Professional Documents

Culture Documents

Report Painting PDF

Report Painting PDF

Uploaded by

EnyCopyright:

Available Formats

You might also like

- Painting Inspection ReportDocument1 pagePainting Inspection ReportAlfian Imaduddin100% (4)

- Sample For Painting ReportDocument1 pageSample For Painting ReportSơn Nguyễn TháiNo ratings yet

- SOP - 06 - Visual and Dimensional ProcedureDocument22 pagesSOP - 06 - Visual and Dimensional ProcedureSuci YatiningtiyasNo ratings yet

- Surface Preparation & Painting ReportDocument1 pageSurface Preparation & Painting ReportChethan100% (1)

- Sample Painting ReportDocument2 pagesSample Painting ReportvinothNo ratings yet

- ITP PaintingDocument1 pageITP PaintingAmer Y KNo ratings yet

- Surface Preparation & Painting ProcedureDocument18 pagesSurface Preparation & Painting ProcedureAAISAT100% (1)

- PQT and Applicator Qualification Test Report: Report Date: Report NumberDocument10 pagesPQT and Applicator Qualification Test Report: Report Date: Report Numberirwan100% (2)

- Peter Hopkirk Foreign Devils On The Silk Road The Search For Lost Cities and Treasures of Chinese CDocument218 pagesPeter Hopkirk Foreign Devils On The Silk Road The Search For Lost Cities and Treasures of Chinese Cİskender GüneşNo ratings yet

- Daily Insp Report For SLV (Tape Coating)Document6 pagesDaily Insp Report For SLV (Tape Coating)Richart SembiringNo ratings yet

- Surface Prep & Primer PaintingDocument4 pagesSurface Prep & Primer PaintingrajuNo ratings yet

- Pt. Duta Utama Tehnik Abadi: Blasting & PaintingDocument3 pagesPt. Duta Utama Tehnik Abadi: Blasting & Paintingmarifa tullahNo ratings yet

- Painting Inspection ReportDocument1 pagePainting Inspection Reportعبداللة العبداللةNo ratings yet

- Painting Report Cd2Document139 pagesPainting Report Cd2sivaNo ratings yet

- Quality Assurance Protocol: Raw MaterialDocument2 pagesQuality Assurance Protocol: Raw MaterialShah Newaz Kabir100% (1)

- Touch-Up Paint On Steel StructureDocument1 pageTouch-Up Paint On Steel StructurejawyanaNo ratings yet

- Dimensional Inspection ReportDocument1 pageDimensional Inspection ReportAlfian ImaduddinNo ratings yet

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- Hydro Test 7109Document3 pagesHydro Test 7109YuwantoniAl100% (2)

- Painting RecordDocument1 pagePainting RecordHimawan Setyarso100% (1)

- Painting ReportDocument1 pagePainting Reportbaidu1980No ratings yet

- 24 Pressure Testing Report - FormatDocument1 page24 Pressure Testing Report - FormatRrgs Bandara50% (2)

- 36 - Painting Procedure - Rev0Document21 pages36 - Painting Procedure - Rev0Duc ThinNo ratings yet

- Dance EssayDocument3 pagesDance Essayapi-516273974No ratings yet

- Painting 1Document2 pagesPainting 1Kilerz 91100% (2)

- Daily Painting & Inspection Report (WI-05-A2) 170&pipe 1Document1 pageDaily Painting & Inspection Report (WI-05-A2) 170&pipe 1pstechnical_433126970% (1)

- Painting Report FormatDocument1 pagePainting Report Formatdangariya pradipNo ratings yet

- Daily Work Report - Structural Steel Painting: Field AppliedDocument2 pagesDaily Work Report - Structural Steel Painting: Field ApplieddilipNo ratings yet

- 09-Surface Preparation and Painting RecordDocument1 page09-Surface Preparation and Painting RecordJOSHUA SULLEGUE100% (1)

- MNT - QC - BP - 001 Blasting & Painting ReportDocument1 pageMNT - QC - BP - 001 Blasting & Painting Reportsivagnanam sNo ratings yet

- Painting Inspection Report-534 - GALVACOATDocument1 pagePainting Inspection Report-534 - GALVACOATRahul MoottolikandyNo ratings yet

- Painting Report FormatDocument1 pagePainting Report Formatrengaps0% (1)

- Painting ReportDocument2 pagesPainting ReporthikmahNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- Qaqc Format - Sandblasting y PinturaDocument2 pagesQaqc Format - Sandblasting y Pinturaosdavid0490100% (1)

- Organization Chart For Pipe Line Project 01Document1 pageOrganization Chart For Pipe Line Project 01MaherNo ratings yet

- Hardness Test Quality Control and Inspection Report FormDocument17 pagesHardness Test Quality Control and Inspection Report FormAlif Rahmat Febrianto0% (1)

- Flange Face Inspection Record CCPP R5Document1 pageFlange Face Inspection Record CCPP R5asfaruk2556100% (1)

- Bolt Tightening Inspection Report Format FinalDocument2 pagesBolt Tightening Inspection Report Format FinalHugo FloresNo ratings yet

- Blasting & Painting ReportDocument2 pagesBlasting & Painting ReportSanjay KumarNo ratings yet

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- FM-16 Material Verification RecordDocument1 pageFM-16 Material Verification RecordBleep NewsNo ratings yet

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesNo ratings yet

- SA MP LE: Company NameDocument4 pagesSA MP LE: Company NameAnonymous P8XHEXyIZLNo ratings yet

- Paint Batch CertificateDocument1 pagePaint Batch CertificateAJMAL KAREEM100% (1)

- 07blasting and Painting ReportDocument2 pages07blasting and Painting ReportVenkateswaraRaoNo ratings yet

- 3.painting InspectionDocument2 pages3.painting InspectionSRINIVASAN S M100% (1)

- Method Statement For Blasting and PaintingDocument11 pagesMethod Statement For Blasting and PaintingAbdullah Abdullah100% (2)

- Painting Report TemplateDocument1 pagePainting Report TemplateFrancisco Ona Amponin Jr.0% (1)

- F-035 (Valve Erection Format)Document1 pageF-035 (Valve Erection Format)Rajeev Kumar100% (1)

- Work Procedure For Touch Up Painting (Restoration)Document9 pagesWork Procedure For Touch Up Painting (Restoration)ResearcherNo ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument4 pagesPiping Daily Fit Up Quality Control and Inspection Report FormnguyenquanghiepNo ratings yet

- Blasting & Painting Report: Surface PreparationDocument1 pageBlasting & Painting Report: Surface PreparationSandra SandersNo ratings yet

- Bolt Tightening ReportDocument2 pagesBolt Tightening Reportrimshadtp67% (3)

- Blasting & Painting Inspection Report Format For Bottom Plate 01Document7 pagesBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MP100% (1)

- Welding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotDocument3 pagesWelding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotRicardo LourençoNo ratings yet

- Comment Response Sheet of Surface Preparation and Painting ProcedureDocument22 pagesComment Response Sheet of Surface Preparation and Painting ProcedureAgung PrasetyooNo ratings yet

- Daily Paint ReportDocument2 pagesDaily Paint Reportcarey stewart100% (3)

- Contoh Laporan Harian Pek CoatingDocument7 pagesContoh Laporan Harian Pek CoatingRindu Fazar Hasta BayuNo ratings yet

- Compressor Cb01Document3 pagesCompressor Cb01Adnan FrrNo ratings yet

- Shop Drawing Daily Tank 10 Feb 2019-Bottom Plate (1.1)Document1 pageShop Drawing Daily Tank 10 Feb 2019-Bottom Plate (1.1)EnyNo ratings yet

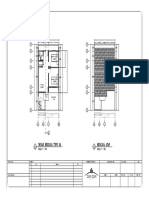

- MBJ-CVL-DG-051-00 (Drawing Struktur Shelter Jembatan Timbang)Document6 pagesMBJ-CVL-DG-051-00 (Drawing Struktur Shelter Jembatan Timbang)EnyNo ratings yet

- Punch List FormDocument1 pagePunch List FormEnyNo ratings yet

- Zam Zam: Kamar Tidur 0.00 KM / WC - 0.05Document10 pagesZam Zam: Kamar Tidur 0.00 KM / WC - 0.05EnyNo ratings yet

- Material Take Off (Mto) : Materiall Cable Tray and AccessoriesDocument2 pagesMaterial Take Off (Mto) : Materiall Cable Tray and AccessoriesEnyNo ratings yet

- Industrial Valves: 150/300UTDZ (M) (G-150UTDZ (M) ) 150/300UTAZM 300UTDZ (M) (G-300UTDZ (M) ) 150/300UTDRZ (M)Document2 pagesIndustrial Valves: 150/300UTDZ (M) (G-150UTDZ (M) ) 150/300UTAZM 300UTDZ (M) (G-300UTDZ (M) ) 150/300UTDRZ (M)EnyNo ratings yet

- Heavy Hex Nuts Dimensions, Weight Imperial Metric SizesDocument5 pagesHeavy Hex Nuts Dimensions, Weight Imperial Metric SizesEnyNo ratings yet

- Honor Thy Father FHE Lesson (Perfect For Father's Day)Document14 pagesHonor Thy Father FHE Lesson (Perfect For Father's Day)Lara Goold100% (1)

- Radoslav Lale Vujadinović - Slobodan MarkovićDocument1 pageRadoslav Lale Vujadinović - Slobodan MarkovićDario KršićNo ratings yet

- (Paralyzed On One) Sideman: Disability Studies Meets Jazz, Through The Hands of Horace ParlanDocument8 pages(Paralyzed On One) Sideman: Disability Studies Meets Jazz, Through The Hands of Horace ParlanSoad KhanNo ratings yet

- "Pervious Concrete": Gujarat Technological UniversityDocument26 pages"Pervious Concrete": Gujarat Technological UniversityRutvikNo ratings yet

- Final EL Digital Guide April 2019 PDFDocument97 pagesFinal EL Digital Guide April 2019 PDFShota IasashviliNo ratings yet

- Abu Bin AdhamDocument9 pagesAbu Bin AdhamMuntaqim AhmedNo ratings yet

- Jack: The True Story of Jack and The Beanstalk by Liesl Shurtliff - Chapter SamplerDocument37 pagesJack: The True Story of Jack and The Beanstalk by Liesl Shurtliff - Chapter SamplerRandom House Kids100% (1)

- Consumo de La Generation Z - Trifecta Research PDFDocument14 pagesConsumo de La Generation Z - Trifecta Research PDFDamian SorianoNo ratings yet

- BATTLESTORM STALINGRAD S1 - E1 - The 6th Army Strikes! (Description)Document2 pagesBATTLESTORM STALINGRAD S1 - E1 - The 6th Army Strikes! (Description)Assd SassNo ratings yet

- War of The WorldDocument12 pagesWar of The Worlddebnathsuman49No ratings yet

- Reported Speech-Mixed ExercisesDocument2 pagesReported Speech-Mixed ExercisesSanny S. AstralNo ratings yet

- CFD Post AnsysDocument80 pagesCFD Post AnsysDaymisrinconNo ratings yet

- Color Psychology: The Emotional Effects of ColorsDocument6 pagesColor Psychology: The Emotional Effects of Colorsvale paezNo ratings yet

- Notification No. 477 (E) Dated 25th July, 1991 of The Department of Industrial Policy and Promotion, Ministry of IndustryDocument39 pagesNotification No. 477 (E) Dated 25th July, 1991 of The Department of Industrial Policy and Promotion, Ministry of IndustryHarish100% (3)

- Creative Writing PortfolioDocument20 pagesCreative Writing PortfolioLj Johansson50% (2)

- Amid The Ever-RushingDocument132 pagesAmid The Ever-RushingAmrita ShankarNo ratings yet

- Graham Balls !: Business Mathematics Project Grade 7 Group 5Document17 pagesGraham Balls !: Business Mathematics Project Grade 7 Group 5Vincent William RodriguezNo ratings yet

- Luke 18-35-43 Removing BlindersDocument7 pagesLuke 18-35-43 Removing BlindersDave McNeffNo ratings yet

- The Great Gatsby SummaryDocument3 pagesThe Great Gatsby SummaryPaul.S.M.No ratings yet

- Neu Jorker, Singles, High-Res PDFDocument82 pagesNeu Jorker, Singles, High-Res PDFCaronte 221bNo ratings yet

- En User Manual ARCHOS 5-7 v2Document75 pagesEn User Manual ARCHOS 5-7 v2Cindi RauchNo ratings yet

- My Style - Natalie OldfieldDocument6 pagesMy Style - Natalie OldfieldAmanda KarakoudasNo ratings yet

- Aguinaldo's Controversial InterviewDocument3 pagesAguinaldo's Controversial InterviewNouvie AguirreNo ratings yet

- Greetings, Introducings, Leave Takings Lesson1Document68 pagesGreetings, Introducings, Leave Takings Lesson1Juanito CernaNo ratings yet

- ExtraClear v1 Low ResDocument1 pageExtraClear v1 Low ResSarinNo ratings yet

- Bigshanty Music Choice Board May2Document1 pageBigshanty Music Choice Board May2api-260793932No ratings yet

- Working With Platinum LightDocument3 pagesWorking With Platinum LightGoddessLight100% (8)

- New Media in Media PracticesDocument4 pagesNew Media in Media PracticesjonCatesNo ratings yet

Report Painting PDF

Report Painting PDF

Uploaded by

EnyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report Painting PDF

Report Painting PDF

Uploaded by

EnyCopyright:

Available Formats

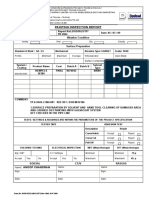

PT.

INDUSTRI KERETA API (PERSERO)

Proyek EPCC Pembangunan Workshop

ADHI Dwg :

INKA Banyuwangi

KARYA Steel Structure Conventional Sheet 1 of 1

TECHNICAL SERVICES REPORT FOR PAINTING MECHANICAL TESTING

PROJECT NAME : Steel Structure Conventional TESTING DATE :

OWNER/CONTRATOR : PT. INKA SEGMENT :

SUBCONTRACTOR NAME : PT. SAS OWNER REPRESENTATIVE : PT. INKA

PAINT MANCFACTURE : PT. SAS CONTRACTOR REPRESENTAT IVE : PT. ADHI KARYA

OF TEST : SUBCONTRACTOR REPRESENTATIVE : PT. SAS

OBJECT/SUBSTRATE : PIPE PLATE PAINT MANUCFACTURE REPRESENTATIVE : PT. SAS

DIMENSION:

A.MICROCLIMATE READINGS (ISO 8502)

ITEM TO BE CHECK TIME OF TEST Srf.Prep 1st 2nd 3rd

1 Air (Dry Bulb) Temp.C 20 TO 35 30º C

2 Air (Wet Bulb) Temp.C - 26

3 % Relativo humidity 85% MAX 78%

4 Dew Point temp.C 3-5ST 30º C

5 Steel surface temp.C 3-5DP 34º C

Specific Remarks:

B.SURFACE PREPARATION

ITEM TO BE CHECK STANDARD/REQUIREMENT ACTUAL CONDITION REMARK

1 Blotter test No Oil/No water YES

2 Abrasives Media Metallic non- Metallic Non Metalic

3 Clean liness grade SA 2,5 SSPC-SP10 SAND VULKANIC

4 Roughness/Anchor profile Grit Medium 35 µm

C.PAINT APPLICATION

NO. COAT TYPE CLEANESS CONDITION PAINT PRODUCT NAME THINNER REMARK

GOOD FAIR POOR COLOR ADDED

1 PRIMER COAT OK GRAY ZINCH 300

2 INTERMEDIATE COAT OK GRAY POLIYAMIDE 7-44

3 FINISH COAT OK GRAY POLYURETHENE 7-25

.PAINT INSPECTION

NO. FILM THICRNESS MEASUREMENT WFT MEASUREMENT DRY FILM THICKNESS

ACHIEVED

1 2 3 1 2 3 4 5 6 7 9 10 AVERAGE

1 PRIMER COAT

2 INTERMEDIATE COAT

3 FINISH COAT

Specific Remarks :

NO. COAT TYPE SPEC. APPLICATIONMETHOD MIXING METHOD

THICKNESS REMARK

DFT DFT Airless Roller Brush AGITATION STICKS

(um) (um) Spray

1 PRIMER COAT

2 INTERMEDIATE COAT

3 FINISH COAT

PT. SAS PT. SAS PT.ADHI KARYA PT. INKA

PRESS-0-FILM PRESS-0-

PAINT INSPECTOR QC QA/ QC FILM

SIGNATURE SIGNATUR SIGNATURE SIGNATURE

You might also like

- Painting Inspection ReportDocument1 pagePainting Inspection ReportAlfian Imaduddin100% (4)

- Sample For Painting ReportDocument1 pageSample For Painting ReportSơn Nguyễn TháiNo ratings yet

- SOP - 06 - Visual and Dimensional ProcedureDocument22 pagesSOP - 06 - Visual and Dimensional ProcedureSuci YatiningtiyasNo ratings yet

- Surface Preparation & Painting ReportDocument1 pageSurface Preparation & Painting ReportChethan100% (1)

- Sample Painting ReportDocument2 pagesSample Painting ReportvinothNo ratings yet

- ITP PaintingDocument1 pageITP PaintingAmer Y KNo ratings yet

- Surface Preparation & Painting ProcedureDocument18 pagesSurface Preparation & Painting ProcedureAAISAT100% (1)

- PQT and Applicator Qualification Test Report: Report Date: Report NumberDocument10 pagesPQT and Applicator Qualification Test Report: Report Date: Report Numberirwan100% (2)

- Peter Hopkirk Foreign Devils On The Silk Road The Search For Lost Cities and Treasures of Chinese CDocument218 pagesPeter Hopkirk Foreign Devils On The Silk Road The Search For Lost Cities and Treasures of Chinese Cİskender GüneşNo ratings yet

- Daily Insp Report For SLV (Tape Coating)Document6 pagesDaily Insp Report For SLV (Tape Coating)Richart SembiringNo ratings yet

- Surface Prep & Primer PaintingDocument4 pagesSurface Prep & Primer PaintingrajuNo ratings yet

- Pt. Duta Utama Tehnik Abadi: Blasting & PaintingDocument3 pagesPt. Duta Utama Tehnik Abadi: Blasting & Paintingmarifa tullahNo ratings yet

- Painting Inspection ReportDocument1 pagePainting Inspection Reportعبداللة العبداللةNo ratings yet

- Painting Report Cd2Document139 pagesPainting Report Cd2sivaNo ratings yet

- Quality Assurance Protocol: Raw MaterialDocument2 pagesQuality Assurance Protocol: Raw MaterialShah Newaz Kabir100% (1)

- Touch-Up Paint On Steel StructureDocument1 pageTouch-Up Paint On Steel StructurejawyanaNo ratings yet

- Dimensional Inspection ReportDocument1 pageDimensional Inspection ReportAlfian ImaduddinNo ratings yet

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- Hydro Test 7109Document3 pagesHydro Test 7109YuwantoniAl100% (2)

- Painting RecordDocument1 pagePainting RecordHimawan Setyarso100% (1)

- Painting ReportDocument1 pagePainting Reportbaidu1980No ratings yet

- 24 Pressure Testing Report - FormatDocument1 page24 Pressure Testing Report - FormatRrgs Bandara50% (2)

- 36 - Painting Procedure - Rev0Document21 pages36 - Painting Procedure - Rev0Duc ThinNo ratings yet

- Dance EssayDocument3 pagesDance Essayapi-516273974No ratings yet

- Painting 1Document2 pagesPainting 1Kilerz 91100% (2)

- Daily Painting & Inspection Report (WI-05-A2) 170&pipe 1Document1 pageDaily Painting & Inspection Report (WI-05-A2) 170&pipe 1pstechnical_433126970% (1)

- Painting Report FormatDocument1 pagePainting Report Formatdangariya pradipNo ratings yet

- Daily Work Report - Structural Steel Painting: Field AppliedDocument2 pagesDaily Work Report - Structural Steel Painting: Field ApplieddilipNo ratings yet

- 09-Surface Preparation and Painting RecordDocument1 page09-Surface Preparation and Painting RecordJOSHUA SULLEGUE100% (1)

- MNT - QC - BP - 001 Blasting & Painting ReportDocument1 pageMNT - QC - BP - 001 Blasting & Painting Reportsivagnanam sNo ratings yet

- Painting Inspection Report-534 - GALVACOATDocument1 pagePainting Inspection Report-534 - GALVACOATRahul MoottolikandyNo ratings yet

- Painting Report FormatDocument1 pagePainting Report Formatrengaps0% (1)

- Painting ReportDocument2 pagesPainting ReporthikmahNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- Qaqc Format - Sandblasting y PinturaDocument2 pagesQaqc Format - Sandblasting y Pinturaosdavid0490100% (1)

- Organization Chart For Pipe Line Project 01Document1 pageOrganization Chart For Pipe Line Project 01MaherNo ratings yet

- Hardness Test Quality Control and Inspection Report FormDocument17 pagesHardness Test Quality Control and Inspection Report FormAlif Rahmat Febrianto0% (1)

- Flange Face Inspection Record CCPP R5Document1 pageFlange Face Inspection Record CCPP R5asfaruk2556100% (1)

- Bolt Tightening Inspection Report Format FinalDocument2 pagesBolt Tightening Inspection Report Format FinalHugo FloresNo ratings yet

- Blasting & Painting ReportDocument2 pagesBlasting & Painting ReportSanjay KumarNo ratings yet

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- FM-16 Material Verification RecordDocument1 pageFM-16 Material Verification RecordBleep NewsNo ratings yet

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesNo ratings yet

- SA MP LE: Company NameDocument4 pagesSA MP LE: Company NameAnonymous P8XHEXyIZLNo ratings yet

- Paint Batch CertificateDocument1 pagePaint Batch CertificateAJMAL KAREEM100% (1)

- 07blasting and Painting ReportDocument2 pages07blasting and Painting ReportVenkateswaraRaoNo ratings yet

- 3.painting InspectionDocument2 pages3.painting InspectionSRINIVASAN S M100% (1)

- Method Statement For Blasting and PaintingDocument11 pagesMethod Statement For Blasting and PaintingAbdullah Abdullah100% (2)

- Painting Report TemplateDocument1 pagePainting Report TemplateFrancisco Ona Amponin Jr.0% (1)

- F-035 (Valve Erection Format)Document1 pageF-035 (Valve Erection Format)Rajeev Kumar100% (1)

- Work Procedure For Touch Up Painting (Restoration)Document9 pagesWork Procedure For Touch Up Painting (Restoration)ResearcherNo ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument4 pagesPiping Daily Fit Up Quality Control and Inspection Report FormnguyenquanghiepNo ratings yet

- Blasting & Painting Report: Surface PreparationDocument1 pageBlasting & Painting Report: Surface PreparationSandra SandersNo ratings yet

- Bolt Tightening ReportDocument2 pagesBolt Tightening Reportrimshadtp67% (3)

- Blasting & Painting Inspection Report Format For Bottom Plate 01Document7 pagesBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MP100% (1)

- Welding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotDocument3 pagesWelding Daily Report Piping: Rel. Rev. Spool Type Welder Root HotRicardo LourençoNo ratings yet

- Comment Response Sheet of Surface Preparation and Painting ProcedureDocument22 pagesComment Response Sheet of Surface Preparation and Painting ProcedureAgung PrasetyooNo ratings yet

- Daily Paint ReportDocument2 pagesDaily Paint Reportcarey stewart100% (3)

- Contoh Laporan Harian Pek CoatingDocument7 pagesContoh Laporan Harian Pek CoatingRindu Fazar Hasta BayuNo ratings yet

- Compressor Cb01Document3 pagesCompressor Cb01Adnan FrrNo ratings yet

- Shop Drawing Daily Tank 10 Feb 2019-Bottom Plate (1.1)Document1 pageShop Drawing Daily Tank 10 Feb 2019-Bottom Plate (1.1)EnyNo ratings yet

- MBJ-CVL-DG-051-00 (Drawing Struktur Shelter Jembatan Timbang)Document6 pagesMBJ-CVL-DG-051-00 (Drawing Struktur Shelter Jembatan Timbang)EnyNo ratings yet

- Punch List FormDocument1 pagePunch List FormEnyNo ratings yet

- Zam Zam: Kamar Tidur 0.00 KM / WC - 0.05Document10 pagesZam Zam: Kamar Tidur 0.00 KM / WC - 0.05EnyNo ratings yet

- Material Take Off (Mto) : Materiall Cable Tray and AccessoriesDocument2 pagesMaterial Take Off (Mto) : Materiall Cable Tray and AccessoriesEnyNo ratings yet

- Industrial Valves: 150/300UTDZ (M) (G-150UTDZ (M) ) 150/300UTAZM 300UTDZ (M) (G-300UTDZ (M) ) 150/300UTDRZ (M)Document2 pagesIndustrial Valves: 150/300UTDZ (M) (G-150UTDZ (M) ) 150/300UTAZM 300UTDZ (M) (G-300UTDZ (M) ) 150/300UTDRZ (M)EnyNo ratings yet

- Heavy Hex Nuts Dimensions, Weight Imperial Metric SizesDocument5 pagesHeavy Hex Nuts Dimensions, Weight Imperial Metric SizesEnyNo ratings yet

- Honor Thy Father FHE Lesson (Perfect For Father's Day)Document14 pagesHonor Thy Father FHE Lesson (Perfect For Father's Day)Lara Goold100% (1)

- Radoslav Lale Vujadinović - Slobodan MarkovićDocument1 pageRadoslav Lale Vujadinović - Slobodan MarkovićDario KršićNo ratings yet

- (Paralyzed On One) Sideman: Disability Studies Meets Jazz, Through The Hands of Horace ParlanDocument8 pages(Paralyzed On One) Sideman: Disability Studies Meets Jazz, Through The Hands of Horace ParlanSoad KhanNo ratings yet

- "Pervious Concrete": Gujarat Technological UniversityDocument26 pages"Pervious Concrete": Gujarat Technological UniversityRutvikNo ratings yet

- Final EL Digital Guide April 2019 PDFDocument97 pagesFinal EL Digital Guide April 2019 PDFShota IasashviliNo ratings yet

- Abu Bin AdhamDocument9 pagesAbu Bin AdhamMuntaqim AhmedNo ratings yet

- Jack: The True Story of Jack and The Beanstalk by Liesl Shurtliff - Chapter SamplerDocument37 pagesJack: The True Story of Jack and The Beanstalk by Liesl Shurtliff - Chapter SamplerRandom House Kids100% (1)

- Consumo de La Generation Z - Trifecta Research PDFDocument14 pagesConsumo de La Generation Z - Trifecta Research PDFDamian SorianoNo ratings yet

- BATTLESTORM STALINGRAD S1 - E1 - The 6th Army Strikes! (Description)Document2 pagesBATTLESTORM STALINGRAD S1 - E1 - The 6th Army Strikes! (Description)Assd SassNo ratings yet

- War of The WorldDocument12 pagesWar of The Worlddebnathsuman49No ratings yet

- Reported Speech-Mixed ExercisesDocument2 pagesReported Speech-Mixed ExercisesSanny S. AstralNo ratings yet

- CFD Post AnsysDocument80 pagesCFD Post AnsysDaymisrinconNo ratings yet

- Color Psychology: The Emotional Effects of ColorsDocument6 pagesColor Psychology: The Emotional Effects of Colorsvale paezNo ratings yet

- Notification No. 477 (E) Dated 25th July, 1991 of The Department of Industrial Policy and Promotion, Ministry of IndustryDocument39 pagesNotification No. 477 (E) Dated 25th July, 1991 of The Department of Industrial Policy and Promotion, Ministry of IndustryHarish100% (3)

- Creative Writing PortfolioDocument20 pagesCreative Writing PortfolioLj Johansson50% (2)

- Amid The Ever-RushingDocument132 pagesAmid The Ever-RushingAmrita ShankarNo ratings yet

- Graham Balls !: Business Mathematics Project Grade 7 Group 5Document17 pagesGraham Balls !: Business Mathematics Project Grade 7 Group 5Vincent William RodriguezNo ratings yet

- Luke 18-35-43 Removing BlindersDocument7 pagesLuke 18-35-43 Removing BlindersDave McNeffNo ratings yet

- The Great Gatsby SummaryDocument3 pagesThe Great Gatsby SummaryPaul.S.M.No ratings yet

- Neu Jorker, Singles, High-Res PDFDocument82 pagesNeu Jorker, Singles, High-Res PDFCaronte 221bNo ratings yet

- En User Manual ARCHOS 5-7 v2Document75 pagesEn User Manual ARCHOS 5-7 v2Cindi RauchNo ratings yet

- My Style - Natalie OldfieldDocument6 pagesMy Style - Natalie OldfieldAmanda KarakoudasNo ratings yet

- Aguinaldo's Controversial InterviewDocument3 pagesAguinaldo's Controversial InterviewNouvie AguirreNo ratings yet

- Greetings, Introducings, Leave Takings Lesson1Document68 pagesGreetings, Introducings, Leave Takings Lesson1Juanito CernaNo ratings yet

- ExtraClear v1 Low ResDocument1 pageExtraClear v1 Low ResSarinNo ratings yet

- Bigshanty Music Choice Board May2Document1 pageBigshanty Music Choice Board May2api-260793932No ratings yet

- Working With Platinum LightDocument3 pagesWorking With Platinum LightGoddessLight100% (8)

- New Media in Media PracticesDocument4 pagesNew Media in Media PracticesjonCatesNo ratings yet