Professional Documents

Culture Documents

Mas-Rtcf-Ms-El-001-Cable Tray

Mas-Rtcf-Ms-El-001-Cable Tray

Uploaded by

ASHIQUE ZAFAROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mas-Rtcf-Ms-El-001-Cable Tray

Mas-Rtcf-Ms-El-001-Cable Tray

Uploaded by

ASHIQUE ZAFARCopyright:

Available Formats

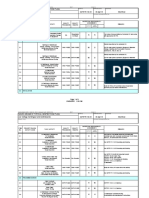

Rastanura Refinery Clean Fuel Project E & I Work Package 2

Subcontract No: 10100 Job No: 10100-25342

CATEGORY METHOD OF STATEMENT

DISCIPLINE ELECTRICAL

TITLE METHOD OF STATEMENT CABLE TRAY INSTALLATION

DOC.NUMBER MAS-RTCF-MS-EL-001, Rev.-01

SUBCONTRACTOR DOC REVIEW STATUS (CONTRACTOR/COMPANY)

Status Status Code Code Description

APPROVED WITHOUT COMMENT(SUBJECT TO CLIENT

□ 1

APPROVAL)

REVISE AND RESUBMIT, WORK MAY PROCEED SUBJECT TO

□ 2

INCORPORATION OF CHANGES INDICATED

□ 3 REJECTED, REVISE & RE-SUBMIT, WORK MAY NOT PROCEED

INFORMATION ONLY,REVIEW NOT REQUIRED ,WORK MAY

□ 4

PROCEED

□ 5 CANCELLED/DELETED

REVIEWED BY TECNICAS REUNIDAS APPROVED BY SAUDI ARAMCO

NAME : NAME :

SIGN : SIGN :

DATE : DATE :

For Girish M.A

01 12/26/2018 Shankar

approval Kumar Mallick

Reason Prepared Checked Approved

Revision Date

for issue By By By

REVISION HISTORY

DOCUMENT NO. REVISION DATE PAGE

MAS-RTCF-MS-EL-001 01 26-DEC-2018 Page 1 of 10

Rastanura Refinery Clean Fuel Project E & I Work Package 2

Subcontract No: 10100 Job No: 10100-25342

CONTENTS

1.0 SCOPE OF WORK

2.0 PURPOSE

3.0 REFERENCE STANDARDS AND CODES

4.0 DEFINITIONS

5.0 RESPONSIBILITIES

6.0 WORK PROCEDURE

7.0 INSPECTION

8.0 SAFETY PLAN

9.0 ATTACHEMENT

DOCUMENT NO. REVISION DATE PAGE

MAS-RTCF-MS-EL-001 01 26-DEC-2018 Page 2 of 10

Rastanura Refinery Clean Fuel Project E & I Work Package 2

Subcontract No: 10100 Job No: 10100-25342

1.0 SCOPE OF WORK

This work method statement is made to cover the work procedure for proper

installation of Cable Tray (Metal/Fiberglass) during construction of The Rastanura

clean fuel project.

2.0 PURPOSE

This method statement is intended for effective installation of cable trays.

3.0 REFERENCES

SAES-P-104 : Wiring Methods and Materials.

SAES-J-902 : Electrical System for Instrumentation

SAES -P -111 : Grounding

NEMA VE2 : As NEC Refers To NEMA VE2 for Cable Tray Installation

NEMA FG1 : As NEC refers to NEMA FG1 for Fiber Glass cable tray installation

SATIP-P-104-03 : Cable tray fittings and accessories

NEC : National Electrical Code

01 NEMA VE1 : Metal Cable tray System

1

Work Permit GI. 2.100,

G.I. 07.025 Heavy Equipment Operator Testing & Certification.

G.I. 07.028 Crane Lifts Types And Procedures

G.I. 07.030 Crane Inspection And Testing Requirements

GI 2.709, Gas Testing Procedure

DOCUMENT NO. REVISION DATE PAGE

MAS-RTCF-MS-EL-001 01 26-DEC-2018 Page 3 of 10

Rastanura Refinery Clean Fuel Project E & I Work Package 2

Subcontract No: 10100 Job No: 10100-25342

GI 6.030, Traffic And Vehicle Safety

GI 8.001, Safety Requirements For Scaffold

SA Construction Safety Manual & CSAR

4.0 DEFINITIONS

4.1 PM - Project Manager

4.2 CM - Construction Manager

4.3 QCM - QC Manager

4.4 QCS - Quality Control Supervisor

4.5 SC - Construction Supervisor

4.6 QCI - Quality Control Inspector

4.7 P&C - Planning and Control

5.0 RESPONSIBILITIES

5.1 Project Manager

Project Manager shall be responsible for the overall implementation of this Work

Procedure.

5.2 Construction Manager

Construction Manager shall analyze all construction activities to include manpower and

equipment line up as well as other related resources required for the successful

implementation of the cable tray installation system. Study all aspects of work

procedure in accordance to project drawings and specifications.

5.3 Site Superintendent

01

Site Superintendent shall study and review all necessary documents for the

1 installation works to include, technical scope of work, specification, bill of

quantities, planned milestone dates and construction procedure in support to his

supervisors . He shall be directly reporting to the Construction Manager.

DOCUMENT NO. REVISION DATE PAGE

MAS-RTCF-MS-EL-001 01 26-DEC-2018 Page 4 of 10

Rastanura Refinery Clean Fuel Project E & I Work Package 2

Subcontract No: 10100 Job No: 10100-25342

5.4 QC Supervisor

01

QC Supervisor shall have sufficient and well defined responsibilities, qualifications

1 authority, and organizational freedom to identify quality problems and area of non-

conformance and to initiate, recommend and substantiate corrective actions during all

phase of work.

5.5 QC Inspector

QC Inspector shall be responsible in monitoring and controlled the activity inspection

and related test to 100% acceptability and proper documents, and ensure that the

works are performed in accordance with Rastanura Clean Fuels Project scope of work.

5.6 Construction Supervisor

Construction Supervisor shall be directly reporting to the Site superintendent and

responsible for the implementation and control of all site activities in accordance to

project scope of work and latest approved construction drawings. He shall ensure that

the planned milestone dates are followed and met by monitoring the progress of the

activity in periodic basis.

6.0 WORK PROCEDURES

6.1 Tools & Equipment’s

a) Metal cutting saw.

b) Screw drivers

c) Spanners

d) Drill machine with bits

e) Level meter

f) Measurement meter

g) Torque wrench

h) Ratchet wrench

i) L angle

DOCUMENT NO. REVISION DATE PAGE

MAS-RTCF-MS-EL-001 01 26-DEC-2018 Page 5 of 10

Rastanura Refinery Clean Fuel Project E & I Work Package 2

Subcontract No: 10100 Job No: 10100-25342

j) Touch up materials

k) Wire mesh

6.2 Sequence of Work

6.2.1 Check the route of cable trays to make sure that it is free from debris and

obstruction of any other activity.

6.2.2 Arrange scaffolding of sufficient height which is checked by scaffolding

inspector/ safety officer before using the same for installation.

6.2.3 Mark the reference points on wall /column required for the cable tray routing.

6.2.4 Identify the circuit start point and end points to mark the cable tray route as per

approved drawings.

6.2.5 Use recommended and approved cable tray and fittings as per site condition and

drawings.

6.2.6 Install cable trays and all accessories as per approved drawings and secure with

proper supports.

6.3 Cable Tray Supports

6.3.1 Cable tray shall be adequately supported by non-combustible racks, hangers or

other reliable means (such as structural steel of pipe ways) at intervals

compatible with the building structure and lengths of cable tray sections.

6.3.2 All the supports should be as per drawing or Site requirements.

6.3.3 Process piping shall not be used to support cable trays.

6.3.4 Generally cable tray located indoors around electrical apparatus and where

ceiling hangers are used should be supported every 3 meters (10 Feet) or less,

where structural steel is used to support tray a nominal 6 meters (20feet).

Spacing should be maintained.

6.3.5 Supports should be located in such a manner and the tray installed so as to avoid

supporting the tray at each section. Connections and splices between horizontal

sections of tray should fall at the quarter point of the span.

DOCUMENT NO. REVISION DATE PAGE

MAS-RTCF-MS-EL-001 01 26-DEC-2018 Page 6 of 10

Rastanura Refinery Clean Fuel Project E & I Work Package 2

Subcontract No: 10100 Job No: 10100-25342

6.4 Installation Procedure

6.4.1 Cable Tray installation shall be in strict accordance with the applicable Electrical

Codes and Latest approved drawing.

6.4.2 Cable trays shall be of the ladder (two side-rails) type. Cable tray installed

outdoors shall have ventilated covers. Only flanged type covers shall be used

and secured with stainless steel banding and fasteners, one band per 1/2 m of

cover length, with a minimum of six bands per cover.

6.4.3 Cable trays run vertically in outdoor areas shall have covers on both sides,

Conduit installation shall be in strict accordance with the applicable Electrical

Codes. All conduit material installed shall be in new and perfect condition.

6.4.4 Cable trays containing only instrument and communications cables may have

unventilated covers. Cable tray covers are not required if cable trays are

installed inside switchgear buildings.

6.4.5 Prior to install the cables in the cable tray, examine cable paths to ensure all

areas are free of debris that may interfere with the cables installation.

6.4.6 Cable trays should never be used as walkways at any phase of construction.

6.4.7 If cable tray covers are not installed, cable trays should be located to minimize

the potential for mechanical damage and to minimize the effects of sunlight on

the cables.

6.4.8 Stainless steel cable trays shall be used when required by SAES-B-006, to satisfy

fireproofing requirements. Stainless steel cable trays shall meet all other

requirements of this section.

6.4.9 Aluminum and galvanized carbon steel cable tray shall be designed,

manufactured, rated, tested and installed in accordance with NEMA VE 1 and

NEMA VE 2. Minimum individual rung load capacity shall be 90 kg. Minimum

thickness of covers shall be 1mm.

6.4.10 Fiberglass cable tray shall be designed, manufactured, rated, and tested in

accordance with NEMA FG 1. Minimum individual rung load capacity shall be 90

kg. Fiber glass cable trays shall be sunlight (ultraviolet radiation) resistant.

DOCUMENT NO. REVISION DATE PAGE

MAS-RTCF-MS-EL-001 01 26-DEC-2018 Page 7 of 10

Rastanura Refinery Clean Fuel Project E & I Work Package 2

Subcontract No: 10100 Job No: 10100-25342

6.4.11 The working load for cable trays shall be as per SAES-P-104.

6.4.12 Cable trays can be stored outside. But the cable tray storage area must be

loosely stacked, elevated off the ground and ventilated.

6.4.13 Cable tray shall be stored at work site covered with tarpaulin sheet and keep in a

grated wood, Keep away from water, chemical & other corrosive materials.

6.4.14 While unloading cable trays using forklift, the forks must supported with the reel

flanges.

6.4.15 The cable tray area should be away from high traffic areas. Tray should be

stacked by width and size.

6.4.16 The storage area must be barricaded and trays can placed above the wood

pieces to avoid contact with the soil.

6.4.17 Small accessories should be stored to prevent losses

6.4.18 Cable tray must be protected from scratching.

6.4.19 Splice plates (joints) shall not be located over supports, and shall be located

between supports and quarter points. No more than one splice shall be located

between two adjacent supports.

6.4.20 Cable trays shall be installed as a complete system, Cable tray systems shall not

have mechanically discontinuous segments of cable tray runs.

6.4.21 Cables may be extended from cable trays to equipment if they are armored or

metal clad and are properly supported in accordance with the

Requirements, or they are installed in rigid or flexible conduits

6.4.22 Cable Trays shall not have sharp edges, burrs or projections that could Damage

the insulation or jacket of the wiring.

6.4.23 Location of supports for cable tray systems shall be in accordance with the

recommendations of NEMA VE 2.

6.4.24 Touch up paints shall be applied to the scratches/ Coating damaged surface of

cable Trays, if required.

DOCUMENT NO. REVISION DATE PAGE

MAS-RTCF-MS-EL-001 01 26-DEC-2018 Page 8 of 10

Rastanura Refinery Clean Fuel Project E & I Work Package 2

Subcontract No: 10100 Job No: 10100-25342

6.4.25 Cable trays should not extend through a fire wall unless an adequate fire seal can

be developed for the specific application. Select a fire seal that has a fire rating

at least equal to the wall being penetrated.

6.4.26 Metallic cable trays shall be bonded to the local grounding grid or ground

01 electrode at both end points ensuring that bonding continuity is met throughout

all the racks in the system.

1

6.4.27 During Cable tray installation; when gap between Side rail of the tray and

structural support is observed 10mm and below; then shim plate (max. 2

pieces)shall be used to fix the gap. The material of the shim plate shall became

as the cable tray material; preferably the side rail pieces from unused cut cable

tray sections.

6.4.28 When the gap between Side rail of the tray and structural support exceeds

10mm; report to the Contractor engineering department for further advice to

proceed the work.

6.4.29 While installing cable trays at high elevation areas like pipe racks, proper safety

procedures to be followed.

6.4.30 Safe scaffolding platform with handrails should be provided on the cable tray

platform on pipe racks and all the workers must be trained for safe work at

height and they should wear safety harness.

6.4.31 While erecting cable trays to pipe rack by crane, 2 riggers should be there one

rigger on top of the pipe rack, where the trays should be erected and another

one rigger near the crane.

6.4.32 While doing tray joints bolting and tightening works , cover the working flat

form by some mates or polyethylene sheets to prevent the tools or materials

falling to the lower platforms

6.4.33 On installing cable trays on top elevation on sleepers, scaffold should be erected.

6.4.34 Cable trays should never be used as walkway at any phase of construction.

DOCUMENT NO. REVISION DATE PAGE

MAS-RTCF-MS-EL-001 01 26-DEC-2018 Page 9 of 10

Rastanura Refinery Clean Fuel Project E & I Work Package 2

Subcontract No: 10100 Job No: 10100-25342

6.4.35 While tray fabrication works like grinding or cutting, the work area should be

covered with fire blankets and a trained fire watch with fire extinguisher must be

on the working area.

6.4.36 Barricade the work area to avoid unwanted entries and work disturbances.

7.0 INSPECTION

Mastoura QC inspector shall carry out all the inspection work related to the installation

of cable tray in proper Co-ordination with contractor and company inspection

department.

8.0 SAFETY PLAN

8.1 Mastoura Safety Supervisor shall carry out the safety site inspections to

ensure that safety requirements are followed during and after the Cable

trays/Conduits installation activities. Safety supervisor shall review safety plan

and secure work permit if necessary prior to start of any activities.

8.2 Regular tool box meeting shall be conducted at site before starting the work.

8.3 Sufficient lighting system shall be provided on site during extended night

operation.

8.4 Proper housekeeping shall be implemented on site during the work.

8.5 Mastoura will comply contractor safety standard while executing the job.

8.6 Subcontractor shall follow the Saudi Aramco procedures-GI, SACSM CSAR etc.

01 and TR HSE Plan and procedures.

1 8.7 Approved JSA Shall be attached in this MOS prior to start the work.

DOCUMENT NO. REVISION DATE PAGE

MAS-RTCF-MS-EL-001 01 26-DEC-2018 Page 10 of 10

You might also like

- 5140520-0000-SOW-TE-0204 Rev 01CDocument37 pages5140520-0000-SOW-TE-0204 Rev 01CEngTamerRabahNo ratings yet

- Saes T 494Document9 pagesSaes T 494Ahamedulla KhanNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Low Voltage CablesDocument2 pagesSaudi Aramco Pre-Commissioning Form: Low Voltage CablesHaleem Ur Rashid BangashNo ratings yet

- SAP 8000 Registry For Contractor/Sub-Contractor QC PersonnelDocument2 pagesSAP 8000 Registry For Contractor/Sub-Contractor QC PersonnelMudabbir HussainNo ratings yet

- PP-965006 - C Analyzer Shelter & Local PanelsDocument50 pagesPP-965006 - C Analyzer Shelter & Local Panelszizu1234100% (2)

- Tes-B-106-06-R0-Fk 5-1-12 Fixed Installation Total Flooding Clean-Agent Fire Extinguishing SystemDocument12 pagesTes-B-106-06-R0-Fk 5-1-12 Fixed Installation Total Flooding Clean-Agent Fire Extinguishing SystemUtkucan KILIÇNo ratings yet

- Billy Elliott ScriptDocument18 pagesBilly Elliott ScriptAna SquillaceNo ratings yet

- Bluesletter June 2012Document32 pagesBluesletter June 2012Todd HarrisonNo ratings yet

- Aphakia and Its CorrectionDocument61 pagesAphakia and Its CorrectionPradita Dhriti Indriyani100% (1)

- PQ 2012Document63 pagesPQ 2012Awais TahirNo ratings yet

- H348837 - FP Sys StudyDocument15 pagesH348837 - FP Sys Studyxxmorph3u5xx0% (1)

- New Sih Building: Extension of Instrument Room FOR (BI-10-00043-001)Document25 pagesNew Sih Building: Extension of Instrument Room FOR (BI-10-00043-001)John Philip BuntalesNo ratings yet

- CHECK-LIST PR-03 P&ID - Fr.enDocument6 pagesCHECK-LIST PR-03 P&ID - Fr.enYousef SalahNo ratings yet

- Be958823113 PDFDocument113 pagesBe958823113 PDFbabadapbadapNo ratings yet

- FPF1-ST-G00001-E-SPE-0009 - CableDocument49 pagesFPF1-ST-G00001-E-SPE-0009 - Cablebmanojkumar16No ratings yet

- B 126163001 PaDocument7 pagesB 126163001 Pazizu1234No ratings yet

- Saudi Arabian Oil Company: SECTION 13300 InstrumentationDocument7 pagesSaudi Arabian Oil Company: SECTION 13300 InstrumentationMECHKARTHIKRAJNo ratings yet

- bdb001380008 - 000 Grounding PDFDocument40 pagesbdb001380008 - 000 Grounding PDFJayce PinedaNo ratings yet

- King Salman International Complex For Maritime Industries and ServicesDocument7 pagesKing Salman International Complex For Maritime Industries and ServicesratheeshNo ratings yet

- Helipad Lighting SystemDocument11 pagesHelipad Lighting SystemEhsan ShaukatNo ratings yet

- TE-419843 - Rev.A - MR For Chemical Injection PackageDocument76 pagesTE-419843 - Rev.A - MR For Chemical Injection Packagerizwan.zamanNo ratings yet

- TE-419895-001 - 863-U-3001 - Gas Corrosion Inhibitor Injection Package - Rev.BDocument16 pagesTE-419895-001 - 863-U-3001 - Gas Corrosion Inhibitor Injection Package - Rev.Brizwan.zamanNo ratings yet

- General Description of The Facility 688 REV 00Document5 pagesGeneral Description of The Facility 688 REV 00syedkhaffoorNo ratings yet

- SATIP-P-116-03 Rev 7 FinalDocument4 pagesSATIP-P-116-03 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Elect SpecsDocument74 pagesElect SpecsNaveedNo ratings yet

- BCD3-315-48-DS-4-001-00 Data Sheet For Fiber Optic Cable - Rev 1Document7 pagesBCD3-315-48-DS-4-001-00 Data Sheet For Fiber Optic Cable - Rev 1rofingi ajiNo ratings yet

- HCIS-SECSAF Status - Updated 04dec23Document3 pagesHCIS-SECSAF Status - Updated 04dec23Siva GuruNo ratings yet

- Sg6427-Sy-ck0p-Mtd-736-009 - Method Statement of Cable Transit & Multi Cable Transit Installation - Rev.cDocument9 pagesSg6427-Sy-ck0p-Mtd-736-009 - Method Statement of Cable Transit & Multi Cable Transit Installation - Rev.cbrian sanchezNo ratings yet

- Marjan Development Program BI-10-09003: Tanajib Gas Plant (TGP)Document14 pagesMarjan Development Program BI-10-09003: Tanajib Gas Plant (TGP)Maged GalalNo ratings yet

- Area Hazard ClassificatinsDocument3 pagesArea Hazard ClassificatinsshujjatNo ratings yet

- SATIP-P-113-01 Rev 8 Final Induction Motor PDFDocument3 pagesSATIP-P-113-01 Rev 8 Final Induction Motor PDFSabheeh AliNo ratings yet

- DOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0Document11 pagesDOD-MST-INS-003 Insta. & Testing of Inst. Cables-Rev-0BharathiNo ratings yet

- Calculation Sheets: Saudi Arabian Oil CompanyDocument9 pagesCalculation Sheets: Saudi Arabian Oil CompanybillNo ratings yet

- Saudi Arabian Oil Company: Table 1 Minimum Cover RequirementsDocument1 pageSaudi Arabian Oil Company: Table 1 Minimum Cover RequirementsAswin KurupNo ratings yet

- Yasref: Saudi Arabian Oil CompanyDocument7 pagesYasref: Saudi Arabian Oil CompanyAdnan100% (1)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNo ratings yet

- 5140520-0000-SOW-TE-0204 Rev 01CDocument37 pages5140520-0000-SOW-TE-0204 Rev 01CEngTamerRabahNo ratings yet

- 4422-Yz-Pc-000000004001 - A1-Vendor DocumentationDocument50 pages4422-Yz-Pc-000000004001 - A1-Vendor DocumentationPaul NieNo ratings yet

- 000-A-JD-801400-231 - Rev B SOW - Part-3Document6 pages000-A-JD-801400-231 - Rev B SOW - Part-3Senthil KumarNo ratings yet

- Method Statement For Data & Communication Equipments & FOC InstallationDocument13 pagesMethod Statement For Data & Communication Equipments & FOC InstallationziaurrehmanNo ratings yet

- R789977015 PDFDocument15 pagesR789977015 PDFElie AouadNo ratings yet

- ITP InstrumentationDocument9 pagesITP InstrumentationzhangyiliNo ratings yet

- Technical Specification Fire Detection and Alarm System: Saudi Arabian Oil CompanyDocument13 pagesTechnical Specification Fire Detection and Alarm System: Saudi Arabian Oil CompanyJohn Philip BuntalesNo ratings yet

- Electrical Specs-00f1 - Fire StationDocument203 pagesElectrical Specs-00f1 - Fire StationQC WeldingNo ratings yet

- SG6427-SY-CK0P-MTD-736-005 - Method Statement of Local Panel & Enclosure Installattion - Rev.BDocument12 pagesSG6427-SY-CK0P-MTD-736-005 - Method Statement of Local Panel & Enclosure Installattion - Rev.Bbrian sanchezNo ratings yet

- Detail Design: Instrument Air Back Up System by Nitrogen (N2) GasDocument16 pagesDetail Design: Instrument Air Back Up System by Nitrogen (N2) Gasnas_mech8208No ratings yet

- Sep Mgse DC Pro 0001 3Document22 pagesSep Mgse DC Pro 0001 3guoNo ratings yet

- Spare Parts Data Package Phase-17 (SPDP)Document1,116 pagesSpare Parts Data Package Phase-17 (SPDP)Muhammad FaizalNo ratings yet

- SAIPEM MS Grounding & Lightning ProtectionDocument20 pagesSAIPEM MS Grounding & Lightning Protectionsyam prasad50% (2)

- Scope of Work PDFDocument113 pagesScope of Work PDFaliNo ratings yet

- 000-ZA-E-M09407 - B MS For Cabinets, Panels, Cubicle & Power & Lighting Panel-Boards - RECTIFIEDDocument20 pages000-ZA-E-M09407 - B MS For Cabinets, Panels, Cubicle & Power & Lighting Panel-Boards - RECTIFIEDsyam prasadNo ratings yet

- Project One - Ecr Epcm Services Contract: Level Instruments DatasheetsDocument105 pagesProject One - Ecr Epcm Services Contract: Level Instruments DatasheetsKhan Akhtar HusainNo ratings yet

- KDOCS-040-LST-0001 - A01 SEC 01 (31-Aug-14)Document15 pagesKDOCS-040-LST-0001 - A01 SEC 01 (31-Aug-14)Abdul Rahim Shaikh100% (1)

- T80-ZA-E-2204072 - Installation of Cable Tray, PDFDocument19 pagesT80-ZA-E-2204072 - Installation of Cable Tray, PDFNezinNo ratings yet

- RP 12202Document18 pagesRP 12202kirandevi1981No ratings yet

- Cutover Plan at SUBSTATION 10, 77, 79 AND 215 New BuildingsDocument20 pagesCutover Plan at SUBSTATION 10, 77, 79 AND 215 New Buildingsimri ssNo ratings yet

- H274743003P00 PDFDocument27 pagesH274743003P00 PDFMohamed Amr0% (1)

- Tes-T-111-12-R0-Outside Plant (Communications) Standarts and Practices For Facility Area Plan Design and Remote Distribution Area Plan DesignDocument34 pagesTes-T-111-12-R0-Outside Plant (Communications) Standarts and Practices For Facility Area Plan Design and Remote Distribution Area Plan DesignUtkucan KILIÇNo ratings yet

- Yes Items Instrument Oil and GasDocument3 pagesYes Items Instrument Oil and GasSheraz TariqNo ratings yet

- PLS Refer The Remarks Column All 68 Points Are Not Related To YME: Ready To Close9 Ready To Close1Document6 pagesPLS Refer The Remarks Column All 68 Points Are Not Related To YME: Ready To Close9 Ready To Close1Haleem Ur Rashid BangashNo ratings yet

- D44 A Re 225498 PDFDocument112 pagesD44 A Re 225498 PDFGN SYSTECHNo ratings yet

- B 126179001 PaDocument9 pagesB 126179001 Pazizu1234No ratings yet

- MOS-RO Pressure Vessel InstallationDocument16 pagesMOS-RO Pressure Vessel InstallationShams TabrezNo ratings yet

- Feature Film, Released Between 1950-01-01 and 1959Document29 pagesFeature Film, Released Between 1950-01-01 and 1959joxepoxNo ratings yet

- Modern Devlopment in Garments Sector: History of RMG SectorDocument16 pagesModern Devlopment in Garments Sector: History of RMG SectorTamanna TasnimNo ratings yet

- Boney M-Mary's Boy Child Oh My Lord 1Document99 pagesBoney M-Mary's Boy Child Oh My Lord 1Matthew Windsor50% (2)

- BWV 598Document2 pagesBWV 598DISTIMIA85No ratings yet

- Loss of Cultural Symbols During Migration in Shauna Singh Baldwin's Montreal 1962Document3 pagesLoss of Cultural Symbols During Migration in Shauna Singh Baldwin's Montreal 1962IJELS Research JournalNo ratings yet

- You Will Still Be Mine: From Waitress The MusicalDocument5 pagesYou Will Still Be Mine: From Waitress The MusicalRafael GamboaNo ratings yet

- Portfolio Facundo Juan RevueltaDocument30 pagesPortfolio Facundo Juan RevueltaFacundo RevueltaNo ratings yet

- Onenote RubricDocument5 pagesOnenote Rubricapi-437799613No ratings yet

- Anne Carroll MooreDocument11 pagesAnne Carroll Mooreapi-250093181No ratings yet

- En User Manual ARCHOS 5-7 v2Document75 pagesEn User Manual ARCHOS 5-7 v2Cindi RauchNo ratings yet

- Narrative TextDocument3 pagesNarrative TextRagil ChaplinkNo ratings yet

- Doing Literary Criticism PDFDocument253 pagesDoing Literary Criticism PDFAbegale SotoNo ratings yet

- Jahn-Teller Theorem: Free MCQ Tests Quality NotesDocument14 pagesJahn-Teller Theorem: Free MCQ Tests Quality NotesSandipan SahaNo ratings yet

- Dmitry Shostakovich About Himself and His Times - @lbiz - en - 1981 - ds343Document473 pagesDmitry Shostakovich About Himself and His Times - @lbiz - en - 1981 - ds343Hoyoung Chung100% (1)

- MouridesDocument7 pagesMouridesAbdoul Hakim BeyNo ratings yet

- Final EL Digital Guide April 2019 PDFDocument97 pagesFinal EL Digital Guide April 2019 PDFShota IasashviliNo ratings yet

- Comfort Zone ChallengeDocument16 pagesComfort Zone ChallengeDiana MurtiNo ratings yet

- Norse FolkloreDocument3 pagesNorse FolkloreJr MadredinosNo ratings yet

- Cymatics 30DaySerumSoundDesignGuideDocument13 pagesCymatics 30DaySerumSoundDesignGuideManuel Alejandro Casquino100% (1)

- Cosmopolitan ArtDocument19 pagesCosmopolitan ArtrasrogerNo ratings yet

- College Essay For CompDocument2 pagesCollege Essay For Compapi-527764151No ratings yet

- Assembling The Ineffable in Kurt Schwitters' Architectural ModelsDocument16 pagesAssembling The Ineffable in Kurt Schwitters' Architectural ModelsdvgfgfdhNo ratings yet

- Creative Writing PortfolioDocument20 pagesCreative Writing PortfolioLj Johansson50% (2)

- Graham Balls !: Business Mathematics Project Grade 7 Group 5Document17 pagesGraham Balls !: Business Mathematics Project Grade 7 Group 5Vincent William RodriguezNo ratings yet

- The Invention of The Historic MonumentDocument27 pagesThe Invention of The Historic Monumentwtostello100% (1)

- Feng-Shui Elemen Budaya Tionghoa TradisiDocument30 pagesFeng-Shui Elemen Budaya Tionghoa TradisiHafandri JoenNo ratings yet

- Fingering Scheme For SaxophoneDocument5 pagesFingering Scheme For SaxophonePatris SutrisnoNo ratings yet