical Harness Repair KitjhonyflowNo ratings yet

- CodeWarrior Common Features GuideDocument353 pagesCodeWarrior Common Features GuideAngel CastilloNo ratings yet

- 2014 Miteebite Catalog WebDocument40 pages2014 Miteebite Catalog WebDonald NeislerNo ratings yet

- CombinepdfDocument13 pagesCombinepdfyarshini kumaravel100% (1)

- A Comprehensive Guide On The Aircraft Wire Harness AssemblyDocument13 pagesA Comprehensive Guide On The Aircraft Wire Harness AssemblyjackNo ratings yet

- Latest CNC Cutting Design - Types, Materials and Installation - LivspaceDocument22 pagesLatest CNC Cutting Design - Types, Materials and Installation - Livspacesushil247No ratings yet

- Advanced ManualDocument240 pagesAdvanced ManualLEENo ratings yet

- Unit 3 Vehicle and Their SpecificationsDocument48 pagesUnit 3 Vehicle and Their Specificationssiddh2805No ratings yet

- Kuman K1Arduino KIT TutorialsDocument138 pagesKuman K1Arduino KIT Tutorialsleo100% (1)

- Presentation On Design of Transmission System For A GokartDocument21 pagesPresentation On Design of Transmission System For A GokartNikhil WarungaseNo ratings yet

- 2021 Nissan Sentra Quick Reference GuideDocument31 pages2021 Nissan Sentra Quick Reference GuideLoop AntenasNo ratings yet

- 2002 Air KnifeDocument12 pages2002 Air KnifeWaqas RiazNo ratings yet

- Lesoon Equipment Catalogue 2015Document28 pagesLesoon Equipment Catalogue 2015Jason PerezNo ratings yet

- EGR Carb Cleaner-English (UK & ROI)Document8 pagesEGR Carb Cleaner-English (UK & ROI)Youtube For EducationNo ratings yet

- L112 - Penetrating OilDocument9 pagesL112 - Penetrating OilYoutube For EducationNo ratings yet

- Holts Brake Cleaner-English (UK & ROI)Document7 pagesHolts Brake Cleaner-English (UK & ROI)Youtube For EducationNo ratings yet

- Thermocure Safety Data Sheet 2018Document5 pagesThermocure Safety Data Sheet 2018Youtube For EducationNo ratings yet

- Biozone Ready For Use Liquid 29-05-2012 PDFDocument4 pagesBiozone Ready For Use Liquid 29-05-2012 PDFYoutube For EducationNo ratings yet

- Holts Brake Cleaner-English (UK & ROI)Document9 pagesHolts Brake Cleaner-English (UK & ROI)Youtube For EducationNo ratings yet

- ECSA Recommendations For Surface & Dry Cleaning July 2013 PDFDocument9 pagesECSA Recommendations For Surface & Dry Cleaning July 2013 PDFYoutube For EducationNo ratings yet

- EvapoRust MSDS PDFDocument6 pagesEvapoRust MSDS PDFYoutube For EducationNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument4 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingYoutube For Education0% (1)

- Rust Block MSDSDocument4 pagesRust Block MSDSYoutube For EducationNo ratings yet

- Cuda Liquid Defoamer 1 Gallon 12-5-16 MSDS PDFDocument4 pagesCuda Liquid Defoamer 1 Gallon 12-5-16 MSDS PDFYoutube For EducationNo ratings yet

- Rust Block Safety Data Sheet 2018Document5 pagesRust Block Safety Data Sheet 2018Youtube For EducationNo ratings yet

- Keteka Storm Ultra SDS Ratio 20 To 1 Tech Info PDFDocument3 pagesKeteka Storm Ultra SDS Ratio 20 To 1 Tech Info PDFYoutube For EducationNo ratings yet

- Biozone Liquid Concentrate v1-5 29-05-2012 PDFDocument5 pagesBiozone Liquid Concentrate v1-5 29-05-2012 PDFYoutube For EducationNo ratings yet

- Cuda App-200x C698243 5-18-17 MSDS PDFDocument7 pagesCuda App-200x C698243 5-18-17 MSDS PDFYoutube For EducationNo ratings yet

- Crown Parafin Oil PDFDocument6 pagesCrown Parafin Oil PDFYoutube For EducationNo ratings yet

- CUDA APP 1000 Jet Spray Wash Detergent 12-5-16 MSDS PDFDocument5 pagesCUDA APP 1000 Jet Spray Wash Detergent 12-5-16 MSDS PDFYoutube For EducationNo ratings yet

- CLR Bath Kitchen Cleaner 740319-3-19 PDFDocument7 pagesCLR Bath Kitchen Cleaner 740319-3-19 PDFYoutube For EducationNo ratings yet

- CUDA APP-200X C698243 5-18-17 Tech Info PDFDocument3 pagesCUDA APP-200X C698243 5-18-17 Tech Info PDFYoutube For EducationNo ratings yet

- Brake Parts Cleaner WES W5090 PDFDocument10 pagesBrake Parts Cleaner WES W5090 PDFYoutube For EducationNo ratings yet

- MSDS CLR Calcium Lime Rust Remover PDFDocument5 pagesMSDS CLR Calcium Lime Rust Remover PDFYoutube For EducationNo ratings yet

- CLR-Power-Plumber - Drain Cleaner-SDS PDFDocument11 pagesCLR-Power-Plumber - Drain Cleaner-SDS PDFYoutube For EducationNo ratings yet

- CarQuest Wearever Brake Parts Cleaner WES W7340 PDFDocument1 pageCarQuest Wearever Brake Parts Cleaner WES W7340 PDFYoutube For EducationNo ratings yet

- Brake Parts Cleaner WES W7340 PDFDocument11 pagesBrake Parts Cleaner WES W7340 PDFYoutube For EducationNo ratings yet

- CLR PRO Kitchen SDS-74PK0216-1-16-19 PDFDocument7 pagesCLR PRO Kitchen SDS-74PK0216-1-16-19 PDFYoutube For EducationNo ratings yet

- CLR PRO Bath SDS 74PB0216-1-16-19 PDFDocument7 pagesCLR PRO Bath SDS 74PB0216-1-16-19 PDFYoutube For EducationNo ratings yet

- Brake Parts Cleaner WES W7341 PDFDocument11 pagesBrake Parts Cleaner WES W7341 PDFYoutube For EducationNo ratings yet

- Brake Parts Cleaner WES W5089 PDFDocument10 pagesBrake Parts Cleaner WES W5089 PDFYoutube For EducationNo ratings yet

- Academic Reading TeamDocument10 pagesAcademic Reading TeamД. ДарамNo ratings yet

- Vautid 100Document4 pagesVautid 100emad sabriNo ratings yet

- Darkwing Duck Episode GuideDocument3 pagesDarkwing Duck Episode GuideSA3R7No ratings yet

- Conditionals/ I Wish/ If OnlyDocument51 pagesConditionals/ I Wish/ If OnlyGisela BalcázarNo ratings yet

- Verse 1: @0:11: HappierDocument2 pagesVerse 1: @0:11: HappierKristian GatchalianNo ratings yet

- Verb Tenses ReivewDocument11 pagesVerb Tenses ReivewbobNo ratings yet

- Jaida Pics - Google SearchDocument1 pageJaida Pics - Google SearchsamiraNo ratings yet

- Tira Led SMD 2835 Zigzag Interior Blanco Frio 6500k 60 Leds M 12v 31wDocument5 pagesTira Led SMD 2835 Zigzag Interior Blanco Frio 6500k 60 Leds M 12v 31wnubercard6111No ratings yet

- The Absolutely True Diary of A Part-Time Indian (Summary, Themes & Analysis)Document12 pagesThe Absolutely True Diary of A Part-Time Indian (Summary, Themes & Analysis)M MNo ratings yet

- The Geometry CabinetDocument19 pagesThe Geometry Cabinetdanu_huNo ratings yet

- Sasur 1Document22 pagesSasur 1ghoongruNo ratings yet

- Form 1 Placement TestDocument5 pagesForm 1 Placement TestSyah Ag100% (1)

- Format Guidelines and Integrated Script 090112Document75 pagesFormat Guidelines and Integrated Script 090112Mer Coronejo CondrillonNo ratings yet

- Hands of Ignorance: December 1, 2010Document60 pagesHands of Ignorance: December 1, 2010Simorgh MagazineNo ratings yet

- Power of Love Chords: G D em BM em C D7 G G7Document2 pagesPower of Love Chords: G D em BM em C D7 G G7Jessemar Solante Jaron Wao100% (2)

- Red Cause List For Thursday, 18 March, 2021: Peshawar High Court, PeshawarDocument64 pagesRed Cause List For Thursday, 18 March, 2021: Peshawar High Court, PeshawarFaizan AhmadNo ratings yet

- Ap Art History Course and Exam Description PDFDocument267 pagesAp Art History Course and Exam Description PDFJohnNo ratings yet

- Philips LightingDocument28 pagesPhilips LightingIlhamNo ratings yet

- Reading Task: Complete The Text With The Correct Words From The BoxesDocument13 pagesReading Task: Complete The Text With The Correct Words From The BoxesSyifamawaddah PianidaNo ratings yet

- Pandoras Box3 520in1 Game ListDocument13 pagesPandoras Box3 520in1 Game ListAlysson BastosNo ratings yet

- Owner's Instructions: TFT-LCD TelevisionDocument178 pagesOwner's Instructions: TFT-LCD Televisionkhopdi_number1No ratings yet

- Lab 05 Chap 03Document21 pagesLab 05 Chap 03Muzammil RahimNo ratings yet

- Everything Happens To MeDocument6 pagesEverything Happens To Mejmsklar100% (1)

- Fdocuments - in - Stream of Consciousness in The Sound and The Fury PDFDocument10 pagesFdocuments - in - Stream of Consciousness in The Sound and The Fury PDFsubhadyutidasNo ratings yet

- The Model MillionerDocument6 pagesThe Model MillionerAdzi ZurrahmanNo ratings yet

- A Narrow Fellow in The GrassDocument22 pagesA Narrow Fellow in The GrassKenneth Arvin Tabios100% (1)

- Steamboat WillieDocument2 pagesSteamboat WilliewafflebertoNo ratings yet

- BG2EE SpellsDocument6 pagesBG2EE SpellsTomás Vallejo MoraNo ratings yet

Blasting Basics - Empire Abrasive

Blasting Basics - Empire Abrasive

Uploaded by

Youtube For EducationOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blasting Basics - Empire Abrasive

Blasting Basics - Empire Abrasive

Uploaded by

Youtube For EducationCopyright:

Available Formats

Blasting Basics

Section H: Table of Contents

Air-Blast Cabinet Capabilities H1

Air-Blast Cabinet Operating Principles H2

Pressure-Blast Spray Diameters H3

Pressure-Blast Air Requirements H3

Suction-Blast Spray Diameters H3

Suction-Blast Air Requirements H3

Media Guide H4

Surface Profile H4

Blasting Basics: Cabinet Capabilities

Air-Blast Cabinet Capabilities

Air-blast cabinets excel in a multitude of surface-treatment jobs ranging from cleaning to peening. A short list of

the most common applications follows.

Finishing Surface Treatment and Preparation

• Add matte or satin finish, or decorative frost

• Strengthen

• Remove glare or imperfections

• Add fatigue resistance

• Blend marks

• Reduce design weights, porosity or friction

• Hone and burnish

• Boost resistance to corrosion

• Mark identifications

• Improve lubrication

• Expose flaws for inspection

Cleaning and Removal • Etch for bonding and adhesion

• Chemical impurities • Cut

• Coatings

• Paint

• Sealants and adhesives

• Carbon deposits

• Scale

• Excess brazing

• Casting materials

• Flashing

• Burrs

• Rust

• Oxidation

Never use silica sand in any Empire equipment.

08/12 Page H1 www.empire-airblast.com • 215.752.8800

Blasting Basics: Operating Principles

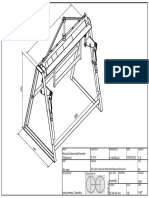

Operating Principles of Pressure Systems

Air-Blast Cabinets

Air-blast cabinets use one of two operating

systems: pressure or suction.

As shown in the drawing to the right, pressure

systems apply compressor power all the way

from the media storage hopper to the nozzle

outlet, resulting in faster work, more precise

control at both high and low pressures and,

in many applications, more efficient use of

compressed air than is possible with suction

systems.

Suction systems, which rely on a venturi effect

to draw media from the storage hopper, offer the

enticements of lower capital costs and easier

deployment of multiple blast guns.

Tunable reclaimers (see right) recycle media of

various densities. By adjusting a fine-tuning band DIRECTION OF AIR FLOW

on the reclaimer, the amount of air introduced COMPRESSED AIR

into the system can be controlled to assure MEDIA

precise separation of functional media from dust DUST

and other unwanted debris.

DEBRIS

As spent media, dust and debris are pulled by

air flow to the reclaimer inlet, incoming air and

Suction Systems

media spiral in a downward vortex, throwing

larger particles against the outer reclaimer wall.

An air stream forms an upward counter vortex

through the center tube, which carries out dust

while heavier particles drop into the storage

hopper below for reuse. A screen catches any

oversized debris.

Dust and undersized debris are drawn from the

reclaimer into the bottom of the dust collector.

Sudden expansion forces heavier dust particles

to the bottom. Remaining fine dust is pulled to

the surface of the dust filters. Clean air can then

be discharged to the work area.

NOTE: The CFM of Empire reclaimers is rated at

nominal static working pressure of 6” water, with Media/Reclaimer Compatibility

the exception of the 1200 CFM model, rated at

10” static pressure. Competitive units may appear RECLAIMER GLASS ALUMINUM STEEL STEEL

CFM BEADS OXIDE GRIT SHOT

to achieve higher CFM due to ratings based on

400 ALL 46 120 S-70

inadequate working static pressure.

600 ALL 36 80 S-110

900 ALL 36 80 S-110

1200 ALL 30 40 S-170

Chart shows the maximum media sizes recoverable with single-gun/nozzle

systems. Multiple guns, larger nozzles, operation at altitudes above 5000

feet, or use of a 50 Hz electrical supply may require a larger reclaimer and

dust-collector blower. Larger sizes may be used. Consult factory.

08/12 Page H2 www.empire-airblast.com • 215.752.8800

Blasting Basics: Pressure-System Nozzles

Nozzle

Hot Spot Brush-off

Spray Diameter

Pressure-Blast Spray Diameters

Pressure-Blast Air Requirements (SCFM) Distance from Workpiece

Nozzle ID 6" 12" 18"

Pressure (PSI) 20 30 40 50 60 80 100 120 1⁄8” ¾” 1” 1” 1½” — 11⁄8”

1⁄8” nozzle 6 8 10 13 14 17 20 25 3∕16” 1¼” 13∕8” 1½” 2” 1 ∕8”

5 2½”

3∕16” nozzle 15 18 22 26 30 38 45 55 ¼” 1¼” 1½” 17∕8” 2¼” 21⁄8” 2¾”

¼” nozzle 27 32 41 49 55 68 81 97 3∕8” 15∕8” 1¾” 2” 2¼” 2¼” 3”

5∕16” nozzle 42 50 64 76 88 113 137 152

Brush-off Hot Spot

3∕8” nozzle 55 73 91 109 126 161 196 220

4 SCFM = 1 horsepower

Compressors should be sized to the next larger nozzle to

allow for nozzle wear.

Blasting Basics: Suction-System Nozzles

Gun

Hot Spot Brush-off

Spray Diameter

Suction-Blast Spray Diameters

Suction-Blast Air Requirements (SCFM) Distance from Workpiece

Nozzle ID 6" 12" 18"

Pressure (PSI) 30 40 50 60 70 80 90 100

¼” 13∕8” 25∕8” — 2¾” — 1”

¼” nozzle, 3∕32” air jet 6 7 8 10 11 12 13 15

5∕16” 1½” 3½” 1¾” 4½” — 3¾”

¼” nozzle, 1⁄8” air jet 10 12 15 17 19 21 23 26

7∕16” 2” 3¾” 2” 4½” — 3¾”

5∕16” nozzle, 5∕32” air jet* 15 19 23 27 31 37 38 42

7∕16” nozzle, 7∕32” air jet

Brush-off Hot Spot

31 38 45 52 59 66 73 80

4 SCFM = 1 horsepower

Never use silica sand in any Empire equipment.

08/12 Page H3 www.empire-airblast.com • 215.752.8800

Blasting Basics: Media Guide

Media Guide

Glass Ceramic Stainless Steel Steel Aluminum Silicon Bicarb Crushed Plastic Agri

Bead Shot Cut Wire Shot Grit Oxide Carbide of Soda Glass Media Shell

Finishing YES YES YES YES YES YES YES YES YES NO NO

Cleaning/Removal YES YES YES YES YES YES YES YES YES YES YES

Peening YES YES YES YES NO NO NO NO NO NO NO

Surface Profiling (Etch) NO NO YES NO YES YES YES NO YES YES YES

Working Speed MED MED MED MED MED-HIGH HIGH VERY-HIGH LOW HIGH MED-HIGH LOW-HIGH

Recyclability HIGH-LOW HIGH HIGH VERY-HIGH VERY-HIGH MED-HIGH MED-LOW NONE MED-LOW MED LOW

Probability of Metal Removal VERY LOW VERY LOW VERY LOW VERY LOW MED MED-HIGH MED-HIGH NONE LOW-MED VERY LOW VERY LOW

Hardness, MOH Scale 5.5 7 6-7.5 6-7.5 8-9 8-9 9 2.5 5.5 3-4 1-4.5

(Rockwell RC) (57-63) (35-55) (20-66) (40-66)

Bulk Density (lb/cu. ft.) 100 150 280 280 230 125 95 60 100 45-60 40-80

Mesh Size 30-440 8-46 20-62 8-200 10-325 12-325 36-220 70-220 30-400 12-80 MANY

Typical Blast Pressures (psi) 20-55 20-90 20-90 20-90 20-90 20-90 20-90 40-80 20-50 20-60 10-40

Shapes: Angular; • Spherical • • • • or •

NOTES: Above information is intended as a general reference guide. Consult your authorized Empire distributor for more specific guidance.

1) Sodium bicarbonate must be treated with a flow agent.

2) Do not use silica sand in any Empire blast equipment.

3) See “Media/Reclaimer Compatibility” chart on Page H2 for mesh sizes compatible with reclaimer systems.

Blasting Basics: Surface Profile

Profile: A Critical Aspect of Surface Prep

Blast Class defines surface cleanliness. Surface Profile describes surface shape. For coatings—and the parts

they protect—to perform successfully, surfaces must be clean and properly profiled.

In the blasting process, grains of The texture created affects the

abrasives carry kinetic energy to the appearance and friction coefficients

work surface. Upon impact, the grains of “finished” parts (those requiring

of aggressive abrasives dig out holes, no coating) most directly, but profile

creating a “mountain & valley” texture plays a major roll in the performance of

on the surface. coated surfaces as well.

Blasting

“Profiled” Surface

Tailor Profiles to Coatings

When a profile protrudes When a primer just covers Basic guidelines, shown

through the primer, the the profile, little room below, provide a good start

surface soon rusts. remains for error. for best coating results.

Guide 1: Profile height should not exceed the dry-film-thickness (DFT) of the primer coat.

Guide 2: Profile height should not exceed a third of the total coating system’s dry-film-thickness (DFT).

Note: Consult the coating supplier for surface-profile specifications.

08/12 Page H4 www.empire-airblast.com • 215.752.8800

Blasting Basics: Surface Profile

Blast Factors Affecting Surface Profile

Low Durability High Durability High Durability Abrasive Durability & SurfaIe Hardness

More durable abrasives dig a deeper profile more quickly

than less durable media, which waste kinetic energy in the

process of fracturing.

Harder surfaces resist the action of the abrasives more than

Mild Steel softer ones.

Hardened Steel

Spherical Angular Abrasive Shape

Spherical media produce a dimpled/peened profile that

normally enhances part strength.

Angular media cut a jagged profile receptive to coatings.

High-Density Grain Low-Density Grain Abrasive Density

High-density grains dig a deeper profile than low-density

grains when all other blast factors remain constant.

High Intensity Blast Intensity

Low Intensity The maximum amount of work a particle can perform on

a surface depends on its energy, a function of its mass

and velocity. When all other variables — including fracture

rates, shape, and density remain constant — faster moving

particles dig a deeper profile.

High Angle

ImpaIt Angle

Low Angle Abrasives arriving at steep angles to the work surface dig

deeper than those arriving at lower trajectories.

Irregular Embedment

Concentric Larger, irregular, friable abrasives can embed in work

surfaces, leading to poor results. Smaller, regular, more

durable media reduce the risk.

For more information, contact Empire’s Applications’ Engineering Department.

Never use silica sand in any Empire equipment.

08/12 Page H5 www.empire-airblast.com • 215.752.8800

You might also like

- Rosemarie Garland Thomson Extraordinary BodiesDocument224 pagesRosemarie Garland Thomson Extraordinary Bodiescourursula89% (9)

- PSC 1000 Parts Washer SDS PDFDocument9 pagesPSC 1000 Parts Washer SDS PDFYoutube For EducationNo ratings yet

- Springride Air Bellows PDFDocument123 pagesSpringride Air Bellows PDFMichael AkhramovichNo ratings yet

- IQ3 Haltech LD Manual v2 PDFDocument92 pagesIQ3 Haltech LD Manual v2 PDFEdwinNo ratings yet

- CarQuest Wearever Brake Parts Cleaner WES W5089 PDFDocument1 pageCarQuest Wearever Brake Parts Cleaner WES W5089 PDFYoutube For EducationNo ratings yet

- Azuregreen Catalog 2013Document298 pagesAzuregreen Catalog 2013zadkiel20037309100% (3)

- Autel Scanner MaxiCOM MK808BT Diagnostic Tool, Upgraded Version of MK808, With MaxiVCI Supports Full System Scan & IMMOEPBSASDocument1 pageAutel Scanner MaxiCOM MK808BT Diagnostic Tool, Upgraded Version of MK808, With MaxiVCI Supports Full System Scan & IMMOEPBSASRashid RazaNo ratings yet

- Truck Type AppendixDocument25 pagesTruck Type AppendixHoang Minh HungNo ratings yet

- Ammco 800OTV Operation ManualDocument27 pagesAmmco 800OTV Operation Manualabul hussainNo ratings yet

- Aerator Type ABS Venturi Jet: ApplicationsDocument4 pagesAerator Type ABS Venturi Jet: ApplicationsRafael ZimmermannNo ratings yet

- CNC Milling: Adam YouensDocument21 pagesCNC Milling: Adam YouensGundhi AsmoroNo ratings yet

- Zedfull BrochureDocument4 pagesZedfull BrochureAdil SejadNo ratings yet

- Guyson Formula Blast ManualDocument33 pagesGuyson Formula Blast ManualYoutube For EducationNo ratings yet

- Design and Development of The Valve Train of A Motorcycle EngineDocument15 pagesDesign and Development of The Valve Train of A Motorcycle EngineDimitris MakrisNo ratings yet

- 1 PDFsam Book Adams-Tutorial-3rdEditionDocument96 pages1 PDFsam Book Adams-Tutorial-3rdEditionShevon FernandoNo ratings yet

- DME Power Screw Dr. F. TauheedDocument13 pagesDME Power Screw Dr. F. TauheedDr Praveen KumarNo ratings yet

- GMAcronymsDocument320 pagesGMAcronymsRadamez RangelNo ratings yet

- 285-700 Glasurit® Primer FillerDocument2 pages285-700 Glasurit® Primer FillerJordanNo ratings yet

- (Metalworking) Welding and MachiningDocument1,767 pages(Metalworking) Welding and MachiningEugeneNo ratings yet

- Discontinued: Liebert® PSI XR™Document38 pagesDiscontinued: Liebert® PSI XR™josmelNo ratings yet

- A Survey On Low Speed Low Power Axial Flux Generator Design andDocument18 pagesA Survey On Low Speed Low Power Axial Flux Generator Design andZiqing L100% (1)

- Wiper and Washer SystemsDocument14 pagesWiper and Washer SystemsArt DoeNo ratings yet

- Wire Arc Additive ManufacturingDocument8 pagesWire Arc Additive ManufacturingSerdar MermerNo ratings yet

- International Business Environment and Market Entry Strategy AnalysisDocument14 pagesInternational Business Environment and Market Entry Strategy AnalysisAshuNo ratings yet

- John Deere 46 Backhoe BrochureDocument2 pagesJohn Deere 46 Backhoe Brochurevovoboss0% (1)

- High Flow Hydraulics (S - N A5GK20356 & Below, A5GL20029 & Below) - S220Document3 pagesHigh Flow Hydraulics (S - N A5GK20356 & Below, A5GL20029 & Below) - S220Joan CzNo ratings yet

- Sheet Bending PlansDocument47 pagesSheet Bending Plansleonardo fabio pasichana ricaurte100% (1)

- 121E Gear Cutting by Hobbing (20070930)Document51 pages121E Gear Cutting by Hobbing (20070930)Jaskaran SinghNo ratings yet

- 2020 Ford F 150 Owners Manual Version3 - Om - EN US - 04 - 2020 PDFDocument625 pages2020 Ford F 150 Owners Manual Version3 - Om - EN US - 04 - 2020 PDFHuawei ITMOVP7P8No ratings yet

- Manufacturer Directory: AmeriquipDocument16 pagesManufacturer Directory: AmeriquipAbdou AbdouNo ratings yet

- RAS-3015T 1000W: Technical ProposalDocument15 pagesRAS-3015T 1000W: Technical ProposalAhmed ShafeekNo ratings yet

- EV Go KartDocument19 pagesEV Go KartShrimant H. Nikam100% (1)

- DrillbitDocument4 pagesDrillbitColeen SiazonNo ratings yet

- Wiring Harness DesignDocument5 pagesWiring Harness Designerfan_nugroho9063No ratings yet

- FP 3400 DatasheetDocument4 pagesFP 3400 DatasheetVictor Bermejo0% (1)

- Gs 3 MDocument316 pagesGs 3 MNazielNo ratings yet

- EscortsDocument2 pagesEscortspratikNo ratings yet

- Complete PDFDocument82 pagesComplete PDFleonardoNo ratings yet

- KliteDocument47 pagesKliteDwiyan FitraNo ratings yet

- Automotive Paint MarketDocument5 pagesAutomotive Paint Marketsurendra choudharyNo ratings yet

- Additive Manufacturing 2Document12 pagesAdditive Manufacturing 2Gourav SamaNo ratings yet

- Catalogo Grimme WR 200Document6 pagesCatalogo Grimme WR 200Soledad Navarro LazoNo ratings yet

- Tekla Structures: Task Manager User GuideDocument61 pagesTekla Structures: Task Manager User GuideMG Xie100% (1)

- ViktorDocument140 pagesViktorDani Sherlock100% (1)

- Manual - AR2 Wiring HarnessDocument77 pagesManual - AR2 Wiring HarnessMickNo ratings yet

- Pressure Balancing of Duct For Duct ExtrDocument15 pagesPressure Balancing of Duct For Duct ExtrCarlos BarrazaNo ratings yet

- CATALOGUE FORD 2020 - Portrait - Anglais - LIGHTDocument64 pagesCATALOGUE FORD 2020 - Portrait - Anglais - LIGHTAnxo Ferreira ParadaNo ratings yet

- Caliber SOP Guidelines - 3M & Akzo - Final PDFDocument43 pagesCaliber SOP Guidelines - 3M & Akzo - Final PDFAnonymous ZNIVWABX1No ratings yet

- Cit Sio Bsit At112 FLPDocument68 pagesCit Sio Bsit At112 FLPEric JacobsNo ratings yet

- Flow of Fluids Through Valves, Fittings and PipeDocument129 pagesFlow of Fluids Through Valves, Fittings and PipeAugusta FacvestNo ratings yet

- Electrical Harness Repair KitDocument5 pagesElectrical Harness Repair KitjhonyflowNo ratings yet

- CodeWarrior Common Features GuideDocument353 pagesCodeWarrior Common Features GuideAngel CastilloNo ratings yet

- 2014 Miteebite Catalog WebDocument40 pages2014 Miteebite Catalog WebDonald NeislerNo ratings yet

- CombinepdfDocument13 pagesCombinepdfyarshini kumaravel100% (1)

- A Comprehensive Guide On The Aircraft Wire Harness AssemblyDocument13 pagesA Comprehensive Guide On The Aircraft Wire Harness AssemblyjackNo ratings yet

- Latest CNC Cutting Design - Types, Materials and Installation - LivspaceDocument22 pagesLatest CNC Cutting Design - Types, Materials and Installation - Livspacesushil247No ratings yet

- Advanced ManualDocument240 pagesAdvanced ManualLEENo ratings yet

- Unit 3 Vehicle and Their SpecificationsDocument48 pagesUnit 3 Vehicle and Their Specificationssiddh2805No ratings yet

- Kuman K1Arduino KIT TutorialsDocument138 pagesKuman K1Arduino KIT Tutorialsleo100% (1)

- Presentation On Design of Transmission System For A GokartDocument21 pagesPresentation On Design of Transmission System For A GokartNikhil WarungaseNo ratings yet

- 2021 Nissan Sentra Quick Reference GuideDocument31 pages2021 Nissan Sentra Quick Reference GuideLoop AntenasNo ratings yet

- 2002 Air KnifeDocument12 pages2002 Air KnifeWaqas RiazNo ratings yet

- Lesoon Equipment Catalogue 2015Document28 pagesLesoon Equipment Catalogue 2015Jason PerezNo ratings yet

- EGR Carb Cleaner-English (UK & ROI)Document8 pagesEGR Carb Cleaner-English (UK & ROI)Youtube For EducationNo ratings yet

- L112 - Penetrating OilDocument9 pagesL112 - Penetrating OilYoutube For EducationNo ratings yet

- Holts Brake Cleaner-English (UK & ROI)Document7 pagesHolts Brake Cleaner-English (UK & ROI)Youtube For EducationNo ratings yet

- Thermocure Safety Data Sheet 2018Document5 pagesThermocure Safety Data Sheet 2018Youtube For EducationNo ratings yet

- Biozone Ready For Use Liquid 29-05-2012 PDFDocument4 pagesBiozone Ready For Use Liquid 29-05-2012 PDFYoutube For EducationNo ratings yet

- Holts Brake Cleaner-English (UK & ROI)Document9 pagesHolts Brake Cleaner-English (UK & ROI)Youtube For EducationNo ratings yet

- ECSA Recommendations For Surface & Dry Cleaning July 2013 PDFDocument9 pagesECSA Recommendations For Surface & Dry Cleaning July 2013 PDFYoutube For EducationNo ratings yet

- EvapoRust MSDS PDFDocument6 pagesEvapoRust MSDS PDFYoutube For EducationNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument4 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingYoutube For Education0% (1)

- Rust Block MSDSDocument4 pagesRust Block MSDSYoutube For EducationNo ratings yet

- Cuda Liquid Defoamer 1 Gallon 12-5-16 MSDS PDFDocument4 pagesCuda Liquid Defoamer 1 Gallon 12-5-16 MSDS PDFYoutube For EducationNo ratings yet

- Rust Block Safety Data Sheet 2018Document5 pagesRust Block Safety Data Sheet 2018Youtube For EducationNo ratings yet

- Keteka Storm Ultra SDS Ratio 20 To 1 Tech Info PDFDocument3 pagesKeteka Storm Ultra SDS Ratio 20 To 1 Tech Info PDFYoutube For EducationNo ratings yet

- Biozone Liquid Concentrate v1-5 29-05-2012 PDFDocument5 pagesBiozone Liquid Concentrate v1-5 29-05-2012 PDFYoutube For EducationNo ratings yet

- Cuda App-200x C698243 5-18-17 MSDS PDFDocument7 pagesCuda App-200x C698243 5-18-17 MSDS PDFYoutube For EducationNo ratings yet

- Crown Parafin Oil PDFDocument6 pagesCrown Parafin Oil PDFYoutube For EducationNo ratings yet

- CUDA APP 1000 Jet Spray Wash Detergent 12-5-16 MSDS PDFDocument5 pagesCUDA APP 1000 Jet Spray Wash Detergent 12-5-16 MSDS PDFYoutube For EducationNo ratings yet

- CLR Bath Kitchen Cleaner 740319-3-19 PDFDocument7 pagesCLR Bath Kitchen Cleaner 740319-3-19 PDFYoutube For EducationNo ratings yet

- CUDA APP-200X C698243 5-18-17 Tech Info PDFDocument3 pagesCUDA APP-200X C698243 5-18-17 Tech Info PDFYoutube For EducationNo ratings yet

- Brake Parts Cleaner WES W5090 PDFDocument10 pagesBrake Parts Cleaner WES W5090 PDFYoutube For EducationNo ratings yet

- MSDS CLR Calcium Lime Rust Remover PDFDocument5 pagesMSDS CLR Calcium Lime Rust Remover PDFYoutube For EducationNo ratings yet

- CLR-Power-Plumber - Drain Cleaner-SDS PDFDocument11 pagesCLR-Power-Plumber - Drain Cleaner-SDS PDFYoutube For EducationNo ratings yet

- CarQuest Wearever Brake Parts Cleaner WES W7340 PDFDocument1 pageCarQuest Wearever Brake Parts Cleaner WES W7340 PDFYoutube For EducationNo ratings yet

- Brake Parts Cleaner WES W7340 PDFDocument11 pagesBrake Parts Cleaner WES W7340 PDFYoutube For EducationNo ratings yet

- CLR PRO Kitchen SDS-74PK0216-1-16-19 PDFDocument7 pagesCLR PRO Kitchen SDS-74PK0216-1-16-19 PDFYoutube For EducationNo ratings yet

- CLR PRO Bath SDS 74PB0216-1-16-19 PDFDocument7 pagesCLR PRO Bath SDS 74PB0216-1-16-19 PDFYoutube For EducationNo ratings yet

- Brake Parts Cleaner WES W7341 PDFDocument11 pagesBrake Parts Cleaner WES W7341 PDFYoutube For EducationNo ratings yet

- Brake Parts Cleaner WES W5089 PDFDocument10 pagesBrake Parts Cleaner WES W5089 PDFYoutube For EducationNo ratings yet

- Academic Reading TeamDocument10 pagesAcademic Reading TeamД. ДарамNo ratings yet

- Vautid 100Document4 pagesVautid 100emad sabriNo ratings yet

- Darkwing Duck Episode GuideDocument3 pagesDarkwing Duck Episode GuideSA3R7No ratings yet

- Conditionals/ I Wish/ If OnlyDocument51 pagesConditionals/ I Wish/ If OnlyGisela BalcázarNo ratings yet

- Verse 1: @0:11: HappierDocument2 pagesVerse 1: @0:11: HappierKristian GatchalianNo ratings yet

- Verb Tenses ReivewDocument11 pagesVerb Tenses ReivewbobNo ratings yet

- Jaida Pics - Google SearchDocument1 pageJaida Pics - Google SearchsamiraNo ratings yet

- Tira Led SMD 2835 Zigzag Interior Blanco Frio 6500k 60 Leds M 12v 31wDocument5 pagesTira Led SMD 2835 Zigzag Interior Blanco Frio 6500k 60 Leds M 12v 31wnubercard6111No ratings yet

- The Absolutely True Diary of A Part-Time Indian (Summary, Themes & Analysis)Document12 pagesThe Absolutely True Diary of A Part-Time Indian (Summary, Themes & Analysis)M MNo ratings yet

- The Geometry CabinetDocument19 pagesThe Geometry Cabinetdanu_huNo ratings yet

- Sasur 1Document22 pagesSasur 1ghoongruNo ratings yet

- Form 1 Placement TestDocument5 pagesForm 1 Placement TestSyah Ag100% (1)

- Format Guidelines and Integrated Script 090112Document75 pagesFormat Guidelines and Integrated Script 090112Mer Coronejo CondrillonNo ratings yet

- Hands of Ignorance: December 1, 2010Document60 pagesHands of Ignorance: December 1, 2010Simorgh MagazineNo ratings yet

- Power of Love Chords: G D em BM em C D7 G G7Document2 pagesPower of Love Chords: G D em BM em C D7 G G7Jessemar Solante Jaron Wao100% (2)

- Red Cause List For Thursday, 18 March, 2021: Peshawar High Court, PeshawarDocument64 pagesRed Cause List For Thursday, 18 March, 2021: Peshawar High Court, PeshawarFaizan AhmadNo ratings yet

- Ap Art History Course and Exam Description PDFDocument267 pagesAp Art History Course and Exam Description PDFJohnNo ratings yet

- Philips LightingDocument28 pagesPhilips LightingIlhamNo ratings yet

- Reading Task: Complete The Text With The Correct Words From The BoxesDocument13 pagesReading Task: Complete The Text With The Correct Words From The BoxesSyifamawaddah PianidaNo ratings yet

- Pandoras Box3 520in1 Game ListDocument13 pagesPandoras Box3 520in1 Game ListAlysson BastosNo ratings yet

- Owner's Instructions: TFT-LCD TelevisionDocument178 pagesOwner's Instructions: TFT-LCD Televisionkhopdi_number1No ratings yet

- Lab 05 Chap 03Document21 pagesLab 05 Chap 03Muzammil RahimNo ratings yet

- Everything Happens To MeDocument6 pagesEverything Happens To Mejmsklar100% (1)

- Fdocuments - in - Stream of Consciousness in The Sound and The Fury PDFDocument10 pagesFdocuments - in - Stream of Consciousness in The Sound and The Fury PDFsubhadyutidasNo ratings yet

- The Model MillionerDocument6 pagesThe Model MillionerAdzi ZurrahmanNo ratings yet

- A Narrow Fellow in The GrassDocument22 pagesA Narrow Fellow in The GrassKenneth Arvin Tabios100% (1)

- Steamboat WillieDocument2 pagesSteamboat WilliewafflebertoNo ratings yet

- BG2EE SpellsDocument6 pagesBG2EE SpellsTomás Vallejo MoraNo ratings yet