Professional Documents

Culture Documents

Power Management For Rail

Power Management For Rail

Uploaded by

itsataurCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- XAF Application From ScratchDocument18 pagesXAF Application From Scratchitsataur25% (4)

- List of Isuzu engines-4H-SeriesDocument2 pagesList of Isuzu engines-4H-SeriesitsataurNo ratings yet

- Hyva Tipping Underbody BrochureDocument8 pagesHyva Tipping Underbody BrochureitsataurNo ratings yet

- pfSenseTutorial by Chris Buechler and Scott UllrichDocument91 pagespfSenseTutorial by Chris Buechler and Scott UllrichitsataurNo ratings yet

- Hydraulic Cylinder PT 1 CV01Document50 pagesHydraulic Cylinder PT 1 CV01itsataurNo ratings yet

- Bangladesh Succession Act, 1925 (Act No. XXXIX of 1925)Document132 pagesBangladesh Succession Act, 1925 (Act No. XXXIX of 1925)itsataurNo ratings yet

- Hyva Wet-KitDocument4 pagesHyva Wet-KititsataurNo ratings yet

- BTS-MW-Scope of Work and ServicesDocument2 pagesBTS-MW-Scope of Work and ServicesitsataurNo ratings yet

- Check-List-Installation & Commissioning of BTS EquipmentDocument1 pageCheck-List-Installation & Commissioning of BTS EquipmentitsataurNo ratings yet

- Asterisk V1.6.0.8, Freepbx V2.5.1, and A2Billing V1.3.4: Installation Guide For Linux Ubuntu 8.10Document15 pagesAsterisk V1.6.0.8, Freepbx V2.5.1, and A2Billing V1.3.4: Installation Guide For Linux Ubuntu 8.10itsataur100% (1)

- Asterisk V1.6.0.8, Freepbx V2.5.1, and A2Billing V1.3.4: Installation Guide For Linux Ubuntu 8.10Document15 pagesAsterisk V1.6.0.8, Freepbx V2.5.1, and A2Billing V1.3.4: Installation Guide For Linux Ubuntu 8.10itsataur100% (1)

- Windows Solutions For Point of Service Empower Your Devices With ConnectivityDocument2 pagesWindows Solutions For Point of Service Empower Your Devices With ConnectivityitsataurNo ratings yet

- Asterisk V1.6.0.8, Freepbx V2.5.1, and A2Billing V1.3.4: Installation Guide For Linux Ubuntu 8.10Document15 pagesAsterisk V1.6.0.8, Freepbx V2.5.1, and A2Billing V1.3.4: Installation Guide For Linux Ubuntu 8.10itsataur100% (1)

- Presentation TitleDocument4 pagesPresentation TitleitsataurNo ratings yet

- World's Largest Virtualisedesktop ProjectsDocument5 pagesWorld's Largest Virtualisedesktop ProjectsitsataurNo ratings yet

- Rice MillDocument7 pagesRice MillgoalbreakerNo ratings yet

- Rice MachinesDocument3 pagesRice MachinesitsataurNo ratings yet

- Components of A CCTV SystemDocument15 pagesComponents of A CCTV Systemricky100% (1)

- Onkyo Universal Remote HT-R410Document4 pagesOnkyo Universal Remote HT-R410RodrigoNo ratings yet

- Radio 4418 Install RadioDocument42 pagesRadio 4418 Install RadioМилан100% (1)

- Erc Form Du-M02 - Mer June 2017xlsDocument36 pagesErc Form Du-M02 - Mer June 2017xlsJess DoodsNo ratings yet

- D-Bot Electrical DiagramDocument1 pageD-Bot Electrical DiagramSpencer ColeNo ratings yet

- Advance ElectronicsDocument8 pagesAdvance ElectronicswazidulNo ratings yet

- P246101-E-BE-00-000-EL-EDS-005 (Diesel Generator)Document11 pagesP246101-E-BE-00-000-EL-EDS-005 (Diesel Generator)hafid CJSPNo ratings yet

- D.P. Kothari, J.S. Dhillon. - Digital Circuits & Design-Pearson Education (2015)Document1,081 pagesD.P. Kothari, J.S. Dhillon. - Digital Circuits & Design-Pearson Education (2015)Rashid ShababNo ratings yet

- Midtronics Mpusensors Brochure-2Document4 pagesMidtronics Mpusensors Brochure-2JulioNo ratings yet

- Problems Load CharacteristicsDocument20 pagesProblems Load Characteristicshafiz858100% (1)

- Grounding: - According To IEEE Standard 142Document12 pagesGrounding: - According To IEEE Standard 142Nasirul HaqueNo ratings yet

- 8-Channel Dac With PLL and Differential Outputs, 192 KHZ, 24 BitsDocument28 pages8-Channel Dac With PLL and Differential Outputs, 192 KHZ, 24 BitsIvan AlyaevNo ratings yet

- Catalogo ServomotorDocument36 pagesCatalogo ServomotorLuis LopezNo ratings yet

- Preview - ISO+12405 1 2011Document5 pagesPreview - ISO+12405 1 2011ShubhamRaiNo ratings yet

- Kvi 3Document3 pagesKvi 3FaustoBerasateguiNo ratings yet

- Brochure Commerciale Studer Next 3Document12 pagesBrochure Commerciale Studer Next 3SINES FranceNo ratings yet

- Scalable Dry Processing of Binder-Free Lithium-Ion BatteryDocument8 pagesScalable Dry Processing of Binder-Free Lithium-Ion BatteryRinox RachidNo ratings yet

- 01 Philips StreetStar BRP210 Datasheet 2018 (757G-V1)Document4 pages01 Philips StreetStar BRP210 Datasheet 2018 (757G-V1)Poom PPWNo ratings yet

- 7sj63 Catalog Sip E7Document39 pages7sj63 Catalog Sip E7alexns84No ratings yet

- EIM 3rd Quarter Exam Questions EditedDocument3 pagesEIM 3rd Quarter Exam Questions Editedalnoel oleroNo ratings yet

- Section 5.0 ElectronicsDocument46 pagesSection 5.0 ElectronicsKennedy MudawarimaNo ratings yet

- Dixell XH240K - GBDocument4 pagesDixell XH240K - GBionut ciobanuNo ratings yet

- Digital Transducer Electronics: Special FeaturesDocument2 pagesDigital Transducer Electronics: Special Featuresproduccion multipackNo ratings yet

- Electronics II: Lab ManualDocument52 pagesElectronics II: Lab ManualGaurav SharmaNo ratings yet

- Eaton 269471 Emt6 KDB en GBDocument4 pagesEaton 269471 Emt6 KDB en GBAriel TorresNo ratings yet

- MS-PS1-1 Matter and Its InteractionsDocument28 pagesMS-PS1-1 Matter and Its Interactionsosama100% (1)

- BLRCS250A300B44: Product Data SheetDocument2 pagesBLRCS250A300B44: Product Data SheetHeru NugrohoNo ratings yet

- Lead Acid BatteryDocument8 pagesLead Acid BatteryRavinder SinghNo ratings yet

- Radwan Almasri PresentationDocument29 pagesRadwan Almasri PresentationHamza KhanNo ratings yet

- 7SX80003AB501CA0-Z+P05 Datasheet enDocument4 pages7SX80003AB501CA0-Z+P05 Datasheet enAnurag KaushikNo ratings yet

Power Management For Rail

Power Management For Rail

Uploaded by

itsataurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Management For Rail

Power Management For Rail

Uploaded by

itsataurCopyright:

Available Formats

Power management for Rail

Technical details supplement

BAE Systems: A leader in power

management

• 8,000 equipped locomotives, 500 million revenue hours,

MTBF greater than 200,000 hours

• Investing in new technology to improve customer value and

adapt to the future

• Mature energy storage systems and advanced energy

management maximize energy reuse through regenerative

braking

• BAE Systems’ proven power management experience reduces

development time and risk, and allows for quicker time to

market

• Power management for rail provides a path to lighter weight,

higher energy efficiency, and improved performance

System configuration and specifications

Power Specifications Dry Weight/size

Energy storage Building block • Lightweight, nano-phosphate-based lithium ion technology 365 kg

system +/- 200 kW peak, • High power and charge capacity

11.2 kWhr • Longer life with extended warranty

• Best power and energy density of any commercially available solution

Propulsion 465 kW • Integrates control of the propulsion system 79 kg

control system • Customized performance for optimal fuel economy and emissions Liquid-cooled – WEG

• Standard vehicle multiplex interface

• Controls generator and traction motor

• Onboard diagnostics

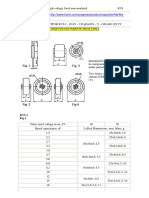

Motor 200 kW peak • Compact, oil-cooled, high-power-density machine design RATINGS SIZE

Torque: 5,100 Nm • AC induction motor eliminates brush maintenance 361 kg

• Self-contained cooling Liquid-cooled –

integrated WEG and oil

Integral starter- 200 kW continuous • Compact, brushless machine design 145 kg

generator • Optimized for high efficiency, lightweight, low maintenance, and low

emissions

• Integrated starter

• Fully sealed and liquid-cooled standardized interface to engine

Auxiliary power 17 kW DC/DC 600 • Eliminates oil blow-by in air compressor, which contaminates the pneumatic 102 kg

system V to 28 V 30 kW system Liquid-cooled – WEG

(208V AC inverter, • Eliminates the need for belt drives

37.5 kVA, 3-phase, • Provides capability for electric accessories

50/60 Hz) 60 kW • Increased fuel economy with electric accessories

Inverter (3-phase, • Safer — no engine fires due to hydraulic leakage

variable voltage/ • Reduced emissions

variable frequency)

System cooling Heat rejection of • Integrated water-ethylene-glycol-based cooling system 41 kg

package 24 kW • Flexible mounting options

• Built-in fluid level sensor

• SAE J1939 CAN-based controls

Power management for Rail

Technical details supplement

System configuration and specifications

Power Specifications Dry Weight/size

Diesel electronic N/A • Provides direct control of the injector solenoids of 6- to 18-cylinder diesel Operating temperature:

fuel injection engines Controls fueling to prevent smoke discharge and protects the engine 40 deg. C

(currently in use against: to +85 deg. C

in rail and mining • Overspeed

vehicles) • Overload

• Low oil pressure

• Low coolant pressure

• Crankshaft overpressure

• Provides diagnostic capability to support engine maintenance

Battery charger Power rating: • Input: 73 kg

(currently in use 18 kW • 480 VAC, 60Hz

in rail and mining • Outputs:

vehicles) • Three output connections

• Externally controlled load contactors

• 72 VDC +/-1% nominal at 0 to 250 A

• Software adjustable from 40 VDC to 85 VDC

• Vibration and shock in accordance with IEC77

Logic power 1.6 kW peak • Used to supply regulated power to electronics onboard AC and DC locomotives Convection cooling

supply • Provides six independently regulated outputs

(currently in use • All outputs are phase-shifted to reduce EMI Input voltage range: 25 VDC to 85

in rail and mining VDC

vehicles)

Cycle skipper (3X) 120 kW continuous • Input power: 33 kg

(currently in use • Three-phase AC-generator-supplied power

in rail and mining • 21 to 115 Hz (105 Hz nom.)

vehicles) • 80 to 440 VAC (402 VAC nom.)

• Outputs:

• Three-phase silicon-controlled rectifier variable output

• Constant V/Hz motor control

• Full-synchronous speed operation (reverse)

• Phase currents up to 165 A continuous at 105Hz (nom.)

• Microcontroller-based design

Phase controller Power rating: • Converts three-phase variable voltage and variable frequency source power to 68 kg

(3X) (currently 44 kVA variable-voltage DC power

in use in rail and • Programmable output to:

mining vehicles) • Charge a battery

• Control the field current of an AC generator z

• Input voltage: 0 Vrms to 1212 Vrms

• Output phase current: 110 Arms

• Output frequency: 30 Hz to 60 Hz

• Output voltage: 230 Vrms L-L

BAE Systems

1098 Clark Street

Endicott, NY 13760 This document gives only a general description of products and services and except where

expressly provided otherwise shall not form part of any contract. From time to time, changes

BAE Systems may be made in the products or conditions of supply.

Marconi Way Published work © 2014 BAE SYSTEMS. All rights reserved.

Rochester Kent ME1 2XX BAE SYSTEMS is a registered trade mark of BAE Systems plc.

www.hybridrive.com CS-16-B63

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- XAF Application From ScratchDocument18 pagesXAF Application From Scratchitsataur25% (4)

- List of Isuzu engines-4H-SeriesDocument2 pagesList of Isuzu engines-4H-SeriesitsataurNo ratings yet

- Hyva Tipping Underbody BrochureDocument8 pagesHyva Tipping Underbody BrochureitsataurNo ratings yet

- pfSenseTutorial by Chris Buechler and Scott UllrichDocument91 pagespfSenseTutorial by Chris Buechler and Scott UllrichitsataurNo ratings yet

- Hydraulic Cylinder PT 1 CV01Document50 pagesHydraulic Cylinder PT 1 CV01itsataurNo ratings yet

- Bangladesh Succession Act, 1925 (Act No. XXXIX of 1925)Document132 pagesBangladesh Succession Act, 1925 (Act No. XXXIX of 1925)itsataurNo ratings yet

- Hyva Wet-KitDocument4 pagesHyva Wet-KititsataurNo ratings yet

- BTS-MW-Scope of Work and ServicesDocument2 pagesBTS-MW-Scope of Work and ServicesitsataurNo ratings yet

- Check-List-Installation & Commissioning of BTS EquipmentDocument1 pageCheck-List-Installation & Commissioning of BTS EquipmentitsataurNo ratings yet

- Asterisk V1.6.0.8, Freepbx V2.5.1, and A2Billing V1.3.4: Installation Guide For Linux Ubuntu 8.10Document15 pagesAsterisk V1.6.0.8, Freepbx V2.5.1, and A2Billing V1.3.4: Installation Guide For Linux Ubuntu 8.10itsataur100% (1)

- Asterisk V1.6.0.8, Freepbx V2.5.1, and A2Billing V1.3.4: Installation Guide For Linux Ubuntu 8.10Document15 pagesAsterisk V1.6.0.8, Freepbx V2.5.1, and A2Billing V1.3.4: Installation Guide For Linux Ubuntu 8.10itsataur100% (1)

- Windows Solutions For Point of Service Empower Your Devices With ConnectivityDocument2 pagesWindows Solutions For Point of Service Empower Your Devices With ConnectivityitsataurNo ratings yet

- Asterisk V1.6.0.8, Freepbx V2.5.1, and A2Billing V1.3.4: Installation Guide For Linux Ubuntu 8.10Document15 pagesAsterisk V1.6.0.8, Freepbx V2.5.1, and A2Billing V1.3.4: Installation Guide For Linux Ubuntu 8.10itsataur100% (1)

- Presentation TitleDocument4 pagesPresentation TitleitsataurNo ratings yet

- World's Largest Virtualisedesktop ProjectsDocument5 pagesWorld's Largest Virtualisedesktop ProjectsitsataurNo ratings yet

- Rice MillDocument7 pagesRice MillgoalbreakerNo ratings yet

- Rice MachinesDocument3 pagesRice MachinesitsataurNo ratings yet

- Components of A CCTV SystemDocument15 pagesComponents of A CCTV Systemricky100% (1)

- Onkyo Universal Remote HT-R410Document4 pagesOnkyo Universal Remote HT-R410RodrigoNo ratings yet

- Radio 4418 Install RadioDocument42 pagesRadio 4418 Install RadioМилан100% (1)

- Erc Form Du-M02 - Mer June 2017xlsDocument36 pagesErc Form Du-M02 - Mer June 2017xlsJess DoodsNo ratings yet

- D-Bot Electrical DiagramDocument1 pageD-Bot Electrical DiagramSpencer ColeNo ratings yet

- Advance ElectronicsDocument8 pagesAdvance ElectronicswazidulNo ratings yet

- P246101-E-BE-00-000-EL-EDS-005 (Diesel Generator)Document11 pagesP246101-E-BE-00-000-EL-EDS-005 (Diesel Generator)hafid CJSPNo ratings yet

- D.P. Kothari, J.S. Dhillon. - Digital Circuits & Design-Pearson Education (2015)Document1,081 pagesD.P. Kothari, J.S. Dhillon. - Digital Circuits & Design-Pearson Education (2015)Rashid ShababNo ratings yet

- Midtronics Mpusensors Brochure-2Document4 pagesMidtronics Mpusensors Brochure-2JulioNo ratings yet

- Problems Load CharacteristicsDocument20 pagesProblems Load Characteristicshafiz858100% (1)

- Grounding: - According To IEEE Standard 142Document12 pagesGrounding: - According To IEEE Standard 142Nasirul HaqueNo ratings yet

- 8-Channel Dac With PLL and Differential Outputs, 192 KHZ, 24 BitsDocument28 pages8-Channel Dac With PLL and Differential Outputs, 192 KHZ, 24 BitsIvan AlyaevNo ratings yet

- Catalogo ServomotorDocument36 pagesCatalogo ServomotorLuis LopezNo ratings yet

- Preview - ISO+12405 1 2011Document5 pagesPreview - ISO+12405 1 2011ShubhamRaiNo ratings yet

- Kvi 3Document3 pagesKvi 3FaustoBerasateguiNo ratings yet

- Brochure Commerciale Studer Next 3Document12 pagesBrochure Commerciale Studer Next 3SINES FranceNo ratings yet

- Scalable Dry Processing of Binder-Free Lithium-Ion BatteryDocument8 pagesScalable Dry Processing of Binder-Free Lithium-Ion BatteryRinox RachidNo ratings yet

- 01 Philips StreetStar BRP210 Datasheet 2018 (757G-V1)Document4 pages01 Philips StreetStar BRP210 Datasheet 2018 (757G-V1)Poom PPWNo ratings yet

- 7sj63 Catalog Sip E7Document39 pages7sj63 Catalog Sip E7alexns84No ratings yet

- EIM 3rd Quarter Exam Questions EditedDocument3 pagesEIM 3rd Quarter Exam Questions Editedalnoel oleroNo ratings yet

- Section 5.0 ElectronicsDocument46 pagesSection 5.0 ElectronicsKennedy MudawarimaNo ratings yet

- Dixell XH240K - GBDocument4 pagesDixell XH240K - GBionut ciobanuNo ratings yet

- Digital Transducer Electronics: Special FeaturesDocument2 pagesDigital Transducer Electronics: Special Featuresproduccion multipackNo ratings yet

- Electronics II: Lab ManualDocument52 pagesElectronics II: Lab ManualGaurav SharmaNo ratings yet

- Eaton 269471 Emt6 KDB en GBDocument4 pagesEaton 269471 Emt6 KDB en GBAriel TorresNo ratings yet

- MS-PS1-1 Matter and Its InteractionsDocument28 pagesMS-PS1-1 Matter and Its Interactionsosama100% (1)

- BLRCS250A300B44: Product Data SheetDocument2 pagesBLRCS250A300B44: Product Data SheetHeru NugrohoNo ratings yet

- Lead Acid BatteryDocument8 pagesLead Acid BatteryRavinder SinghNo ratings yet

- Radwan Almasri PresentationDocument29 pagesRadwan Almasri PresentationHamza KhanNo ratings yet

- 7SX80003AB501CA0-Z+P05 Datasheet enDocument4 pages7SX80003AB501CA0-Z+P05 Datasheet enAnurag KaushikNo ratings yet