Professional Documents

Culture Documents

FUNCTION48

FUNCTION48

Uploaded by

Datsun FernandesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FUNCTION48

FUNCTION48

Uploaded by

Datsun FernandesCopyright:

Available Formats

AKRAMANUJAN.

ORG

14Th OCTOBER 2019

FUNCTION 4(7)

ramanujan1933@gmail.com

MAIN ENGINE

NOTE:- i am once again repeating the request for

questions from other centres so that it helps you all in

preparing for the orals. you can send hand written scanned

sheets of questions to my e-mail given at the head. Please

treat this as urgent.

(11)In a four stroke engine cylinder head are the diameters

of exhaust and inlet valves same or different. If different why

the difference and which is bigger.

Answer:- The exhaust valve diameters are bigger than the inlet

valve diameters because the volume of the exhaust gases is

high due to the higher temperature after combustion.

(12)Using a mechanical indicator can we take the power card

of any unit in a medium speed engine. Give reasons for your

answer.

Answer:- With the mechanical indicator the power card of a

medium speed engine cannot be taken because the RPM of the

medium speed engine is high(between 700 and 1000 RPM) and

the drum return speed is low and hence the drum return speed

will not correspond with the piston speed . This drawback will

not reflect the true piston speed and hence the power card of

the medium speed engine cannot be taken

(13) Why tappet clearances are necessary in an engine.

Answer:- The clearance between the rotappet roller and the cam

ensure that the valves are positively shut when they are not in

operation. The clearance must be measured when the engine

has reached its ambient temperature during operation.

(14)In some high speed engines two concentric coil springs are

fitted in each valve instead of one. What is the reason for

this arrangement.

Answer:- The spring compression is raised to suit the speed

of the engine so that the valve closes smartly and wire drawing

is prevented. Hence two springs are used.

(15) In high speed engines aluminium alloy pistons are fitted

instead of cast iron pistons. What is the reason or advantage

of this modification.

Answer:- In high speed engines , to increase the power weight

ratio, it is necessary to reduce the mass of the moving

components. Hence the mass of the piston as well as the con-

rod are made light and hence aluminium alloy is suitable

because of its higher strength than aluminium and it is light.

(16)Why are auxiliary engines fitted in the longitudinal

direction on the ship and not in the transverse direction.

Answer:- The ship gets its directional stability because of its

symmetrical shape about the longitudinal centre line and the

angular momentum of the main engine rotating components

including the propeller. To increase the angular momentum the

auxiliary engines are also placed in the longitudinal direction so

that their angular momentum s of their rotating components

including the rotors are added to the total angular momentum

which adds to the directional stability.

(17) In some auxiliary engines balance weights are fitted to the

crank webs. Why is this arrangement necessary.

Answer:- All four stroke in-line engines with odd number of units

are not completely balanced for primary and secondary couples.

To reduce the unbalanced resultant primary and secondary

couple balance weights are fitted on the crank webs of these

engines. The maximum balance weight is about 50% of the

piston and part of the con-rod mass.

(18)What is the purpose of the expansion tank in a jacket

cooling water system. What observations are done during watch

keeping on this tank.

Answer:- The expansion tank in the jacket cooling water system

of the main engine is to provide the following needs:

it gives a steady positive head for the cooling water

pump which is a centrifugal pump and hence prevents air

lock in the system.

* It is a reserve make up feed tank when losses occur due

to leakage in the system or even by evaporation.

* The vent pipe/pipes which are led from the individual

cylinder heads ensure release of air from the system.

* In any vent /vents if the flow is intermittent it

indicates a leak of gas from either a crack in the cylinder

head or liner of the corresponding unit.

(19)What is the difference between wet sump and dry sump with

reference to auxiliary engines.

Answer:- In auxiliary engines where the bedplate forms the oil

sump, it is called wet sump. Whereas in auxiliary engines where

a separate oil sump is fitted below the bedplate , it is called

dry sump since the oil leaking into the bedplate flows into the

sump through the drain fitted in the bedplate.

(20) Explain the principle of the radial flow turbine as fitted in

an auxiliary engine.

Answer:- The construction of the radial flow exhaust gas turbine is

similar to the single stage centrifugal pump with volute casing.

In the case of the turbine the exhaust enters at the

volute end of the casing and exits the rotor from the centre

Because of its ease of fitting and convenient flow direction it is

favoured for auxiliary engines

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Upload7k HR EmailsDocument226 pagesUpload7k HR EmailsDavid100% (3)

- DAEWOO H.N0.2210/1: Water Treatment ProcedureDocument37 pagesDAEWOO H.N0.2210/1: Water Treatment ProcedureDatsun FernandesNo ratings yet

- Meo Class1 Unknown QuestionsDocument2 pagesMeo Class1 Unknown QuestionsDatsun FernandesNo ratings yet

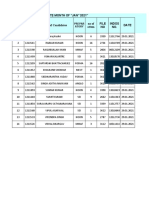

- CL Iib Oral Exam Date Month of "Jan" 2021" Name of Candidates Date No of Attem File NO Indos NODocument2 pagesCL Iib Oral Exam Date Month of "Jan" 2021" Name of Candidates Date No of Attem File NO Indos NODatsun FernandesNo ratings yet

- CL Iib Oral Exam Date Month of "Jan" 2021" Name of Candidates Date Time No of Atte M File NO Indos NODocument2 pagesCL Iib Oral Exam Date Month of "Jan" 2021" Name of Candidates Date Time No of Atte M File NO Indos NODatsun FernandesNo ratings yet

- CL Iib Oral Exam Date Month of "Jan" 2021" Name of Candidates Date No of Attem File NO Indos NODocument2 pagesCL Iib Oral Exam Date Month of "Jan" 2021" Name of Candidates Date No of Attem File NO Indos NODatsun FernandesNo ratings yet

- Regulation 28 - Subdivision and Damage Stability 1. Every Oil Tanker Delivered After 31 December 1979, As Defined in RegulationDocument3 pagesRegulation 28 - Subdivision and Damage Stability 1. Every Oil Tanker Delivered After 31 December 1979, As Defined in RegulationDatsun FernandesNo ratings yet

- CL Iib Oral Exam Date Month of "Jan" 2021" Name of Candidates No of Attem File NO Indos NODocument2 pagesCL Iib Oral Exam Date Month of "Jan" 2021" Name of Candidates No of Attem File NO Indos NODatsun FernandesNo ratings yet

- Compressor Start ProcedureDocument1 pageCompressor Start ProcedureDatsun FernandesNo ratings yet

- Directorate General of Shipping, MumbaiDocument9 pagesDirectorate General of Shipping, MumbaiDatsun FernandesNo ratings yet

- Miller CycleDocument4 pagesMiller CycleDatsun FernandesNo ratings yet

- Alarm and Trip List For Safety Devices: Setting NormalDocument1 pageAlarm and Trip List For Safety Devices: Setting NormalDatsun FernandesNo ratings yet

- Steering Gear Solas RegulationDocument2 pagesSteering Gear Solas RegulationDatsun FernandesNo ratings yet

- Design of Goods and Services PPT at BEC DOMSDocument78 pagesDesign of Goods and Services PPT at BEC DOMSBabasab Patil (Karrisatte)No ratings yet

- Varistor Products Overview Radial Lead VaristorsDocument106 pagesVaristor Products Overview Radial Lead VaristorsIgor PNo ratings yet

- Reading Practise: Read The Passage Below and Answer 10 QuestionsDocument2 pagesReading Practise: Read The Passage Below and Answer 10 QuestionsFarabi AksuNo ratings yet

- 3.0 Cooling Load CalculationDocument29 pages3.0 Cooling Load CalculationRenneil De PabloNo ratings yet

- GW 136-4.8MW - enDocument2 pagesGW 136-4.8MW - enalamoura50No ratings yet

- Evaluation of Modified Bituminous Concrete Mix Developed Using Rubber and Plastic Waste MaterialsDocument7 pagesEvaluation of Modified Bituminous Concrete Mix Developed Using Rubber and Plastic Waste MaterialsnicholasNo ratings yet

- Garlock PDFDocument8 pagesGarlock PDFnNo ratings yet

- Motor StandardsDocument17 pagesMotor Standardskodandaram100% (4)

- Miroslav Philharmonik Sound Set User ManualDocument63 pagesMiroslav Philharmonik Sound Set User ManualYanier HechavarriaNo ratings yet

- Recruitment in Smes: Presented By: Manish Gupta Surendra Singh YadavDocument20 pagesRecruitment in Smes: Presented By: Manish Gupta Surendra Singh YadavSmriti KhannaNo ratings yet

- Genima 485 Parts CatalogueDocument30 pagesGenima 485 Parts Cataloguecupid75No ratings yet

- Computer Virus (Trojan Horse & Salami Attack)Document10 pagesComputer Virus (Trojan Horse & Salami Attack)Chester JunusNo ratings yet

- Synchro Check A216 220KV - D09Document4 pagesSynchro Check A216 220KV - D09m khNo ratings yet

- Parker Veriflo - UHP Stainless Steel Diaphragm Valve HF - 25000016 - V2 - 955 SeriesDocument4 pagesParker Veriflo - UHP Stainless Steel Diaphragm Valve HF - 25000016 - V2 - 955 SeriesXavierNo ratings yet

- How To Use Group Policy To Remotely Install Software in Windows Server 2003 and in Windows Server 2008Document5 pagesHow To Use Group Policy To Remotely Install Software in Windows Server 2003 and in Windows Server 2008citiprogmtn3798No ratings yet

- Arrow-Pak 7.0 X 4Document9 pagesArrow-Pak 7.0 X 4Tech AlfaNo ratings yet

- Zvldor - Quot 20211013073547Document2 pagesZvldor - Quot 20211013073547ULLAS KRISHNAN J NNo ratings yet

- Ansys CFX - Reference GuideDocument324 pagesAnsys CFX - Reference GuideLucas Diego Rodrigues FerreiraNo ratings yet

- Bom 217856Document7 pagesBom 217856BohordoNo ratings yet

- Audrey Vu Resume Summer 24 GeDocument1 pageAudrey Vu Resume Summer 24 Geapi-706482491No ratings yet

- Ultramid: PA6-GF20 FRDocument2 pagesUltramid: PA6-GF20 FRLjubivoje MićićNo ratings yet

- Heat ExchangersDocument12 pagesHeat ExchangersGnanavel GNo ratings yet

- Product Name Seeded Paper Packet: DescriptionDocument16 pagesProduct Name Seeded Paper Packet: DescriptionshowmelocalNo ratings yet

- Abaqus QuestionsDocument12 pagesAbaqus Questionsmadhu77No ratings yet

- Filter-Separator Vessel ManualDocument40 pagesFilter-Separator Vessel ManualHien Van PhanNo ratings yet

- A Novel Offset Based PWMDocument13 pagesA Novel Offset Based PWMLindsay ClarkNo ratings yet

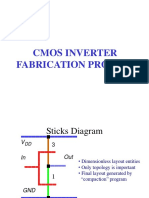

- CMOS Fabrication Steps 3Document54 pagesCMOS Fabrication Steps 3Yogesh MisraNo ratings yet

- KF-Butterfly Hale & BG SeriesDocument8 pagesKF-Butterfly Hale & BG SeriesKasthuri Rangan KNo ratings yet

- EDC Model Document Revision 2Document33 pagesEDC Model Document Revision 2milomeixell50% (2)