Professional Documents

Culture Documents

Lift Plan Form

Lift Plan Form

Uploaded by

خالد نسیمOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lift Plan Form

Lift Plan Form

Uploaded by

خالد نسیمCopyright:

Available Formats

CM CBA 106—Crane Operations Construction Safety User Manual

Lift Plan Form

Ref no: PG-DL-LP-01

A lift plan should be completed prior to mobilization of equipment and rigging Date:

Location:____________________________________________________ Date of Lift:______________________________________

Load Description:______________________________________________________________________________________________

Lift Description:________________________________________________________________________________________________

A. Weight E. Sizing of Slings

1. Equipment Condition ________New ________Used 1. Sling Selection

2. Weight Empty_____________________________________ a. Type of Arrangement______________________________

3. Weight of Headache Ball_____________________________ b. Number of Slings in Hook-Up______________________

4. Weight of Block___________________________________ c. Sling Size______________________________________

5. Weight of Lifting Bar_______________________________ d. Sling Length____________________________________

6. Weight of Slings and Shackles_________________________ e. Rated Capacity of Sling___________________________

7. Weight of Jib______________________________________ 2. Shackle Selection

Erected Stored a. Pin Diameter____________________________________

8. Weight of Headache Ball on Jib_______________________ b. Capacity_______________________________________

9. Weight of Cable (Loud Fall)__________________________ c. Shackle Attached to Load by________________________

10. Allowance for Unaccounted d. Number of Shackles______________________________

Material in Equipment_____________________________

11. Other___________________________________________ F. Crane

1. Type of Crane_____________________________________

Total Weight 2. Crane Capacity____________________________________

3. Lifting Arrangement

Source of Load Weight________________________________ a. Maximum Distance—Center of Load

Weights Verified by___________________________________ to Center Pin of Crane____________________________

b. Length of Boom_________________________________

B. Jib c. Angle of Boom at Pick-Up_________________________

Erected ________________ Stored_______________ d. Angle of Boom at Set_____________________________

1. Is Jib to be Used?__________________________________ e. Rated Capacity of Crane under Most Severe Lifting

2. Length of Jib______________________________________ Conditions (from Chart)

3. Angle of Jib_______________________________________ 1. Over Rear___________________________________

4. Rated Capacity of Jib_______________________________ 2. Over Front___________________________________

(From Chart)_____________________________________ 3. Over Side____________________________________

4. From Chart—Rated Capacity

C. Crane Placement of Crane for This Lift___________________________

1. Any Deviation from Smooth Solid 5. Maximum Load on Crane_______________________

Foundation in the Area?_____________________________ 6. Lift is __________% of Crane’s Rated Capacity

Suitable steel plate/mats to be provided. All exception to be

approved. G. Pre-Lift Checklist Yes No

2. Electrical Hazards in the Area?________________________ 1. Matting Acceptable

__________________________________________________ 2. Outriggers Fully Extended

3. Obstacles or Obstructions to Lift or Swing? 3. Crane in Good Condition

__________________________________________________ 4. Swing Room

4. Swing Direction and Degree (Boom Swing)______________ 5. Head Room Checked

__________________________________________________ 6. Maximum Counterweights Used

7. Tag Line Used

D. Cable 8. Experienced Operator

1. Number of Parts of Cable____________________________ 9. Experienced Signal person (Designated)

2. Size of Cable______________________________________ 10. Experienced Rigger

Special Instructions or Restrictions for Crane, Rigging, 11. Load Chart in Crane

Lift, and so on ( Contractor supervisor will be present all 12. Wind Conditions__________________________________

time for crane operations. A dedicated Mechanical 13. Crane Inspected by________________________________

Engineer will ensure that lifts are carried out as per P&G 14. Functional Test of Crane b

requirements)______________________________________

Diagram Crane and Load Placement Diagram Rigging Configuration

0) Multiple crane lifts require a separate lift plan for each crane. 2) Any changes in the configuration of the crane, placement, rigging, lifting scheme, and so on,

or changes made in any calculations require that a new lift plan be developed.

Signature and name Signature and name Signature and name Signature and name

___________________________ ______________________ ____________________ _______________________

(Contractor Construction Manager ) (Contractor Safety Manager) (P&G Safety Manager) (P&G Construction Manager)

106-1 September 2005

You might also like

- Method Statement For FRP Tank Panel ReplacementDocument8 pagesMethod Statement For FRP Tank Panel ReplacementJawNo ratings yet

- Method Statement - Pressing of Plate To Be Pipe - SignDocument9 pagesMethod Statement - Pressing of Plate To Be Pipe - SignrichadNo ratings yet

- Method Statement - Erection, Installation of Above Ground Piping - POXDocument11 pagesMethod Statement - Erection, Installation of Above Ground Piping - POXHabib ur rahmanNo ratings yet

- Is Constant Use of Electronic Media Changing Our MindsDocument4 pagesIs Constant Use of Electronic Media Changing Our MindsVi Le50% (4)

- Method Statement For Assembly of 200 Ton Crawler CraneDocument7 pagesMethod Statement For Assembly of 200 Ton Crawler CraneAnjo MolinaNo ratings yet

- Occupational Health and Safety ReportDocument6 pagesOccupational Health and Safety Reportخالد نسیمNo ratings yet

- 80k+ Priv8 IPTV (Userpass) CombolistDocument1,472 pages80k+ Priv8 IPTV (Userpass) CombolistJohn AndresNo ratings yet

- Star Wars Republic Holonet NewsDocument13 pagesStar Wars Republic Holonet NewsJessie Abraham LaidlawNo ratings yet

- Module 6.9 TLEDocument115 pagesModule 6.9 TLEroseavy90% (10)

- 001-Sample Method Statement Piping ShutdownDocument10 pages001-Sample Method Statement Piping ShutdownS.C.Satish ChanderNo ratings yet

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage TankABDELKADER BENABDALLAHNo ratings yet

- AST Nozzle Repair Req.Document10 pagesAST Nozzle Repair Req.Irvansyah RazadinNo ratings yet

- 105-Structural Steel ErectionDocument7 pages105-Structural Steel Erectionzaki fadl100% (1)

- Vessel Final BoxDocument14 pagesVessel Final Boxmanoj thakkarNo ratings yet

- 2 Contractor Quality Control Plan For Civil WorkDocument6 pages2 Contractor Quality Control Plan For Civil Workbehzad esNo ratings yet

- Pig Launcher Fabrication Activity PlanDocument1 pagePig Launcher Fabrication Activity PlanbeqsNo ratings yet

- Lifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneDocument7 pagesLifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneHtin Lin Aung100% (1)

- IFR Installation Manual March 2016Document26 pagesIFR Installation Manual March 2016Navin KumarNo ratings yet

- Erection of Steel StructureDocument4 pagesErection of Steel StructureParth AnajwalaNo ratings yet

- Method Statement: Al-Khafji FDP Phase-I Onshore FacilitiesDocument8 pagesMethod Statement: Al-Khafji FDP Phase-I Onshore FacilitiesSiddiqui Muhammad AshfaqueNo ratings yet

- Miscellaneous Metal WorksDocument6 pagesMiscellaneous Metal WorksYuvaraj PonrajNo ratings yet

- TIMAS-PR-PI-002 - Installation Procedure For Pipe SupportDocument14 pagesTIMAS-PR-PI-002 - Installation Procedure For Pipe SupportMechanical Static WRKNo ratings yet

- Method Statement For Vertical StructureDocument7 pagesMethod Statement For Vertical StructureAdel SaqqaNo ratings yet

- Pre-Commissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose ReelDocument2 pagesPre-Commissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose ReelDong VanraNo ratings yet

- Work Method Statement of Hydrotest: Sirteoil CompanyDocument15 pagesWork Method Statement of Hydrotest: Sirteoil Companyahmed08839494100% (1)

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- O - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlDocument8 pagesO - (TOC) - SOP - 008 - R0 - SOP For Welding Consumables Handling and ControlMDhana SekarNo ratings yet

- Lecture 3.2.3: Erection III: Steel Construction: Fabrication and ErectionDocument4 pagesLecture 3.2.3: Erection III: Steel Construction: Fabrication and ErectionMihajloDjurdjevicNo ratings yet

- Fuel Tank Lifting REV01Document7 pagesFuel Tank Lifting REV01armagan55No ratings yet

- Safe Work Method For Hydro TestDocument1 pageSafe Work Method For Hydro TestEswar RaoNo ratings yet

- Grating Control ProcedureDocument25 pagesGrating Control ProcedureMuneeb Rehman100% (1)

- 8-Piping Final InspectionDocument1 page8-Piping Final InspectionM.A.NNo ratings yet

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- Weld Identification Record FormDocument2 pagesWeld Identification Record FormDimitris NikouNo ratings yet

- Tank Procedure by Conventional MethodDocument8 pagesTank Procedure by Conventional Methodsatish04No ratings yet

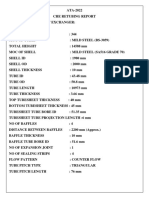

- CHE Retubing ReportDocument29 pagesCHE Retubing ReportRajesh KtrNo ratings yet

- MOS of BackfillingDocument2 pagesMOS of BackfillingPoru ManNo ratings yet

- Pipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerDocument2 pagesPipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerCherif GhalebNo ratings yet

- Jacking Procedurefor Construction of Tanks OLDDocument10 pagesJacking Procedurefor Construction of Tanks OLDVikram RangasamyNo ratings yet

- Tank Lorry Safety & Security Check-Step 1Document3 pagesTank Lorry Safety & Security Check-Step 1fawad haider100% (1)

- Oman-India Fertilizer Project OIFDocument24 pagesOman-India Fertilizer Project OIFBassam Dahham83% (6)

- Released: Company Document No: Document ClassDocument32 pagesReleased: Company Document No: Document ClassShajahan AsanarNo ratings yet

- 0610.1 - Shell and Tube Heat ExchangersDocument30 pages0610.1 - Shell and Tube Heat Exchangersvenkatrangan2003No ratings yet

- WMS Infineon Project Tower ( Lightning Protection System Installation) - Rev-1Document8 pagesWMS Infineon Project Tower ( Lightning Protection System Installation) - Rev-1tanaNo ratings yet

- Welding Procedure For PVCDocument4 pagesWelding Procedure For PVCVince Tuyulab0% (1)

- Installation of Columns: Installation Recommendations For Precast Reinforced Concrete Production Edition 1 September 2008Document14 pagesInstallation of Columns: Installation Recommendations For Precast Reinforced Concrete Production Edition 1 September 2008j_herndz100% (1)

- 4.1 - ANX-1 Definition of Mechanical Completion PDFDocument18 pages4.1 - ANX-1 Definition of Mechanical Completion PDFLegend AnbuNo ratings yet

- Scrap ProcedureDocument6 pagesScrap Procedurecaolanhng1No ratings yet

- 18-Weld Joint NumberingDocument5 pages18-Weld Joint NumberingAkhilesh Kumar100% (2)

- Klamflexproduct BrochureDocument24 pagesKlamflexproduct BrochureblindjaxxNo ratings yet

- Guide To Scaffold Inspection and Maintenance: General Guide For S Caffolds and Scaffolding WorkDocument6 pagesGuide To Scaffold Inspection and Maintenance: General Guide For S Caffolds and Scaffolding WorkSandeep KumarNo ratings yet

- 350 - Tray Installation Manual - EngDocument36 pages350 - Tray Installation Manual - EngRashid MadathilNo ratings yet

- Method of Transportation GIS Ternate Transformers PDFDocument10 pagesMethod of Transportation GIS Ternate Transformers PDFAditya FirgiantoNo ratings yet

- NCR Action PlanDocument5 pagesNCR Action PlandasNo ratings yet

- Method Statement For DX AC UnitDocument28 pagesMethod Statement For DX AC UnitBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Installing BlindsDocument1 pageInstalling Blinds최승원No ratings yet

- QATAR Pin Braze pdfr1Document14 pagesQATAR Pin Braze pdfr1Karunanithi NagarajanNo ratings yet

- Method Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Document19 pagesMethod Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Habib ur rahmanNo ratings yet

- Method Statement For Drying OperationDocument22 pagesMethod Statement For Drying OperationNaveed Ahmed Get-InfoNo ratings yet

- Sample Work Activities For Process Tank FabricationDocument4 pagesSample Work Activities For Process Tank FabricationMuhammad Zubair100% (1)

- Method Statement Pipe Re-Routing Saudi BinladinDocument11 pagesMethod Statement Pipe Re-Routing Saudi BinladinShyju MelepurathNo ratings yet

- Nmo Critical Lift Plan SheetDocument2 pagesNmo Critical Lift Plan SheetIhsan AhmedNo ratings yet

- FC 4.1.8 - Critical Lift PlanDocument1 pageFC 4.1.8 - Critical Lift PlanJosef Demner Tiu PaspeNo ratings yet

- Critical Lift PlanDocument2 pagesCritical Lift Planmahir_feelNo ratings yet

- Critical Lift Plan FormDocument2 pagesCritical Lift Plan FormSagun AlmarioNo ratings yet

- Agenda National Safety Day CelebrationDocument1 pageAgenda National Safety Day Celebrationخالد نسیمNo ratings yet

- Mnemonics For NEBOSHDocument5 pagesMnemonics For NEBOSHخالد نسیمNo ratings yet

- Safety SlogansDocument28 pagesSafety Slogansخالد نسیمNo ratings yet

- 6 Feasibility Assessment ToolDocument5 pages6 Feasibility Assessment Toolalibaba1888No ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Jay ParkheNo ratings yet

- Chapter#3 - Assignmnet ProblemDocument36 pagesChapter#3 - Assignmnet ProblemHarishNo ratings yet

- Care Sheet - Neon Tree Dragon (Japalura Splendida)Document2 pagesCare Sheet - Neon Tree Dragon (Japalura Splendida)John Gamesby100% (1)

- Bendix Actuator Competitive Cross Reference ListDocument1 pageBendix Actuator Competitive Cross Reference ListFernando PadillaNo ratings yet

- NI-Predictive Maintenance and Machine Health MonitoringDocument34 pagesNI-Predictive Maintenance and Machine Health Monitoringtườngt_14No ratings yet

- Pawan's ResumeDocument1 pagePawan's ResumePAWAN YADAVNo ratings yet

- R (Ax) 30 KipsDocument9 pagesR (Ax) 30 KipsRey Kevin OrtuosteNo ratings yet

- Autonomous Ships ChallengesDocument5 pagesAutonomous Ships ChallengesCristianAlbaArrietaNo ratings yet

- NOVATHERABBITPATTERNDocument10 pagesNOVATHERABBITPATTERNTejidos Castillo Amigurumis con Amor100% (3)

- XAI P T A Brief Review of ExplainableDocument9 pagesXAI P T A Brief Review of Explainableghrab MedNo ratings yet

- BPC Midterm Exam Math Hrs 2019Document4 pagesBPC Midterm Exam Math Hrs 2019Clara Jane CaparasNo ratings yet

- Hilti HIT-V and HAS Threaded Rod and Hilti HIT-Z Anchor Rod: Specifications and Technical DataDocument8 pagesHilti HIT-V and HAS Threaded Rod and Hilti HIT-Z Anchor Rod: Specifications and Technical DataEdwin Ramos PolicarpioNo ratings yet

- May Chronology JuneDocument80 pagesMay Chronology Junesahil popliNo ratings yet

- An Experiment of DensityDocument4 pagesAn Experiment of DensitySamuel TumewaNo ratings yet

- Castel Airco 2014-15Document68 pagesCastel Airco 2014-15Anderson Giovanny Herrera DelgadoNo ratings yet

- Semikron Datasheet SKB 30Document3 pagesSemikron Datasheet SKB 30Kleber Milton de SouzaNo ratings yet

- Buying Vs Renting: Net Gain by Buying A HomeDocument2 pagesBuying Vs Renting: Net Gain by Buying A HomeAnonymous 2TgTjATtNo ratings yet

- Solar CoolingDocument9 pagesSolar CoolingHua Hidari YangNo ratings yet

- Everything You Need To Know About Solvent DyesDocument2 pagesEverything You Need To Know About Solvent DyesRoyceintlNo ratings yet

- Pregnancy-Related Pelvic Girdle Pain: Second Stage of LabourDocument4 pagesPregnancy-Related Pelvic Girdle Pain: Second Stage of LabourSravan Ganji100% (1)

- Cost Justifying HRIS InvestmentsDocument19 pagesCost Justifying HRIS InvestmentsJessierene ManceraNo ratings yet

- FS2 Ep 1Document9 pagesFS2 Ep 1Jovinson LozanoNo ratings yet

- Website ErrorDocument5 pagesWebsite ErrorJosé DavidNo ratings yet

- LG 29FG1RL 12950 Chassis CW-62C Manual de ServicioDocument34 pagesLG 29FG1RL 12950 Chassis CW-62C Manual de Serviciopepe sanchezNo ratings yet

- Bhopal Chapter of ISSS 1st NewsletterDocument8 pagesBhopal Chapter of ISSS 1st NewsletterBankesh ChatterjeeNo ratings yet